Step 5: Clear the Ductwork of Debris

Time to clean! If you have an air compressor with a long handled nozzle, you're in good shape. Set the regulator to 80+ PSI as you'll want to try and dislodge as many leaves, dirt, and whatever else is lurking in there with strong blasts of air (Vid. 3).

Video 3. Cleaning PEM airflow inlets. Compressed air @ 80+ PSI was used to blow the airflow inlets clean. Note the massive amount of leaves and other organic debris that gets expelled from the PEM side once the air is forced through. Two additional passes were needed before the ductwork was relatively free of potential blockage.

Step 6: Check the Dual Fan Unit for Concentricity

With the fan assembly removed, you can now clean and test it too. To check for concentricity, I used compressed air to get the fan blades spinning without electricity. A cursory viewing of both fans rotating at high speeds showed no signs of eccentricity (Vid. 4). BTW, the TM P/N for the fan assembly in my 2.5 Sport is 1003208-00-A_Rev.AB.

Video 4. Checking the dual fan unit for concentricity. Using compressed air to spin the fan blades, both sides of the fan unit were tested for concentricity. No overt eccentricity was noticed while the blades were rotating.

Step 7: Remove and Replace Old Weatherstripping

The fan assembly had the remnants of some heavily worn out and disintegrated insulation on the bottom of the flange mounting position for the inlets (Figs. 11 and 12). I removed the majority of it with a paint scraper (Figs. 13 and 14) and followed that up with WD40 to break down the adhesive. Finally, isopropyl alcohol was used to prepare the freshly cleaned surface for new weatherstripping (Fig. 15).

Figure 11. Left side of dual fan assembly. Note the disintegrating weatherstripping that's only located on the bottom portion of the flange.

Figure 12. Side view of the vestigial weatherstripping on the dual fan unit's mounting flange.

Figure 13. Paint scraper being used to remove old weatherstripping.

Figure 14. Remnants of the old weatherstripping. The rubber had virtually disintegrated over time and wasn't providing a proper seal.

Figure 15. Final surface prep completed with flange having been sprayed down with WD40 to remove any remaining adhesive followed by an isopropyl alcohol rubdown to give the new weatherstripping a better opportunity for adherence.

I purchased an 8' roll of Super-stik® Weatherstrip from the local auto parts store (Fig 16). I specifically wanted to go with a slightly thicker diameter for a tighter seal but you can also use the thinner version which makes it easier during reassembly. I proceeded to measured the various dimensions and cut five separate strips of weatherstripping: two for the top and bottom and three for the sides and center. After applying them with great care, the refurbished unit was ready for reinstallation (Fig 17).

Figure 16. Roll of Super-stik® Weatherstrip (P/N 01058) purchased from my local auto parts store. This product was thicker than standard weatherstripping and would provide a tighter, better seal.

Figure 17. The final refurbished dual fan unit read for reinstallation.

Step 8: Reinstallation & Reassembly

This step was the most time-consuming (why... why is it always the case?) as the thicker weatherstripping required me to apply substantial pressure to the dual fan unit's flange in order to get the locknuts started on the tips of the threaded mounting bolts. I eventually resorted to brute force with a pry bar for leverage and was finally able to get all the locknuts on. After lightly torquing things down, I inspected the weatherstripping and could see it was providing a much better seal than before (Fig. 18).

Figure 18. View of the remounted dual fan assembly looking up from directly below. The light gray "bump" you see beneath the fan motor is the bulging weatherstripping between the two ports.

Next up was the reattachment of the rear sway bar mounting clamps. Three of the clamp bolts went on just fine. However, the installation of the very last one in the upper right was complicated by the fact that the JdeMO unit blocked almost all access angles and lines of site to the bolt screw location so I couldn't see where to get it started. After two hours of squirming on the garage floor contorting myself in every which angle, I

finally got the bolt to properly align with the threaded hole. Following a few cautious turns to ensure it wasn't cross-threaded, I torqued everything down, reconnected the detached fan connectors, zip tied everything back, buttoned up the plastic rear pan, and rolled the car down off the ramps.

Step 9: Test Drive

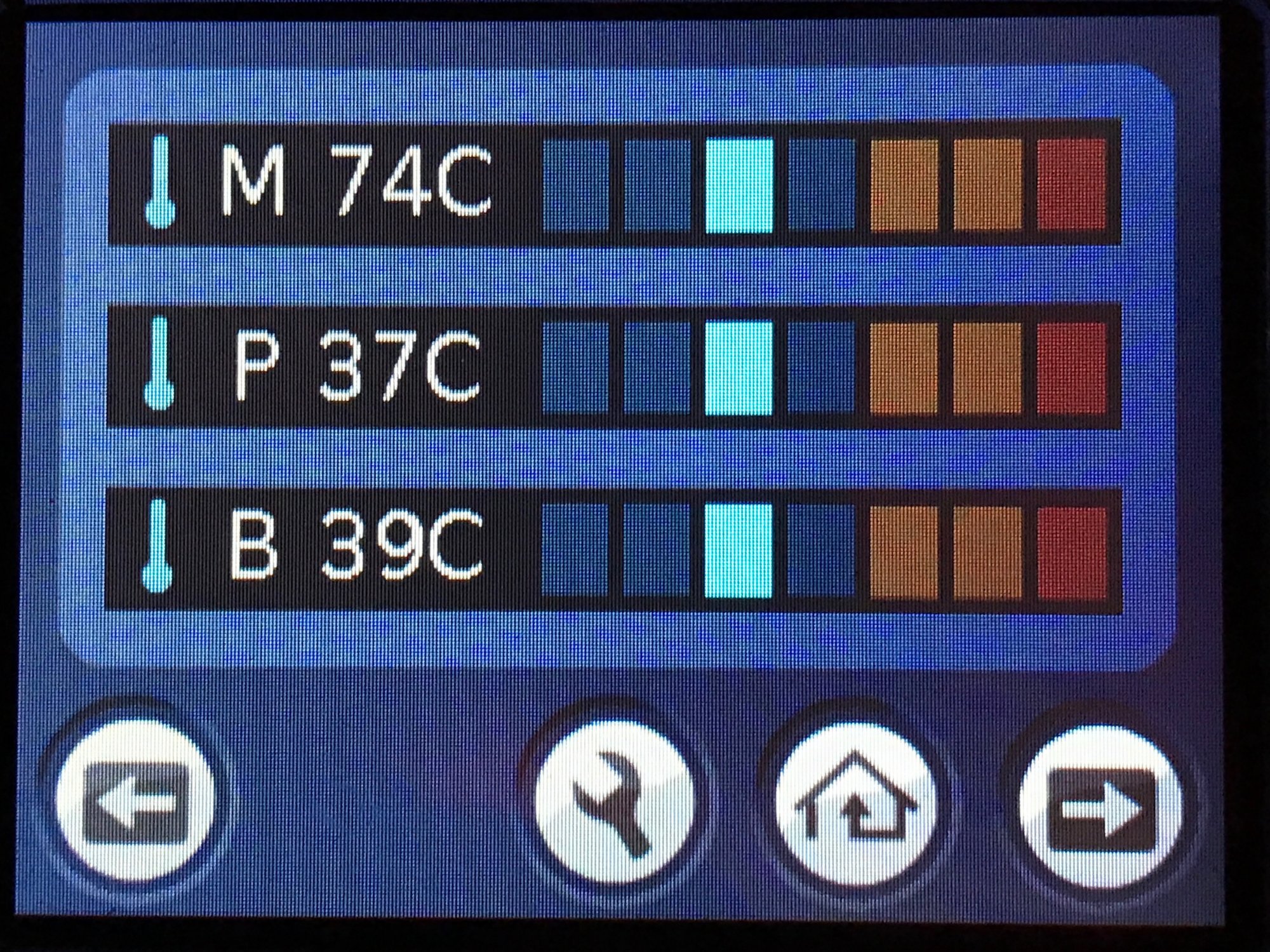

The moment of truth. The debug notification would typically appear merely seconds into my drive. Also, the PEM temperature on the VDS temp screen would rapidly progress from the 2nd blue bar to the 4th in a matter of minutes. This time, neither of these things happened. No annoying beeps, no yellow ring of mockery, and a steady hold of PEM temps on the 3rd bar. After a few hard acceleration runs in Performance mode, the PEM eventually moved into the 4th blue bar but quickly dropped back down to the 3rd which meant the cooling was indeed more responsive. After 45 minutes of hard launches, heavy driving, the motor temp eventually crept up to the 3rd blue bar as did the ESS. By the end of the night, when I pulled back into my garage, not a single debug notification had appeared and the temps of all three vitals were right where you'd expect to see them (Fig. 19).

Figure 19. Final set of vital temperature after about an hour of very spirited driving in Performance mode. More importantly, no beeps or debug notifications.

Thx again to everyone for your input and guidance! I truly hope the steps above addresses this error once and for all