I helped a friend install a Wall Connector tonight for his soon-to-arrive Model 3. I thought others might find the pictures and parts list useful! (and I am pretty pleased with how the conduit bending came out - five bends in one stick of EMT!)

Parts list (all purchased at Home Depot locally other than the Wall Connector):

The final product. This is the Wall Connector with the 8.5 foot cord. We mounted it so the cable does not drag on the ground.

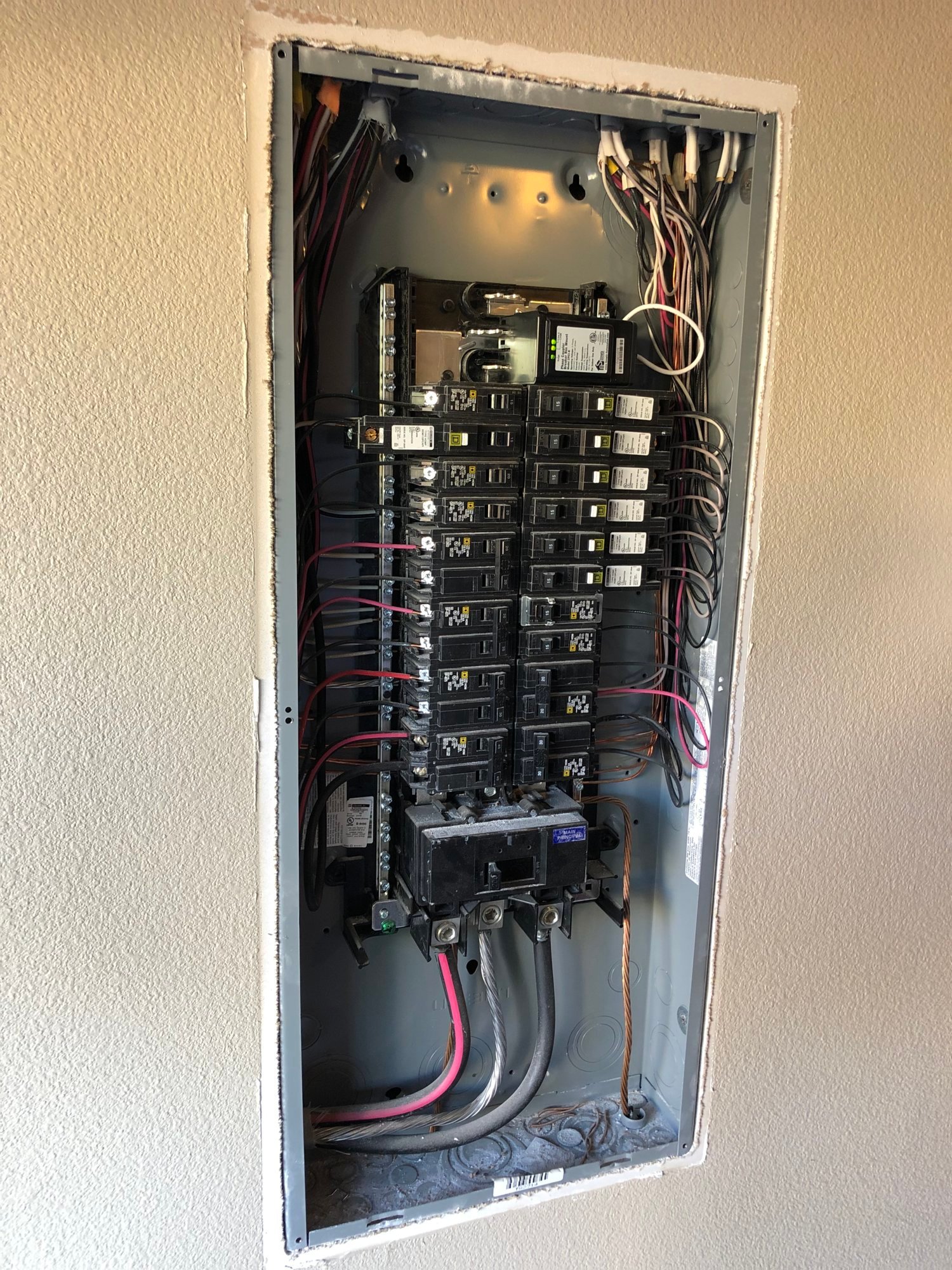

What we started with. The panel was extremely clean and very well done. The house is only a few years old.

Wired for a range, but it has a gas stove, so fairly limited 240v loads. (A number of multi wire branch circuits though which is what all the 20a handle tied breakers are)

This was the starting point prior to cutting the sheetrock.

I helped on the conduit bending part. YouTube is your friend!

Even got the offset bend in there to enter the bottom of the Wall Connector. Note he used 3/4ths inch EMT conduit but the Wall Connector has a 1” port, so we used a 1” to 3/4 in Rigid (threaded) reducing bushing before the 3/4 in threaded coupler.

6 awg conductors. Properly stripped (Tesla has no strip gauge on the device which is dumb and it is not in the manual and they mounted it so you can’t see what you are doing - really stupid). 10 awg ground.

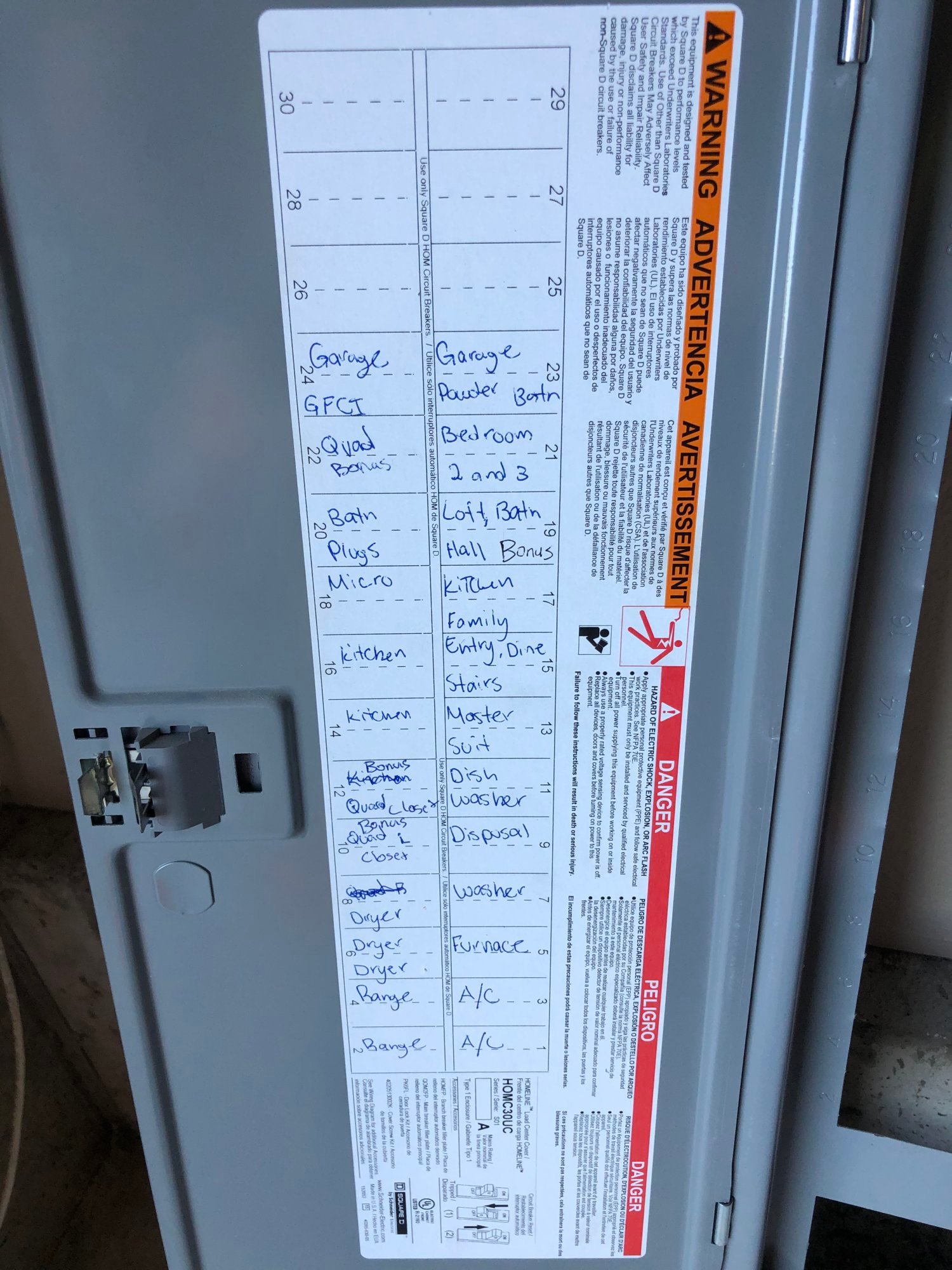

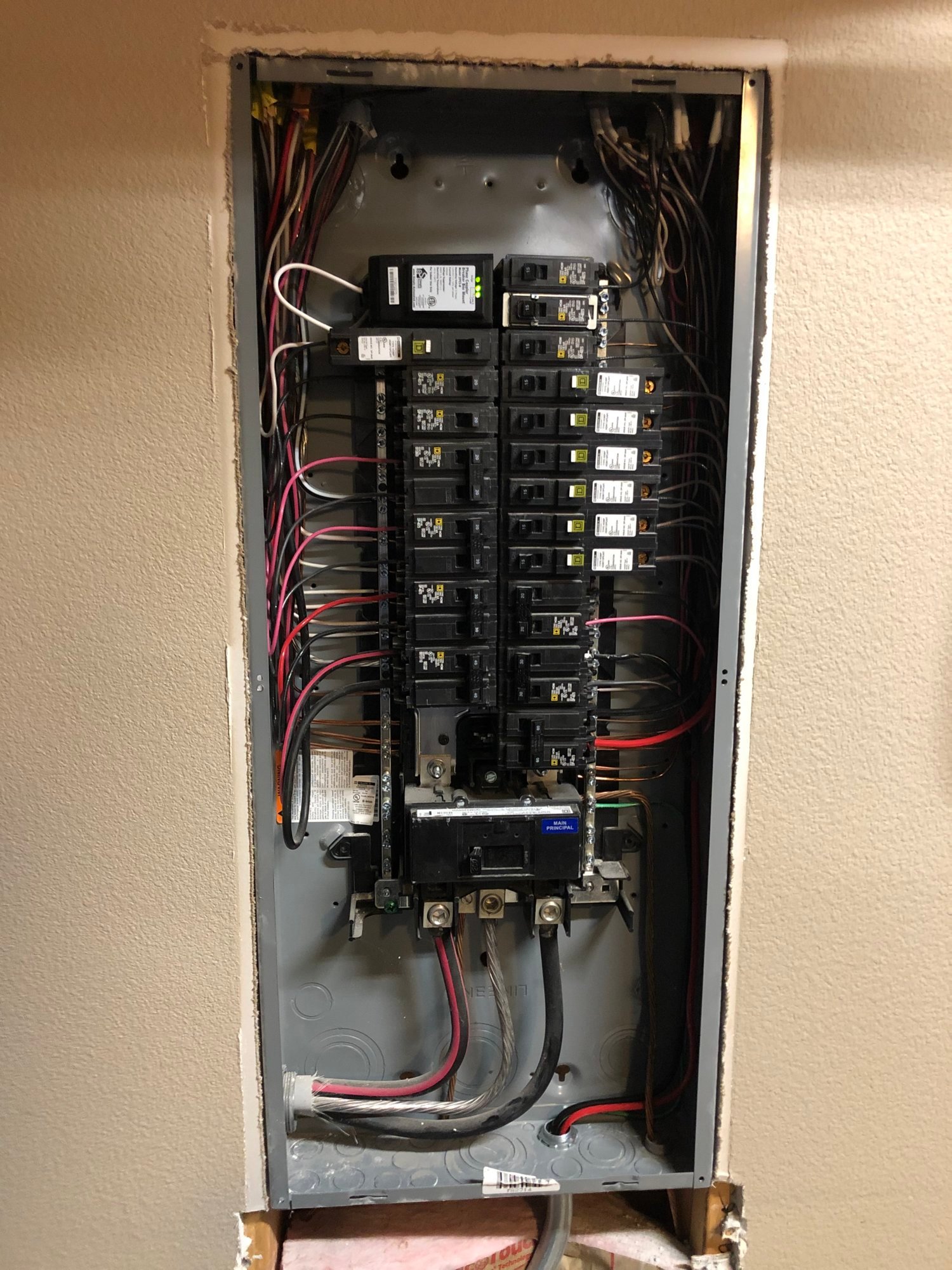

Had to (or chose to) re-arrange the entire panel to have it laid out the way he wanted. Left a spot to add a generator back feed breaker with interlock kit in the bottom left.

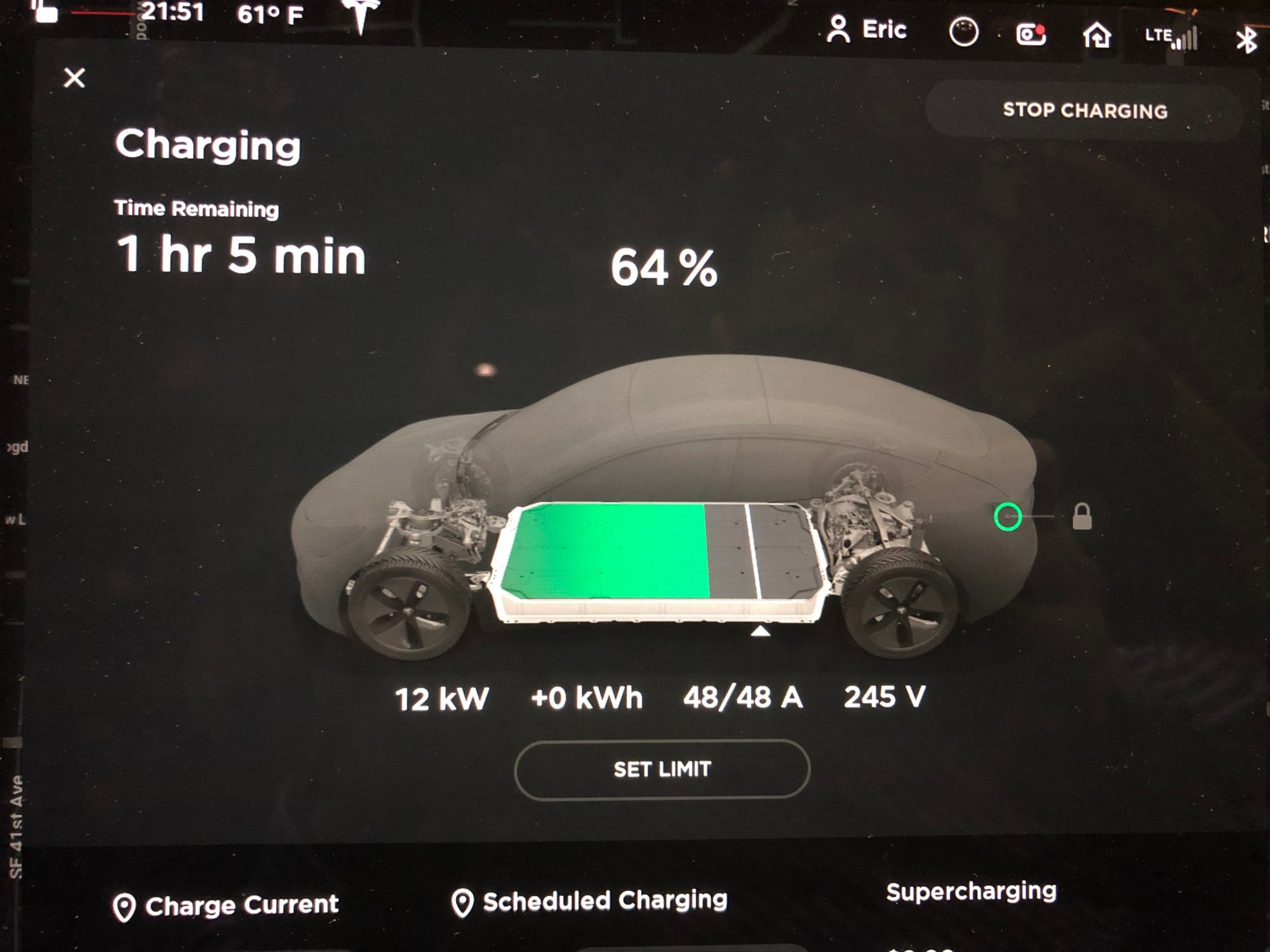

It works! Close to the substation. Good voltage.

A reminder: Electricians (even really good ones like the ones that did this house) make mistakes. Check out the end of the wire that my friend had melt the insulation off shortly after he bought the house. This wire was not screwed into the breaker at all. Just sitting there barely touching. He found the issue years ago and fixed it by simply tightening down the screw, but while we had the entire panel powered down he cut off the end and stripped it back to where the insulation was still good.

Parts list (all purchased at Home Depot locally other than the Wall Connector):

- Wall Connector, 8.5 foot cord.

- 10' stick of 3/4 inch EMT conduit - 786692020020

- 2x EMT "Set screw connector" (aka the conduit ends with threaded fittings for going into the electrical box/Wall Connector) - 051411262723

- 1" to 3/4 in Rigid reducing bushing ("Rigid" because it is threaded - this part is tiny and you can't see it in any of my pictures) - 051411913328

- 60a Square D Homeline double pole breaker - 047569062803

- 3/4 in EMT half saddle clips - 051411261528

- Decking screws (used to screw the conduit to the wall - they were what I had bouncing around my garage)

- 16 feet 6 AWG Black, 6 AWG Red, and 10 AWG Green (had way more than needed)

The final product. This is the Wall Connector with the 8.5 foot cord. We mounted it so the cable does not drag on the ground.

What we started with. The panel was extremely clean and very well done. The house is only a few years old.

Wired for a range, but it has a gas stove, so fairly limited 240v loads. (A number of multi wire branch circuits though which is what all the 20a handle tied breakers are)

This was the starting point prior to cutting the sheetrock.

I helped on the conduit bending part. YouTube is your friend!

Even got the offset bend in there to enter the bottom of the Wall Connector. Note he used 3/4ths inch EMT conduit but the Wall Connector has a 1” port, so we used a 1” to 3/4 in Rigid (threaded) reducing bushing before the 3/4 in threaded coupler.

6 awg conductors. Properly stripped (Tesla has no strip gauge on the device which is dumb and it is not in the manual and they mounted it so you can’t see what you are doing - really stupid). 10 awg ground.

Had to (or chose to) re-arrange the entire panel to have it laid out the way he wanted. Left a spot to add a generator back feed breaker with interlock kit in the bottom left.

It works! Close to the substation. Good voltage.

A reminder: Electricians (even really good ones like the ones that did this house) make mistakes. Check out the end of the wire that my friend had melt the insulation off shortly after he bought the house. This wire was not screwed into the breaker at all. Just sitting there barely touching. He found the issue years ago and fixed it by simply tightening down the screw, but while we had the entire panel powered down he cut off the end and stripped it back to where the insulation was still good.