Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Traction arm on my Model Y is forged aluminum

- Thread starter osunick

- Start date

nicpottier

Member

My theory, sheet metal arm did not do well in high corrosion environments, and unlike an ICE car, you get torque in both directions with an EV, so I am guessing that metal fatigue, perhaps combined with corrosion, was an issue in some cars. The purpose of this arm is to prevent windup (where the upright twists in reaction to torque applied to it).

Virtually all aluminum control arms are forged, so it would be very surprising if they were cast. Because of the relatively simple shape, the tooling isn’t as crazy as it would be for a wheel, and the reasons for doing Al over steel is either for unsprung weight or strength, and I assume this is the latter. Cost of failure is high for a control arm, manufacturers don’t want to mess with the risk of failure. Ford found this out the hard way when they did a semi solid forging for the Ford GT suspension back in 2003 or so and had to replace all the parts (I was at Ford at the time).Curious how you know it is forged and not cast?

BreatheEasier

Member

I'll have to check mine out...June 2020 build. Are both of your MYs LR? Agree this was an expensive change in design that must have been the result of something...makes we wonder if looking for these from a front-wrecked MY and doing a retrofit is worth it in the future.

CorneliusRox

Member

My theory, sheet metal arm did not do well in high corrosion environments, and unlike an ICE car, you get torque in both directions with an EV, so I am guessing that metal fatigue, perhaps combined with corrosion, was an issue in some cars. The purpose of this arm is to prevent windup (where the upright twists in reaction to torque applied to it).

I'm thinking BOM cost and environmental.

You still get torque reversals on ICE vehicles. (brakes, engine braking esp on diesels with VGTs, reverse, backlash, etc...)

I bet tooling on that forged part was 3X what the stamped weldment was, but unit cost on a raw forged aluminum peice is likely a bit cheaper than the blank/stamp/weld/ecoat/powder paint on the old one.

Who knows, but living in MN and MI most my life, I'm a big fan of things that don't turn into red rust!

I only have the one LR, friend with the stamped steel bit has an MYP. It was cool to discover for sure.I'll have to check mine out...June 2020 build. Are both of your MYs LR? Agree this was an expensive change in design that must have been the result of something...makes we wonder if looking for these from a front-wrecked MY and doing a retrofit is worth it in the future.

I doubt it's BOM at all given what other manufacturers do. For instance on the 3 series, the rear suspension is either welded or stamped aluminum and the M3/M4 have forged components that have identical geometry. If it were cheaper BOM all cars would have the aluminum rear given the volumes involved and the relationships BMW has in place with TRW as the supplier for the aluminum parts. Remember that forged parts still need to be machined, which adds to the cost.I'm thinking BOM cost and environmental.

You still get torque reversals on ICE vehicles. (brakes, engine braking esp on diesels with VGTs, reverse, backlash, etc...)

I bet tooling on that forged part was 3X what the stamped weldment was, but unit cost on a raw forged aluminum peice is likely a bit cheaper than the blank/stamp/weld/ecoat/powder paint on the old one.

Who knows, but living in MN and MI most my life, I'm a big fan of things that don't turn into red rust!

I doubt it, Munro is upset when you are forced to go forged because you didn't package well and have to use a curved arm, which requires the extra strength conferred by a forged aluminum part. The arm is still bone straight so Tesla is doing this for some reason other than packaging which Munro views as a avoidable self-own, especially on a clean sheet platform like MEB.Sandy Munro is going to be upset!

nicpottier

Member

I doubt it, Munro is upset when you are forced to go forged because you didn't package well and have to use a curved arm, which requires the extra strength conferred by a forged aluminum part. The arm is still bone straight so Tesla is doing this for some reason other than packaging which Munro views as a avoidable self-own, especially on a clean sheet platform like MEB.

Sure, sure, was only in jest as I found it funny given how specifically he called that out. He seems to value cost over anything else though and seems to make his judgements based on a lot of conjecture. (informed to some extent yes, but give some credit to VW for not being idiots for god sakes) For example, perhaps VW knew that a stamped part wasn't going to cut it and decided that since they were having to use a forged one then using a curved part had advantages of its own. This is based on absolutely nothing of course, just found it amusing to see the switch over on the Tesla part.

Sure, sure, was only in jest as I found it funny given how specifically he called that out. He seems to value cost over anything else though and seems to make his judgements based on a lot of conjecture. (informed to some extent yes, but give some credit to VW for not being idiots for god sakes) For example, perhaps VW knew that a stamped part wasn't going to cut it and decided that since they were having to use a forged one then using a curved part had advantages of its own. This is based on absolutely nothing of course, just found it amusing to see the switch over on the Tesla part.

Yeah, I suspect VW knows their suspension kinematics, they did invent the four link zero scrub front suspensions in the audis because someone must have given them a sweetheart deal on ball joints! What VW really has no clue about is what people like about Teslas. I drove an ID4 and they did stupid things like electronic door handles that are indistinguishable aerodynamically from normal ones, put in capacitive switches with fixed labels (do a touch screen if you're going to have to look at the controls to use them), and replaced a bunch of the world renowned switchgear with laggy touchscreens. Maybe the most amazing thing is they decided to make the power window switch assembly contain two switches with a toggle between front and rear windows, taking up the exact same space as four switches without a stupid toggle.

CorneliusRox

Member

Man I do love that front suspension. Super fun to adjust camber on... But pretty awesome in any other way.They did invent the four link zero scrub front suspensions in the audis because someone must have given them a sweetheart deal on ball joints!

Ferdinand Piech demanding perfection with a well time open palm slamming on a boardroom table can make magic happen. I agree that if the suspension is in good shape it's very impressive, especially for 1994 when it debuted in the A8 in Europe. That car was designed to be the best luxury sedan in the world and the A4 and everything after benefited.Man I do love that front suspension. Super fun to adjust camber on... But pretty awesome in any other way.

thesmokingman

Active Member

I'm curious how you can use a blanket statement like that. I know for a fact Porsche uses cast arms ALOT. Forging is more for the track prepared models.Virtually all aluminum control arms are forged, so it would be very surprising if they were cast.

You're not talking about the control arms in a modern Porsche, maybe cast trailing arms on a 951 transaxle car or something. The primary difference with the GT3s (besides the 992) is their use of double shear joints, rose joints, and shimmable control arms for camber not the composition. Maybe on an older 951 turbo you may have cast trailing arms but a modern multilink, they are virtually all forged links. Uprights and such may be cast, but links are small and strong and easier to forge and they are under a fair bit of stress.I'm curious how you can use a blanket statement like that. I know for a fact Porsche uses cast arms ALOT. Forging is more for the track prepared models.

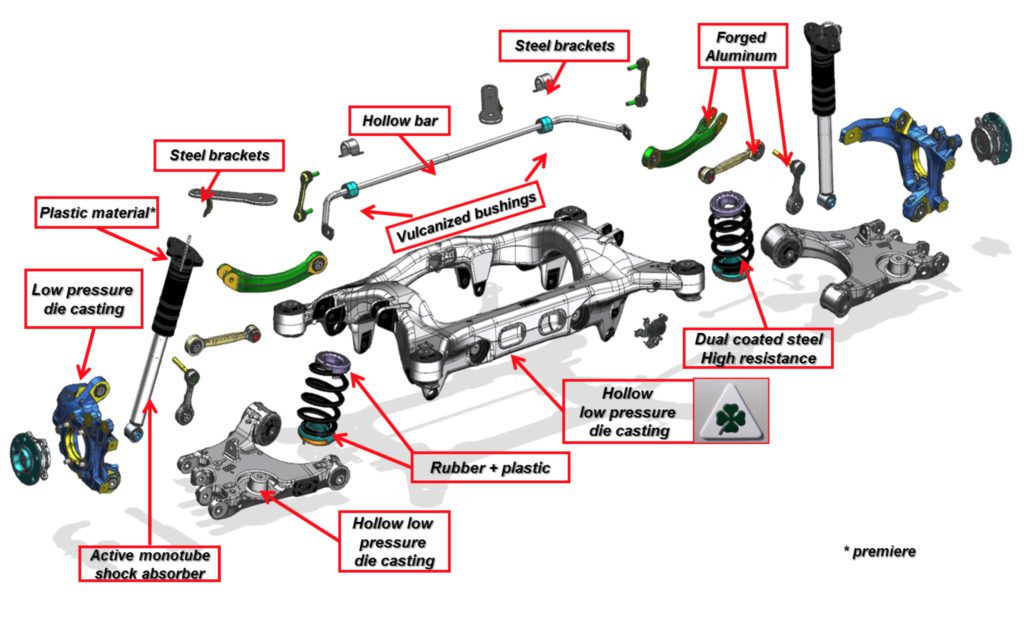

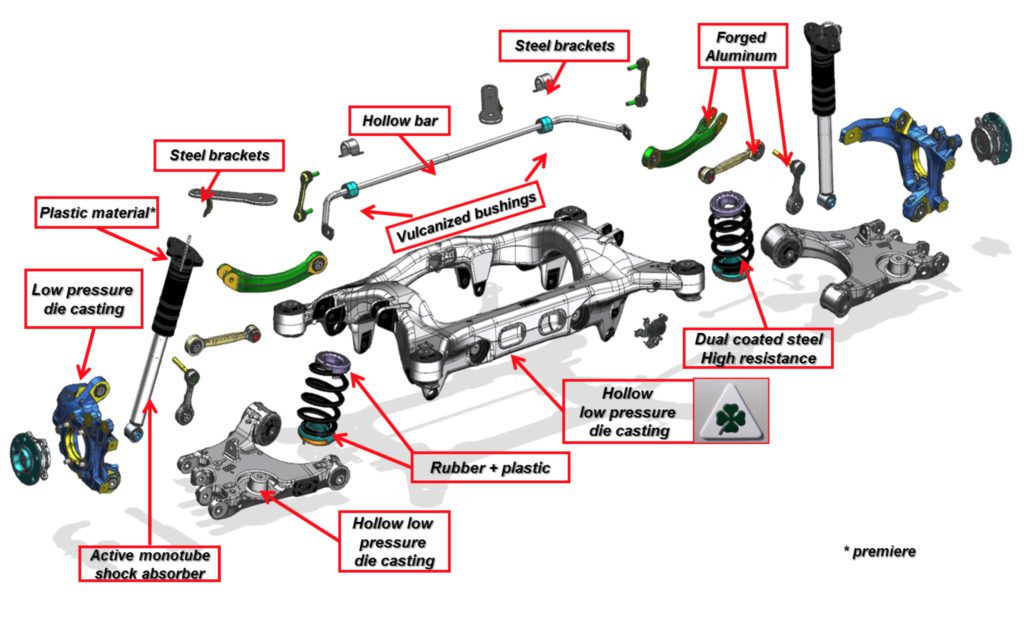

Here's an Alfa Giulia rear suspension, a near luxury rwd sedan with a substantially similar layout to the Tesla, with a bit more aluminum. Links are all forged. They're small, they're straight, you don't have the same sort of complexity you would with an LCA w/spring perch or an upgright.

thesmokingman

Active Member

Pretty sure the 991/996/997 lca are cast.You're not talking about the control arms in a modern Porsche, maybe cast trailing arms on a 951 transaxle car or something. The primary difference with the GT3s (besides the 992) is their use of double shear joints, rose joints, and shimmable control arms for camber not the composition. Maybe on an older 951 turbo you may have cast trailing arms but a modern multilink, they are virtually all forged links. Uprights and such may be cast, but links are small and strong and easier to forge and they are under a fair bit of stress.

Here's an Alfa Giulia rear suspension, a near luxury rwd sedan with a substantially similar layout to the Tesla, with a bit more aluminum. Links are all forged. They're small, they're straight, you don't have the same sort of complexity you would with an LCA w/spring perch or an upgright.

Hell, to be fair I'm pretty sure Tesla avoids forgings on purpose. They went thru the trouble of creating their own alu metalurgy to prevent the need for FORGING and heat treating. That said a lot of bits on Teslas are actually extrusions. Their material science is far ahead of the rest of the auto industry which stopped pushing material science decades ago. Thus, I was curious how you could make a bold statement like that...

Tesla invents new aluminum alloys for die casting electric car parts

Tesla has invented new aluminum alloys that can maintain high-yield strength and high conductivity while still being used for die...

electrek.co

electrek.co

Model S indeed uses extrusions, some of the early cars looked like handbuilt show cars with all the CNC underneath, but the extruded components have a very particular look and these look like what you'd find on a BMW which does indeed have forged links. But in this particular case, given the application and simplicity of the design, combined with the volume, my bet is on forged. They're definitely not extruded because extruded parts have a specific look with a fixed cross section (see rear suspension links on S here)Pretty sure the 991/996/997 lca are cast.

Hell, to be fair I'm pretty sure Tesla avoids forgings on purpose. They went thru the trouble of creating their own alu metalurgy to prevent the need for FORGING. That said a lot of bits on Teslas are actually extrusions. Their material science is far ahead of the rest of the auto industry which stopped pushing martial science decades ago. Thus, I was curious how you could make a bold statement like that...

Tesla invents new aluminum alloys for die casting electric car parts

Tesla has invented new aluminum alloys that can maintain high-yield strength and high conductivity while still being used for die...electrek.co

2012 Tesla Model S Signature Performance Suspension Walkaround | Edmunds

We put the all-new 2012 Tesla Model S up on our rotary lift and take a close look at the Suspension that underpins this premium rear-drive electric vehicle.

www.edmunds.com

Coffin arms on 991/997/996 are supplied by TRW which heavily suggests forged not cast, but I could see it either way. Links in multilink rear suspension are generally forged due to simplicity of design and huge gains in strength vs weight tradeoff and their limited cross section. 944/951/968 transaxle cars are definitely cast.

Jigglypuff

Member

Yeah I bet it's not that different. Stamped steel is light. I assume strength or corrosion was the reason.I'd be curious to see weights on the steel vs aluminum part.

Similar threads

- Replies

- 2

- Views

- 383

- Marketplace listing

- Replies

- 0

- Views

- 319

- Replies

- 17

- Views

- 563

- Replies

- 10

- Views

- 1K

- Replies

- 18

- Views

- 7K