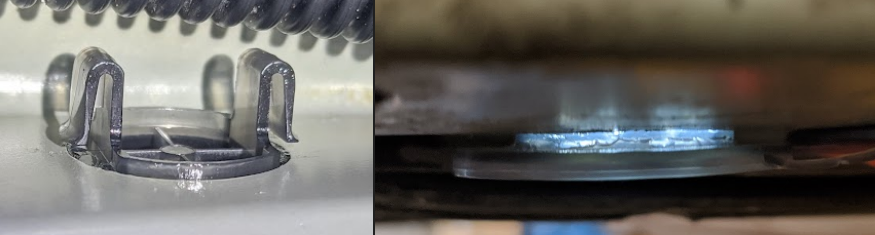

One other thing i noticed that isn't mentioned anywhere is each module's connections had grease and some glue.

When removing modules i had to pry bus bars lightly to break the glue.

Not sure what the significance of these are... I tested with multi-meter and both are non-conductive.

I wiped the grease from touching points and lightly wire brushed bus bars before assembly.

FYI, bolts for these connections are actually non-conductive so only the flat contact area of module/bus bar is conducting electricity.

I believe with such large bolts the pressure it creates is sufficient to squeeze everything out and make solid contact for 1000+ amps.

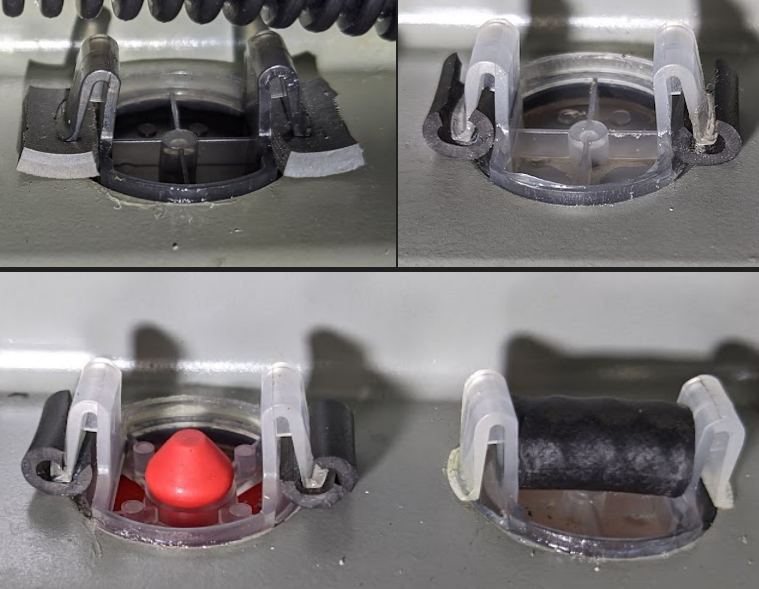

After replacing one of the umbrella valves strips, i discovered that they have some up/down play. New ones had even larger gap.

I looked through all of them and most had a play.

Battery case also has chamfered edge at the bottom.

On some of these valves/plugs (esp the new ones) it felt like o-ring was sitting on chamfer, causing even more down force.

This didn't feel right to me and to prevent future water/dirt ingress 100% i experimented with few ways to fix it.

Btw, o-rings are covered with grease from factory.

First i cut old HP printer roller in pieces, but this takes long time. Then i used rubber hose split on one end, and finally just a piece of rubber hose between legs to keep em closer to case. Ended up using combination of last 2, cause there's not enough room for large hose due to umbrellas..

Now all my valves/plugs are flush and shouldn't move down at all.

In addition i wanted something visual for water detection in the future, so i bought a sheet of water detection stickers and placed a couple in each of 14 sections. I tested one out (left) just to make sure they work. This way i can see where water is/was next time i inspect these valves.

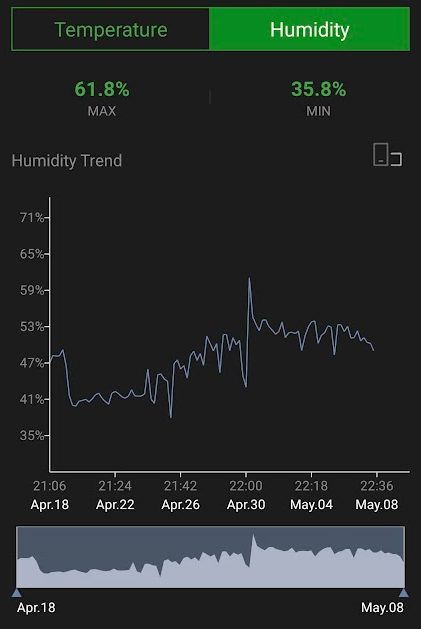

And i also mentioned in earlier post, i added a bluetooth temp/humidity sensor.

It would only fit behind pyro fuse, in the side cavity. It's still accessible from outside just have to remove cover and fuse.

Range is very small due to all the metal around but it gets enough signal to sync with phone around the passenger side door/wheel.

Not really sure what would be the normal humidity inside the pack but so far its been in the range of 40-60% after closing the pack and driving through few light rains.

@howardc64 asked if i can do the pressure test of the pack in place, it is possible but i didn't do it cause i was out of time at that moment and for proper test i feel like you need to tape/cover the breathers and rear pack connectors cause those are not 100% sealed when pack is out (maybe even when its in)..

The fitting for testing is accessible with just a shear plate removed. On earlier packs it looks like its location is even more to the left.

PS. Driven about 1k miles but only couple of light rains, so far so good. Will update the thread after another 10kmi for true comparison

When removing modules i had to pry bus bars lightly to break the glue.

Not sure what the significance of these are... I tested with multi-meter and both are non-conductive.

I wiped the grease from touching points and lightly wire brushed bus bars before assembly.

FYI, bolts for these connections are actually non-conductive so only the flat contact area of module/bus bar is conducting electricity.

I believe with such large bolts the pressure it creates is sufficient to squeeze everything out and make solid contact for 1000+ amps.

After replacing one of the umbrella valves strips, i discovered that they have some up/down play. New ones had even larger gap.

I looked through all of them and most had a play.

Battery case also has chamfered edge at the bottom.

On some of these valves/plugs (esp the new ones) it felt like o-ring was sitting on chamfer, causing even more down force.

This didn't feel right to me and to prevent future water/dirt ingress 100% i experimented with few ways to fix it.

Btw, o-rings are covered with grease from factory.

First i cut old HP printer roller in pieces, but this takes long time. Then i used rubber hose split on one end, and finally just a piece of rubber hose between legs to keep em closer to case. Ended up using combination of last 2, cause there's not enough room for large hose due to umbrellas..

Now all my valves/plugs are flush and shouldn't move down at all.

In addition i wanted something visual for water detection in the future, so i bought a sheet of water detection stickers and placed a couple in each of 14 sections. I tested one out (left) just to make sure they work. This way i can see where water is/was next time i inspect these valves.

And i also mentioned in earlier post, i added a bluetooth temp/humidity sensor.

It would only fit behind pyro fuse, in the side cavity. It's still accessible from outside just have to remove cover and fuse.

Range is very small due to all the metal around but it gets enough signal to sync with phone around the passenger side door/wheel.

Not really sure what would be the normal humidity inside the pack but so far its been in the range of 40-60% after closing the pack and driving through few light rains.

@howardc64 asked if i can do the pressure test of the pack in place, it is possible but i didn't do it cause i was out of time at that moment and for proper test i feel like you need to tape/cover the breathers and rear pack connectors cause those are not 100% sealed when pack is out (maybe even when its in)..

The fitting for testing is accessible with just a shear plate removed. On earlier packs it looks like its location is even more to the left.

PS. Driven about 1k miles but only couple of light rains, so far so good. Will update the thread after another 10kmi for true comparison

Last edited: