Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

beachbum77

Banned

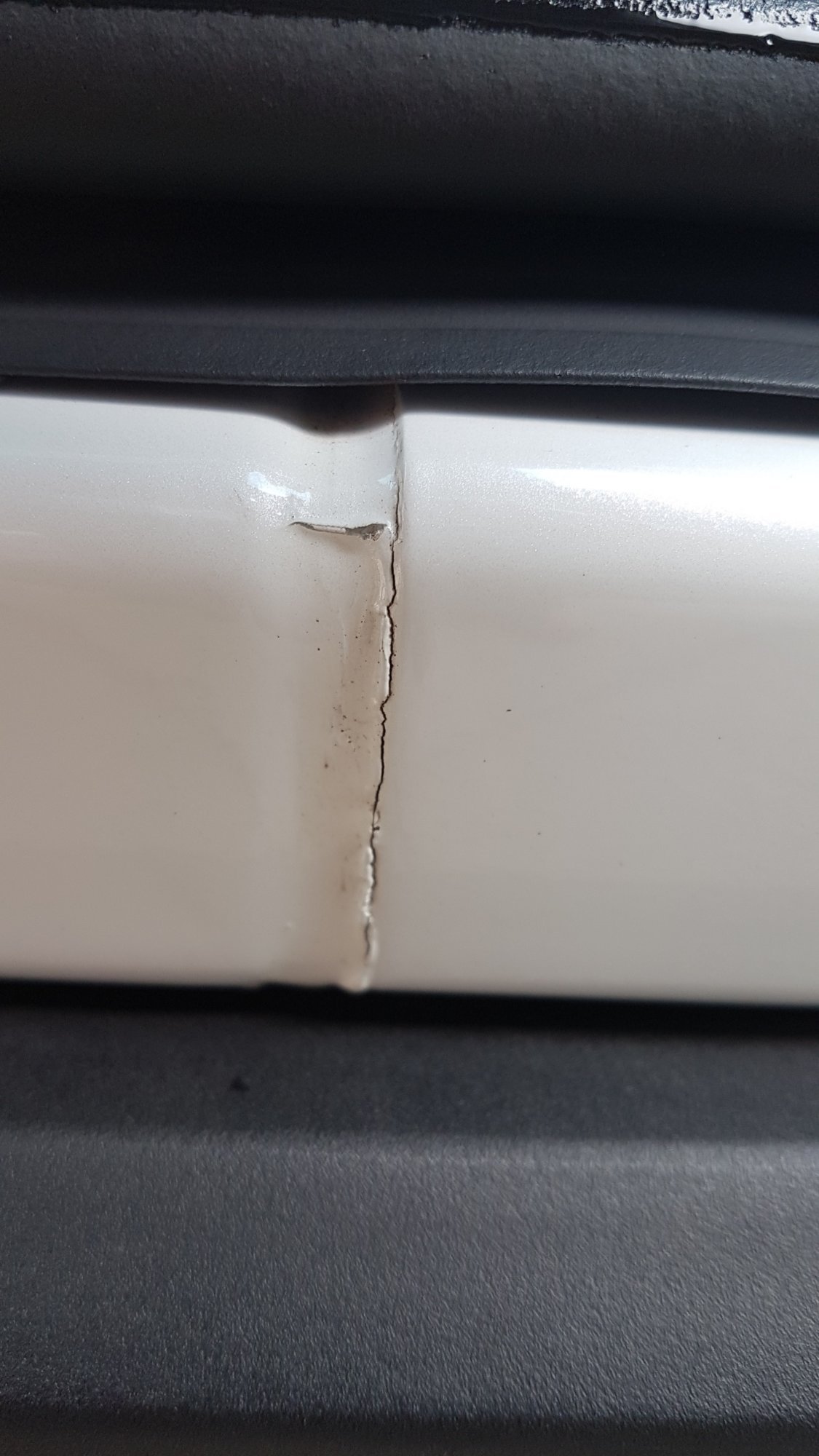

That is one of the worst weld jobs I have ever seen. Where is QA at Tesla? This should have never made it out of the weld station. This is what you get when machines build machines without any humans checking the work.

Lbkmxp100d

Member

I just took a look at both our MX’s. The white X is a December ‘16 build and black is June ‘17 build. As you can see, my white December ‘16 build is cracked as well and the June ‘17 build is perfect. Is your X a performance model? Reason I ask is, my white X is a P100DL while the black is a 100D and I’m wondering if the additional stress with performance models could cause the crack. Although, the weld itself looks much better with our newer black X.

I just took a look at both our MX’s. The white X is a December ‘16 build and black is June ‘17 build. As you can see, my white December ‘16 build is cracked as well and the June ‘17 build is perfect. Is your X a performance model? Reason I ask is, my white X is a P100DL while the black is a 100D and I’m wondering if the additional stress with performance models could cause the crack. Although, the weld itself looks much better with our newer black X.

Last edited:

Jays200

Member

Both sides of mine are the same VIN 42xxx

Not that happy about it but it's more cosmetic than structural. It's like the seam filler has pulled away from one side. I've had it recorded with Tesla.

I'm sure you're familiar with the saying, "My bum's got a crack in it but it still works".

Not that happy about it but it's more cosmetic than structural. It's like the seam filler has pulled away from one side. I've had it recorded with Tesla.

I'm sure you're familiar with the saying, "My bum's got a crack in it but it still works".

Super_Popular

Well-Known Member

It is filler sealant and not weld as I originally thought.

Mine is a July 17 75D so is not related to power/performance.

I’m taking mine next week for other items and definitely pointing this out for them and get it recorded at Tesla.

Mine is a July 17 75D so is not related to power/performance.

I’m taking mine next week for other items and definitely pointing this out for them and get it recorded at Tesla.

Evoforce

Active Member

Yes, I was going to say, that is not structural, that is seam filler. It helps against corrosion and provides some aesthetic value.

oneplusinc

Member

oneplusinc

Member

Oppajer

Member

Showed my 2018 July 75D weld crack to the service advisor and they said they can send it to the body shop to smooth out and fill in/repaint. Should take about a week.

Evoforce

Active Member

Showed my 2018 July 75D weld crack to the service advisor and they said they can send it to the body shop to smooth out and fill in/repaint. Should take about a week.

By the way, as earlier reported, that is not a weld crack. It is also not a structural failure. It is a glue/sealant

filled connection and is sealing against corrosion/dirt and also makes the joint look better.

oneplusinc

Member

By the way, as earlier reported, that is not a weld crack. It is also not a structural failure. It is a glue/sealant

filled connection and is sealing against corrosion/dirt and also makes the joint look better.

Why would Tesla put body paint over a flexible sealant? I don't recon I've ever seen this on a car - yes on baseboard and sheet rock junction, but not a car.

Prior poster said it took a week to repair at body shop. Mine went in yesterday and they said it would be ready today. I'm curious what they're doing to fix mine. Will report back.

Evoforce

Active Member

Why would Tesla put body paint over a flexible sealant? I don't recon I've ever seen this on a car - yes on baseboard and sheet rock junction, but not a car.Seems the proper design would have been a gasket.

Prior poster said it took a week to repair at body shop. Mine went in yesterday and they said it would be ready today. I'm curious what they're doing to fix mine. Will report back.

That is standard industry practice to use sealants and epoxy and many are made to be painted over. Many brands have done that in the past and will do in the future. It fills in a body seam and has a little flexibility. Sometimes the paint isn't quite as flexible or the body flexes enough that it can also crack the sealant/epoxy. Bottom line, not a weld crack, aesthetic only! Nothing to worry about. An additive can be added to the paint but it is not usually done for one small seam like that. It is possible that they will use a little more flexible sealant/epoxy in that spot in the future but it is such a minor thing that they may not.

Last edited:

Oppajer

Member

I don't get why people say it's flexible. When I touch it it seems like it's part of the metal. It was bent like metal and does not feel like rubber at all.

Evoforce

Active Member

Some are more flexible than others. A large variety of different seam fillers/body epoxies are used depending on what its needed application calls for. They may wish they would have used a slightly more flexible one in this location. It would have stopped the panic of some who think it is a mechanical weld failing. There is much more glue/adhesives/epoxies being used in modern manufacturing than ever before.I don't get why people say it's flexible. When I touch it it seems like it's part of the metal. It was bent like metal and does not feel like rubber at all.

Last edited:

If any one else is curious about this seam sealer, watch this video showing how they use it and other compounds in modern car construction and repair.

A.N. Gineer

Member

Similar threads

- Replies

- 0

- Views

- 424

- Replies

- 4

- Views

- 265

- Replies

- 1

- Views

- 405

- Replies

- 0

- Views

- 135