Interesting. They may be surprised that 1146 errors may be diagnostic, but they do show up very clearly in the logs (which are customer accessible). Mine did. So they can't say you shouldn't have seen them.

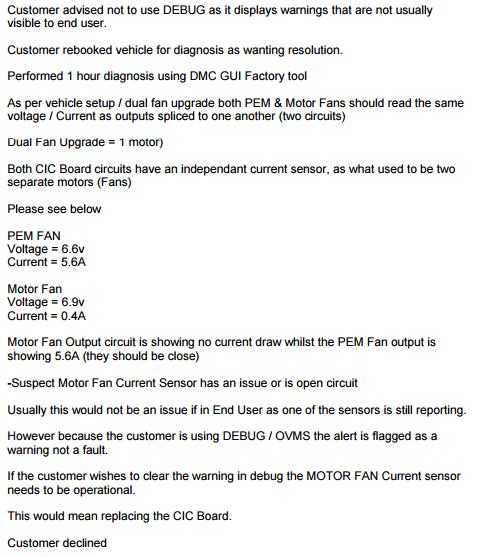

Also, putting a couple of random threads together, I would ask them to verify the wiring of the PEM fan wiring harness Apparently mine wasn't done right at some point in its history, leading to less than expected cooling of the PEM. One very astute tech at the Rocklin SC figured this out, corrected it, and my PEM temps came down very noticeably. This is a wild guess, but it may be that the two PEM circuits drivers were wired in parallel instead of in series. I believe the upgraded motor is 24v, and from what I read they get that by wiring the original two separate 12v drivers in series. I could be all wrong in this - I have a hard time believing that the two PEM drivers had floating grounds - but that's what I concluded. Your data with one driver producing almost no current would be consistent with a parallel wiring, where the driver with the ever-so-slightly higher output would take all the load. If they were in series, the current would indeed be the same.