Can you show the line for the rigid stops too?I should perhaps also mention that the measurements are made on a 10s section of the same stretch of Swiss Autobahn, at 77.7 mph.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ear pain/Pressure help

- Thread starter justobuf

- Start date

-

- Tags

- sound proofing

azeteg

Member

Can you show the line for the rigid stops too?

I didn't put that graph in specifically, because I have a feeling that something is not correct with this measurement. It shows an even higher resonance peak, which I couldn't verify with my ears. With just the rigid stoppers (purple), it was better than stock (blue). But as I wrote earlier, the hatch countermeasures do not affect the resonance problem, only the buffeting/pressure problem. This graph at least confirms this, becuase that issue is related to frequencies below 30Hz.

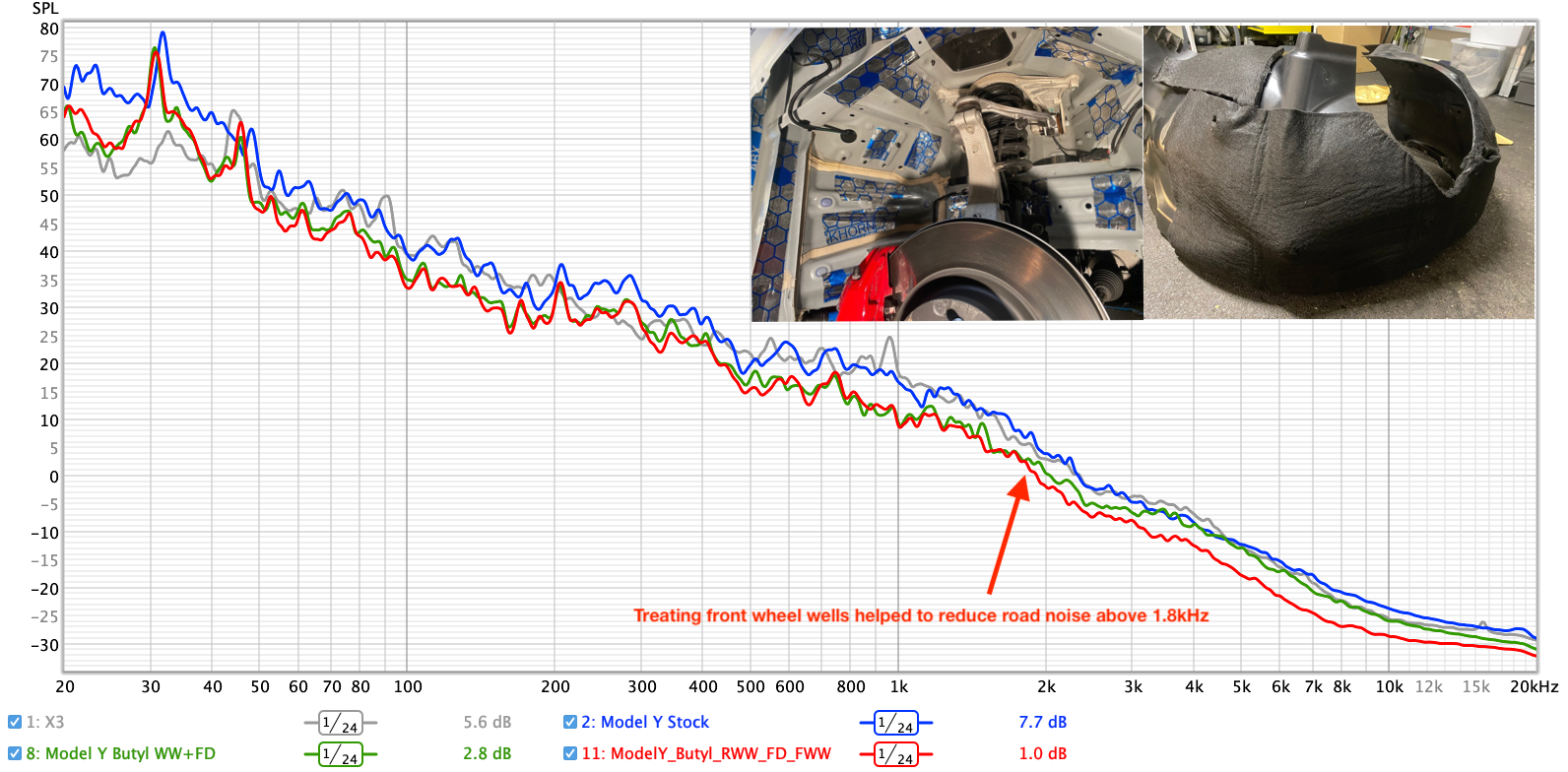

I have also performed additional measures after this, shown in green here. This includes 4 layers of Alubutyl on the rear wheel wells, and 1 layer of alubutyl + 1 layer of 10mm felt in the front doors. This helps slightly to reduce the resonance, but it does more for frequencies above 40Hz.

azeteg

Member

Small update:

I continued this quest by further treating the front wheel wells. I didn't go overboard with the alubutyl here, only applied it to spots which resonated when knocking on them. I was however very liberal with the 10mm fleece. Most likely this is what took care of the reduction of the high frequency road noise, above 1.8kHz. No discernable difference for the low frequencies.

This weekend I'll be experimenting with a 33Hz tuned mass damper from BMW. I'll try fixing this to various resonant parts, to see if it has any impact on the low frequency rumble. I also have a Tesla service appointment next Friday (for Auto Garage Opener install and Supermanifold replacement). I also asked them about the low frequency noise issue, and they will have a look - but I don't think that will bring much. They'll probably just be surprised how quiet my car is

I continued this quest by further treating the front wheel wells. I didn't go overboard with the alubutyl here, only applied it to spots which resonated when knocking on them. I was however very liberal with the 10mm fleece. Most likely this is what took care of the reduction of the high frequency road noise, above 1.8kHz. No discernable difference for the low frequencies.

This weekend I'll be experimenting with a 33Hz tuned mass damper from BMW. I'll try fixing this to various resonant parts, to see if it has any impact on the low frequency rumble. I also have a Tesla service appointment next Friday (for Auto Garage Opener install and Supermanifold replacement). I also asked them about the low frequency noise issue, and they will have a look - but I don't think that will bring much. They'll probably just be surprised how quiet my car is

sanjayjp99

Member

Here is what I did in terms of sound proofing which helps me to reduce booming noise and road noise.

azeteg

Member

Wow, you really went all out here!Here is what I did in terms of sound proofing which helps me to reduce booming noise and road noise.

Did you also do any measurements, so you know what actually helped and what didn't do anything to improve things?

Did this all in all help to reduce the low frequency boominess?

Dang, power to you guys.Here is what I did in terms of sound proofing which helps me to reduce booming noise and road noise.

I’m not in my 20’s anywhere (when I used to strip down the whole interior of a car and do this to upgrade the sound systems).

I’d rather just buy another EV than have to do all this to a $50K Tesla. It gives me new appreciation for how well built the higher end German, Japanese, and Korean cars are with regards to comfort.

azeteg

Member

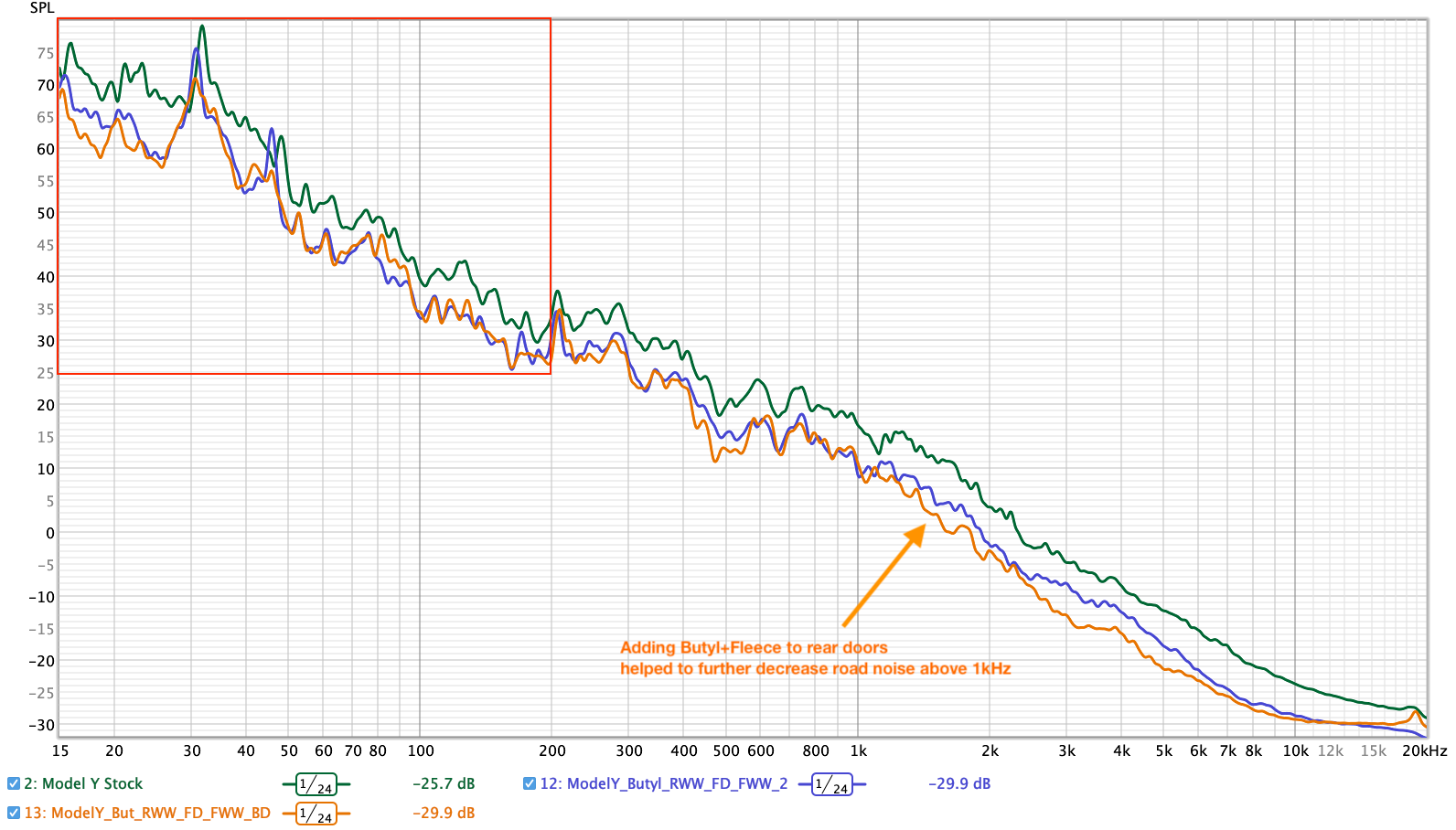

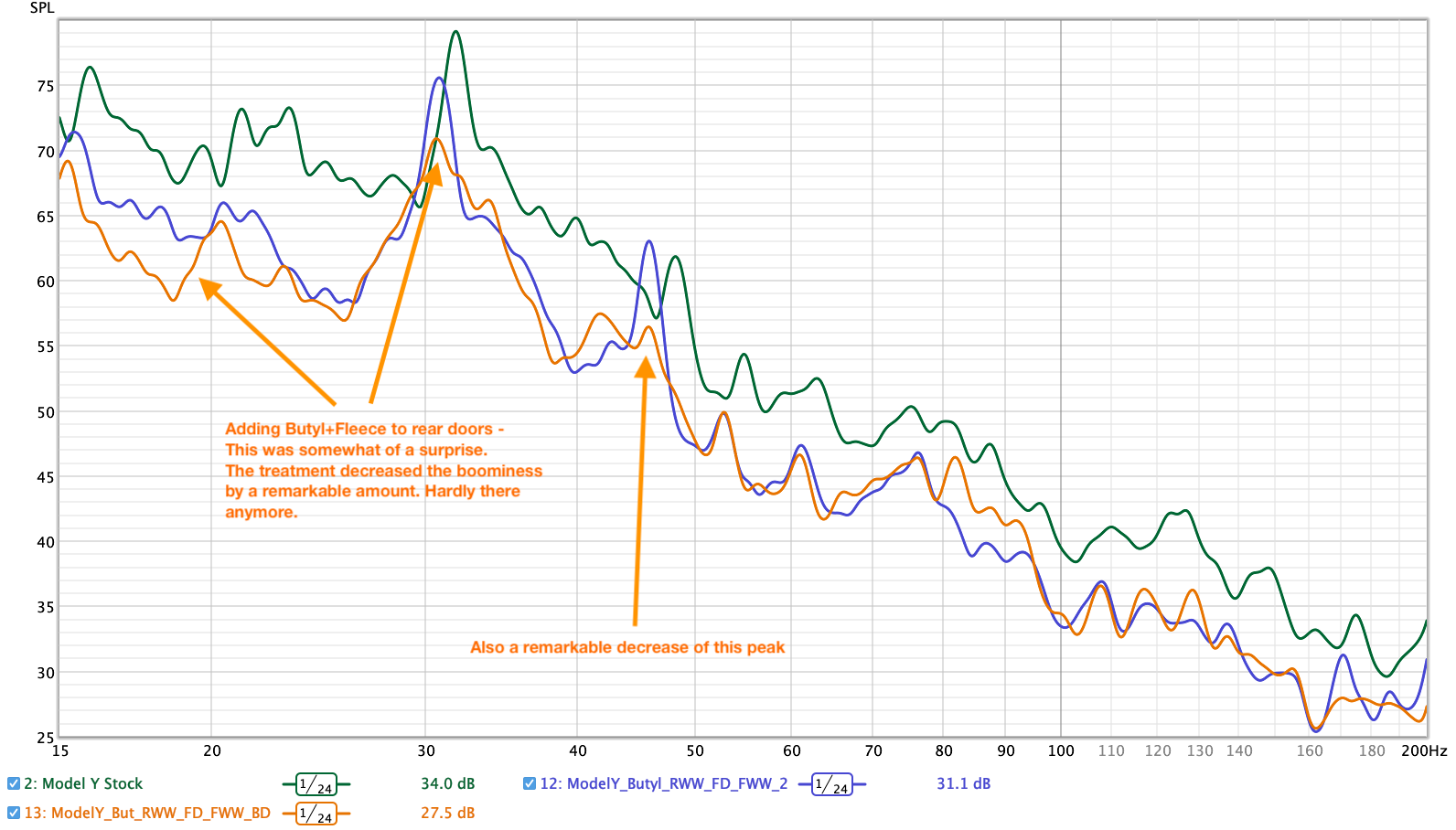

In my next step I proceeded with deadening the rear doors, in the same way as I did the front doors. The difference this time is that I used 2mm Butyl instead of 2.5mm, and I also added some small strips to the plastic molding.

To be honest, I didn't expect much from this additional treatment, but I was astonished about how much this helped to reduce the low-end boominess. I hope I don't have a measurement error here, since I had my son in the front seat while performing this. However, I have had him there before, and still experienced the same boominess. After treating the rear doors, it is almost unnoticable!

I proceeded to measure at the same piece of Autobahn at 125kmh, and here are the results:

To ensure that this is not just due to my (7y old) son sitting in the front seat, I'll re-do the measurement tomorrow, so we can know for certain.

To be honest, I didn't expect much from this additional treatment, but I was astonished about how much this helped to reduce the low-end boominess. I hope I don't have a measurement error here, since I had my son in the front seat while performing this. However, I have had him there before, and still experienced the same boominess. After treating the rear doors, it is almost unnoticable!

I proceeded to measure at the same piece of Autobahn at 125kmh, and here are the results:

To ensure that this is not just due to my (7y old) son sitting in the front seat, I'll re-do the measurement tomorrow, so we can know for certain.

In my next step I proceeded with deadening the rear doors, in the same way as I did the front doors. The difference this time is that I used 2mm Butyl instead of 2.5mm, and I also added some small strips to the plastic molding.

To be honest, I didn't expect much from this additional treatment, but I was astonished about how much this helped to reduce the low-end boominess. I hope I don't have a measurement error here, since I had my son in the front seat while performing this. However, I have had him there before, and still experienced the same boominess. After treating the rear doors, it is almost unnoticable!

I proceeded to measure at the same piece of Autobahn at 125kmh, and here are the results:

View attachment 986256

View attachment 986257

To ensure that this is not just due to my (7y old) son sitting in the front seat, I'll re-do the measurement tomorrow, so we can know for certain.

Thank you for your report, excellent results!

I'm impressed how big differences there are between the stock and treated case. I have done similar project which I have reported on this thread (from message #36 on): MYLR7 Sound Deadening I think I have even done heavier damping with 2mm vibration damper (butyl+aluminum) and depending on location 6-8mm multi layer absorbing material on top of that. I have done all the doors trunk+hatch and inside rear wheel wells. On latest update I did outside front wheel wells (2mm butyl+4mm multi layer absorber on metal and 15mm closed cell acoustic foam on plastic wheel well trims) and I have a plan to make also the rear as soon as I have time. I also added vinyl tubing to the hatch seal. In my case the noise difference was only around 3dB or less, maybe at lower frequencies it was better because of the tubing. I can say my observations go along with my measurements, there is some reduction in noise but definitely not enough. My question is: why is your noise reduction way better? I would say it's around 7-10dB through the scale. Can you hear the difference? It should be huge. What did you use measuring the noise levels? I have used UMIK-1 and REW and I calibrated the levels before each measurement run. I did measurements on different speeds, mainly 80 and 100 km/h (on the same locations). I measured the noise spectrum (20-20000hz)and used around 30s average for noise levels.

azeteg

Member

Kippis!

I think that the main difference comes from the use of multiple layers inside the rear wheel wells. Although I don't have any measurement on a layer-per-layer basis, it is what I felt (and measured!) to make the biggest difference, especially in the lower (sub-1kHz) frequencies. I'm also not sure what kind of wheels you are having. I have the 21" Uberturbines with Hankook Winter tires, and they are (were) very loud.

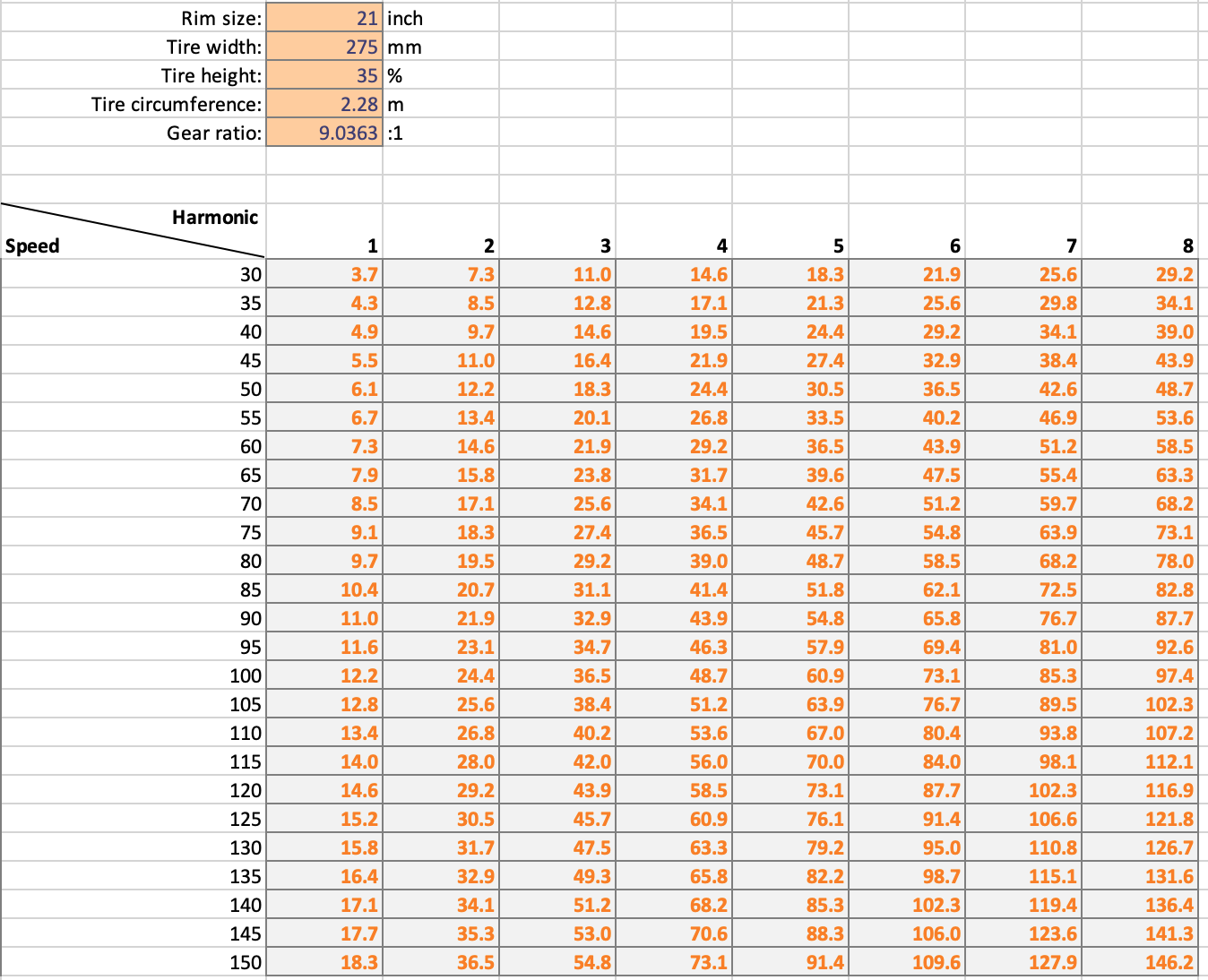

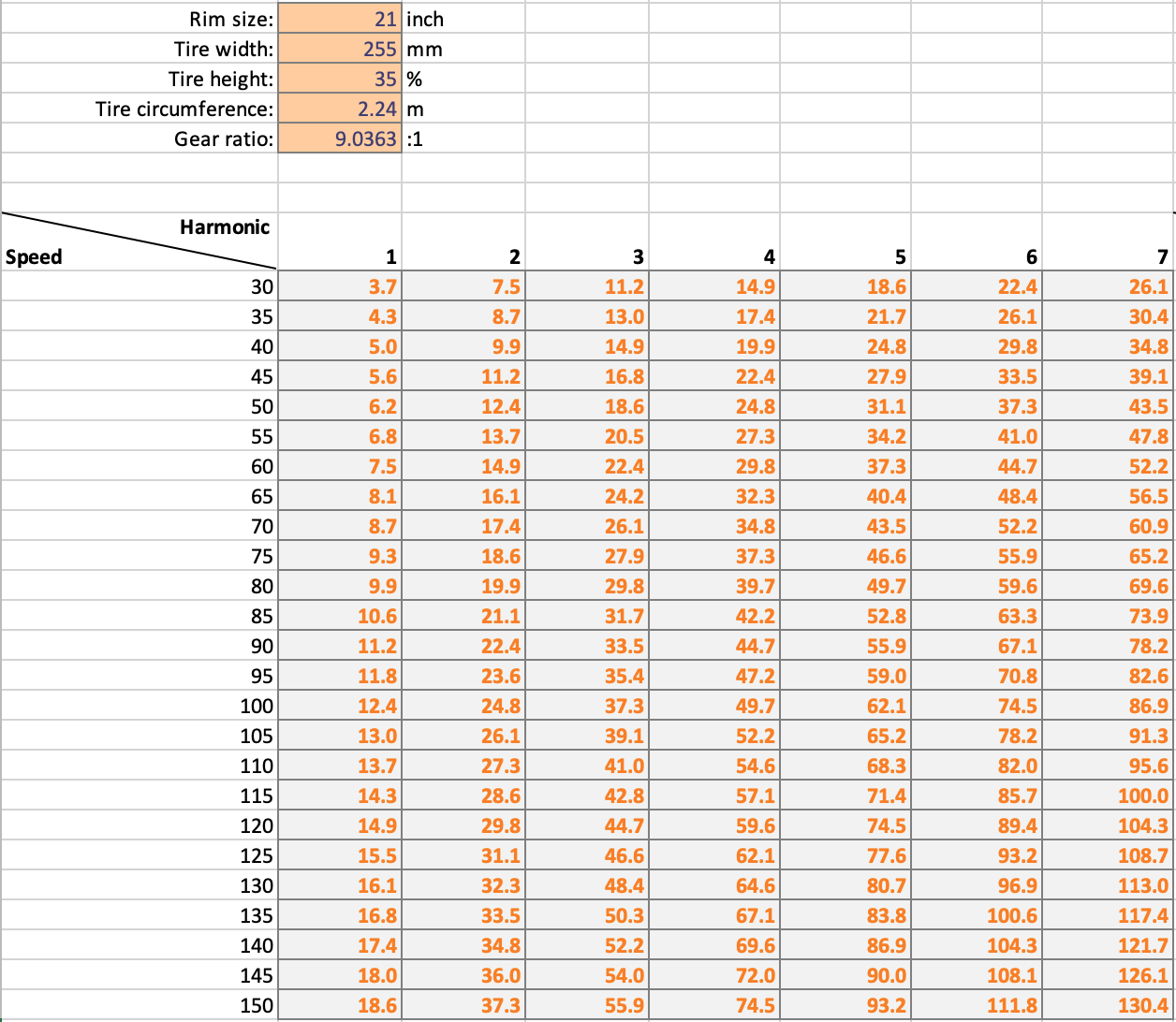

On these, I used 2 layers of 2mm Alubutyl, then 2 layers of 2.5mm Alubutyl over it. So in total 4 layers and 9mm of alubutyl, which is quite substantial. If you want to reduce low frequency transmission and vibrations, there is no replacement for mass. I also figured that a lot of the (low frequent) noise also originates from the rear tires. If you do a harmonic analysis of the tires at different speeds, you'll find this (for the rear wheels):

You'll see that your harmonics from the rear wheels will mostly match up with the peaks in your spectrum. The front wheels actually have a little bit less of a circumference, causing slightly higher frequencies:

The peaks, although close, will tend to occur at the rear wheel harmonics. I also thought that the motor rotation could be related, but since the gear ratio is 9:1, the frequencies get quite high, and I cannot measure anything related to this.

I found that the doors gave a remarkable improvement. As I wrote in my last post, treating the REAR doors is what made the biggest difference for me, for low frequencies. Not sure why but that's what the data (and my ears) say. I have treated the front doors with 2.5mm Alubytyl and 10mm of fleece mat. On the rear doors I just used 2mm Alubutyl and the 10mm fleece.

I am measuring the same stretch of swiss Autobahn at 125kmh. I tried doing some measurements at lower speeds as well, but traffic here always makes it hard to maintain a 20-30s stretch of even speed. 125kmh on the swiss Autobahn tends to be the average tempo, so I can keep that nicely fixed.

The difference is night and day. Car feels more like a Mercedes S-class than a Tesla now. I may have to do the same to my wife's Model 3 now, since she has experienced the quietness of the Model Y...1. why is your noise reduction way better? Can you hear the difference? It should be huge.

I think that the main difference comes from the use of multiple layers inside the rear wheel wells. Although I don't have any measurement on a layer-per-layer basis, it is what I felt (and measured!) to make the biggest difference, especially in the lower (sub-1kHz) frequencies. I'm also not sure what kind of wheels you are having. I have the 21" Uberturbines with Hankook Winter tires, and they are (were) very loud.

On these, I used 2 layers of 2mm Alubutyl, then 2 layers of 2.5mm Alubutyl over it. So in total 4 layers and 9mm of alubutyl, which is quite substantial. If you want to reduce low frequency transmission and vibrations, there is no replacement for mass. I also figured that a lot of the (low frequent) noise also originates from the rear tires. If you do a harmonic analysis of the tires at different speeds, you'll find this (for the rear wheels):

You'll see that your harmonics from the rear wheels will mostly match up with the peaks in your spectrum. The front wheels actually have a little bit less of a circumference, causing slightly higher frequencies:

The peaks, although close, will tend to occur at the rear wheel harmonics. I also thought that the motor rotation could be related, but since the gear ratio is 9:1, the frequencies get quite high, and I cannot measure anything related to this.

I found that the doors gave a remarkable improvement. As I wrote in my last post, treating the REAR doors is what made the biggest difference for me, for low frequencies. Not sure why but that's what the data (and my ears) say. I have treated the front doors with 2.5mm Alubytyl and 10mm of fleece mat. On the rear doors I just used 2mm Alubutyl and the 10mm fleece.

I'm also using the Umik-1 and REW. I am recording the audio into Logic first for pre-editing, to ensure that I don't get any accidental noises in the recordings.2. What did you use measuring the noise levels?

I am measuring the same stretch of swiss Autobahn at 125kmh. I tried doing some measurements at lower speeds as well, but traffic here always makes it hard to maintain a 20-30s stretch of even speed. 125kmh on the swiss Autobahn tends to be the average tempo, so I can keep that nicely fixed.

Last edited:

Kippis!

During the measurements I had Hankook Evo summer tires, which came with car (MY-22). I think that my installation should have bigger effect on noise level at least on higher frequencies (between 500-2000Hz) which are bothering me the most.I think that the main difference comes from the use of multiple layers inside the rear wheel wells. Although I don't have any measurement on a layer-per-layer basis, it is what I felt (and measured!) to make the biggest difference, especially in the lower (sub-1kHz) frequencies. I'm also not sure what kind of wheels you are having. I have the 21" Uberturbines with Hankook Winter tires, and they are (were) very loud.

As mentioned before the total mass/sq.meter of material I used in trunk and inner wheel wells is around 12kg/m2 with coverage of >90%, total mass added ~35kg. Your value is 17kg/m2 if I calculated correctly. What was coverage? In doors the surface density is around 6kg/m2 which corresponds to your front door values. I'm really puzzled what to do next.On these, I used 2 layers of 2mm Alubutyl, then 2 layers of 2.5mm Alubutyl over it. So in total 4 layers and 9mm of alubutyl, which is quite substantial. If you want to reduce low frequency transmission and vibrations, there is no replacement for mass. I also figured that a lot of the (low frequent) noise also originates from the rear tires. If you do a harmonic analysis of the tires at different speeds, you'll find this (for the rear wheels):

I found that the doors gave a remarkable improvement. As I wrote in my last post, treating the REAR doors is what made the biggest difference for me, for low frequencies. Not sure why but that's what the data (and my ears) say. I have treated the front doors with 2.5mm Alubytyl and 10mm of fleece mat. On the rear doors I just used 2mm Alubutyl and the 10mm fleece.

I'm also using the Umik-1 and REW. I am recording the audio into Logic first for pre-editing, to ensure that I don't get any accidental noises in the recordings.

@azeteg you mentioned: "I think that the main difference comes from the use of multiple layers inside the rear wheel wells. " Referring your photo, this means probably that you put the damping material between the plastic wheel well trim and chassis OUTSIDE the car? I somehow got confused and thought that you put the material inside the cabin, between the interior trim and chassis. Anyway, have you done sound deadening also on on trunk side of the wheel well or just outside (plus the doors naturally)? I'll just have to find a place to finish this project, because I don't have a garage and it's -8C outside, so that's bad for the material to stick.

Lance From Jax

Member

"The best part is no part" lolThanks all for the replys so far. I am trying some of these, but probably need to be a little more scientific and space out more. It seems to take an hour for me to fully notice the symptoms are gone so need to break out the tests more.

I have Glock shooter ear protectors my wife and I tried. It seemed to prevent the pain, but for me its hard to tell because they are so tight they create some external ear discomfort.

My wife said turning off recirculate seems to help her, but I need to test.

I have noticed it seems that the air conditioner is much louder than in my model 3, but I had heard that is normal.

I went looking for the outflow valves and couldn't easily find information on them. I saw in the hitch install video by I1 that he ran hitch wiring through the vent in red below. The rubber looks so loose and the bumper cover such a pain to take off I may look into this more after more testing. while looking around I did notice that in the back passenger wheel well they didn't install 5 of 6 plastic nuts to secure the felt like material and appears another type of bolt is missing that is on the driver side. Just more signs that could point to the problem being the result of sloppy manufacturing in June.

View attachment 585436

azeteg

Member

This is the location where I put those 4 layers. I don't think the inner side will do anything at all - You have so much steel and an airgap between the wheel well and cabin there, that it won't matter at all.@azeteg you mentioned: "I think that the main difference comes from the use of multiple layers inside the rear wheel wells. " Referring your photo, this means probably that you put the damping material between the plastic wheel well trim and chassis OUTSIDE the car? I somehow got confused and thought that you put the material inside the cabin, between the interior trim and chassis. Anyway, have you done sound deadening also on on trunk side of the wheel well or just outside (plus the doors naturally)? I'll just have to find a place to finish this project, because I don't have a garage and it's -8C outside, so that's bad for the material to stick.

For the outer side of the well it is different - there is only a thin sheet of steel here, and this will pick up most of the sound from the wheels. I've seen a lot of sound dampening/deadening projects by now, and they all seem to be quite cargo cult-y, just splashing materials all over, when in most places this really won't matter at all, and even may make it worse. We shouldn't underestimate the NVH engineers of top car brands. I'm sure that Tesla has some of the best NVH engineers out there.

Ok, this area I also covered in my car without too big a difference.This is the location where I put those 4 layers. I don't think the inner side will do anything at all - You have so much steel and an airgap between the wheel well and cabin there, that it won't matter at all.

But did you repeat this (small image on top right corner=outerwheel well) also rear? ->

This I agree.We shouldn't underestimate the NVH engineers of top car brands.

But not thisI'm sure that Tesla has some of the best NVH engineers out there.

This is my case: before=stock, after: deadening material in trunk, hatch, rear wheel well (as in photo you posted) and all four doors. Differences should be like your stock (blue curve) and first step (green curve) but they are really insignificant and this is also confirmed by ear. I would especially hope for more damping in the area between 70-1800Hz.

I also did a test, what my car should sound like when there is not too much of road noise. I did the measurements on a 80km/h road, on old asphalt and new one. I just wanted a rough estimate which frequencies are involved mostly on road noise:

azeteg

Member

No - I did not do this for the rear wheel wells. I figured that the internal treatment would be enough, which was confirmed through measurements.Ok, this area I also covered in my car without too big a difference.

But did you repeat this (small image on top right corner=outerwheel well) also rear? ->

Don't forget that they have to battle with:But not thisOr if they have the best engineers, their ideas on noise deadening are ignored.\

Weight: Sound deadening is HEAVY. Car manufacturers count grams on fasteners, slapping a bunch of butyl all over the place does not go very well with the hunt for grams. Thus, the Pumpable you see being applied here and there in the car is carefully placed on structural resonant zones to improve the modal behavior of the body-in-white.

Cost: Material isn't too expensive in quantities, but the labour required to apply this stuff is.

Production: Trying to perform the treatment we have done to our cars on a production line is close to impossible. Throughput would be severely impacted. This may work for a Rolls Royce.

THIS confuses me quite a bit. I really cannot explain why you would not see the same effects as I am seeing. I can assure you that the perceived difference is very real, and that I've done my best to measure this as well as I can.This is my case: before=stock, after: deadening material in trunk, hatch, rear wheel well (as in photo you posted) and all four doors. Differences should be like your stock (blue curve) and first step (green curve) but they are really insignificant and this is also confirmed by ear. I would especially hope for more damping in the area between 70-1800Hz.

I would assume our butyl materials are quite similar. I have however extensively used that DV10 fleece, and it "feels" good. To my ears it sounds better / more absorptive than these domed foams I see people using. I haven't done any proper comparative measurements on this however, and I don't have any data on absorption coefficients, so it is purely based on what my ears perceive.

No - I did not do this for the rear wheel wells. I figured that the internal treatment would be enough, which was confirmed through measurements.

That's true. This is unfortunate and Tesla is not alone with this. I noticed, when I was searching sound deadening information that a lot of manufacturers have not paid too much attention to make their cars more quiet. Especially newer models.Don't forget that they have to battle with:

Weight: Sound deadening is HEAVY. Car manufacturers count grams on fasteners, slapping a bunch of butyl all over the place does not go very well with the hunt for grams. Thus, the Pumpable you see being applied here and there in the car is carefully placed on structural resonant zones to improve the modal behavior of the body-in-white.

I believe your measurements are correct and they are confirmed by your observations. I'm just trying to understand why the noise in my car won't be affected with similar treatments.THIS confuses me quite a bit. I really cannot explain why you would not see the same effects as I am seeing. I can assure you that the perceived difference is very real, and that I've done my best to measure this as well as I can.

I think also that the butyl you used is quite similar than mine. The absorption mat I used is multilayered material and it consists of (from bottom up) elastic glue, polyurethane foam, heavy fiber, butyl rubber and wool. On doors I used little bit lighter thinner material to save the hinges, however it's also multilayer material. They both feel like very well sound absorbing materials. I haven't tried fleece but it sounds that it can absorb water or moisture and this is not an option for door sound deadening because the inside of door is "wet" volume. For example, rain water can have access there from window seal. Of course this is not as serious as in wheel well because there the moisture and road salt combination may cause rust.I would assume our butyl materials are quite similar. I have however extensively used that DV10 fleece, and it "feels" good. To my ears it sounds better / more absorptive than these domed foams I see people using. I haven't done any proper comparative measurements on this however, and I don't have any data on absorption coefficients, so it is purely based on what my ears perceive.

Thank you for opening you sound deadening process and thoughts. Do you have any ideas that I could try next?

sanjayjp99

Member

no did not, but adding soundproofing in sub trunk help with boominessWow, you really went all out here!

Did you also do any measurements, so you know what actually helped and what didn't do anything to improve things?

Did this all in all help to reduce the low frequency boominess?

sanjayjp99

Member

I test drove iX50, doesn't justify extra 40K CAD, I rather spend 2k on sound proofingDang, power to you guys.

I’m not in my 20’s anywhere (when I used to strip down the whole interior of a car and do this to upgrade the sound systems).

I’d rather just buy another EV than have to do all this to a $50K Tesla. It gives me new appreciation for how well built the higher end German, Japanese, and Korean cars are with regards to comfort.

Similar threads

- Replies

- 11

- Views

- 221

- Replies

- 0

- Views

- 191

- Replies

- 3

- Views

- 5K