Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ALL CyberTruck discussion

- Thread starter Fact Checking

- Start date

Buckminster

Well-Known Member

https://x.com/SawyerMerritt/status/1735834199435727323?s=20

Cyberbeast: Mid-late 2024 (from early 2024• AWD: Jan-March 2024

Cyberbeast: Mid-late 2024 (from early 2024• AWD: Jan-March 2024

Or skip denial and just jump straight to acceptance...Rationalization...How things get done!

(The longer wait for Beast isn't helpful though...)

jebinc

Well-Known Member

I suspect a lot of changes will be rolled into the beast by the end of 2024 - changes that will not be in the "early adopter" Founder's Edition AWD VINs.Or skip denial and just jump straight to acceptance...

(The longer wait for Beast isn't helpful though...)

Stainless door frames. Stainless door rings black powder coated. I was expecting steel for everything but the outer skins, but they did not hold back.

The outer skins is either 1.4 or 1.8mm thick. Not 3mm as has been previously mentioned/rumored/whatevered.

He said the outer skins provide 75% of the crash strength. That's exoskeleton territory for me. It's not just a flashy exterior.

The outer skins is either 1.4 or 1.8mm thick. Not 3mm as has been previously mentioned/rumored/whatevered.

He said the outer skins provide 75% of the crash strength. That's exoskeleton territory for me. It's not just a flashy exterior.

The 3 mm was the original prototype's thickness.Stainless door frames. Stainless door rings black powder coated. I was expecting steel for everything but the outer skins, but they did not hold back.

The outer skins is either 1.4 or 1.8mm thick. Not 3mm as has been previously mentioned/rumored/whatevered.

He said the outer skins provide 75% of the crash strength. That's exoskeleton territory for me. It's not just a flashy exterior.

jebinc

Well-Known Member

Seems like there is a lot more of "less" than "more" when comparing the prototype to what was delivered - which, BTW, is not what Elon recently said in that "Jay Leno CT video;" link provided below. If you recall, he recently bragged in that video (at around the 1:45 min mark) -The 3 mm was the original prototype's thickness.

"...unlike other manufacturers, Tesla always delivers more than the prototype..." Not even the devotionalists can defend this Charlatan BS...

Last edited:

jebinc

Well-Known Member

Sharing, for those prospective buyers of whatever brand, that may be out there looking at this thread.... If too long, just go to the 16:00 mark for the punchline...

As I recall, after the original announcement, all anyone heard was "it's too big" "it won't fit in my garage". So unsurprisingly it was changed.I’ll defend it. Production vehicles don’t always match prototype one-offs and don’t believe everything Musk says. He exaggerates like a fisherman.

jebinc

Well-Known Member

As I recall, after the original announcement, all anyone heard was "it's too big" "it won't fit in my garage". So unsurprisingly it was changed.

But, the Charlatan quoted comments came way after the design was finalized, and there is a lot not in the delivered version that was in the prototype - that has nothing to do with size....

Buckminster

Well-Known Member

Buckminster

Well-Known Member

This is important. Combined with Lars Moravy's statement to Sandy Munro that they only need the 9,000 ton gigapress for the rear castings (because Tesla tool'n'die maker/engineers have developed a way to make the CT front casting with the 6,500 ton gigapress - BTW they already have 4 of those in Austin).

Now Tesla already has 2 of the 9,000 ton gigapresses installed, so they can very quickly increase installed CT production capacity from 125K/yr (announced) to 250K/yr, just by adding a 2nd shift on the existing line.

A 2nd line takes Ct capacity to 1M/yr, but requires either more 9KT gigapresses, or more magic tricks from die-makers, or a combination of both. All I know is that if the orders are there, Tesla Engineering will make it happen.

BioSehnsucht

Model 3 LR

The Leno's Garage video finally points out where the 48V power connection is for the light bar, I had assumed that was just a receptacle for cargo rack mounting. The wiring hidden under the door is tiny thanks to 48V, for the power level it's supposed to provide.

jebinc

Well-Known Member

Wow!

teslamotorsclub.com

teslamotorsclub.com

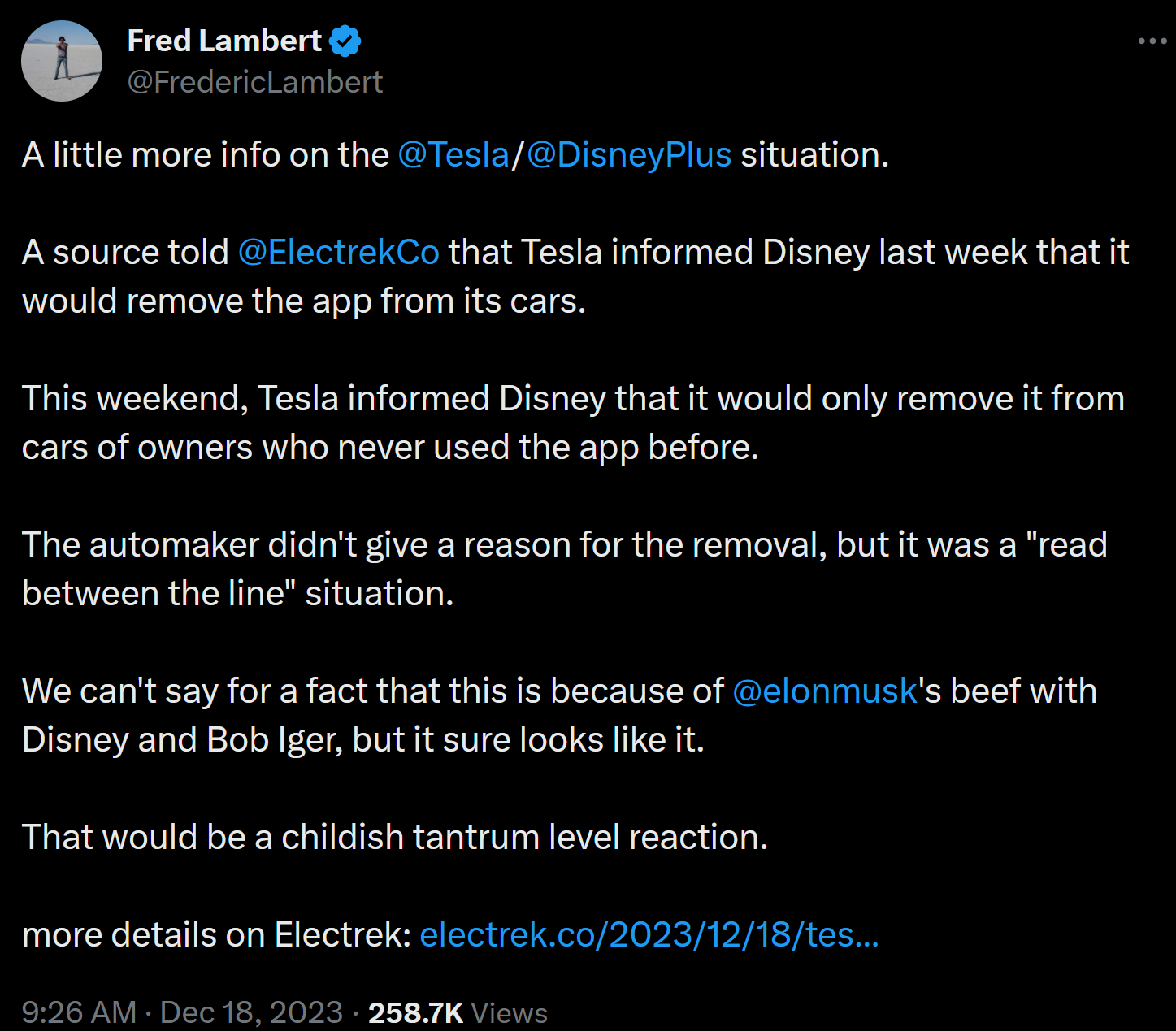

2023 S/W Holiday Update

Next, we will hear he is running for office.... wait for it.... https://x.com/TeslaSoftUpdate/status/1736655366757228746?s=20 My kids will be pissed. What a great way to punish Tesla customers...it's not like people were keeping or buying a D+ subscription just because it was viewable in a...

Seems made up considering they only moved the icon from the Theater option to the Entertainment option...Wow!

2023 S/W Holiday Update

Next, we will hear he is running for office.... wait for it.... https://x.com/TeslaSoftUpdate/status/1736655366757228746?s=20 My kids will be pissed. What a great way to punish Tesla customers...it's not like people were keeping or buying a D+ subscription just because it was viewable in a...teslamotorsclub.com

jebinc

Well-Known Member

Only Elon knows…. will be more telling to see how much time must pass for it to be fixed or Tesla explains what happened. Not a good look.Seems made up considering they only moved the icon from the Theater option to the Entertainment option...

jebinc

Well-Known Member

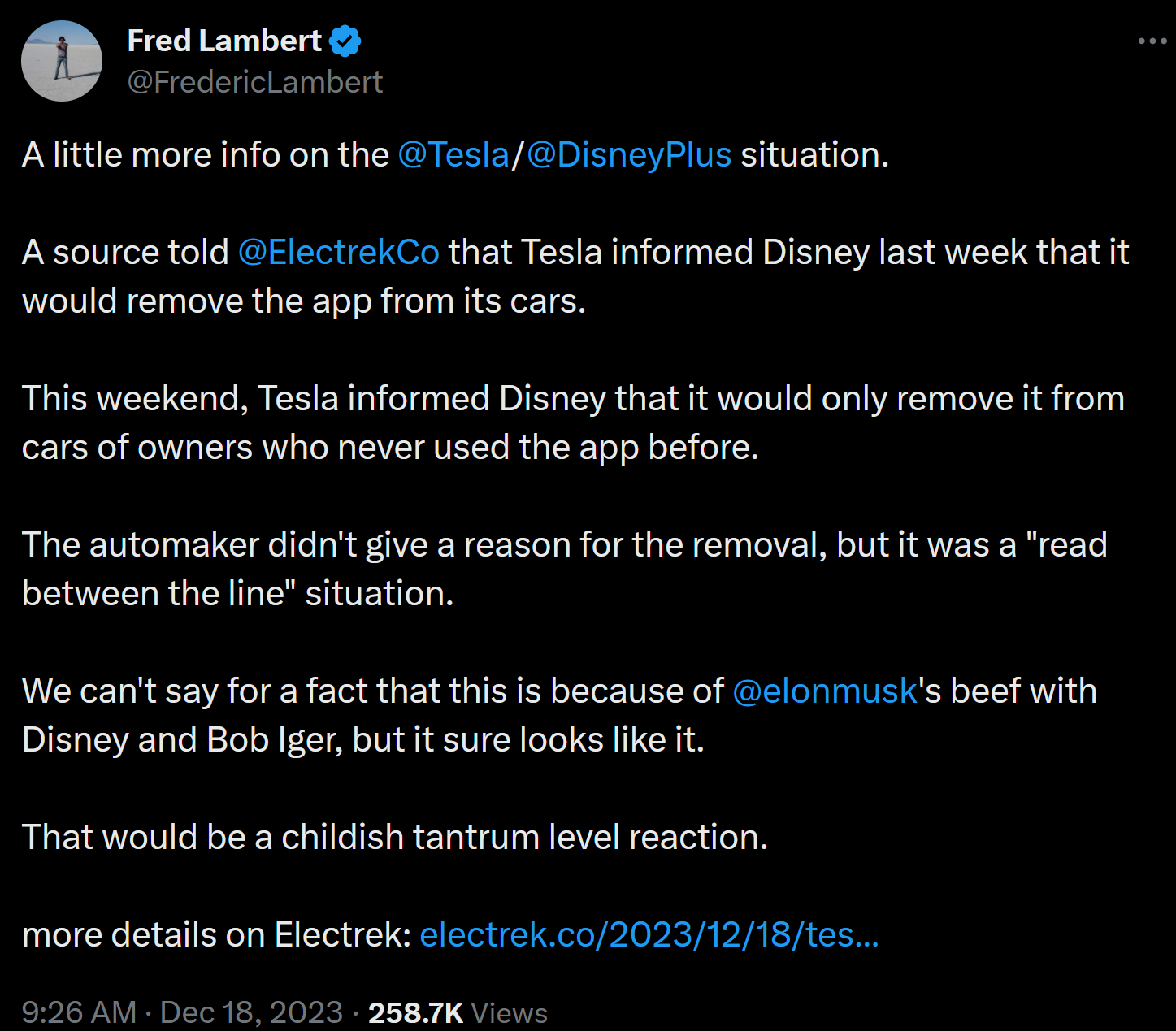

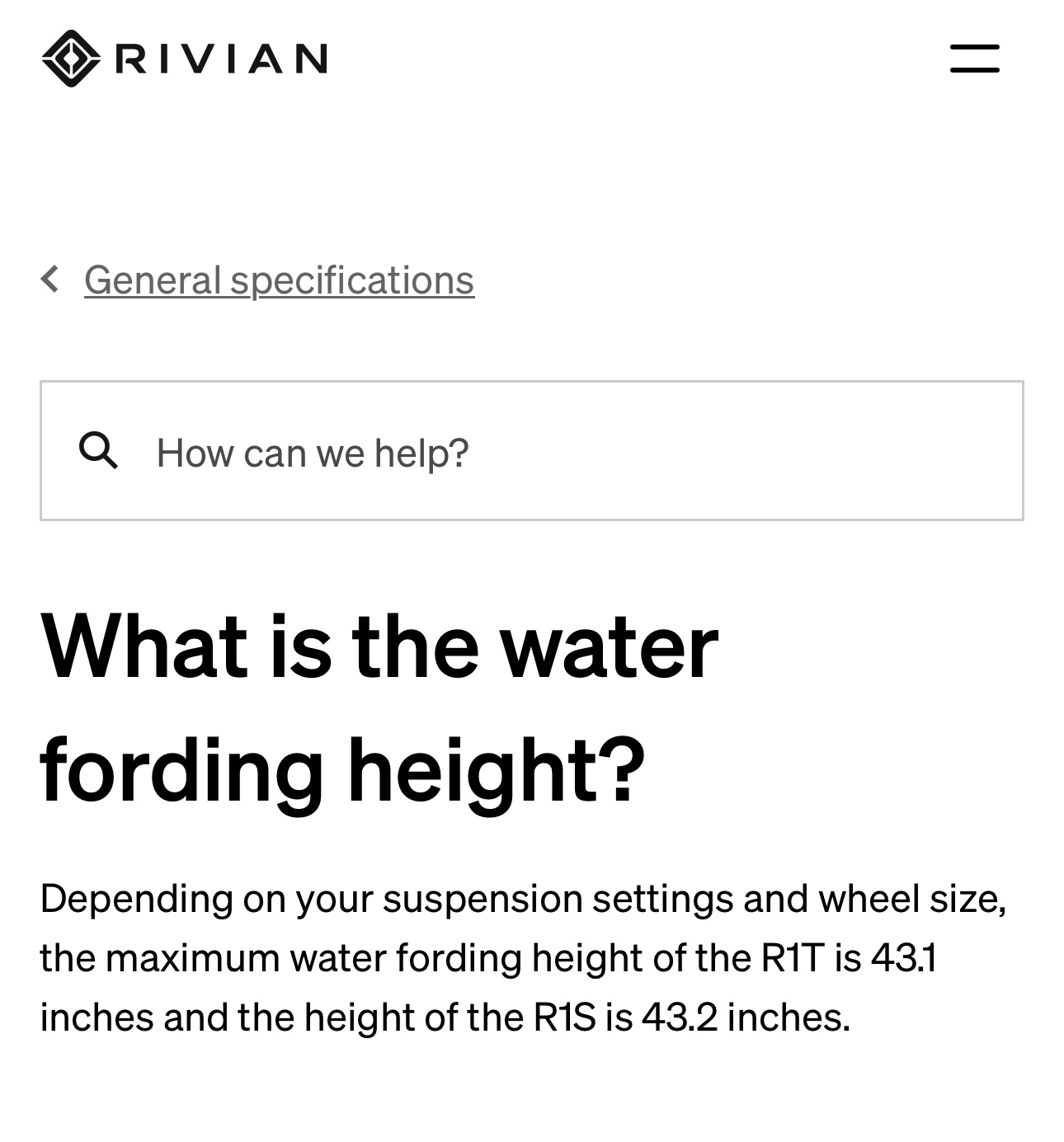

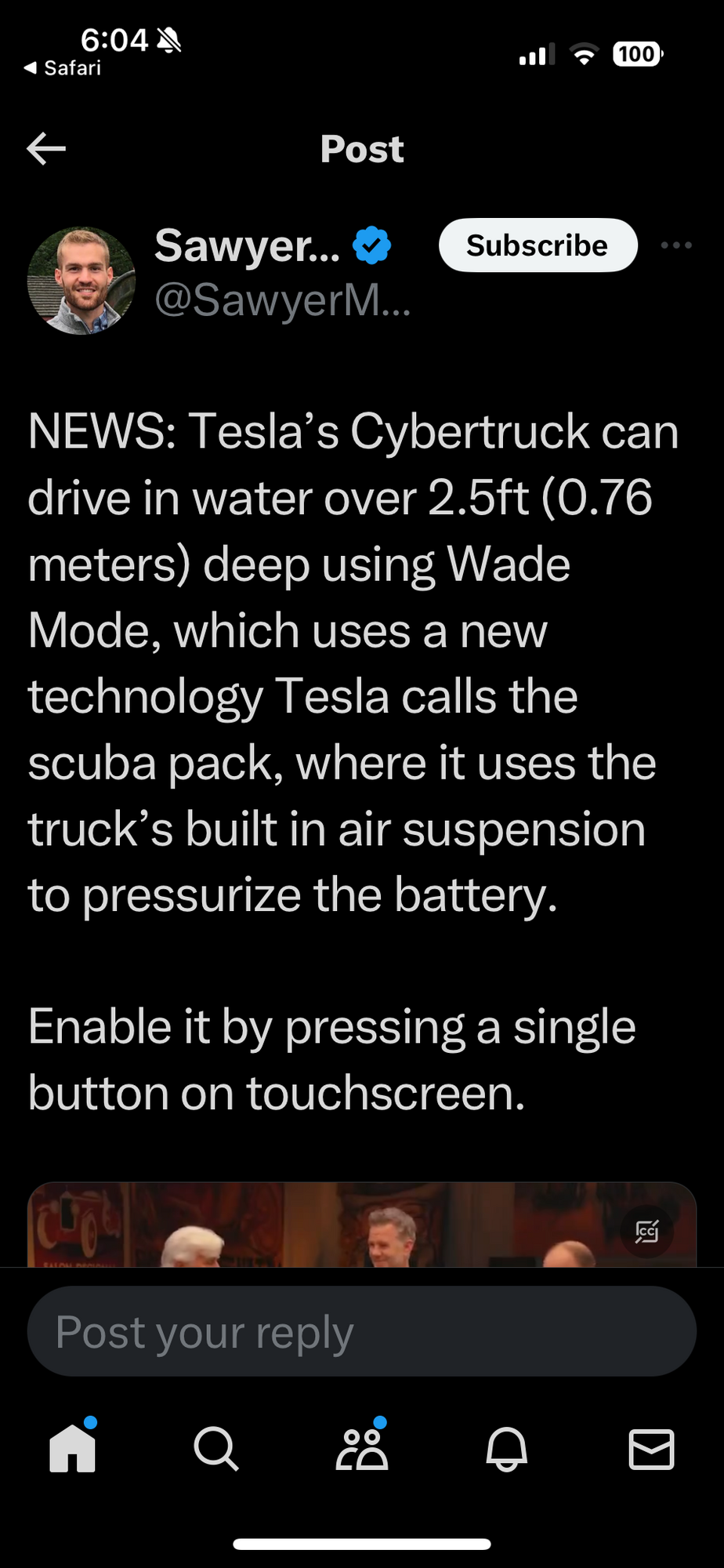

Some “fording” facts….

Looks like with CT, you have to go through a process before fording up to 30”

BUT with the Rivian you can just “have at it,” up to a staggering 43”+ of depth!

Another “win” for the theee year old Rivian….

Looks like with CT, you have to go through a process before fording up to 30”

BUT with the Rivian you can just “have at it,” up to a staggering 43”+ of depth!

Another “win” for the theee year old Rivian….

RobStark

Well-Known Member

Hitting scuba mode isn't a "process."Some “fording” facts….

Looks like with CT, you have to go through a process before fording up to 30”

BUT with the Rivian you can just have at it, up to a staggering 43”+ of depth!

Another “win” for the theee year old Rivian….

View attachment 1000877

View attachment 1000878

And Rivian's pack isn't pressurized 100% of the time.

CT is an all purpose pickup with an over 6' bed.

R1T is an adventure vehicle with a 4.5' bed.

Similar threads

- Replies

- 391

- Views

- 11K

- Replies

- 75

- Views

- 7K

- Replies

- 29

- Views

- 2K

- Replies

- 48

- Views

- 4K

- Replies

- 19

- Views

- 735