Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HPWC SER vs Romex Wire?

- Thread starter SureValla

- Start date

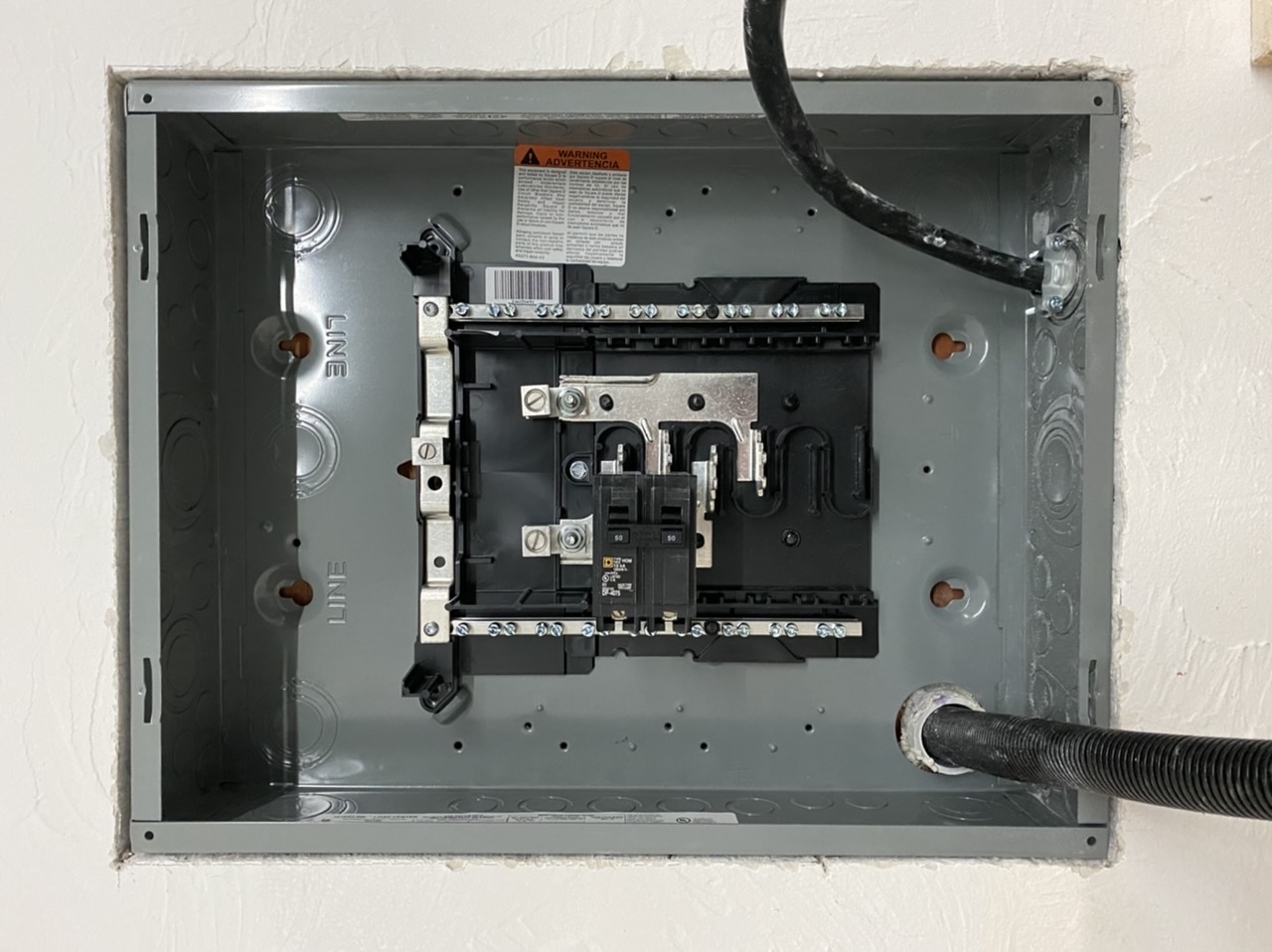

Using the first location as a main breaker vs load breaker is equivalent electrically.Not sure to make of this. Schneider Electric sent it to me saying this first space can be used for a 100 amp breaker.

Is that only when used for back feeding, or could it be used for a normal 100 amp branch?

View attachment 488860

Since this is a main lug panel, it seems like putting 100A dual pole in the first position is supported.

There is no real benefit to 100 amps as Tesla only charges at a max using a 60 amp breaker (48 amps),

The advantage is if/when you have two chained HPWC. With a 100A circuit, you can charge two vehicles at once at 40A apiece.

True, but even with a 90 Amp breaker, 72A charge limit, you get 17kW which would let you full recharge two 100kWh vehicles in about 12 hours (ignoring taper).The advantage is if/when you have two chained HPWC. With a 100A circuit, you can charge two vehicles at once at 40A apiece.

Also assumes the house load is light enough to allow that rate.

Now, if you have two cybertrucks

True, but even with a 90 Amp breaker, 72A charge limit, you get 17kW which would let you full recharge two 100kWh vehicles in about 12 hours (ignoring taper).

Also assumes the house load is light enough to allow that rate.

Now, if you have two cybertrucks

Oh, totally agree. In fact, my garage has an X and a 3 sharing a 60A circuit, so maxing out at a combined 11.5 kW. And that's enough for an overnight fill for all but the most ridiculous scenario (eg needing both cars to go from 5% to 100% ASAP).

Trebor Srevlis

Member

I am preparing for CyberTruck, which may end up with a 300kwh battery. So it may take 3x as long for a full charge as current cars. Not that it would ever need a full charge since it is charged every night.

In other news, Schneider Electric swears you are not supposed to use a 100 amp branch breaker even for the first position, even though it is allowed to be 100 amp for back-feed use.

Here is what their customer rep said:

"Yes I have also confirmed this with one of our Senior Engineers. Those first two spots are designed, tested and UL listed to accept a 100A QO breaker only if that 100A breaker is used as a back fed main and that is the reason why you can see 2 wiring diagrams. The one above is if the load center is used as an MLO. The wiring diagram below it is used if the load center is used a back fed Main breaker load center."

In other news, Schneider Electric swears you are not supposed to use a 100 amp branch breaker even for the first position, even though it is allowed to be 100 amp for back-feed use.

Here is what their customer rep said:

"Yes I have also confirmed this with one of our Senior Engineers. Those first two spots are designed, tested and UL listed to accept a 100A QO breaker only if that 100A breaker is used as a back fed main and that is the reason why you can see 2 wiring diagrams. The one above is if the load center is used as an MLO. The wiring diagram below it is used if the load center is used a back fed Main breaker load center."

I am preparing for CyberTruck, which may end up with a 300kwh battery. So it may take 3x as long for a full charge as current cars. Not that it would ever need a full charge since it is charged every night.

In other news, Schneider Electric swears you are not supposed to use a 100 amp branch breaker even for the first position, even though it is allowed to be 100 amp for back-feed use.

Here is what their customer rep said:

"Yes I have also confirmed this with one of our Senior Engineers. Those first two spots are designed, tested and UL listed to accept a 100A QO breaker only if that 100A breaker is used as a back fed main and that is the reason why you can see 2 wiring diagrams. The one above is if the load center is used as an MLO. The wiring diagram below it is used if the load center is used a back fed Main breaker load center."

Ah, and the notes regarding securing the breaker are part of the bottom diagram.

Also explains the difference in terminology on the lugs: Line on the top, and S/F subalimentación on the bottom which is apparently Spanish for sub panel feed (literally: under nourished).

I'm guessing Cybertruck will be around 200kWh. Real factor for home changing is Wh/mile and daily usage.

Trebor Srevlis

Member

I asked if there was one that would work, and they said HOM1224L125PC or HOM816L125PC

Is it against the NEC to drive a main-lug 125 bus-bar panel from another panel using a 100 amp breaker over wire that is rated for 100 amps?

The Schneider rep said it was fine because "HOM816L125PGC just have a 125A rated bus bars. It does not imply that it will pull more than 100A from your main panel. Also, it has a main lug interior so its load capacity will solely depend on the breaker from the main panel where it would be connected to" but who knows - NEC might say that if it says 125 on it, it is not allowed to be driven with wires that can't take 125 because some future person may want to change the breaker that is feeding it.

Is it against the NEC to drive a main-lug 125 bus-bar panel from another panel using a 100 amp breaker over wire that is rated for 100 amps?

The Schneider rep said it was fine because "HOM816L125PGC just have a 125A rated bus bars. It does not imply that it will pull more than 100A from your main panel. Also, it has a main lug interior so its load capacity will solely depend on the breaker from the main panel where it would be connected to" but who knows - NEC might say that if it says 125 on it, it is not allowed to be driven with wires that can't take 125 because some future person may want to change the breaker that is feeding it.

I asked if there was one that would work, and they said HOM1224L125PC or HOM816L125PC

Is it against the NEC to drive a main-lug 125 bus-bar panel from another panel using a 100 amp breaker over wire that is rated for 100 amps?

The Schneider rep said it was fine because "HOM816L125PGC just have a 125A rated bus bars. It does not imply that it will pull more than 100A from your main panel. Also, it has a main lug interior so its load capacity will solely depend on the breaker from the main panel where it would be connected to" but who knows - NEC might say that if it says 125 on it, it is not allowed to be driven with wires that can't take 125 because some future person may want to change the breaker that is feeding it.

It is fine to feed a sub panel with less than its max capacity.

There are solar intent main panels build with oversized bus bars specifically for that reason (to handle main + generation).

Anyone could over breaker any circuit.

qdeathstar

Completely Serious

I asked if there was one that would work, and they said HOM1224L125PC or HOM816L125PC

Is it against the NEC to drive a main-lug 125 bus-bar panel from another panel using a 100 amp breaker over wire that is rated for 100 amps?

The Schneider rep said it was fine because "HOM816L125PGC just have a 125A rated bus bars. It does not imply that it will pull more than 100A from your main panel. Also, it has a main lug interior so its load capacity will solely depend on the breaker from the main panel where it would be connected to" but who knows - NEC might say that if it says 125 on it, it is not allowed to be driven with wires that can't take 125 because some future person may want to change the breaker that is feeding it.

You aren’t necessarily responsible for what someone may do in the future. Of your current continuous load is under 80 amps and your wire is sized for at least 100 amps and your panel is rated for at least 100 amps you are good.

Trebor Srevlis

Member

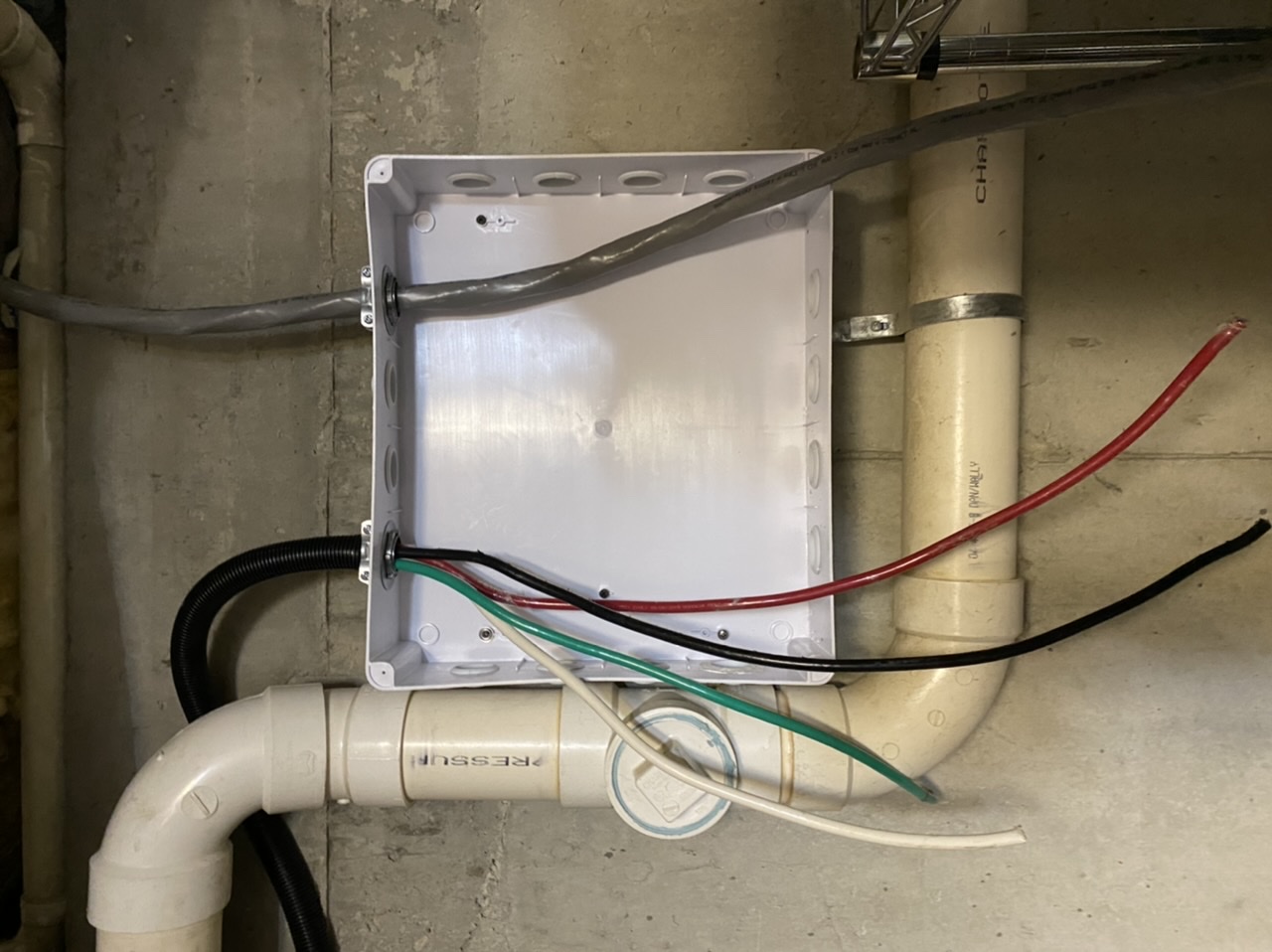

This 125 amp panel is way better. Feels about 3x the weight and has a 125 amp bus bar. Still only about $45.

Somehow I managed to have my conduit come through the wall at exactly the right spot.

Waiting on some parts now to finish this. Had to return the splice kit as it was not rated for AL.

Not sure why the site makes my photos sideways.

Somehow I managed to have my conduit come through the wall at exactly the right spot.

Waiting on some parts now to finish this. Had to return the splice kit as it was not rated for AL.

Not sure why the site makes my photos sideways.

Couple tips you may already know:This 125 amp panel is way better. Feels about 3x the weight and has a 125 amp bus bar. Still only about $45.

Somehow I managed to have my conduit come through the wall at exactly the right spot.

Waiting on some parts now to finish this. Had to return the splice kit as it was not rated for AL.

Not sure why the site makes my photos sideways.

View attachment 489807

View attachment 489806

That is a sub panel box so it needs a separate ground bar and the neutral does not get shorted to the enclosure. (One if the parts you are waiting on?)

Unless you are in Canada, you can only use breakers in the bottom row, like the one in the photo (otherwise off is down).

Your plastic box looks like it has metal clamps. You may need to add grounding rings to those, but I'm not positive.

qdeathstar

Completely Serious

This 125 amp panel is way better. Feels about 3x the weight and has a 125 amp bus bar. Still only about $45.

Somehow I managed to have my conduit come through the wall at exactly the right spot.

Waiting on some parts now to finish this. Had to return the splice kit as it was not rated for AL.

Not sure why the site makes my photos sideways.

View attachment 489807

View attachment 489806

That installation is not compliant. The connector you have used for the flex is meant for NM cable, you need a proper flex connector. The romex connector on the ser cable is installed backwards.

In the second picture, there isn’t s connector installed on the flex.

I’m not even sure that flex is rated for line voltage, as the stuff i’m used to is blue carlon stuff..

Trebor Srevlis

Member

I put that connector in with the screw inside the panel because if I did it the normal way, the plaster would be in the way due to it being recessed. I knew it was backwards.

The flex tubing is not actually used in the panel as conduit. It has a real gray PVC conduit coming into it and the flex was used to protect the clear outer-layer of the wires when bending them to connect them.

The flex tubing is not actually used in the panel as conduit. It has a real gray PVC conduit coming into it and the flex was used to protect the clear outer-layer of the wires when bending them to connect them.

Trebor Srevlis

Member

So when I installed this, it was for a Cybertruck that is 2-3 years away. On Christmas, my wife made a certificate gift for a family Tesla, and wanted something for us now. We don't need a car now since we won't have an extra driver until the summer, but I decided to call Tesla for a test drive to see how much I liked a Model-3.

Today I bought a Model 3 Stealth Performance (which I had never heard of this variant) because it was in stock and the tax credit and Stealth savings would make it cheaper than waiting until the summer (to the best I can predict) - and it was a 2020 VIN so no downside that I could see.

Today I bought a Model 3 Stealth Performance (which I had never heard of this variant) because it was in stock and the tax credit and Stealth savings would make it cheaper than waiting until the summer (to the best I can predict) - and it was a 2020 VIN so no downside that I could see.

qdeathstar

Completely Serious

So when I installed this, it was for a Cybertruck that is 2-3 years away. On Christmas, my wife made a certificate gift for a family Tesla, and wanted something for us now. We don't need a car now since we won't have an extra driver until the summer, but I decided to call Tesla for a test drive to see how much I liked a Model-3.

Today I bought a Model 3 Stealth Performance (which I had never heard of this variant) because it was in stock and the tax credit and Stealth savings would make it cheaper than waiting until the summer (to the best I can predict) - and it was a 2020 VIN so no downside that I could see.

congrats, but, since you already got the tesla please consider getting your work looked at by a professional. It is not code compliant. I’d hate to see a moment of triumph turn to tragedy.

qdeathstar

Completely Serious

I don’t see anything wrong with the blue carlon box. The wires inside that black tubing are not terminated correctly, especially where they enter the panel. The main thing which is impossible to see in a picture but most likely to result in fire is whether or not you have the lugs on the butt splices, breaker, and receptacle.

Improper toque will lead to fire in a relatively short period of time.

Improper connectors can create a shock hazard.

Using a wire that is rated at 90 amps with a 100 amp breaker is unlikely to create a dangerous situation.

But, don’t let me take away from you getting a tesla, congrats, your gonna love it. And you did your homework and got a p3d.... i made the sr+ mistake...

Improper toque will lead to fire in a relatively short period of time.

Improper connectors can create a shock hazard.

Using a wire that is rated at 90 amps with a 100 amp breaker is unlikely to create a dangerous situation.

But, don’t let me take away from you getting a tesla, congrats, your gonna love it. And you did your homework and got a p3d.... i made the sr+ mistake...

Similar threads

- Replies

- 48

- Views

- 1K

- Replies

- 23

- Views

- 4K

- Replies

- 3

- Views

- 842

- Replies

- 58

- Views

- 5K

- Question

- Replies

- 12

- Views

- 560