Yeah that all makes sense, and 220s6p seems quite conceivable as I said

elsewhere. It certainly seems like 6p is for sure, given the approximate voltage (around 924V - 940V max).

Only minor issues:

a)

As I said, 1366, if it is the correct number, doesn't seem to work with this. That leaves 46 cells (1366-220*6) for the 48V system. Only choice is 23s2p which obviously doesn't work at all. Obviously the 1366 number could just not include the 48V system at all, though (48V done with prismatic cells or whatever), and the remaining 46 cells are blanks or something. Or 1366 is just wrong.

b)

110s is called "400V" for the Plaid. So why would 220s be 816V? (Or was it 410V? Can look it up…)

c)

224s6p works better for the "48V inside the pack" issue. (224s6p (main pack) + 11s*2p (48V))

For modules I am not sure which one works better without detailed dimensions of cooling tubes, etc. Model Y 4680 pack was 92s9p. 4 modules of 23 series alongside each other lengthwise (4*23 = 92).

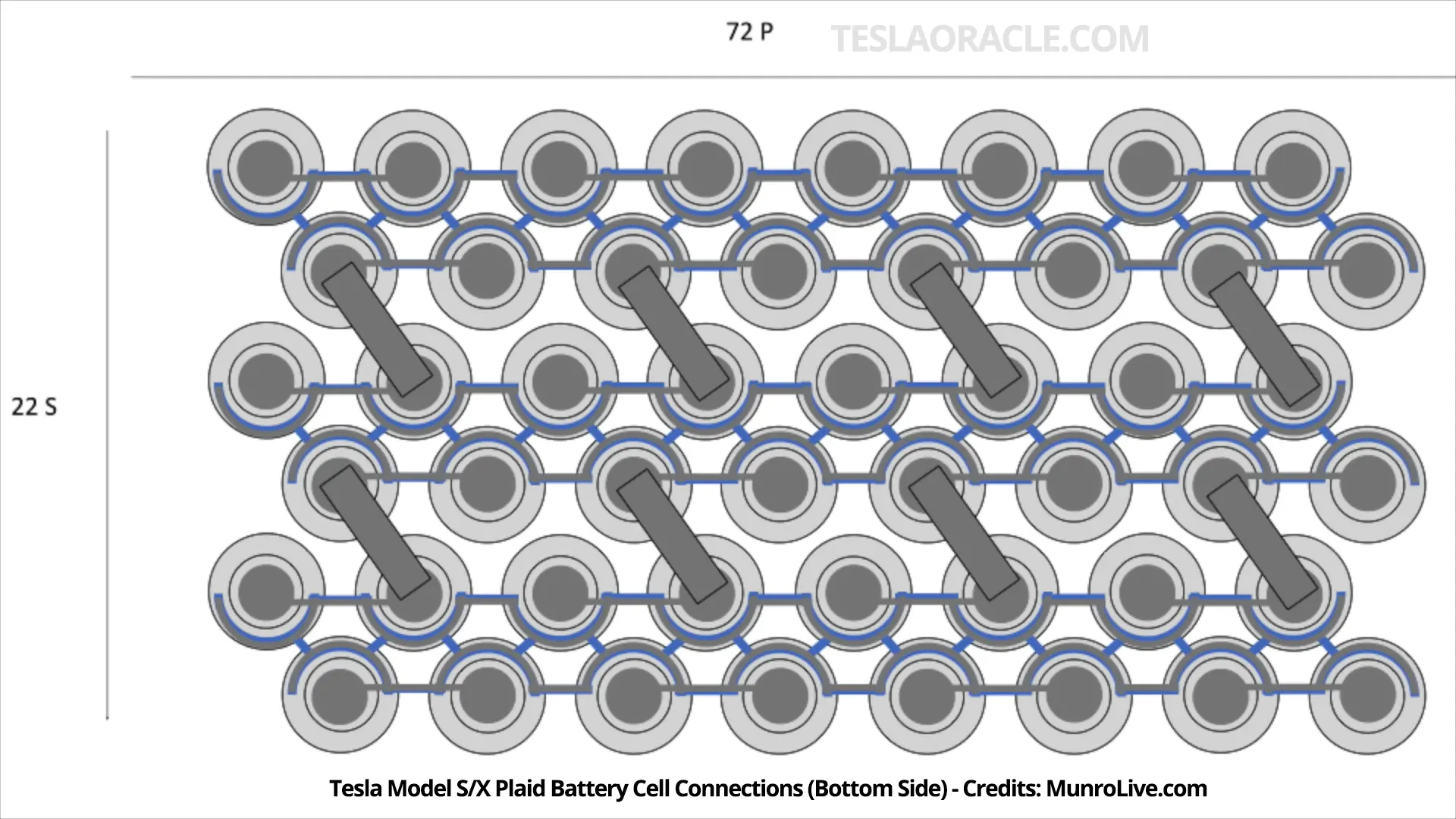

Dimensions: Length: 23 series cells ends up about 35 cells long (2/3 of 35 is about 23) because they're tied in staggered groups of 9 (of width 6!!!), shown

here. Width: Ends up being width 6 for 9 cells in parallel. (6 in parallel as in CT will be 4 cells in width)

110 factors as 2*5*11. 112 factors as 2*2*2*2*7.

110s:

So you only have the choice of 5 modules really per each sub pack with 110s (you could do 2 as well but then you end up with very long and skinny). Each module of 22 series cells would be about the same length as the Model Y; about 33 cells long rather than 35. But width would be too skinny; just 4*5 = 20 cells wide compared to Model Y 24 cells wide. Won't work; we need about 28-32 cell width!

This could be rotated and placed perpendicular to travel direction. 33 series cells might just fit across CT with margin?

So then you'd have 5 modules placed crossways across the truck, times two. Coolant flow might not be ideal this way?

But I think it could work, without going through detailed dimensions.

112s:

Go with 8 modules of length 14.

Width is going to be 4*8 = 32 cells (each 6p module is 4 cells wide). Might work if they make the cooling tubes & pack overhead tighter (otherwise will be too wide). Compare to 24 cells wide in Model Y, plus overhead.

Length of each sub-pack is about 21 cells (14s cells goes to 21 length; in Model Y 23s was about 35 cells long). So two end to end would be 42 cells in length (Cybertruck) vs. 35 cells in length (Model Y). That seems like it would fit easily (wheelbase is ~150 inches vs. 113 for model Y)

114s: (works out to be 1368, 114s*6*2). 48V is not composed of 4680s. 1366 is wrong (should have been 1368).

Could work with modules, six modules of 19s6p. Length about 29 cells, could be laid across the vehicle, which would fit the width (maybe too short). The width of the sub pack would then be about 24 cells (6 of 4-wide rather than 4 of 6-wide), similar to Model Y.

I think this ends up being too narrow and too long for the truck?

Anyway hard to know which one works from a practical standpoint without a good model of the dimensions. If you have that it is possibly easier to see which one works better. There is that other thread you pointed to. They can probably work it out.

Not all modules have to be the same - another complication not covered here. So many options.