I see a lot of significantly misinformed posts with regards to module level optimization. This topic frustrates me because it's a large source of wasted capital as far as solar installs go. By and large there is virtually no financial benefit to using optimizers. Even with the rapid shutdown requirement the additional cost of adding an optimizer is very unlikely to be recovered. Worse is that it adds another point of failure to the PV system. Here is a related thread: Solar Panel Shading

The only task optimizers are suited for is allowing panels in the same string to face different directions. That it. I've encountered very few installations where this task couldn't also be accomplished with a string inverter that had multiple independent MPP channels. Optimizers DO NOT prevent shaded panels from reducing the production of unshaded panels. Bypass diodes do that. Optimizers also generally do not increase the annual production of a panel. The variation from panel to panel is not significant enough that there's a tangible benefit to allowing each panel to operate at a separate MPP.

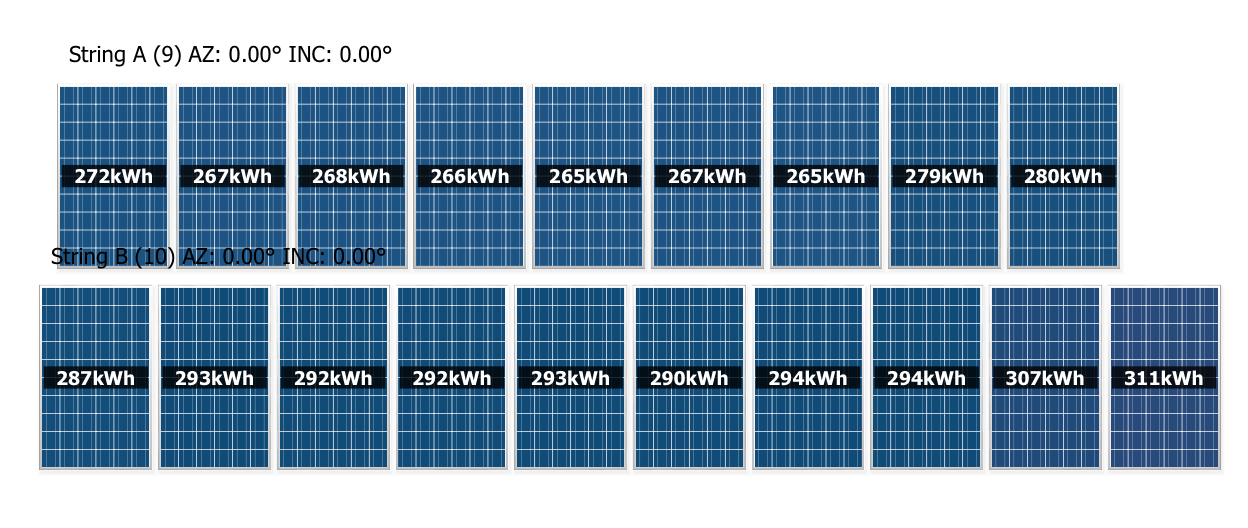

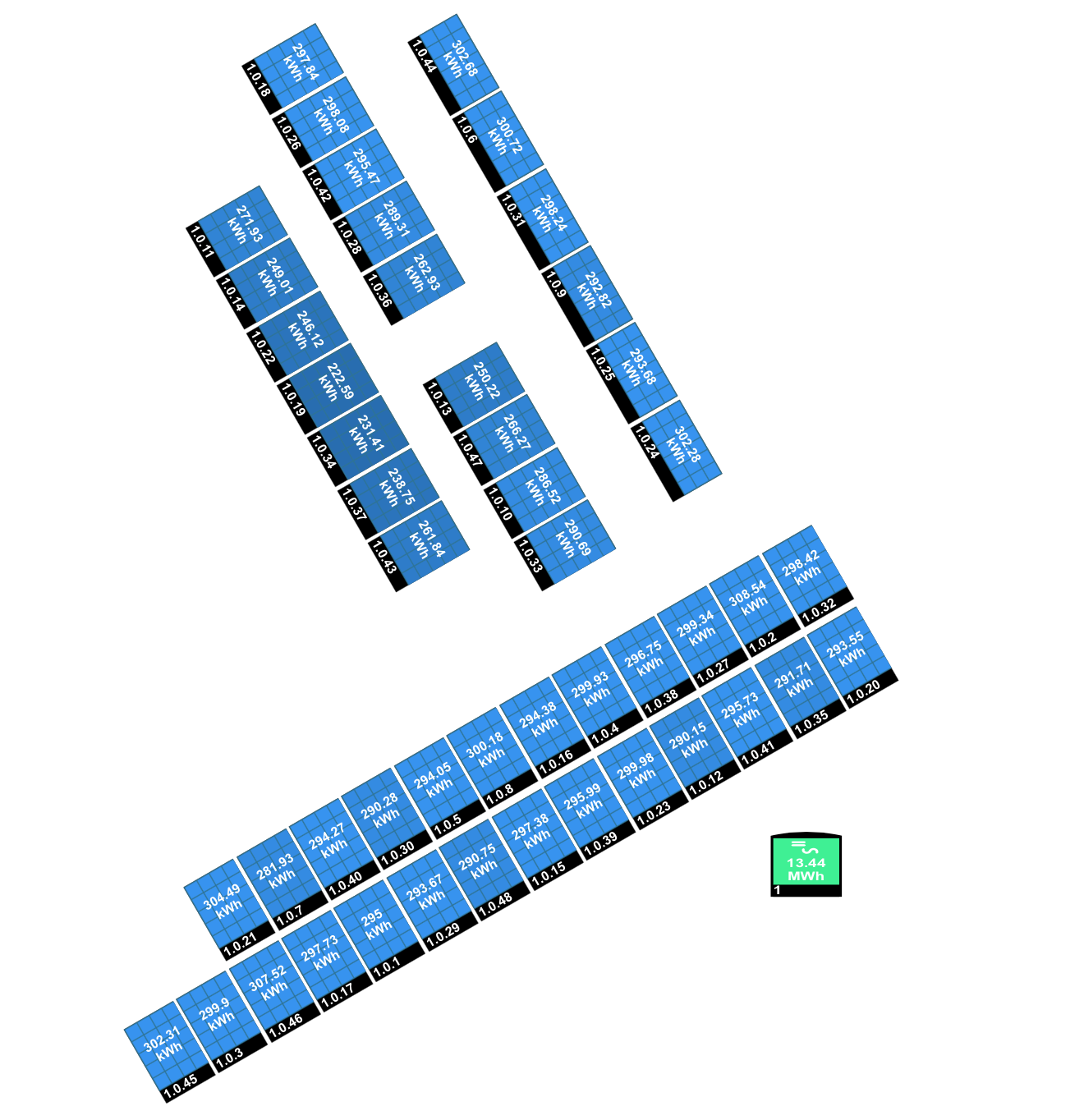

Here is the output from two systems so far in 2020. The top is a SMA string inverter and the bottom is a Solar Edge system with optimization on every panel. The SMA system was expanded at the same time the Solar Edge system was installed. We added 4 310w panels to the existing 15 295w panels. So not only is there no model level optimization in the SMA system but the strings are mixed. The last 2 panels in each string are 310s while the other panels are 295s. The production difference between the top and bottom rows on the SMA system is due to the system being oversized by 50% and SMA inverters clip one channel at a time so all clipping occurs on String A (this also allows to you calculate exactly how much production is lost oversizing by 50%... <5%)

So two systems. One with module level optimization and one without. The panels are from the same batch, installed at roughly the same time, in the same city. The only difference is an orientation of 150 vs 180 which should only yield a benefit of ~2% to the 180 facing panels.

The only task optimizers are suited for is allowing panels in the same string to face different directions. That it. I've encountered very few installations where this task couldn't also be accomplished with a string inverter that had multiple independent MPP channels. Optimizers DO NOT prevent shaded panels from reducing the production of unshaded panels. Bypass diodes do that. Optimizers also generally do not increase the annual production of a panel. The variation from panel to panel is not significant enough that there's a tangible benefit to allowing each panel to operate at a separate MPP.

Here is the output from two systems so far in 2020. The top is a SMA string inverter and the bottom is a Solar Edge system with optimization on every panel. The SMA system was expanded at the same time the Solar Edge system was installed. We added 4 310w panels to the existing 15 295w panels. So not only is there no model level optimization in the SMA system but the strings are mixed. The last 2 panels in each string are 310s while the other panels are 295s. The production difference between the top and bottom rows on the SMA system is due to the system being oversized by 50% and SMA inverters clip one channel at a time so all clipping occurs on String A (this also allows to you calculate exactly how much production is lost oversizing by 50%... <5%)

So two systems. One with module level optimization and one without. The panels are from the same batch, installed at roughly the same time, in the same city. The only difference is an orientation of 150 vs 180 which should only yield a benefit of ~2% to the 180 facing panels.