I was thinking about this over coffee. Anybody who is considering spending $400 for the Macsboost kit could DIY this for next to nothing. I need somebody to confirm the relationship between the spacer thickness and the camber, but I don't have a refresh X. If anybody is in the Bay area I'd be down to shim and measure the camber and toe values so we can share the data freely.

Some notes:

- Another member has already confirmed the $400 shims are off the shelf 2.9mm (approx 1/8").

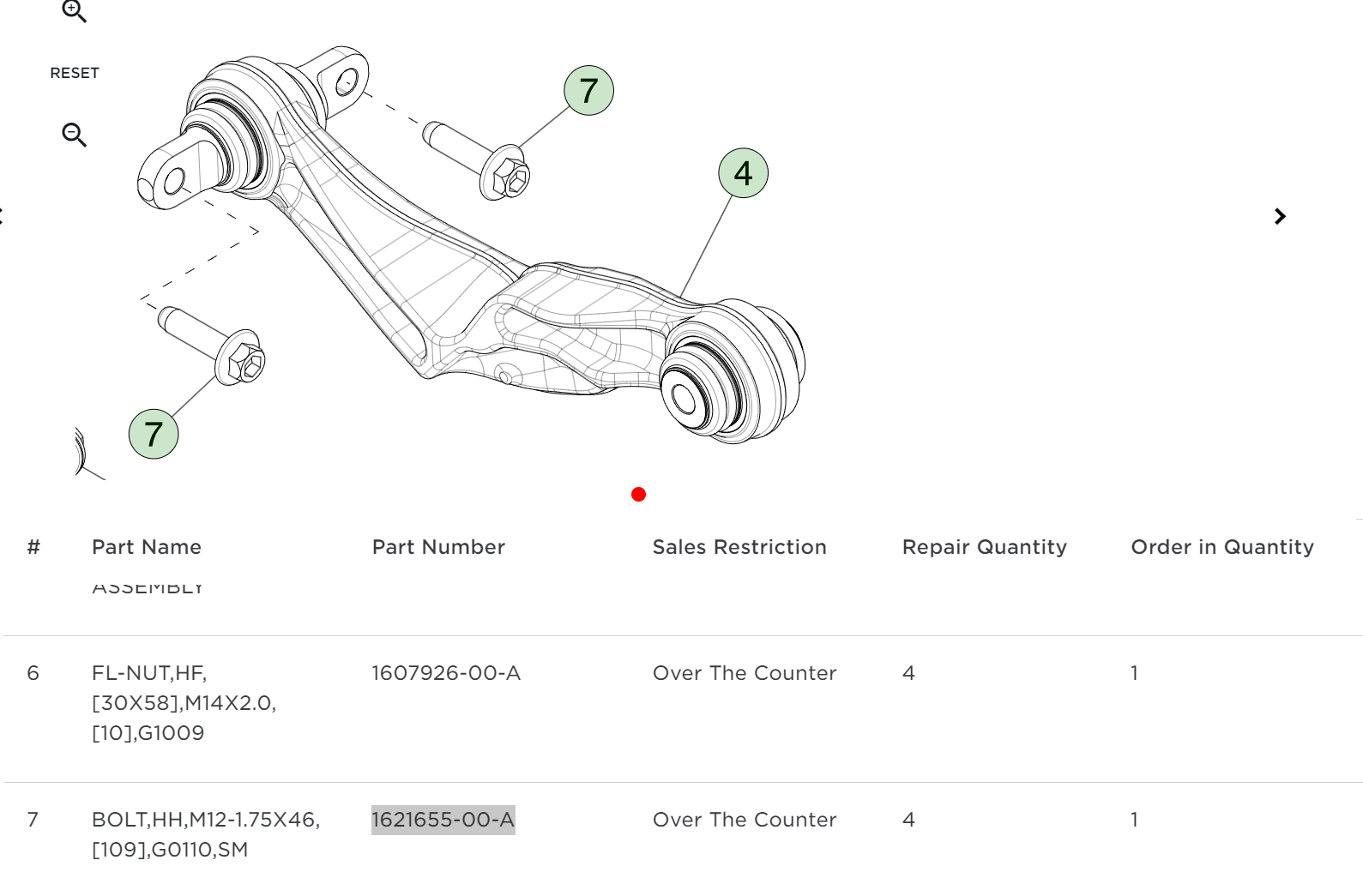

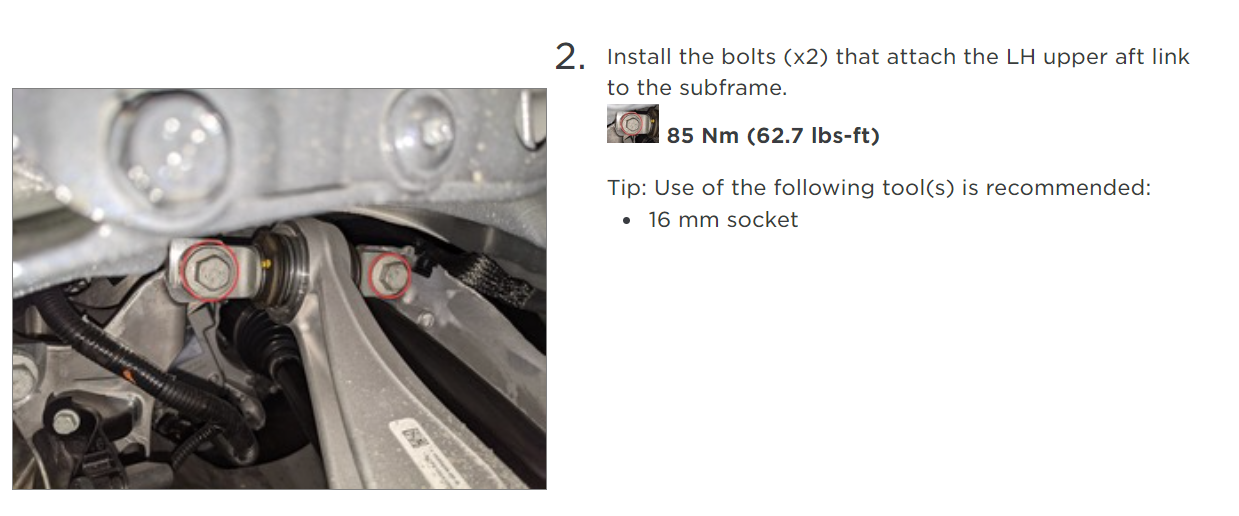

- Factory hardware appears to be M12

To do this at home you will need four M12 (metric, so the nominal diameter is 12mm) washers, approx thickness of 3mm; 1/8" is a close standard equivalent. A correctly sized washer will work in pinch.

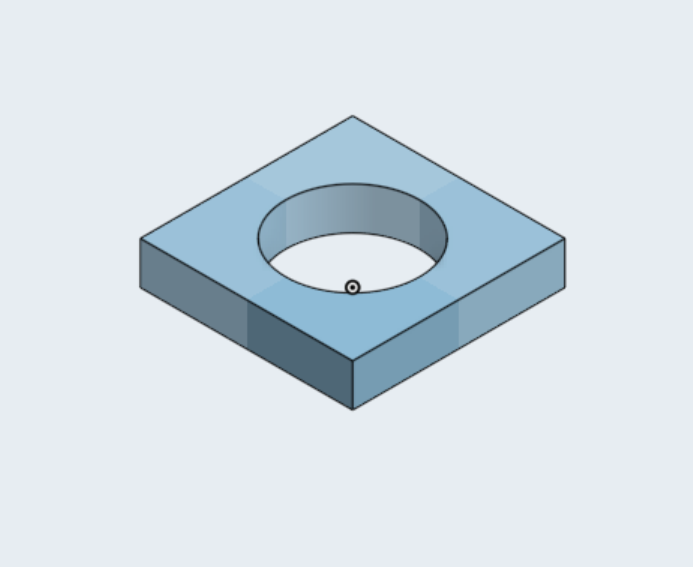

If we can measure the factory arm's flange, I can draw a simple square part that others can customize for their desired thickness, if they want to hit a target alignment. There are plenty of shops that will mill these for you

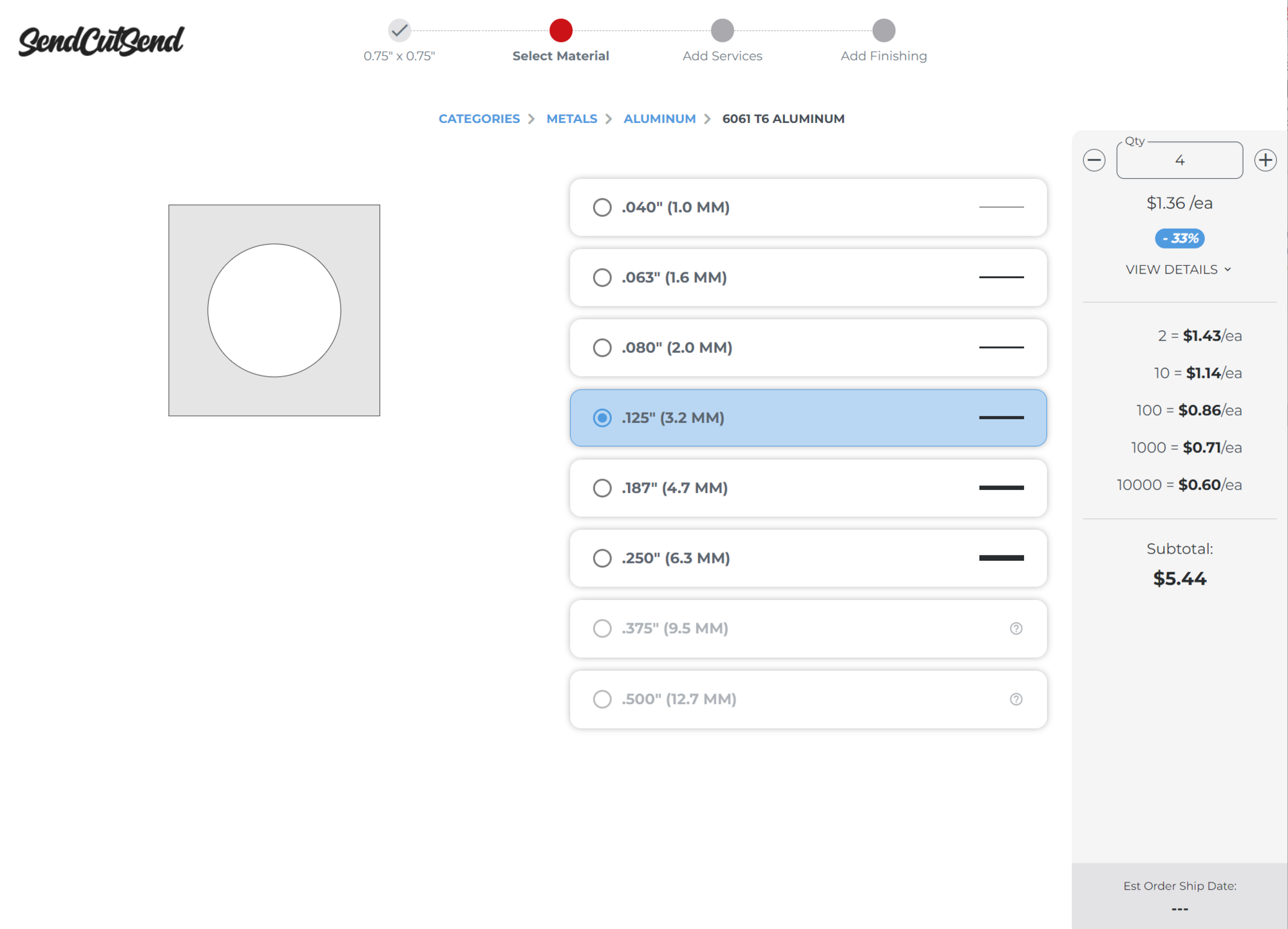

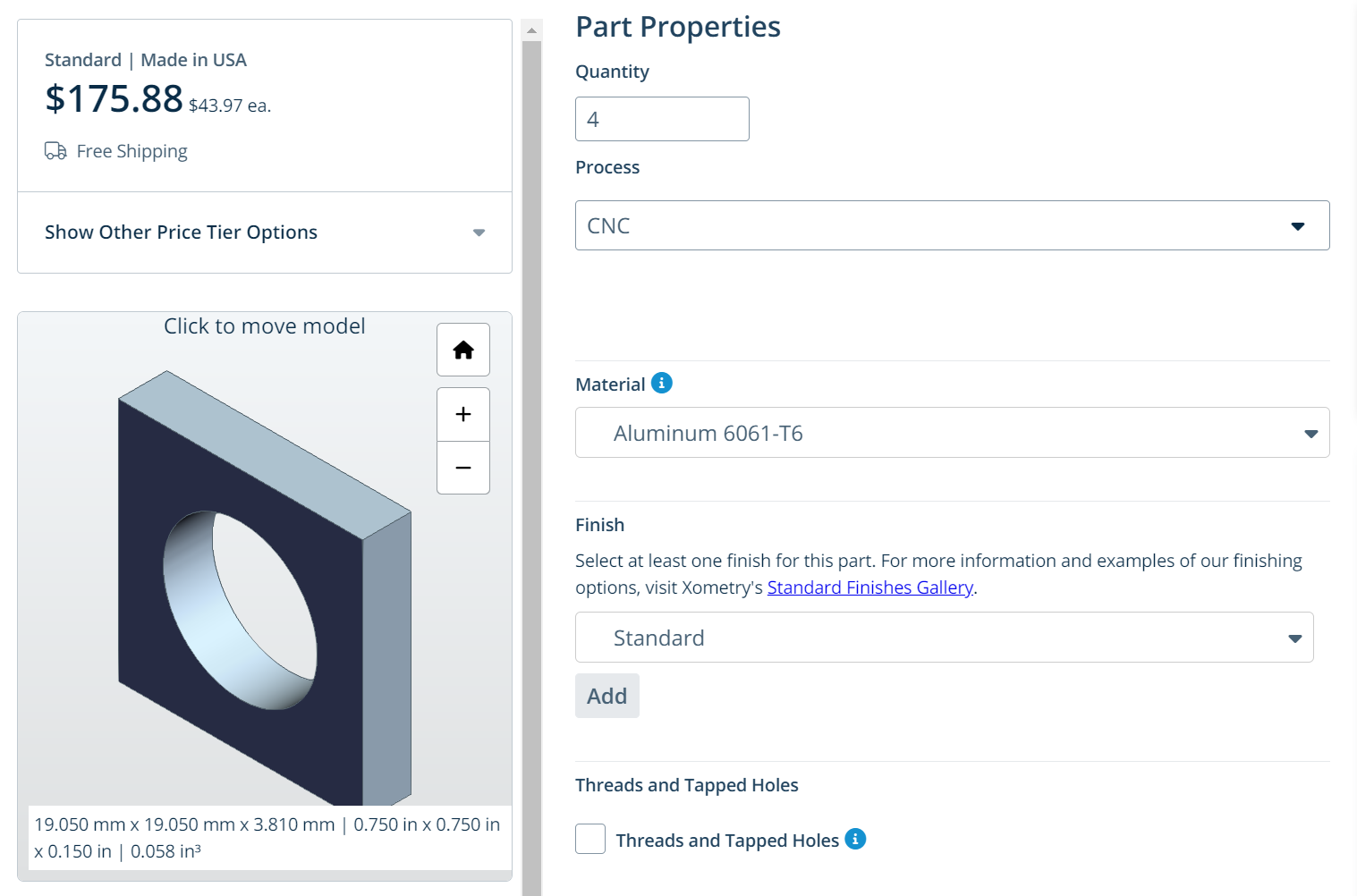

Quick mock up with a non-standard thickness that I priced through Xometry. I quoted laser cut 6061 below but other materials are available for an additional cost. Grade 5 Titanium will double the price...to a whopping $11.

If you are happy with the alignment from the 1/8" thickness there is no reason to have a spacer machined.

Of course, the cost goes way down with volume and we can do cool things like anodize or powdercoat. There are also other manufacturing options available with volume.

If none of these options speak to you grab some 1/8" stock, a hacksaw, and a drill!

Some notes:

- Another member has already confirmed the $400 shims are off the shelf 2.9mm (approx 1/8").

- Factory hardware appears to be M12

To do this at home you will need four M12 (metric, so the nominal diameter is 12mm) washers, approx thickness of 3mm; 1/8" is a close standard equivalent. A correctly sized washer will work in pinch.

If we can measure the factory arm's flange, I can draw a simple square part that others can customize for their desired thickness, if they want to hit a target alignment. There are plenty of shops that will mill these for you

Quick mock up with a non-standard thickness that I priced through Xometry. I quoted laser cut 6061 below but other materials are available for an additional cost. Grade 5 Titanium will double the price...to a whopping $11.

If you are happy with the alignment from the 1/8" thickness there is no reason to have a spacer machined.

Of course, the cost goes way down with volume and we can do cool things like anodize or powdercoat. There are also other manufacturing options available with volume.

If none of these options speak to you grab some 1/8" stock, a hacksaw, and a drill!