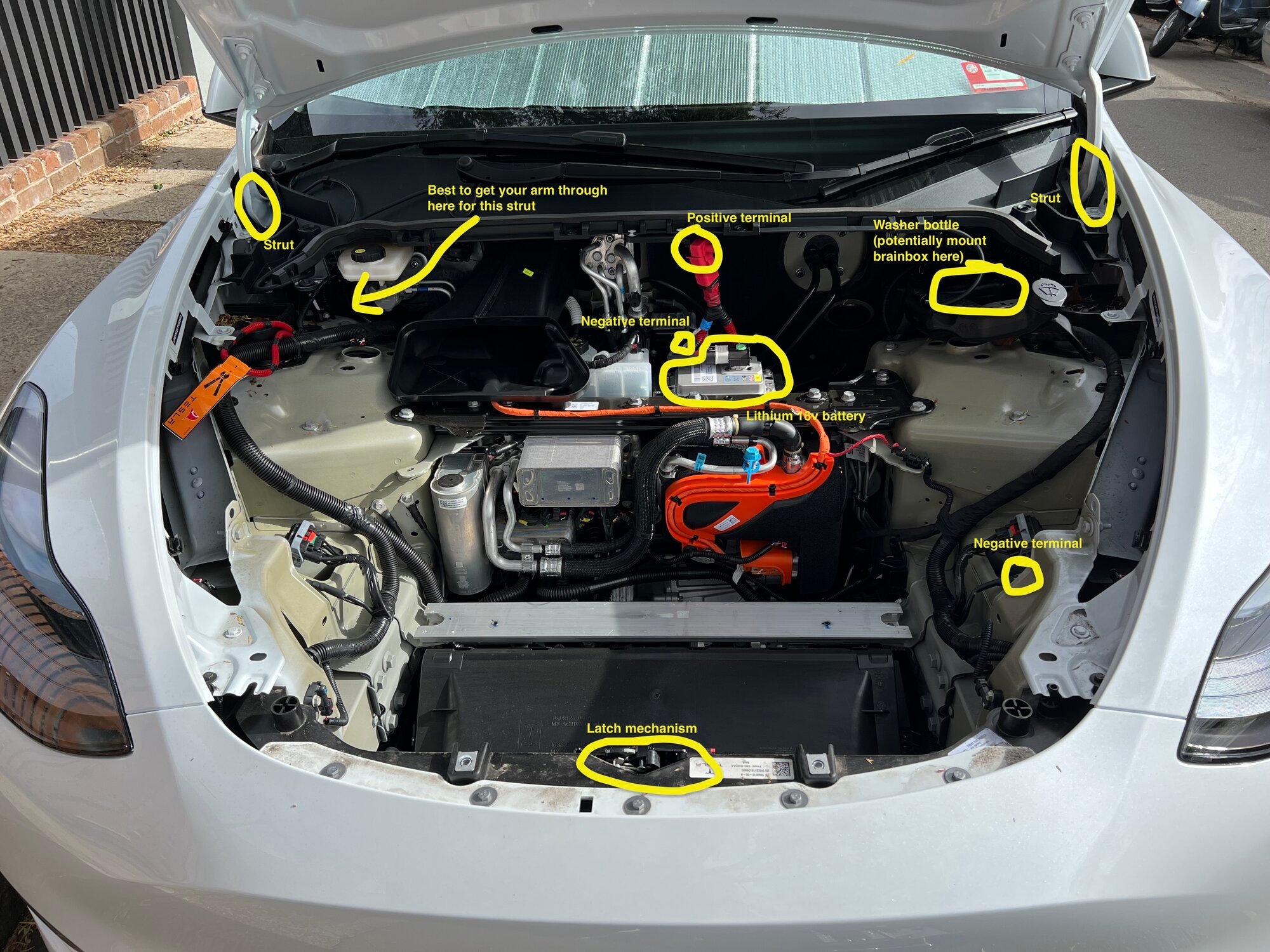

Just done the powered frunk install on my Model Y (build date 26/04/2023 from Shanghai with HEPA) using the Satonic kit. The Hannshows and EVOffer kits will be similar

I heavily referred to the video by The Imperfect Tesla but found a couple things differed and thought I'd share some tips on the process - I still recommend using theirs as the main point of reference but I've taken some detailed photos of where the video missed or are more relevant to the RHD market

Overall this took me 2 hours and 15 minutes; it's not difficult but I spent most of the time trying to reattach the new struts in a very confined space.

There's only 3 key tasks in the project:

1. Replace the struts with the powered struts

2. Attach the new latching mechanism to the OEM one to allow the new motor to unlatch the frunk

3. Attach the wiring harnesses and brainbox

Tools:

6mm hex (or 5mm?) – preferably with a ratchet

10mm socket

13mm spanner

Needlenose pliers

Wood plank or broom handle (to hold the frunk up)

Pick tool

Flathead screwdriver (for prying)

Most are included with the Satonic kit

Tips:

Steps

Part 1: Disassembly

1. Open frunk and remove top cowling by pulling on it around each edge

2. Remove the tub. 4x 10mm bolts. Be aware of the emergency button (next step)

3. For the emergency button, either lift the tub slightly and unplug (you will need something small to push to help release the connector), or use pliers to release the 3 small clips to remove the panel then remove the button connector wire after the tub is out.

4. Remove the HEPA filter section by removing the 2x 10mm bolts (one of each side) + 1 plastic rivet for the washer bottle. Rivet needs a flathead screwdriver or similar to lift the middle part, then you can pull the entire rivet out

Part 2: Struts

5. Work on the harder strut first – for Australia we have RHD vehicles so the right side (sitting in the car) will be first.

6. Prop up the frunk lid with a broom handle or similar

7. Remove the top clip of the strut. The pick tool should be used to pull on the clip away from the ball, then the strut can be pulled away from the hood ball joint

8. Bottom of strut doesn’t need to be removed from the ball as we will remove the ball joint together with it. Use the 13mm spanner to undo the ball joint nut. Tip is to work your right arm deep down into the engine bay around the brake booster, pushing the wiring out of the way, then use your left arm to pass down the spanner once it’s in position as it's super tight down there

9. Remove the strut and lower ball joint together

I heavily referred to the video by The Imperfect Tesla but found a couple things differed and thought I'd share some tips on the process - I still recommend using theirs as the main point of reference but I've taken some detailed photos of where the video missed or are more relevant to the RHD market

Overall this took me 2 hours and 15 minutes; it's not difficult but I spent most of the time trying to reattach the new struts in a very confined space.

There's only 3 key tasks in the project:

1. Replace the struts with the powered struts

2. Attach the new latching mechanism to the OEM one to allow the new motor to unlatch the frunk

3. Attach the wiring harnesses and brainbox

Tools:

6mm hex (or 5mm?) – preferably with a ratchet

10mm socket

13mm spanner

Needlenose pliers

Wood plank or broom handle (to hold the frunk up)

Pick tool

Flathead screwdriver (for prying)

Most are included with the Satonic kit

Tips:

- Tight spaces meant a lot of time was spent getting the struts in – in fact half of the project time for me

- The included tools were pretty crap and the ratchet gave up immediately so best if you have your own tools

- The new hood struts were a challenge to mount due to the space constraints so try practicing removal and reattachment using the first OEM strut you remove. It is very tight on one side so small arms and a lot of patience is key

- The car would turn on the AC every 10-20 minutes for no reason which was very noisy and would draw in dirt without the filter. Turning off on the touchscreen worked and so did turning it on and off in the app each time

- The alarm went off when I reattached the latch plugs as the car had locked itself and then detected an open frunk, triggering the sentry alarm. Ensure the car is unlocked or leave a door/trunk/boot open during the project to avoid this.

- It’s not necessary to remove power as only the 12v / 16v runs through the frunk area and not the 400v battery. Use normal caution.

- Some suggest removing the wiper mechanism and cowling, but after removing the wiper bolt I couldn’t remove the wiper or anything else and still accomplished the project.

Steps

Part 1: Disassembly

1. Open frunk and remove top cowling by pulling on it around each edge

2. Remove the tub. 4x 10mm bolts. Be aware of the emergency button (next step)

3. For the emergency button, either lift the tub slightly and unplug (you will need something small to push to help release the connector), or use pliers to release the 3 small clips to remove the panel then remove the button connector wire after the tub is out.

4. Remove the HEPA filter section by removing the 2x 10mm bolts (one of each side) + 1 plastic rivet for the washer bottle. Rivet needs a flathead screwdriver or similar to lift the middle part, then you can pull the entire rivet out

Part 2: Struts

5. Work on the harder strut first – for Australia we have RHD vehicles so the right side (sitting in the car) will be first.

6. Prop up the frunk lid with a broom handle or similar

7. Remove the top clip of the strut. The pick tool should be used to pull on the clip away from the ball, then the strut can be pulled away from the hood ball joint

8. Bottom of strut doesn’t need to be removed from the ball as we will remove the ball joint together with it. Use the 13mm spanner to undo the ball joint nut. Tip is to work your right arm deep down into the engine bay around the brake booster, pushing the wiring out of the way, then use your left arm to pass down the spanner once it’s in position as it's super tight down there

9. Remove the strut and lower ball joint together