Hi,

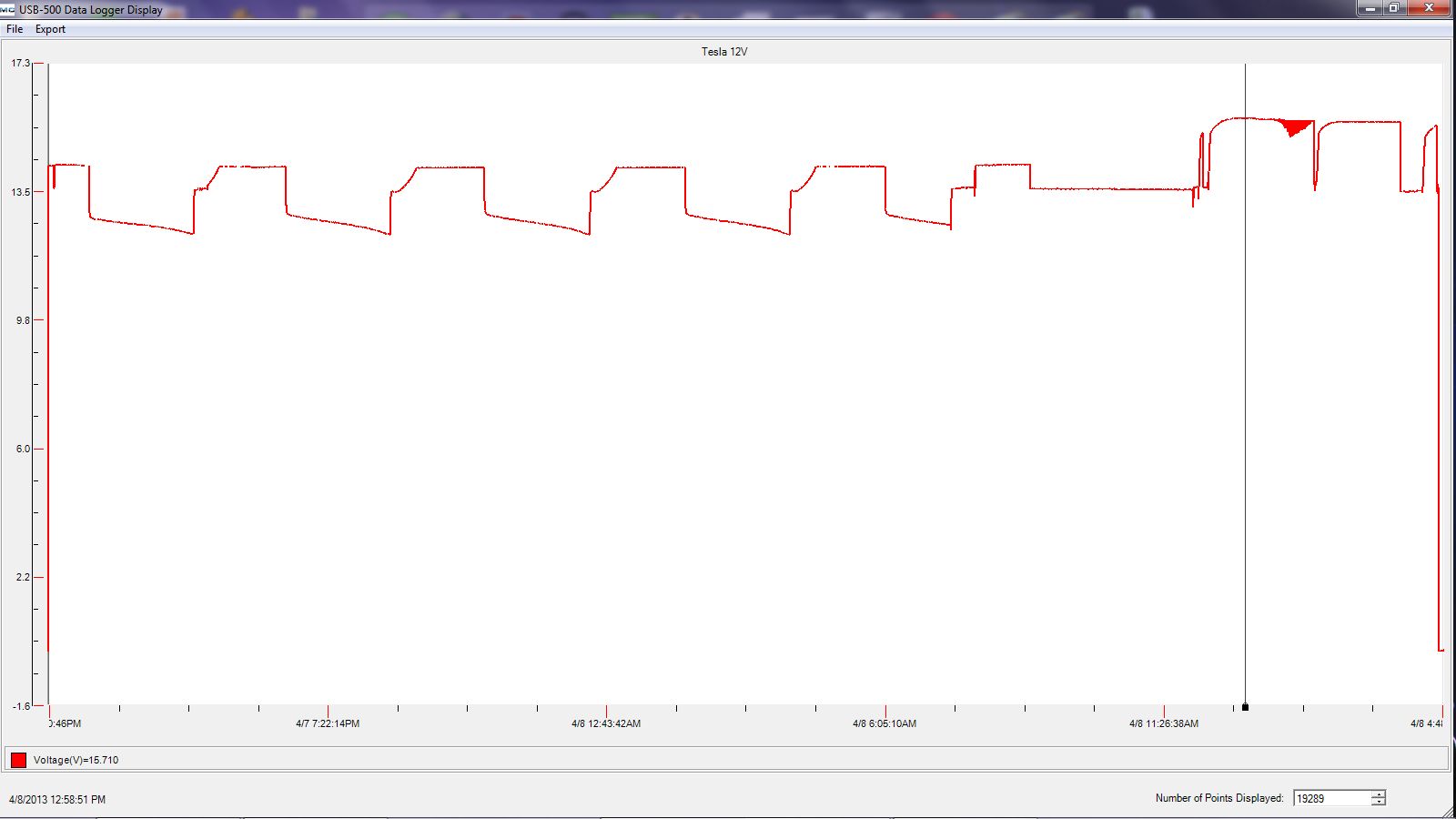

I hooked up a Measurement Computing USB-503 voltage recorder to the charging terminals behind the nose cone and left it there for a day. Here is the graph of the 12V

From the graph, it takes about 2 hours for the 12V battery to discharge to point where the DC-DC converter starts up. Then it charges for another two hours and then starts the cycle all over again.

The scary part is where the voltage goes to over 16V at the cursor. That is way too high to charge a 12V battery. This happened after the car finished fully charging to 190 miles.

I'd be happy send anyone the csv data file.

Michael

Edit: Here is the link to the csv file in my public Dropbox folder.

https://dl.dropbox.com/u/16819482/Tesla%2012V.csv

I hooked up a Measurement Computing USB-503 voltage recorder to the charging terminals behind the nose cone and left it there for a day. Here is the graph of the 12V

From the graph, it takes about 2 hours for the 12V battery to discharge to point where the DC-DC converter starts up. Then it charges for another two hours and then starts the cycle all over again.

The scary part is where the voltage goes to over 16V at the cursor. That is way too high to charge a 12V battery. This happened after the car finished fully charging to 190 miles.

I'd be happy send anyone the csv data file.

Michael

Edit: Here is the link to the csv file in my public Dropbox folder.

https://dl.dropbox.com/u/16819482/Tesla%2012V.csv

Last edited: