Thought I'd post this as it may be helpful for others. Especially if you can DIY and don't want to pay Tesla many £1000's to fix these air compressor/suspension-related issues.

I started to hear my air compressor turning on a lot more than it used to and it was getting a lot noisier than it used to be. At the same time, I started getting 'Air Compressor Disabled, Car Cannot Raise' messages, these increased as the temperature dropped to 0c and below.

The other issue I noticed was that the front left suspension was losing pressure and making the car sag on that front side. Clearly, this air shock or the lines to it were leaking and in turn making the compressor run a huge amount more than it was designed for.

To test the lines and suspension I got some leak detection spray and covered all the lines, connections, pumps and tank with it to see if anything was leaking. It wasn't. On to the shocks and the suspect shock created a nice foam party The other front one is fine as were both the back ones.

The other front one is fine as were both the back ones.

Good one:

Bad one:

Next thing to tackle was the Air Compressor itself. I would have loved to rebuild this but I can't find the parts, unfortunately. I found that this pump is used in the Audi Q5, Lamborghini Huracan, Porshe Panamera and probably others. It's made by Wabco with the motor by Lucas. I took it all apart and it was full of rust and most probably the press-fit piston ring shot. I have pics of this dismantled if anyone wants me to post them. I ordered a 3rd party part for £300. It has arrived and I fitted it today. It works well and is super quiet! The replacement air shock won't be with me for another 10 days so it will have to handle being used a little bit more than usual for a few days.

While changing the compressor I found another issue. One of the lines from the pump had been rubbed away by its surroundings. It's probably 0.1mm away from a pinhole! I'll order a new piece of line for this and move it away from the rubbing parts near it.

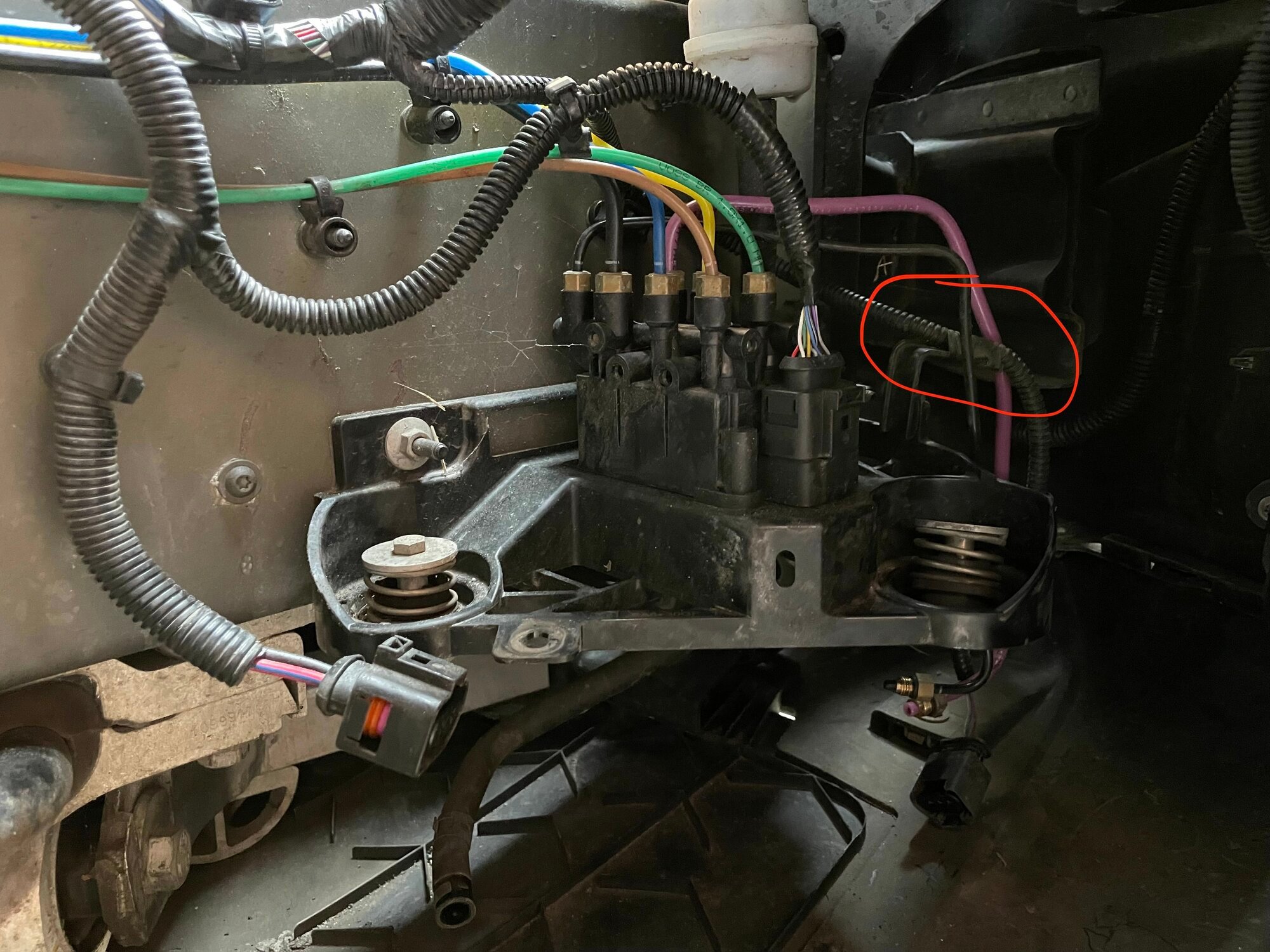

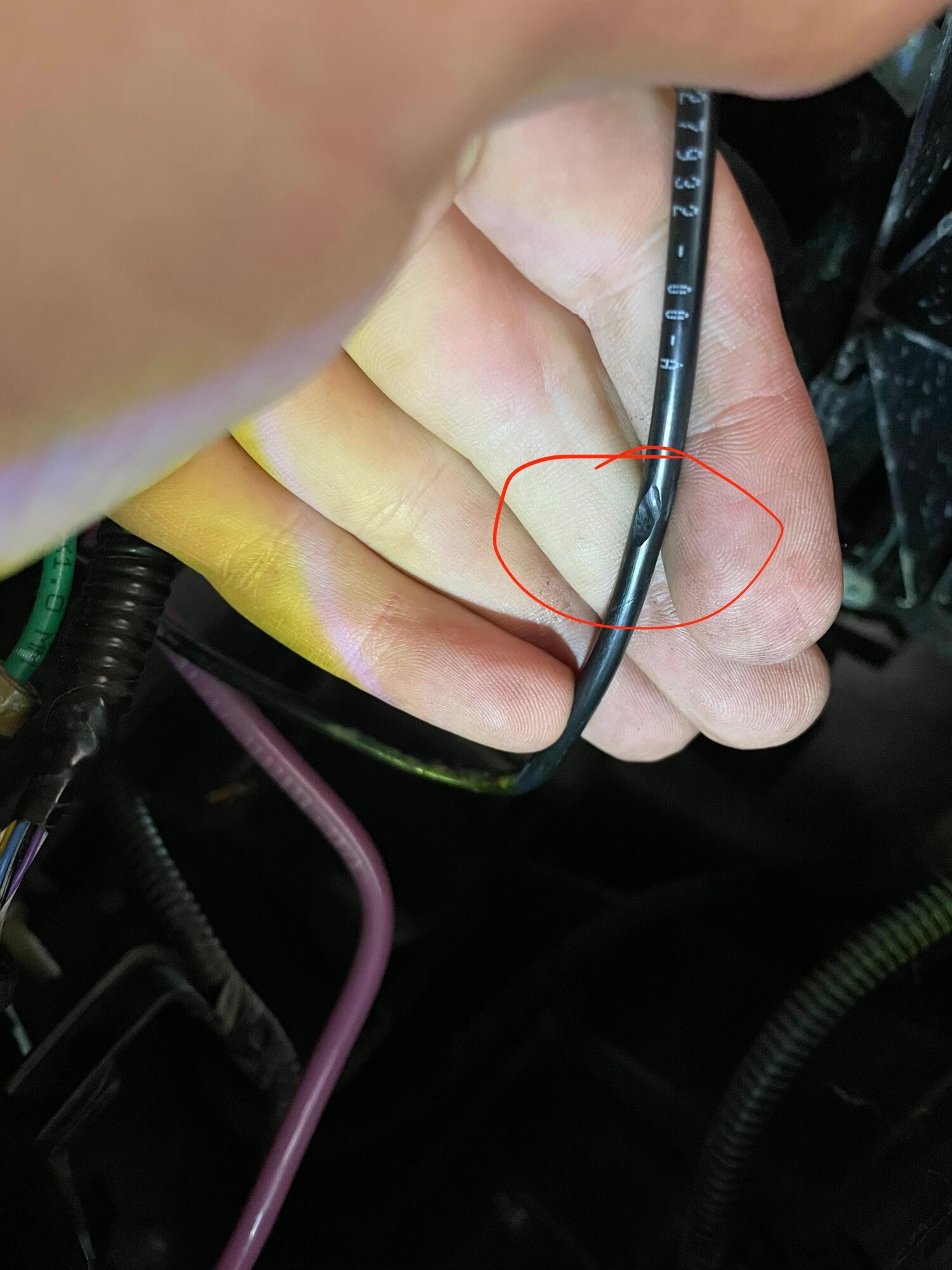

Compressor location (after I removed it) and 2nd pic circled where the black line had been rubbing against the electrical connector:

You need a few hours to troubleshoot, take things apart, and remove and reinstall the air compressor but it's an easy job. You do have to jack up the car (put it in jack mode) and remove the FR wheel so for anyone attempting this, make sure you use the right safety measures, Jack stands etc.

I started to hear my air compressor turning on a lot more than it used to and it was getting a lot noisier than it used to be. At the same time, I started getting 'Air Compressor Disabled, Car Cannot Raise' messages, these increased as the temperature dropped to 0c and below.

The other issue I noticed was that the front left suspension was losing pressure and making the car sag on that front side. Clearly, this air shock or the lines to it were leaking and in turn making the compressor run a huge amount more than it was designed for.

To test the lines and suspension I got some leak detection spray and covered all the lines, connections, pumps and tank with it to see if anything was leaking. It wasn't. On to the shocks and the suspect shock created a nice foam party

Good one:

Bad one:

Next thing to tackle was the Air Compressor itself. I would have loved to rebuild this but I can't find the parts, unfortunately. I found that this pump is used in the Audi Q5, Lamborghini Huracan, Porshe Panamera and probably others. It's made by Wabco with the motor by Lucas. I took it all apart and it was full of rust and most probably the press-fit piston ring shot. I have pics of this dismantled if anyone wants me to post them. I ordered a 3rd party part for £300. It has arrived and I fitted it today. It works well and is super quiet! The replacement air shock won't be with me for another 10 days so it will have to handle being used a little bit more than usual for a few days.

While changing the compressor I found another issue. One of the lines from the pump had been rubbed away by its surroundings. It's probably 0.1mm away from a pinhole! I'll order a new piece of line for this and move it away from the rubbing parts near it.

Compressor location (after I removed it) and 2nd pic circled where the black line had been rubbing against the electrical connector:

You need a few hours to troubleshoot, take things apart, and remove and reinstall the air compressor but it's an easy job. You do have to jack up the car (put it in jack mode) and remove the FR wheel so for anyone attempting this, make sure you use the right safety measures, Jack stands etc.