My late 2016 Model S was one of the earlier cars to exhibit the infamous yellow ring on the 17” MCU screen. I had it replaced early on, right before my warranty expired, before the prevalence of the problem was really known. Now about a year and a half later, the replacement screen has once again yellowed and I’m well out of warranty, about to turn 100,000 miles. I’m far from a service center, have no idea if Tesla would charge me for the UV treatment, if they even have the tool, and frankly don’t have the time or interest to fight with their service organization about it.

But hey, it’s just UV light, right? How hard could this be? I did a little research and determined that most adhesives for glass bonding are cured with UV light in the 365-400nm range. After a little poking around on Amazon looking for a reasonably powerful light in that spectrum, I settled on this bad boy for $35:

https://www.amazon.com/dp/B07MDWKNMK

8/14/2020: Added link to a different product which people have had better luck with

https://www.amazon.com/gp/product/B06X8ZVJSS?tag=tmc064-20

It arrived the next day and I set out to fashion a rig of sorts (read: stack of cardboard boxes) to position the light in front of the screen and see what happened. I took some basic precautions to cover the dash with towels - didn’t want to risk yellowing the lacquer on the wood dash parts or anything.

Long story short, it’s dark now so hard to know for certain but first impression is that after 4 hours of baking the yellowing is dramatically reduced, but not quite gone. I’m going to examine things in the daylight tomorrow and based on what I see do another 4-6 hours and reassess. As of now I’m quite pleased with the results for $35 and am reasonably certain it will get even better with a little more time.

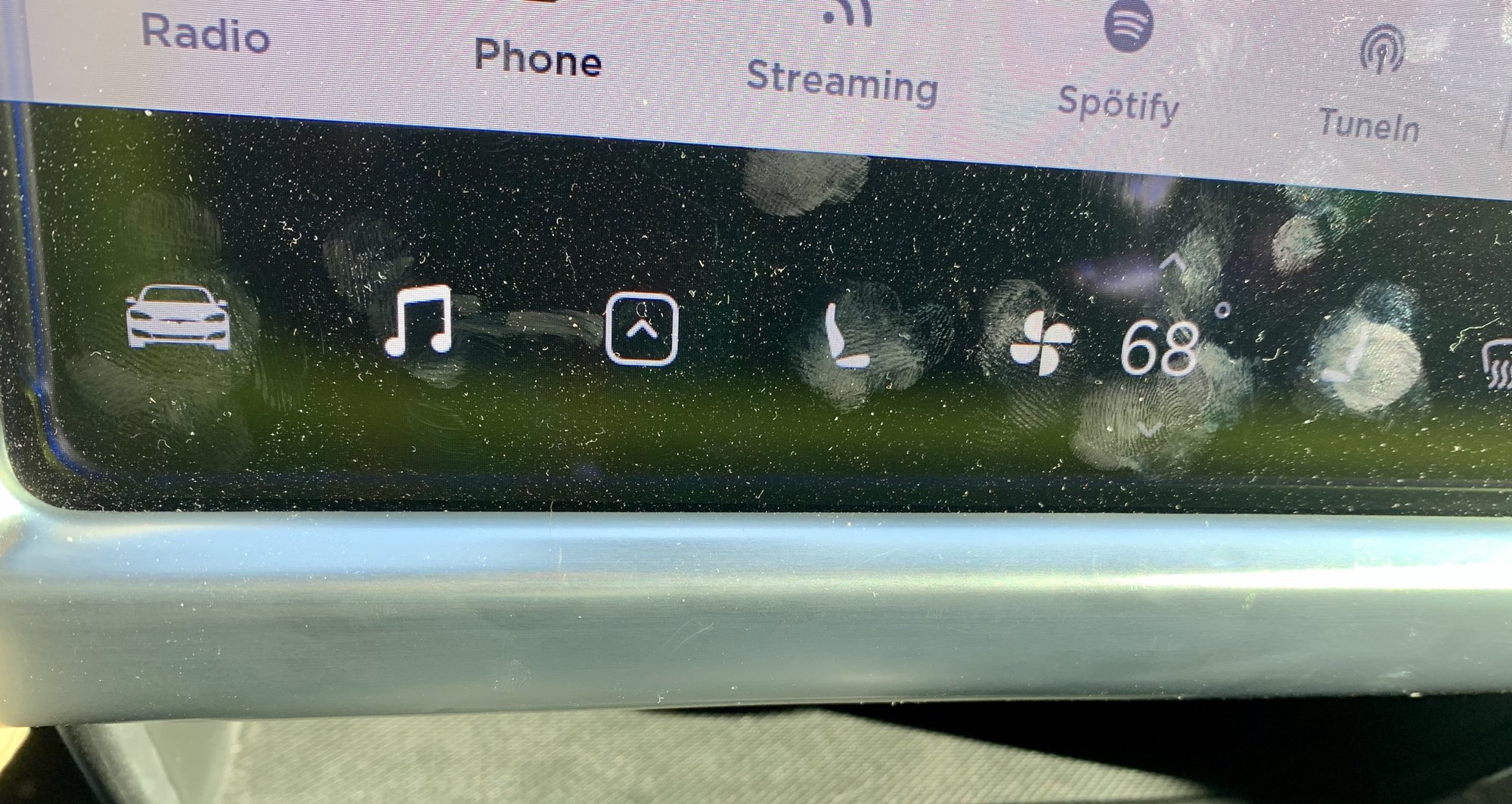

Before:

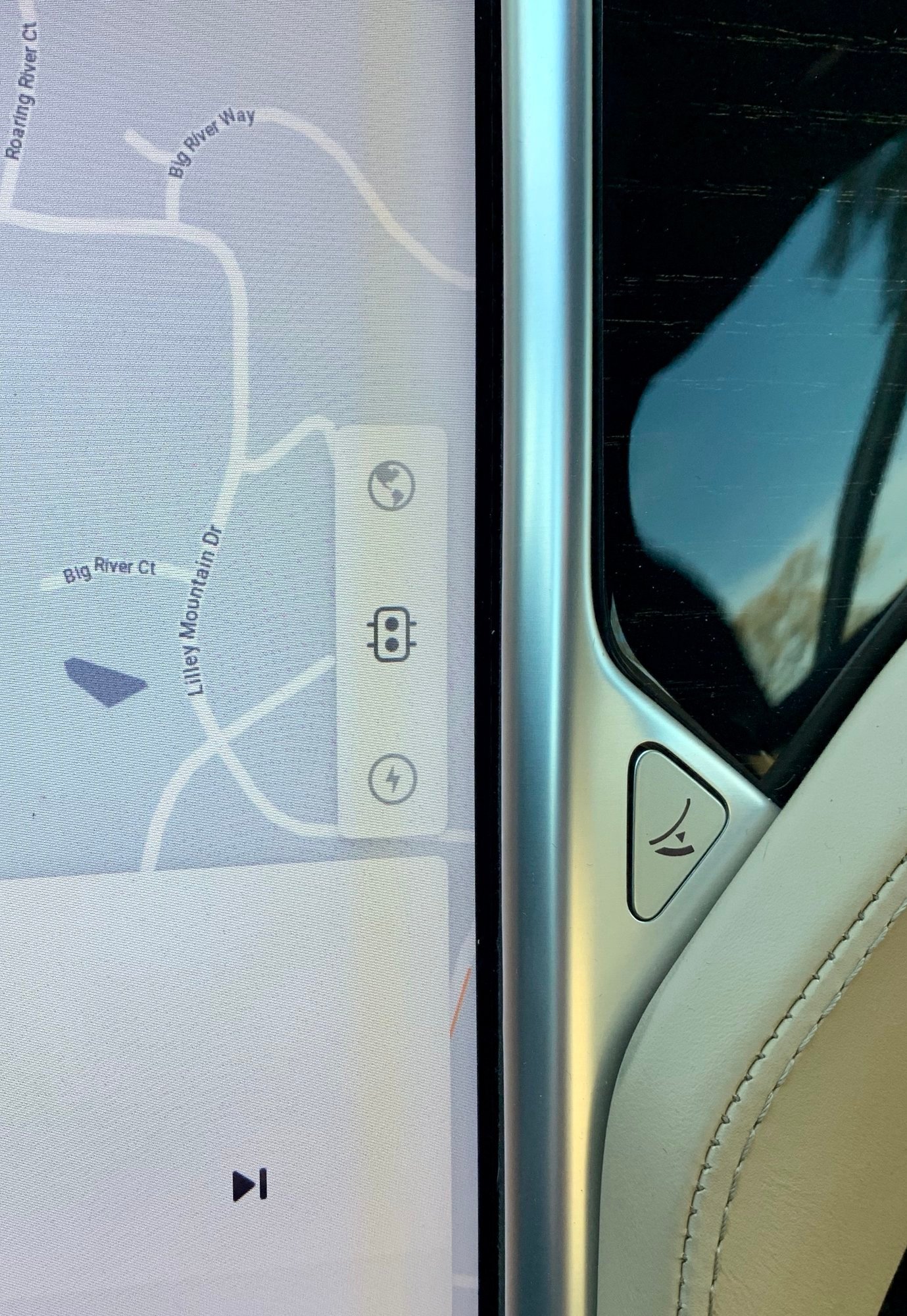

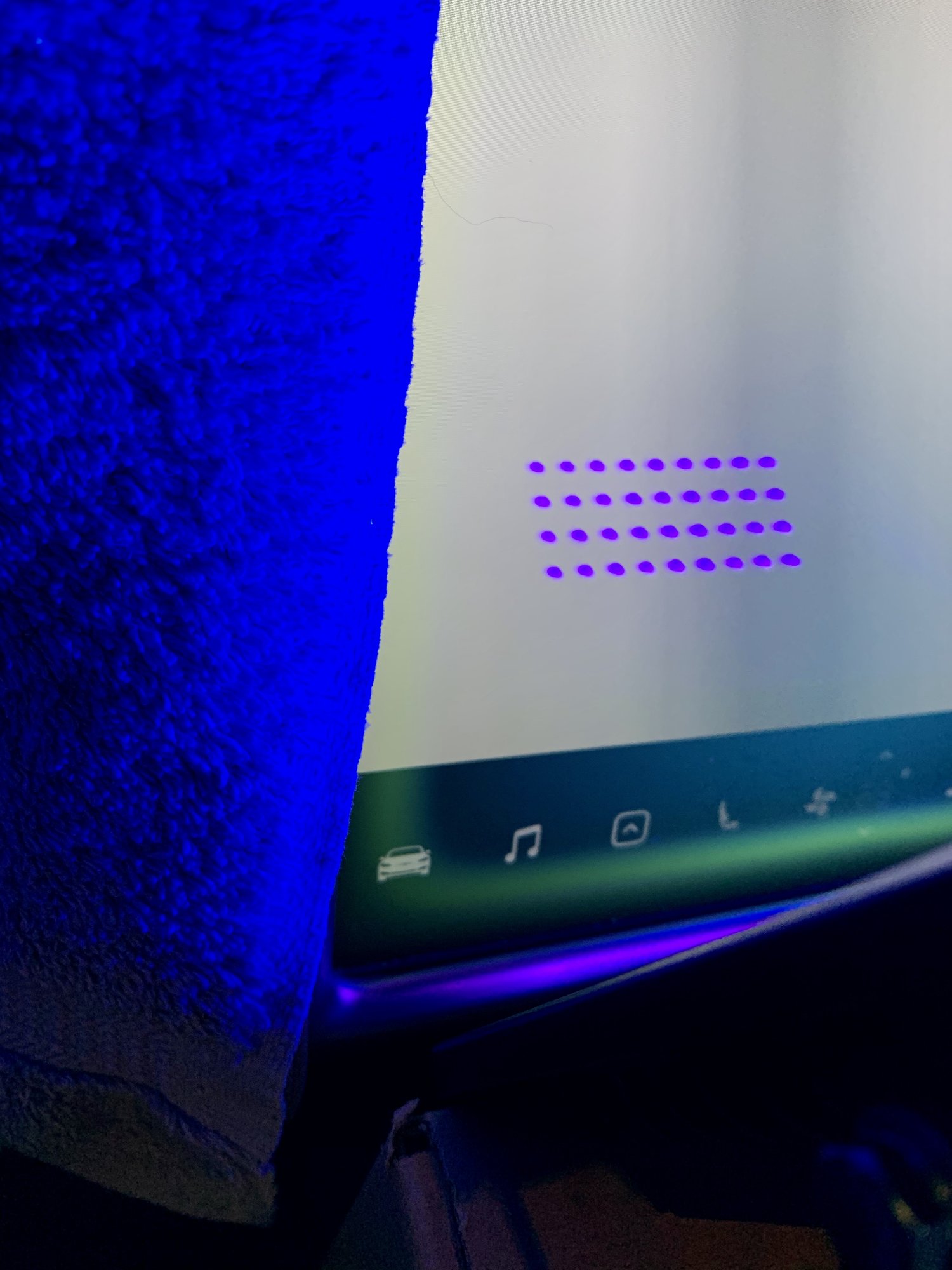

Shots of my “rig”:

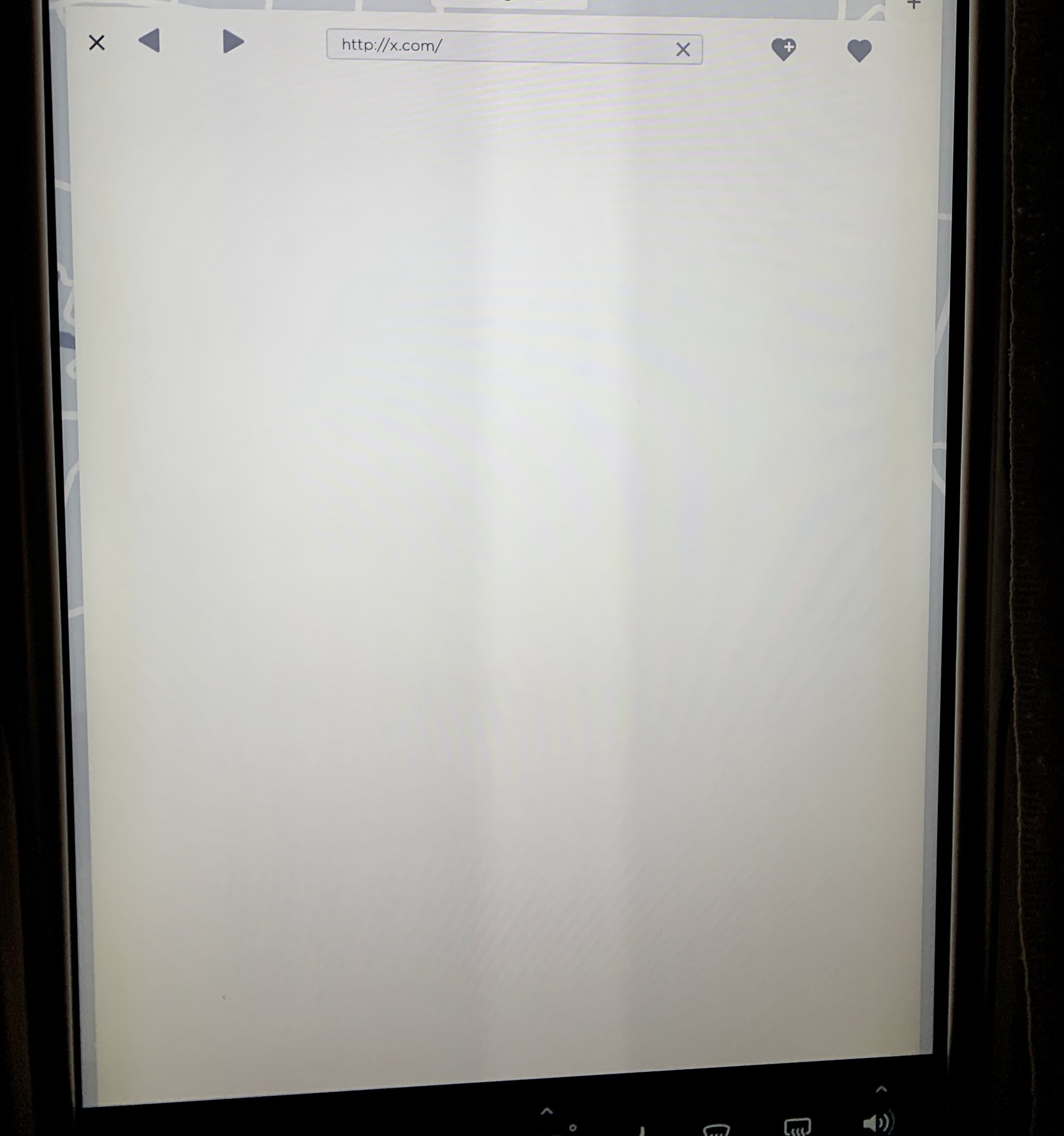

After:

I know it’s kinda hard to see the results in the pics, but it looks markedly better in person. Will try and get some better shots tomorrow.

But hey, it’s just UV light, right? How hard could this be? I did a little research and determined that most adhesives for glass bonding are cured with UV light in the 365-400nm range. After a little poking around on Amazon looking for a reasonably powerful light in that spectrum, I settled on this bad boy for $35:

https://www.amazon.com/dp/B07MDWKNMK

8/14/2020: Added link to a different product which people have had better luck with

https://www.amazon.com/gp/product/B06X8ZVJSS?tag=tmc064-20

It arrived the next day and I set out to fashion a rig of sorts (read: stack of cardboard boxes) to position the light in front of the screen and see what happened. I took some basic precautions to cover the dash with towels - didn’t want to risk yellowing the lacquer on the wood dash parts or anything.

Long story short, it’s dark now so hard to know for certain but first impression is that after 4 hours of baking the yellowing is dramatically reduced, but not quite gone. I’m going to examine things in the daylight tomorrow and based on what I see do another 4-6 hours and reassess. As of now I’m quite pleased with the results for $35 and am reasonably certain it will get even better with a little more time.

Before:

Shots of my “rig”:

After:

I know it’s kinda hard to see the results in the pics, but it looks markedly better in person. Will try and get some better shots tomorrow.