Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon Fiber Rims

- Thread starter AngelArm1110

- Start date

Xenoilphobe

Well-Known Member

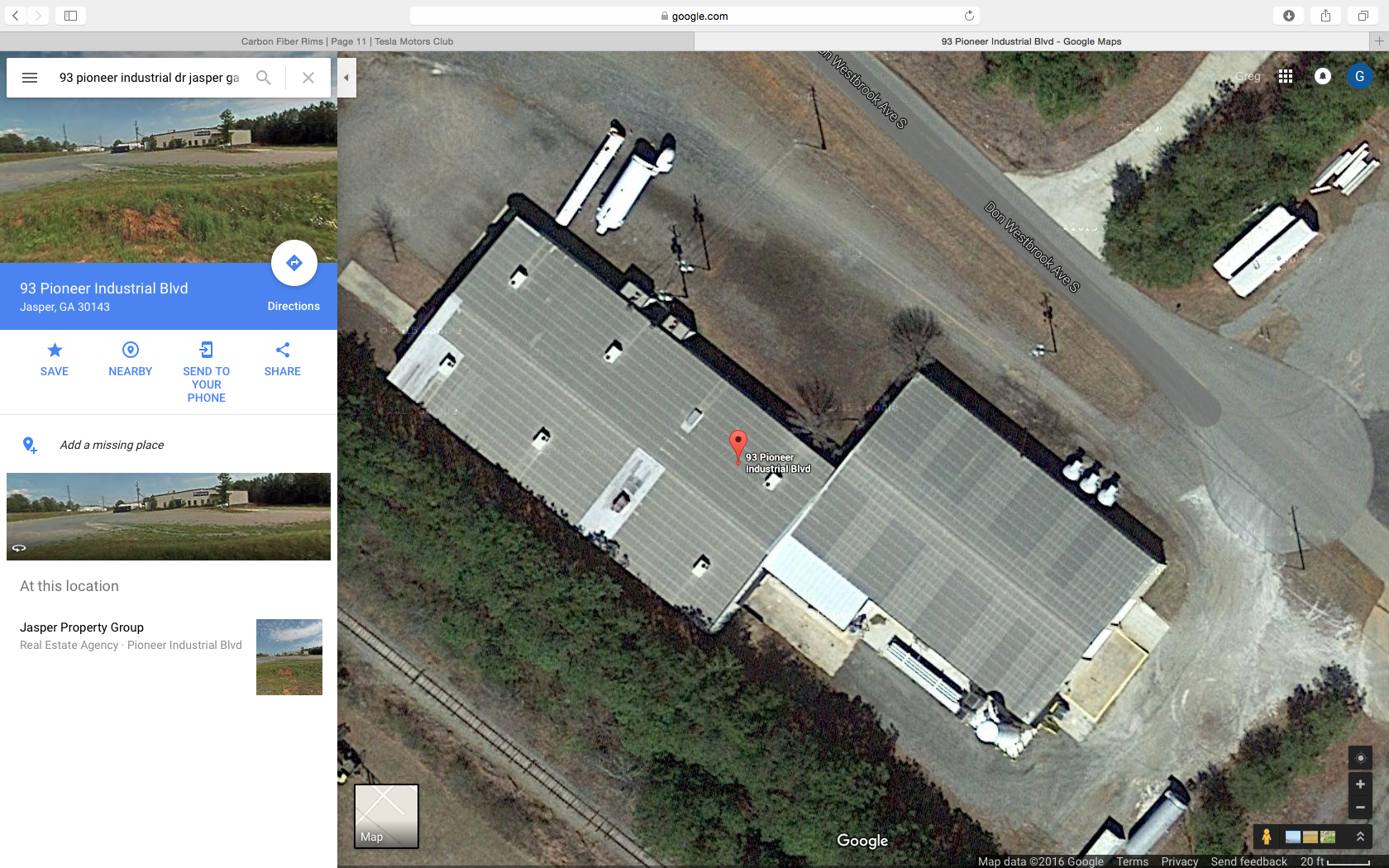

This is were I had them ship the center caps:

Blake Sanchez is VP of Engineering and COO.

ESE Industries

ATTN: Blake Sanchez / Ref: Xenoilphobe

93 Pioneer Industrial BLVD

Jasper, GA 30143

Thank you,

Victor Calvo

Sales Coordinator

ESE Industries

O: (877) 213-8662 x706

E:[email protected]

www.esecomposites.com

Blake Sanchez is VP of Engineering and COO.

ESE Industries

ATTN: Blake Sanchez / Ref: Xenoilphobe

93 Pioneer Industrial BLVD

Jasper, GA 30143

Thank you,

Victor Calvo

Sales Coordinator

ESE Industries

O: (877) 213-8662 x706

E:[email protected]

www.esecomposites.com

Last edited:

artsci

Sponsor

PO Box in Puerto Rico? not encouraging.

My thoughts as well. These guys are everywhere -- Facebook, Linkedin, Twitter, you name it. But there's no evidence yet that they've actually built a real wheel. Victor said he'd have some photos this week. Nada.

I'm concerned.

Last edited:

lolachampcar

Well-Known Member

There was mention on one of the Vette forums that they had done wheels for them......

I did ask Victor to see some product he was bringing out to an event at Palm Beach International Raceway but he said it was not production quality and could not show me.

We have three more weeks.

I did ask Victor to see some product he was bringing out to an event at Palm Beach International Raceway but he said it was not production quality and could not show me.

We have three more weeks.

Xenoilphobe

Well-Known Member

Check out the facility - they definitely have autoclaves and industrial holding tanks for something there. Also note the recent traffic lines on the road to the delivery dock in the rear - not sure when this satellite pass was done, but there is definitely activity at this site. I will check other sources to see if there are cars parked there during business hours.

artsci

Sponsor

Check out the facility - they definitely have autoclaves and industrial holding tanks for something there.

View attachment 171357

I don't think there's much doubt that these folks apparently have the hardware for the work but that fact that none of us have seen any evidence of a real, production carbon fiber wheel should give us pause about the delivery timetable. They certainly talk a good game on the web site and social media, but talk is cheap.

Right now I'm thinking best case is major delays in production and delivery; worst case is that production delays force many buyers to request refunds and the whole thing unravels financially. But I hope very much that I'm wrong.

The fact that the ordering page on the web site required a 50% deposit but that when we ordered they charged our credit cards the full amount suggests to me that the company is cash poor. Therein may lie the problem.

I keep asking myself one question: who would sell such an expensive product without having ever manufactured one? Maybe there's a prototype somewhere, but all of the stuff we see on their web site are digital creations.

Last edited:

Xenoilphobe

Well-Known Member

I have 2 sets of wheels for my Tesla - I'm in no rush and will wait to see what they do. I suspect they are having issues with the visual aspects referenced as "Fish Eyes" in the BST FAQ below, of the carbon fiber fabric - same issues that Carbon Revolution had - which is why they (CR) now paint their wheels for the mass production environment (Ford Mustang SVT).

This production is not that hard - they have been doing this for years in the motorcycle and ATV market. In fact Hiper Technologies just got bought due to their advanced manufacturing methods. BST Carbon (largest motorcycle carbon wheel brand) DOES NOT PAINT THEIR WHEELS..

Check out the part were the guy bounces the wheels off the ground with no tires!

This production is not that hard - they have been doing this for years in the motorcycle and ATV market. In fact Hiper Technologies just got bought due to their advanced manufacturing methods. BST Carbon (largest motorcycle carbon wheel brand) DOES NOT PAINT THEIR WHEELS..

Check out the part were the guy bounces the wheels off the ground with no tires!

Last edited:

Xenoilphobe

Well-Known Member

Some more background from the BST Carbon Fiber Wheel FAQ:

Home > About > FAQ

Q: How does UV affect BST carbon fiber wheels?

A: UV has little effect on BST wheels. Read the full report.Q: How important is the Serial Number on a BST wheel?

A: Each BST wheel has a unique Serial Number which is on the label. This is its ‘DNA’ marker and allows us to trace its entire history and build process. There is no legitimate reason to remove the label. An attempt to remove it it will leave a very clear bare mark. That’s not good. The warranty is immediately invalid and no reputable dealer will support it. Theft? Sounds like it to me.

Q: How do I fit the sprocket to BST wheels?

A: The best description is on Brocks Performance web site with detailed instructions and pics. Thanks Brock!

The look of BST Carbon Fiber wheels

BST wheels are hand crafted from ISO certified materials. BST’s wheels are extensively tested and there is no doubt as to their structural integrity. We take pride in producing wheels that are as aesthetically perfect as possible. Occasionally a wheel may exhibit slight irregularities such as slight weave distortion, light or dark marks from resin flow or natural porosity resulting in small ‘fish eyes’. These irregularities are acceptable by the motor industry and BST and do not affect the structural integrity or performance in any way whatsoever. Should your wheel exhibit such irregularities, please consider it the signature of uniqueness – a product crafted by hand for your enjoyment.

Q: Can I change the hubs on my wheels to fit a different bike or model?

A: BST wheels are made specifically for a type and model of bike. Part of the manufacturing process ensures that the wheel runs absolutely true on its own hub. The hubs have a unique fastening system, and they must not be tampered with. So no, you cannot change the hubs. If you are changing motorcycles, the best solution is to sell your wheels – either separately or as a value-add to your current motorcycle – and buy new BST wheels for your new bike.

The rule generally is:

HUBS can be re-used and be fitted onto NEW Carbon Wheels (but only the BST factory may remove the hubs)

Carbon Blanks cannot be re-used for the purpose of putting new hubs onto them.

Q: Can I use tire warmers on my BST wheels?

A: Yes you can. Make sure that the warmers and regulators are operating correctly. Do NOT use enclosed tire warmers (side covers that blanket the entire wheel) as this pushes the temperature higher than the specification given on the warmers and on the BST wheels. BST wheels are designed to operate up to 80� C which is more than adequate and will work within the requirements of the tire warmer specifications. If used under normal circumstances, a tire warmer set at 90� C will warm the tire accordingly, and the wheel itself will not achieve more than 50-60� C. Carbon does not radiate the heat as quickly as metals so there is no need to over-do it with the warmers.

Q: How should I clean my BST wheels?

A: Use warm water with a mild cleaner, avoid petroleum or alcohol based products and don�t use aggressive or abrasive cleaners. A mild de-greaser will remove any oil. You can polish them with any normal polish for a painted surface.

Q: How should I fit the tires to the BST wheels?

A: A normal good quality shop will be able to fit the tires. Use a tire machine, and turn down the clamping force a touch. Don�t use too much mounting fluid (or soap) as this can make beading more difficult.

Q: How does the BST warranty work?

A: The BST warranty covers all workmanship for a period of 2 years from date of sale to the rider. This is regardless of the date on the wheels – the date on the silver sticker indicates the date of manufacture of the carbon part. There is no shelf life for carbon fiber, so the date does not affect the warranty.

Q: How are the BST hubs fitted to the carbon part of the wheel?

A: The hubs are attached to the carbon fiber wheel using a unique fastening system combining high strength aerospace fasteners with mechanical locking mechanisms as well as high strength aerospace adhesive.

Q: What is the difference between the BST STREET and RACE wheels?

A: BST Street wheels are designed for normal street and track use. BST RACE wheels have a different and lighter carbon layup, as well as 7075 T6 aluminium hubs. These wheels are even lighter than the standard wheels and are designed for race use only.

Q: What sprocket can I use with my BST wheels?

A: The BST wheels come with a 5 bolt hole sprocket carrier – the PCD of the 5 holes is 100mm and the ID is 76mm.

Q: After an accident, how will I know if my wheel is still safe and usable?

A: One of the good things about carbon fiber is that you can see damage immediately. The first test is whether the tire is holding air. If it is not, the wheel is likely damaged beyond repair. Major damage will show cracks through the rim and the wheel will obviously not be usable. If it holds air, remove the tire and check the wheel carefully. Damage can be superficial in which case minor cracks will be visible in the clear coat, and the wheel is usable. If the cracks are deeper and the layers of carbon fiber appear to be torn, this is more serious and the wheel should not be used. Please feel free to send us photos to help assess the damage for you.

Q: If my wheel is damaged, can it be fixed?

A: Hubs can often be re-used if they have not been damaged. If the carbon fiber is damaged beyond repair, you can cut the spokes close to the hub and send the hubs to us. We will likely be able to fit them to new carbon parts, giving you new wheels at a much reduced price. Your ‘new’ wheels will carry the 2 year warranty.

If the hubs have been damaged, the wheel cannot be recovered, as the carbon parts cannot have new hubs attached to them.

All repairs should be done at the BST factory.

Wheels can also be refurbished at the factory for a very reasonable fee.

Q: Where can I buy BST wheels?

A: BST has appointed distributors around the world. See the ‘Where to Buy” link at the top of thr page.

Q: How much stronger are BST Carbon fiber Wheels than conventional wheels?

A: BST Carbon fiber wheels have undergone an intensive programme of very stringent testing to verify their design and to confirm their strength and durability.

A designated test body in the UK performed the following tests and all tests were conducted on a single prototype wheel.

It is important to note that this �single wheel test’ is not usually the case when testing a metal wheel, since due to metal fatigue behaviour a single wheel would not last throughout all the tests. To allow for this weakness in metal wheels, the test regulations actually specify that one new wheel for every test is permissible, whereas in this case a single BST wheel withstood ALL tests. A sample of test results is given below, tests and forces exerted depend upon requirements of the testing body (eg T�V) and the wheel (front or rear).

� Cornering fatigue: 1,000,000 cycles at 530Nm

� Radial fatigue: 3,200,000 cycles at 6082Nm

� Torsional fatigue: 1,000,000 cycles at 890Nm

� Impact test: 337.5kg from 150mm (JWL)

The front wheel was designed for a 150kg static load and the rear wheel for a 250kg static load (this translates into a bike with a total dry weight of up to 400kg). Modern sports bikes normally weigh between 160-220kg and race bikes rarely exceed 170kg, so these static load design parameters comfortably exceed normal conditions.

Q: What weight are the BST wheels designed to carry?

A: Load rating of BST wheels.

BST has derived our load specification from experience in the field of motorcycle physics:

The load rating printed on the wheel sticker will reflect the maximum static load/weight that is permitted on the specific wheel to not exceed the critical loads during the dynamic situation of riding the motorcycle. We design with a safety factor of approximately 4.

To check if the wheels are appropriate for your bike you can use the following rules of thumb:

Scenario 1: Motorcycle with a rider:

The usual weight distribution here is approximately 40% for the front wheel and 60% for the rear wheel.

Total Static Weight or TSW = Weight of bike with all fluids + weight of rider = 220Kg + 90Kg = 310 Kg

This leaves us with the following load ratings:

For Front wheel = 310Kg x 40% = 124Kg

For Rear wheel = 310Kg x 60% = 186Kg

Scenario 2: Motorcycle with a rider and 1 passenger:

The usual weight distribution here is approximately 37.5% for the front wheel and 62.5% for the rear wheel.

TSW = Weight of bike with all fluids + weight of rider + weight of passenger =220Kg + 90Kg + 90Kg =400 Kg

This leaves us with the following load ratings:

For Front wheel = 400Kg x 37.5% = 150Kg

For Rear wheels = 400Kg x 62.5% = 250Kg

Q: How do I set up my bike for fast road riding with BST wheels – tire pressure and suspension settings?

A: For road use, use the same tire pressure that you usually use. For suspension – if the suspension is working OK for you before you put on the BST wheels, you should not have to make adjustments. The carbon wheels make a huge difference to the smaller bikes so there are some things you need to know. If you get chatter on fast corners once you change to the carbon wheels that was not there with metal wheels, you should be able to tune it out with suspension settings, or you could add weight to the swing-arm. The reason is simple: the total weight working on the shock is a lot less and hence you are not working within the range of the rear shock. The shock works at about 5 – 10 hertz and the wheel at +- 30 hertz so the natural frequency can chase the chatter on the smaller bikes. By putting weight on the swingarm you have the same weight working on the rear shock while gaining the advantage of the much lighter rear wheel.

We have about ten 125 Hondas that run the wheels here in SA and they also tend to run lower tire pressures cold as the carbon does not transfer heat very well and they can get a bigger contact patch with lower pressure.

Q: What torque should I use when fitting the brake disc to BST wheels?

A: Use the torque as specified for the OEM wheels. As a rule this means:

M6 bolts � 10Nm

M8 bolts � 16Nm

Make sure the bolts are free of grease or oil, and fasten them with Locktite.

Q: What torque should I use when fitting the BST rear wheel to the axle?

A: Use the torque as specified by the OEM, but do not exceed 90 Nm – this is sufficient to hold the spacers and bearings in place without damaging them. The exceptions are the offset rears – - use approx 150 Nm.

Use the locking mechanism as per the manufacturer, if applicable.

Q: What do BST wheels include?

A: The BST wheels are designed to fit the same way the OEM wheels fit. They are supplied with:

� All internal bearings, spacers and seals pre-installed

� External spacers, where required

� Air valves

� Cush drive (rear conventional swing arm)

� Sprocket carrier (rear conventional swing arm) where required � wheels can be purchased without a sprocket carrier if you wish (for race teams etc.)

� You will need to buy a sprocket that fits the BST sprocket carrier

Q: What are the physical properties of Prepreg Carbon fiber that make it particularly suitable for wheels?

A: Some of the properties of Carbon fiber composites as used in BST wheels:

� Material used – Carbon fiber Prepreg in a woven and unidirectional format, embedded in a resin matrix, made from toughened epoxy.

� Max structural temperature: 100 degrees C

� Min structural temperature: -40 degrees C

� Max operating temperature: 80 degrees C

� Corrosion resistance: Totally corrosion free

� Chemical resistance: Resistant to most dilutants such as acetone, benzene, thinners,

� Automotive fluid resistance: Limited resistance to brake fluids and acids

� Density: Approximately 1.7 kg/qdm (Aluminium 2.7, Titanium 4.5, Steel 7.9)

� Damage Tolerance: Similar to 2024 Aluminium

� Strength: Better than 2024 Aluminium

� Stiffness: Similar to 2024 Aluminium

Variable wall thicknesses can be created anywhere as needed in order to increase strength where required.

Fibers are oriented in the direction of stress in order to increase strength.

BST has a patented process for the manufacture of a monocoque (single unit) hollow spoke wheel.

Q: What is the difference between wet lay-up and the Prepreg construction, as used in BST wheels?

A: In the wet lay-up process, the fibers are positioned in the mould dry and the resin is applied with a brush. The resin is mixed by hand and mistakes can be made during mixing. This is a relatively inexpensive process, but normally the part is heavier and the fibers can distort during the lamination process meaning the process is less controlled. This method does not lend itself to the Autoclave process which cures the part under controlled heat and pressure.

In the Prepreg process used to manufacture BST wheels, the resin is applied by machine onto the fibers in a thin film. Therefore, the resin is very even and controlled. The parts are then cured under a high pressure and temperature environment (Autoclave). This results in a well-compacted laminate with better properties than with wet lay-up. Laminate properties in Prepreg Carbon fiber can be 10%- 20% better than wet lay-up at a lower weight (because less resin is used to do the same job). This Prepreg and Autoclave process is used to manufacture the exceedingly strong, but light, chassis centres (often known as �tubs�) for Formula 1 race cars.

Q: What performance gains can I expect on my bike by changing to BST wheels?

A: You’ll gain in many ways � this is the best performance enhancing product you can buy. BSTs will make a dramatic difference that will gain you speed and responsiveness with less effort and fatigue. It’ll feel like you’ve added a few horses to your engine � but at a very reasonable price. Best BANG per $$ for performance �

Extra performance: Low mass and lowest Moment of Inertia (see our page on The Effects of Inertia) results in a lower unsprung mass; this means faster cornering, later braking, improved acceleration � in all, faster lap times. Imagine the difference you’ll experience from dropping 11.2 lbs off the weight of your bike! That’s the difference in weight between the standard GSXR1000 wheels and the BSTs.

Extra Riding Fun and Rider Safety: The huge drop in weight means that handling improves dramatically � quicker lap times with less effort and astonishing responsiveness means less fatigue.

Extra Safety:

� Carbon fibre is a fatigue free material resulting in longer product life;

� Carbon fiber composite is a very damage tolerant material. In the event that a wheel is damaged, the damage propagates less easily;

� Very low corrosion susceptibility.

Extra Cool Looks:

Whether you are into performance or looks, this wheel attracts attention � gleaming, black, woven-look finish and �soft� styling makes a stunning addition to your motorcycle.

The views of UK SuperBike magazine:

“what else can you do to a bike – for that money – to make it so much faster?”

UK sports bike magazine, SuperBike, performed an independent two day test at the Almeria circuit in Spain using a 2002 Honda CBR900RR (954) FireBlade.

�The first day’s testing took place with standard wheels and the only change for the second day was the substitution of BST wheels.

Weather conditions were unchanged and the following was observed:

� Acceleration was noticeably stronger with the rider reporting �it felt as though it had gained ten horsepower �

� The bike could be braked later

� The bike could be turned more easily

� Top speed at the end of the main straight was increased by 5mph

� Lap times fell by a full 3 seconds � although the rider did report �pulling the pin out� as he felt very confident on the bike during the second day

These results are consistent with performance gains normally found by virtue of the combination of reduced unsprung weight and reduced rotational inertia provided by BST wheels. Even if a bike is not being used on a circuit, the same benefits of increased performance and rideability also apply to road/street use.”

If you would like more information, email the rider, Jamie Wilkins, SuperBike magazine’s Road Test Editor, on: [email protected]

Q: How does Carbon fiber compare with Magnesium and Aluminium alloys?

A: Wheels manufactured from metal are either cast, forged, machined, or manufactured as a combination of the three processes. Aluminium wheels have been around for many years. They are relatively easy to manufacture and also relatively cheap, but they are heavy because of the density to strength ratio of Aluminium (how much strength you can get for a kilogram of Aluminium). To improve the weight you can either choose a material that is lighter or one that is stronger, or one that is lighter and stronger. Using magnesium, which is lighter but not necessarily stronger, you can improve on weight slightly.

The problem with magnesium is two fold: first – its fatigue properties are poor and so are the corrosion properties, so a wheel may not last very long even if perfectly cast and machined. The second problem is worse – very often micro-porosity occurs during the casting process, which has a negative impact on both fatigue life and corrosion. So magnesium wheels can be nice and light but may not last very long, sometimes less than a racing season. This makes magnesium wheels good for racing but unattractive to the man in the street. The only solution is to find a material that is lighter, stronger, fatigue free and corrosion free – Carbon fiber. As an engineering material, carbon fiber is far superior to Magnesium or Aluminium alloys.

Q: Do BST wheels have TUV certification?

A: We achieved TUV certification for the facility and for the wheels � GSXR1000 front and rears, Ducati 916-998 series and 748 front and rears. TUV requires certification per model. BST wheels passed every test. However TUV are currently writing new specifications for carbon wheels and all manufacturers will have to have their carbon wheels tested to the new specifications when this process has been completed.

Q: How much safer are BST Carbon Fiber wheels than standard wheels?

A: Carbon fiber wheels have been around for some considerable time and have been proven to be safe when designed and manufactured properly and, as with any wheel, used within their design parameters. One of the parameters is the maximum static weight of the motorcycle for which the wheel is designed (BST sportbike wheels are designed for motorcycles that weigh up to 280 kg dry) and have more than adequate strength and damage tolerance for any usage within road/street, sport or race environment. Safety is dependant on more than just strength and stiffness. Due to improved handling and therefore lower driver fatigue and effort, BSTs make a positive contribution towards driver safety.

Home > About > FAQ

Q: How does UV affect BST carbon fiber wheels?

A: UV has little effect on BST wheels. Read the full report.Q: How important is the Serial Number on a BST wheel?

A: Each BST wheel has a unique Serial Number which is on the label. This is its ‘DNA’ marker and allows us to trace its entire history and build process. There is no legitimate reason to remove the label. An attempt to remove it it will leave a very clear bare mark. That’s not good. The warranty is immediately invalid and no reputable dealer will support it. Theft? Sounds like it to me.

Q: How do I fit the sprocket to BST wheels?

A: The best description is on Brocks Performance web site with detailed instructions and pics. Thanks Brock!

The look of BST Carbon Fiber wheels

BST wheels are hand crafted from ISO certified materials. BST’s wheels are extensively tested and there is no doubt as to their structural integrity. We take pride in producing wheels that are as aesthetically perfect as possible. Occasionally a wheel may exhibit slight irregularities such as slight weave distortion, light or dark marks from resin flow or natural porosity resulting in small ‘fish eyes’. These irregularities are acceptable by the motor industry and BST and do not affect the structural integrity or performance in any way whatsoever. Should your wheel exhibit such irregularities, please consider it the signature of uniqueness – a product crafted by hand for your enjoyment.

Q: Can I change the hubs on my wheels to fit a different bike or model?

A: BST wheels are made specifically for a type and model of bike. Part of the manufacturing process ensures that the wheel runs absolutely true on its own hub. The hubs have a unique fastening system, and they must not be tampered with. So no, you cannot change the hubs. If you are changing motorcycles, the best solution is to sell your wheels – either separately or as a value-add to your current motorcycle – and buy new BST wheels for your new bike.

The rule generally is:

HUBS can be re-used and be fitted onto NEW Carbon Wheels (but only the BST factory may remove the hubs)

Carbon Blanks cannot be re-used for the purpose of putting new hubs onto them.

Q: Can I use tire warmers on my BST wheels?

A: Yes you can. Make sure that the warmers and regulators are operating correctly. Do NOT use enclosed tire warmers (side covers that blanket the entire wheel) as this pushes the temperature higher than the specification given on the warmers and on the BST wheels. BST wheels are designed to operate up to 80� C which is more than adequate and will work within the requirements of the tire warmer specifications. If used under normal circumstances, a tire warmer set at 90� C will warm the tire accordingly, and the wheel itself will not achieve more than 50-60� C. Carbon does not radiate the heat as quickly as metals so there is no need to over-do it with the warmers.

Q: How should I clean my BST wheels?

A: Use warm water with a mild cleaner, avoid petroleum or alcohol based products and don�t use aggressive or abrasive cleaners. A mild de-greaser will remove any oil. You can polish them with any normal polish for a painted surface.

Q: How should I fit the tires to the BST wheels?

A: A normal good quality shop will be able to fit the tires. Use a tire machine, and turn down the clamping force a touch. Don�t use too much mounting fluid (or soap) as this can make beading more difficult.

Q: How does the BST warranty work?

A: The BST warranty covers all workmanship for a period of 2 years from date of sale to the rider. This is regardless of the date on the wheels – the date on the silver sticker indicates the date of manufacture of the carbon part. There is no shelf life for carbon fiber, so the date does not affect the warranty.

Q: How are the BST hubs fitted to the carbon part of the wheel?

A: The hubs are attached to the carbon fiber wheel using a unique fastening system combining high strength aerospace fasteners with mechanical locking mechanisms as well as high strength aerospace adhesive.

Q: What is the difference between the BST STREET and RACE wheels?

A: BST Street wheels are designed for normal street and track use. BST RACE wheels have a different and lighter carbon layup, as well as 7075 T6 aluminium hubs. These wheels are even lighter than the standard wheels and are designed for race use only.

Q: What sprocket can I use with my BST wheels?

A: The BST wheels come with a 5 bolt hole sprocket carrier – the PCD of the 5 holes is 100mm and the ID is 76mm.

Q: After an accident, how will I know if my wheel is still safe and usable?

A: One of the good things about carbon fiber is that you can see damage immediately. The first test is whether the tire is holding air. If it is not, the wheel is likely damaged beyond repair. Major damage will show cracks through the rim and the wheel will obviously not be usable. If it holds air, remove the tire and check the wheel carefully. Damage can be superficial in which case minor cracks will be visible in the clear coat, and the wheel is usable. If the cracks are deeper and the layers of carbon fiber appear to be torn, this is more serious and the wheel should not be used. Please feel free to send us photos to help assess the damage for you.

Q: If my wheel is damaged, can it be fixed?

A: Hubs can often be re-used if they have not been damaged. If the carbon fiber is damaged beyond repair, you can cut the spokes close to the hub and send the hubs to us. We will likely be able to fit them to new carbon parts, giving you new wheels at a much reduced price. Your ‘new’ wheels will carry the 2 year warranty.

If the hubs have been damaged, the wheel cannot be recovered, as the carbon parts cannot have new hubs attached to them.

All repairs should be done at the BST factory.

Wheels can also be refurbished at the factory for a very reasonable fee.

Q: Where can I buy BST wheels?

A: BST has appointed distributors around the world. See the ‘Where to Buy” link at the top of thr page.

Q: How much stronger are BST Carbon fiber Wheels than conventional wheels?

A: BST Carbon fiber wheels have undergone an intensive programme of very stringent testing to verify their design and to confirm their strength and durability.

A designated test body in the UK performed the following tests and all tests were conducted on a single prototype wheel.

It is important to note that this �single wheel test’ is not usually the case when testing a metal wheel, since due to metal fatigue behaviour a single wheel would not last throughout all the tests. To allow for this weakness in metal wheels, the test regulations actually specify that one new wheel for every test is permissible, whereas in this case a single BST wheel withstood ALL tests. A sample of test results is given below, tests and forces exerted depend upon requirements of the testing body (eg T�V) and the wheel (front or rear).

� Cornering fatigue: 1,000,000 cycles at 530Nm

� Radial fatigue: 3,200,000 cycles at 6082Nm

� Torsional fatigue: 1,000,000 cycles at 890Nm

� Impact test: 337.5kg from 150mm (JWL)

The front wheel was designed for a 150kg static load and the rear wheel for a 250kg static load (this translates into a bike with a total dry weight of up to 400kg). Modern sports bikes normally weigh between 160-220kg and race bikes rarely exceed 170kg, so these static load design parameters comfortably exceed normal conditions.

Q: What weight are the BST wheels designed to carry?

A: Load rating of BST wheels.

BST has derived our load specification from experience in the field of motorcycle physics:

The load rating printed on the wheel sticker will reflect the maximum static load/weight that is permitted on the specific wheel to not exceed the critical loads during the dynamic situation of riding the motorcycle. We design with a safety factor of approximately 4.

To check if the wheels are appropriate for your bike you can use the following rules of thumb:

Scenario 1: Motorcycle with a rider:

The usual weight distribution here is approximately 40% for the front wheel and 60% for the rear wheel.

Total Static Weight or TSW = Weight of bike with all fluids + weight of rider = 220Kg + 90Kg = 310 Kg

This leaves us with the following load ratings:

For Front wheel = 310Kg x 40% = 124Kg

For Rear wheel = 310Kg x 60% = 186Kg

Scenario 2: Motorcycle with a rider and 1 passenger:

The usual weight distribution here is approximately 37.5% for the front wheel and 62.5% for the rear wheel.

TSW = Weight of bike with all fluids + weight of rider + weight of passenger =220Kg + 90Kg + 90Kg =400 Kg

This leaves us with the following load ratings:

For Front wheel = 400Kg x 37.5% = 150Kg

For Rear wheels = 400Kg x 62.5% = 250Kg

Q: How do I set up my bike for fast road riding with BST wheels – tire pressure and suspension settings?

A: For road use, use the same tire pressure that you usually use. For suspension – if the suspension is working OK for you before you put on the BST wheels, you should not have to make adjustments. The carbon wheels make a huge difference to the smaller bikes so there are some things you need to know. If you get chatter on fast corners once you change to the carbon wheels that was not there with metal wheels, you should be able to tune it out with suspension settings, or you could add weight to the swing-arm. The reason is simple: the total weight working on the shock is a lot less and hence you are not working within the range of the rear shock. The shock works at about 5 – 10 hertz and the wheel at +- 30 hertz so the natural frequency can chase the chatter on the smaller bikes. By putting weight on the swingarm you have the same weight working on the rear shock while gaining the advantage of the much lighter rear wheel.

We have about ten 125 Hondas that run the wheels here in SA and they also tend to run lower tire pressures cold as the carbon does not transfer heat very well and they can get a bigger contact patch with lower pressure.

Q: What torque should I use when fitting the brake disc to BST wheels?

A: Use the torque as specified for the OEM wheels. As a rule this means:

M6 bolts � 10Nm

M8 bolts � 16Nm

Make sure the bolts are free of grease or oil, and fasten them with Locktite.

Q: What torque should I use when fitting the BST rear wheel to the axle?

A: Use the torque as specified by the OEM, but do not exceed 90 Nm – this is sufficient to hold the spacers and bearings in place without damaging them. The exceptions are the offset rears – - use approx 150 Nm.

Use the locking mechanism as per the manufacturer, if applicable.

Q: What do BST wheels include?

A: The BST wheels are designed to fit the same way the OEM wheels fit. They are supplied with:

� All internal bearings, spacers and seals pre-installed

� External spacers, where required

� Air valves

� Cush drive (rear conventional swing arm)

� Sprocket carrier (rear conventional swing arm) where required � wheels can be purchased without a sprocket carrier if you wish (for race teams etc.)

� You will need to buy a sprocket that fits the BST sprocket carrier

Q: What are the physical properties of Prepreg Carbon fiber that make it particularly suitable for wheels?

A: Some of the properties of Carbon fiber composites as used in BST wheels:

� Material used – Carbon fiber Prepreg in a woven and unidirectional format, embedded in a resin matrix, made from toughened epoxy.

� Max structural temperature: 100 degrees C

� Min structural temperature: -40 degrees C

� Max operating temperature: 80 degrees C

� Corrosion resistance: Totally corrosion free

� Chemical resistance: Resistant to most dilutants such as acetone, benzene, thinners,

� Automotive fluid resistance: Limited resistance to brake fluids and acids

� Density: Approximately 1.7 kg/qdm (Aluminium 2.7, Titanium 4.5, Steel 7.9)

� Damage Tolerance: Similar to 2024 Aluminium

� Strength: Better than 2024 Aluminium

� Stiffness: Similar to 2024 Aluminium

Variable wall thicknesses can be created anywhere as needed in order to increase strength where required.

Fibers are oriented in the direction of stress in order to increase strength.

BST has a patented process for the manufacture of a monocoque (single unit) hollow spoke wheel.

Q: What is the difference between wet lay-up and the Prepreg construction, as used in BST wheels?

A: In the wet lay-up process, the fibers are positioned in the mould dry and the resin is applied with a brush. The resin is mixed by hand and mistakes can be made during mixing. This is a relatively inexpensive process, but normally the part is heavier and the fibers can distort during the lamination process meaning the process is less controlled. This method does not lend itself to the Autoclave process which cures the part under controlled heat and pressure.

In the Prepreg process used to manufacture BST wheels, the resin is applied by machine onto the fibers in a thin film. Therefore, the resin is very even and controlled. The parts are then cured under a high pressure and temperature environment (Autoclave). This results in a well-compacted laminate with better properties than with wet lay-up. Laminate properties in Prepreg Carbon fiber can be 10%- 20% better than wet lay-up at a lower weight (because less resin is used to do the same job). This Prepreg and Autoclave process is used to manufacture the exceedingly strong, but light, chassis centres (often known as �tubs�) for Formula 1 race cars.

Q: What performance gains can I expect on my bike by changing to BST wheels?

A: You’ll gain in many ways � this is the best performance enhancing product you can buy. BSTs will make a dramatic difference that will gain you speed and responsiveness with less effort and fatigue. It’ll feel like you’ve added a few horses to your engine � but at a very reasonable price. Best BANG per $$ for performance �

Extra performance: Low mass and lowest Moment of Inertia (see our page on The Effects of Inertia) results in a lower unsprung mass; this means faster cornering, later braking, improved acceleration � in all, faster lap times. Imagine the difference you’ll experience from dropping 11.2 lbs off the weight of your bike! That’s the difference in weight between the standard GSXR1000 wheels and the BSTs.

Extra Riding Fun and Rider Safety: The huge drop in weight means that handling improves dramatically � quicker lap times with less effort and astonishing responsiveness means less fatigue.

Extra Safety:

� Carbon fibre is a fatigue free material resulting in longer product life;

� Carbon fiber composite is a very damage tolerant material. In the event that a wheel is damaged, the damage propagates less easily;

� Very low corrosion susceptibility.

Extra Cool Looks:

Whether you are into performance or looks, this wheel attracts attention � gleaming, black, woven-look finish and �soft� styling makes a stunning addition to your motorcycle.

The views of UK SuperBike magazine:

“what else can you do to a bike – for that money – to make it so much faster?”

UK sports bike magazine, SuperBike, performed an independent two day test at the Almeria circuit in Spain using a 2002 Honda CBR900RR (954) FireBlade.

�The first day’s testing took place with standard wheels and the only change for the second day was the substitution of BST wheels.

Weather conditions were unchanged and the following was observed:

� Acceleration was noticeably stronger with the rider reporting �it felt as though it had gained ten horsepower �

� The bike could be braked later

� The bike could be turned more easily

� Top speed at the end of the main straight was increased by 5mph

� Lap times fell by a full 3 seconds � although the rider did report �pulling the pin out� as he felt very confident on the bike during the second day

These results are consistent with performance gains normally found by virtue of the combination of reduced unsprung weight and reduced rotational inertia provided by BST wheels. Even if a bike is not being used on a circuit, the same benefits of increased performance and rideability also apply to road/street use.”

If you would like more information, email the rider, Jamie Wilkins, SuperBike magazine’s Road Test Editor, on: [email protected]

Q: How does Carbon fiber compare with Magnesium and Aluminium alloys?

A: Wheels manufactured from metal are either cast, forged, machined, or manufactured as a combination of the three processes. Aluminium wheels have been around for many years. They are relatively easy to manufacture and also relatively cheap, but they are heavy because of the density to strength ratio of Aluminium (how much strength you can get for a kilogram of Aluminium). To improve the weight you can either choose a material that is lighter or one that is stronger, or one that is lighter and stronger. Using magnesium, which is lighter but not necessarily stronger, you can improve on weight slightly.

The problem with magnesium is two fold: first – its fatigue properties are poor and so are the corrosion properties, so a wheel may not last very long even if perfectly cast and machined. The second problem is worse – very often micro-porosity occurs during the casting process, which has a negative impact on both fatigue life and corrosion. So magnesium wheels can be nice and light but may not last very long, sometimes less than a racing season. This makes magnesium wheels good for racing but unattractive to the man in the street. The only solution is to find a material that is lighter, stronger, fatigue free and corrosion free – Carbon fiber. As an engineering material, carbon fiber is far superior to Magnesium or Aluminium alloys.

Q: Do BST wheels have TUV certification?

A: We achieved TUV certification for the facility and for the wheels � GSXR1000 front and rears, Ducati 916-998 series and 748 front and rears. TUV requires certification per model. BST wheels passed every test. However TUV are currently writing new specifications for carbon wheels and all manufacturers will have to have their carbon wheels tested to the new specifications when this process has been completed.

Q: How much safer are BST Carbon Fiber wheels than standard wheels?

A: Carbon fiber wheels have been around for some considerable time and have been proven to be safe when designed and manufactured properly and, as with any wheel, used within their design parameters. One of the parameters is the maximum static weight of the motorcycle for which the wheel is designed (BST sportbike wheels are designed for motorcycles that weigh up to 280 kg dry) and have more than adequate strength and damage tolerance for any usage within road/street, sport or race environment. Safety is dependant on more than just strength and stiffness. Due to improved handling and therefore lower driver fatigue and effort, BSTs make a positive contribution towards driver safety.

Last edited:

Xenoilphobe

Well-Known Member

I don't think there's much doubt that these folks apparently have the hardware for the work but that fact that none of us have seen any evidence of a real, production carbon fiber wheel should give us pause about the delivery timetable. They certainly talk a good game on the web site and social media, but talk is cheap.

Just like Tesla, their delivery time line is a SWAG.

Right now I'm thinking best case is major delays in production and delivery; worst case is that production delays force many buyers to request refunds and the whole thing unravels financially. But I hope very much that I'm wrong.

I hope you are wrong too, these guys are definitely a start up, but they have market demand and that is key to investment interests.

The fact that the ordering page on the web site required a 50% deposit but that when we ordered they charged our credit cards the full amount suggests to me that the company is cash poor. Therein may lie the problem.

They didn't do that to me - not sure what was going on there...

I keep asking myself one question: who would sell such an expensive product without having ever manufactured one? Maybe there's a prototype somewhere, but all of the stuff we see on their web site are digital creations.

Yeah everything I have seen is digital and I have never seen a prototype. But I am also not in a rush to get these... I'm not racing anyone nor do I need bragging rights for any car shows or anything.

Xenoilphobe

Well-Known Member

It might be worth asking for a factory tour - want to drive down there if we can get one setup?

Wow, that is nuts. Would a P90DL get a 10.8 quarter on Carbons?Came across this Car & Driver test of the effects of carbon fiber wheels versus aluminum on performance. The test compared the carbon fiber wheels on the new Shelby Mustang to aluminum wheels. If this is accurate those of us getting the ESE carbon fiber wheels may experience some real performance gains. I hope so.

Here's the summary table published in the article.

Xenoilphobe

Well-Known Member

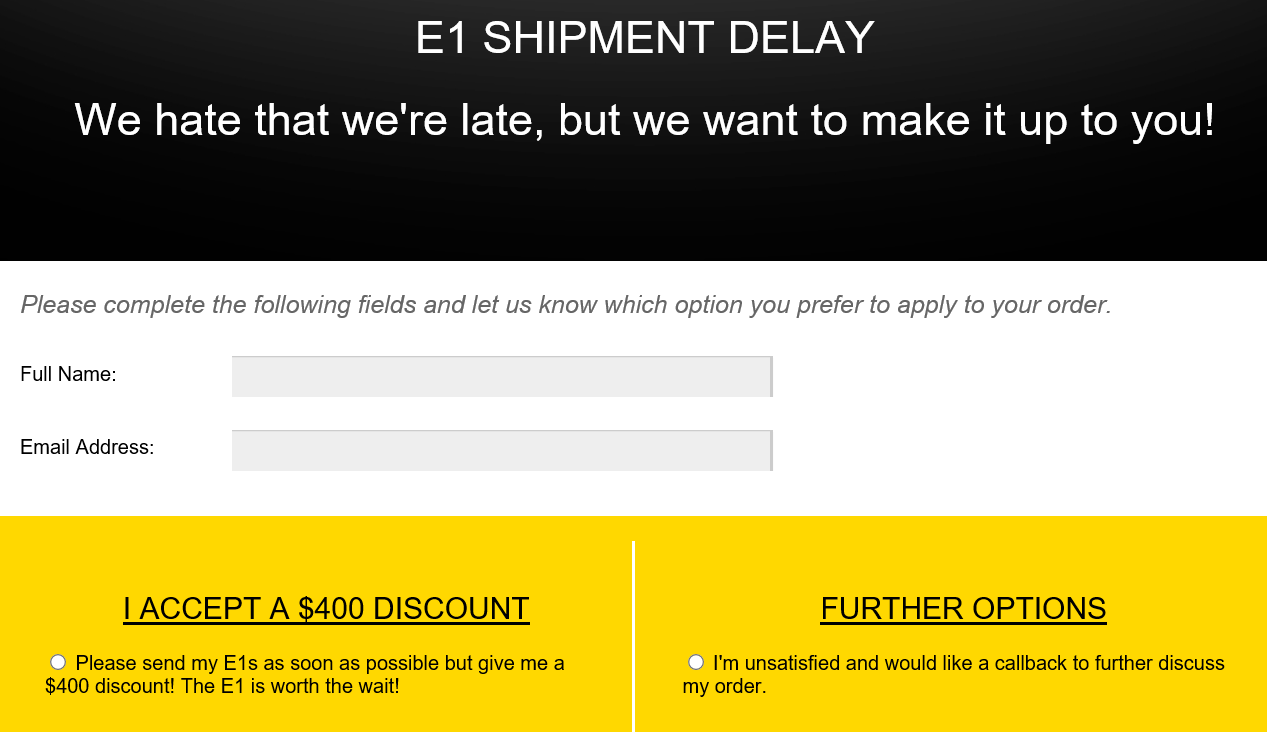

Just got this via email from Adriana Sirven in Marketing a couple of minutes ago

To Our Valued Customers:

Do not fret, we have not forgotten you! We have heard your concerns regarding delays and want to be honest and upfront with our loyal customers.

We have recently brought in-house, advanced CNC machining capabilities that will ultimately allow for faster and improved manufacturing of your custom wheels. It is a great investment for our customers and our growing company! Unfortunately, there were unforeseen technical difficulties in the initial setup of this machine that caused delays in the making of your wheels. At this time, we estimate delays of up to 60 days on our March and April orders, but all orders will be honored. Our factory is back in full force, with employees working around the clock and through weekends to get back up to speed. We assure you that your E1s are on the way and that you will soon be driving with the highest quality, most advanced carbon fiber wheels on the market!

We strive for our customers’ complete satisfaction, and we have no doubt that you will be extremely pleased with your set of E1s! Please be patient and your order will soon be ready, at which time you will receive an email containing tracking information. Please click below for more information.

Let Us Make It Up To You...

To Our Valued Customers:

Do not fret, we have not forgotten you! We have heard your concerns regarding delays and want to be honest and upfront with our loyal customers.

We have recently brought in-house, advanced CNC machining capabilities that will ultimately allow for faster and improved manufacturing of your custom wheels. It is a great investment for our customers and our growing company! Unfortunately, there were unforeseen technical difficulties in the initial setup of this machine that caused delays in the making of your wheels. At this time, we estimate delays of up to 60 days on our March and April orders, but all orders will be honored. Our factory is back in full force, with employees working around the clock and through weekends to get back up to speed. We assure you that your E1s are on the way and that you will soon be driving with the highest quality, most advanced carbon fiber wheels on the market!

We strive for our customers’ complete satisfaction, and we have no doubt that you will be extremely pleased with your set of E1s! Please be patient and your order will soon be ready, at which time you will receive an email containing tracking information. Please click below for more information.

Let Us Make It Up To You...

Last edited:

artsci

Sponsor

Just got this via email from Adriana Sirven in Marketing a couple of minutes ago

To Our Valued Customers:

Do not fret, we have not forgotten you! We have heard your concerns regarding delays and want to be honest and upfront with our loyal customers.

We have recently brought in-house, advanced CNC machining capabilities that will ultimately allow for faster and improved manufacturing of your custom wheels. It is a great investment for our customers and our growing company! Unfortunately, there were unforeseen technical difficulties in the initial setup of this machine that caused delays in the making of your wheels. At this time, we estimate delays of up to 60 days on our March and April orders, but all orders will be honored. Our factory is back in full force, with employees working around the clock and through weekends to get back up to speed. We assure you that your E1s are on the way and that you will soon be driving with the highest quality, most advanced carbon fiber wheels on the market!

We strive for our customers’ complete satisfaction, and we have no doubt that you will be extremely pleased with your set of E1s! Please be patient and your order will soon be ready, at which time you will receive an email containing tracking information. Please click below for more information.

Let Us Make It Up To You...

Looks like our concerns were known and have been addressed.

Xenoilphobe

Well-Known Member

I'm impressed. ARTSCI and LOLCHAMPCAR your perceptions were spot on. I am glad to see them backing up their sales team - good job marketing - now its all on production/engineering to figure out this new CNC Machine integrated.

I can wait for good quality - I did the same thing when I bought the Tesla - ordered in Jan 2013, cancelled because I heard enhancements were coming, and when I reordered for a Dec 2013 delivery they had added Red Calibers, parking sensors and various other bits and it was worth the wait... I feel the same way about these wheels... take your time and do it right...

I would give them the $400 discount back for RFID tracking in each wheel.

I can wait for good quality - I did the same thing when I bought the Tesla - ordered in Jan 2013, cancelled because I heard enhancements were coming, and when I reordered for a Dec 2013 delivery they had added Red Calibers, parking sensors and various other bits and it was worth the wait... I feel the same way about these wheels... take your time and do it right...

I would give them the $400 discount back for RFID tracking in each wheel.

Last edited:

FlatSix911

Porsche 918 Hybrid

Well done ...

Just got this via email from Adriana Sirven in Marketing a couple of minutes ago

To Our Valued Customers:

Do not fret, we have not forgotten you! We have heard your concerns regarding delays and want to be honest and upfront with our loyal customers.

We have recently brought in-house, advanced CNC machining capabilities that will ultimately allow for faster and improved manufacturing of your custom wheels. It is a great investment for our customers and our growing company! Unfortunately, there were unforeseen technical difficulties in the initial setup of this machine that caused delays in the making of your wheels. At this time, we estimate delays of up to 60 days on our March and April orders, but all orders will be honored. Our factory is back in full force, with employees working around the clock and through weekends to get back up to speed. We assure you that your E1s are on the way and that you will soon be driving with the highest quality, most advanced carbon fiber wheels on the market!

We strive for our customers’ complete satisfaction, and we have no doubt that you will be extremely pleased with your set of E1s! Please be patient and your order will soon be ready, at which time you will receive an email containing tracking information. Please click below for more information.

Let Us Make It Up To You...

Looks like our concerns were known and have been addressed.

artsci

Sponsor

Looks like they saw our posts and acted on our concerns. I do recall sending Victor a link to this thread and urging him to follow it so he could know what his customers were thinking.

How about that factory tour Xenoilphobe? I'm still very interested.

How about that factory tour Xenoilphobe? I'm still very interested.

Xenoilphobe

Well-Known Member

I haven't tried to set it up, let me talk the them and see what we can do... weekend trip works for me..

artsci

Sponsor

I haven't tried to set it up, let me talk the them and see what we can do... weekend trip works for me..

Weekend best for me as well.

Similar threads

- Replies

- 2

- Views

- 387

- Replies

- 7

- Views

- 4K

- Replies

- 2

- Views

- 872

- Replies

- 0

- Views

- 801