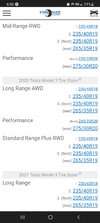

Attached is a list of M3 OEM tire sizes - rolling diameters and theoretical top speeds (20 inch assumed for theoretical top speed, 18 inch as baseline for ratio of rolling diameter) - also a couple of tire options I wanted to see the numbers crunched on.

As you can see, approved OEM tire sizes do have varying rolling diameters - and thus effective gear ratio.

It is my findings that changing tire configuration changes speedometer calibration. - This concept is essential to testing any theory our vehicles are programmed to follow a specific accleration: acquire data a the track or GPS. You will see for yourself that "best effort" is always given: that is to say I believe that - under identical conditions - motor output is limited to the same (current limit?), no matter the wheel/tire configuration. This SUGGESTS there is no connection that the SOFTWARE tire size setting will affect actual measured performance (provided the same wheels and tires are used in the testing). You could validate software behavior by doing dyno testing under identical physical conditions - just software tire/wherl tire selection.

As you can see, approved OEM tire sizes do have varying rolling diameters - and thus effective gear ratio.

It is my findings that changing tire configuration changes speedometer calibration. - This concept is essential to testing any theory our vehicles are programmed to follow a specific accleration: acquire data a the track or GPS. You will see for yourself that "best effort" is always given: that is to say I believe that - under identical conditions - motor output is limited to the same (current limit?), no matter the wheel/tire configuration. This SUGGESTS there is no connection that the SOFTWARE tire size setting will affect actual measured performance (provided the same wheels and tires are used in the testing). You could validate software behavior by doing dyno testing under identical physical conditions - just software tire/wherl tire selection.