J

jbcarioca

Guest

scrutinized not analyzedTesla is likely one of the most scrutinised companies that's ever existed

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

scrutinized not analyzedTesla is likely one of the most scrutinised companies that's ever existed

Here is my logic on finished vehicle shipping: If production is down at every OEM, that frees up car carriers and RoRo ships for Tesla.It will be amazing if Tesla manages to avoid the chip issues, but other supply chain and finished vehicle shipping still will be. huge issue this quarter.

Here is my logic on finished vehicle shipping: If production is down at every OEM, that frees up car carriers and RoRo ships for Tesla.

What's wrong with that logic? What could cause vehicle shipping constraints when demand for carriers and RoRos are down?

/cloudfront-us-east-2.images.arcpublishing.com/reuters/TRQST4FZ7VIZ7E5GNZVZHJYB4Q.jpg)

This is the first time I have understood port hold ups in more than a superficial way. Thank you.

... which is why Tesla is shipping cars to Southern Europe through the Port of Trieste now.

Improvise. Adapt. Overcome. The Mission is all-important.

Cheers!

Yep they have been investing at the edge for a state fund.Not bad

Alaska cashed out 75% of its GameStop stock last quarter - and boosted its Tesla bet by 5%

Alaska cashed out 75% of its GameStop stock last quarter - and boosted its Tesla bet by 5% — Business Insider Australia

The US state's revenue arm sold about 29,000 GameStop shares for around $5 million, thanks to the meme stock's outperformance this year.apple.news

100 house members is less than half the democratic membership. I'd say that is the kiss of death. I'm not going to be surprised to see almost all the EV credit gone.I didn't see this posted. Looks like some significant support for the UAW addendum in the EV bill.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/APUSITMGDBMELBHMC4Y45GD5MY.jpg)

More than 100 U.S. lawmakers urge Pelosi to back union EV tax credit

More than 100 U.S. House lawmakers on Tuesday urged Speaker Nancy Pelosi to keep a $4,500 tax credit incentive for union-built electric vehicles (EV) in a massive spending bill.www.reuters.com

Is that not basically a direct statement that UAW leads to an uncompetitive enterprise? I'm surprised he wasn't a bit more clever with this and frame it as simply supporting unions which are platonically good things not to be questioned because of how much they did for labor back in the 1890s.

But let's work with the premise. It seems to me $4500 far exceeds the actual assembly costs, If it's 100 combined man-hours that's 45$/hour. Does anyone have a better estimate for how much actual UAW labor is required per vehicle?

This continues to be an absolutely absurd estimate. At let's say an average of $8,000 that's predicting ~2m uses of this subsidy over 10 years. seriously wtf?

100 house members is less than half the democratic membership. I'd say that is the kiss of death. I'm not going to be surprised to see almost all the EV credit gone.

I thought it was Koper, down the road in Slovenia?

"Port congestion is still very much with us. Not just at one or two ports. And not just on the West Coast. Of the nation's 10 busiest ports by volume, it is estimated that at least seven face congestion regularly. The causes are varied and complex -- labor disruptions, cargo surges from big ships, infrastructure needs, marine terminal productivity, and equipment shortages, among other causes."

The traditional TMC authority on Europe/UK shippings is @Mr Miserable in this thread... which is why Tesla is shipping cars to Southern Europe through the Port of Trieste now.

Improvise. Adapt. Overcome. The Mission is all-important.

Cheers!

The traditional TMC authority on Europe/UK shippings is @Mr Miserable in this thread

Posts there discuss use of Kotor as a new and seemingly smooth port serving Italy, Eastern Germany, Austria etc. There is no mention of Trieste that I can find, but of course Kotor and Trieste are nearly contiguous anyway.

2021 Shipping Movements

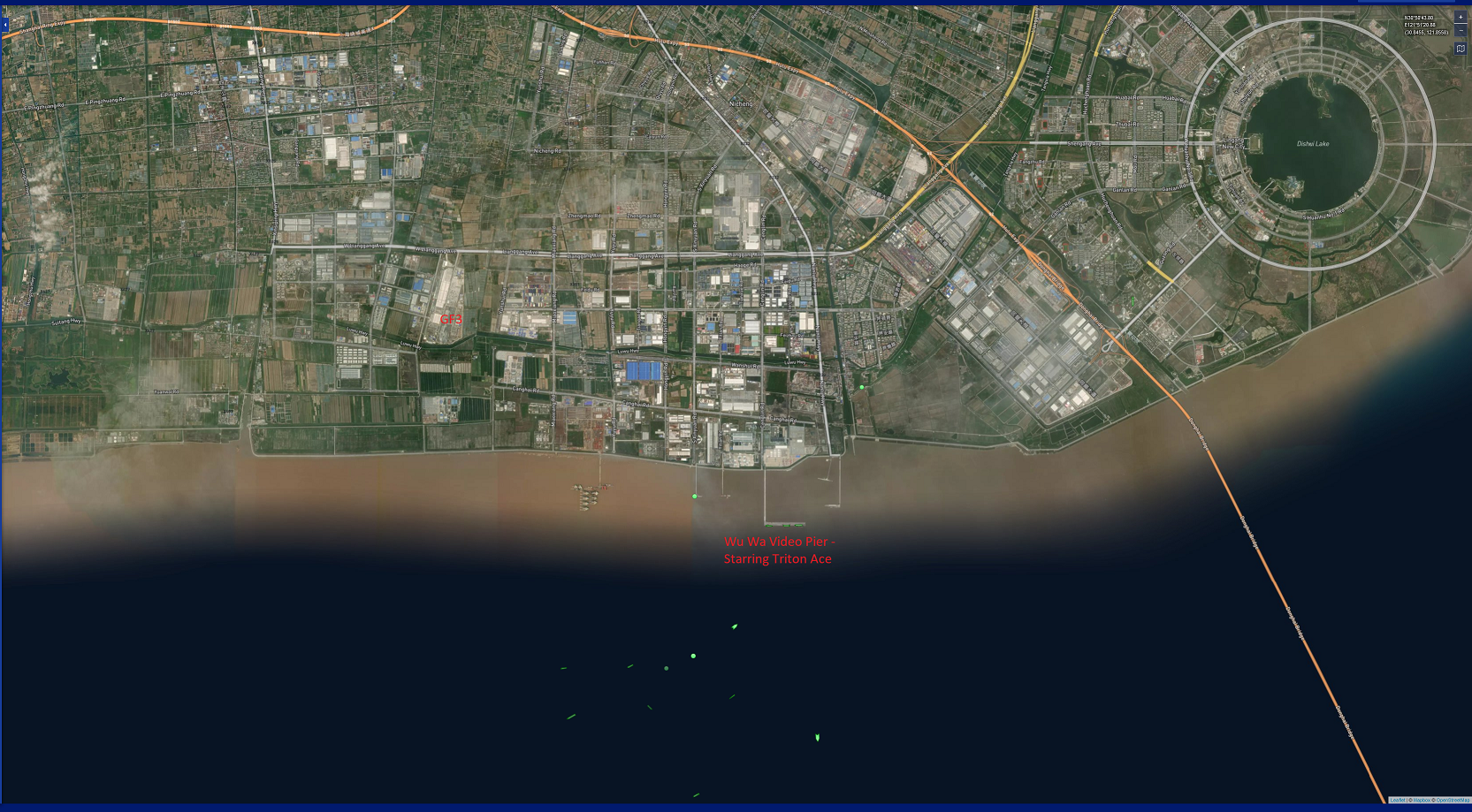

In my net wanderings and reviewing this thread, I of course came across Wu Wa's YT vid of the Triton Ace being loaded with M3s, but didn't notice anyone identifying the pier being used. So just in case its useful I've clipped a screenshot of it from Marine Traffic and also noted that its the...teslamotorsclub.com

Kotor has become a significant vehicle destination from Shanghai, not for Tesla until now. Thus several seemingly well informed people think Teslas have been arriving through Kotor also. However I have no proof of that. The Tesla store in Ljubljana probably knows what ports are being used, since they are by far the closest Tesla store to either fo these ports, I have been there but have no contacts there.

The overall point is that Tesla Shanghai is trying hard to find any way to minimize Shanghai port delays, including use of new berths there. Tesla has been recently using every less-clogged port they can find. of course that includes workarounds for the impossibly backlogged port of Los Angeles/Long Beach, which impedes parts and vehicles.

Thus far it seems Tesla is the only major manufacturer of anything that has not had major stoppages, partly because they seem to have almost superhuman logistics management. Supplier problems are obviously mounting.