Do they each hold paper tight enough to tear it when closed?Happy for you, but my rigid stops didn't do anything.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ear pain/Pressure help

- Thread starter justobuf

- Start date

-

- Tags

- sound proofing

Yep - we discussed it back in February. Had to go back and look to remind my self.Do they each hold paper tight enough to tear it when closed?

Easy and effective low frequency fix

I admit that I am more sensitive to annoying noise and ear pressure in the car, but MY is far from a good built car. I have driven Lexus vehicles for 15 years and never had to put sound deadening pads because the manufacturer already had it there. On the other hand, Honda vehicles seemed like...

Easy and effective low frequency fix

Two theories. 1. Your boom is not coming from the hatch. My vehicle was missing standard insulation. Adding it helped a lot, more than anything I've done to the hatch so far. But I still get plenty of boom on textured pavement. I will be trying the tube insertion and rigid hatch stops over the...

Someone tell me what I am doing wrong, because I see no improvement in the booming. Rubber is screwed all the way in, OE plastic nut it tightened against the metal, pvc cap is sanded until the hatch closes. I did the paper test and there is a rigid connection. Boomy as ever.

View attachment 771771

View attachment 771772

I did the paper test on both, so there is no space. Not sure what you mean by "preloaded", but I'll try the felt.

I tried this first - 2 different sizes of tubing. Responded in the Ear Pain thread. It's definitely firm. There is increased gap and the hatch "pops" upon opening.

I tried this and didn't see any improvement. I made sure the rubber post was screwed all the way in and the plastic nuts were tight against the metal. Added the felt pads. I was surprised the hatch closed with the pads. There was a huge panel gap. There was also a loud pop when opening the hatch. Made me want to take them off right away.

Now that I look at the pic, I wonder if there is a gap between the pvc and the nut. LOL. Well I am working on butyl and foam today. Maybe when that's all done I'll try and remake these.

View attachment 774402

P.S. I admit I didn't go back and try to make them again.

Sorry to hear you are still fighting this issue. I know how frustrating it is.Yep - we discussed it back in February. Had to go back and look to remind my self.

Easy and effective low frequency fix

I admit that I am more sensitive to annoying noise and ear pressure in the car, but MY is far from a good built car. I have driven Lexus vehicles for 15 years and never had to put sound deadening pads because the manufacturer already had it there. On the other hand, Honda vehicles seemed like...teslamotorsclub.com

Easy and effective low frequency fix

Two theories. 1. Your boom is not coming from the hatch. My vehicle was missing standard insulation. Adding it helped a lot, more than anything I've done to the hatch so far. But I still get plenty of boom on textured pavement. I will be trying the tube insertion and rigid hatch stops over the...teslamotorsclub.com

I suggest using the spectroid app (or iPhone equivalent) to identify the problem resonance frequency when driving. Then have someone sit in the car with the app running when you gently use your fists to thump different areas. When your thump lines up with the problem frequency, focus there. That's how I found out that the top hatch stop elasticity was my issue. The top resonated at 41 Hz and the back was closer to 50.

Thanks for the tip!Sorry to hear you are still fighting this issue. I know how frustrating it is.

I suggest using the spectroid app (or iPhone equivalent) to identify the problem resonance frequency when driving. Then have someone sit in the car with the app running when you gently use your fists to thump different areas. When your thump lines up with the problem frequency, focus there. That's how I found out that the top hatch stop elasticity was my issue. The top resonated at 41 Hz and the back was closer to 50.

MickY

Member

I'm happy to report that my booming issue seems to be eradicated by the

The drive before/after foam application is noticeably better.

It appears this was the root of the problem. Ladies and gentlemen.

Thank you Ilovecoffee for your insights and video. You're all the way in Canada, otherwise I'd invite you a coffee..lol

I'm back to fully enjoying the Tesla. Best car ever.

I'm happy to report that my booming issue seems to be eradicated by using foam above the wheel wells as described by Ilovecoffee. I applied foam but only straight above the wheel wells where, at least on the left wheel well, there's a huge cavity that appears to act as a drum. Just tap your finger on the outside of that area and you can totally 'play the drums' there. My goodness, so loud and booming. I also applied a smaller amount of foam on the other wheel well area as there's much less room there.If I climb to the trunk, close all doors, lay on the trunk, face up, head by hatch, and tap the plastic walls of the trunk with my fist (hatch and trunk walls), I feel ear booming and discomfort fairly strongly.

Can someone please confirm this can be replicated on your cars?

If the trunk booms like that, even when the car is stationary, wouldn't the issue be related to some or all internal surfaces such as glass and not-carpeted plastics acting like a drum?

Would then filling all cavities behind all plastic parts (wheel wells, etc) with some type of foam eradicate the issue completely?

This issue prevents me from enjoying the Tesla. I know we will eventually get to the bottom of this. With out without Tesla's help. I know Tesla monitors this forum.

I'm not giving up on my Tesla Y. Best car ever (except for this issue).

Stay tuned.

The drive before/after foam application is noticeably better.

It appears this was the root of the problem. Ladies and gentlemen.

Thank you Ilovecoffee for your insights and video. You're all the way in Canada, otherwise I'd invite you a coffee..lol

I'm back to fully enjoying the Tesla. Best car ever.

That sounds awesome. I’m definitely going to give it a try. Did you take any pictures of your installation? Also, how many layers of sound proofing did you use?I'm happy to report that my booming issue seems to be eradicated by the

I'm happy to report that my booming issue seems to be eradicated by using foam above the wheel wells as described by Ilovecoffee. I applied foam but only straight above the wheel wells where, at least on the left wheel well, there's a huge cavity that appears to act as a drum. Just tap your finger on the outside of that area and you can totally 'play the drums' there. My goodness, so loud and booming. I also applied a smaller amount of foam on the other wheel well area as there's much less room there.

The drive before/after foam application is noticeably better.

It appears this was the root of the problem. Ladies and gentlemen.

Thank you Ilovecoffee for your insights and video. You're all the way in Canada, otherwise I'd invite you a coffee..lol

I'm back to fully enjoying the Tesla. Best car ever.

Yes, please post pics so we can see the type of foam and location. Thanks.I'm happy to report that my booming issue seems to be eradicated by the

I'm happy to report that my booming issue seems to be eradicated by using foam above the wheel wells as described by Ilovecoffee. I applied foam but only straight above the wheel wells where, at least on the left wheel well, there's a huge cavity that appears to act as a drum. Just tap your finger on the outside of that area and you can totally 'play the drums' there. My goodness, so loud and booming. I also applied a smaller amount of foam on the other wheel well area as there's much less room there.

The drive before/after foam application is noticeably better.

It appears this was the root of the problem. Ladies and gentlemen.

Thank you Ilovecoffee for your insights and video. You're all the way in Canada, otherwise I'd invite you a coffee..lol

I'm back to fully enjoying the Tesla. Best car ever.

dasmittyman

I am grout

where did you buy your foam and how much of it would you recommend buying?I'm happy to report that my booming issue seems to be eradicated by the

I'm happy to report that my booming issue seems to be eradicated by using foam above the wheel wells as described by Ilovecoffee. I applied foam but only straight above the wheel wells where, at least on the left wheel well, there's a huge cavity that appears to act as a drum. Just tap your finger on the outside of that area and you can totally 'play the drums' there. My goodness, so loud and booming. I also applied a smaller amount of foam on the other wheel well area as there's much less room there.

The drive before/after foam application is noticeably better.

It appears this was the root of the problem. Ladies and gentlemen.

Thank you Ilovecoffee for your insights and video. You're all the way in Canada, otherwise I'd invite you a coffee..lol

I'm back to fully enjoying the Tesla. Best car ever.

MickY

Member

I used pieces of shipping compressed foam I had laying around. Check out Munro’s tear down of MY which Ilovecoffee posted. This shows the precise location above the wheel well and even shows a loose foam cube Tesla used in that very area. Munro’s video shows the right wheel well and Ilovecoffee‘s video shows in the left wheel well.where did you buy your foam and how much of it would you recommend buying?

For reference, When I accessed the wheel wells, I was somewhat surprised to see how much factory foam there already is both against the car and on the plastic trims. But that area right above the wheel well had no foam.

Good luck to you guys.

You mean like this? Did nothing for my boominess. I did butyl first, then foam:I used pieces of shipping compressed foam I had laying around. Check out Munro’s tear down of MY which Ilovecoffee posted. This shows the precise location above the wheel well and even shows a loose foam cube Tesla used in that very area. Munro’s video shows the right wheel well and Ilovecoffee‘s video shows in the left wheel well.

For reference, When I accessed the wheel wells, I was somewhat surprised to see how much factory foam there already is both against the car and on the plastic trims. But that area right above the wheel well had no foam.

Good luck to you guys.

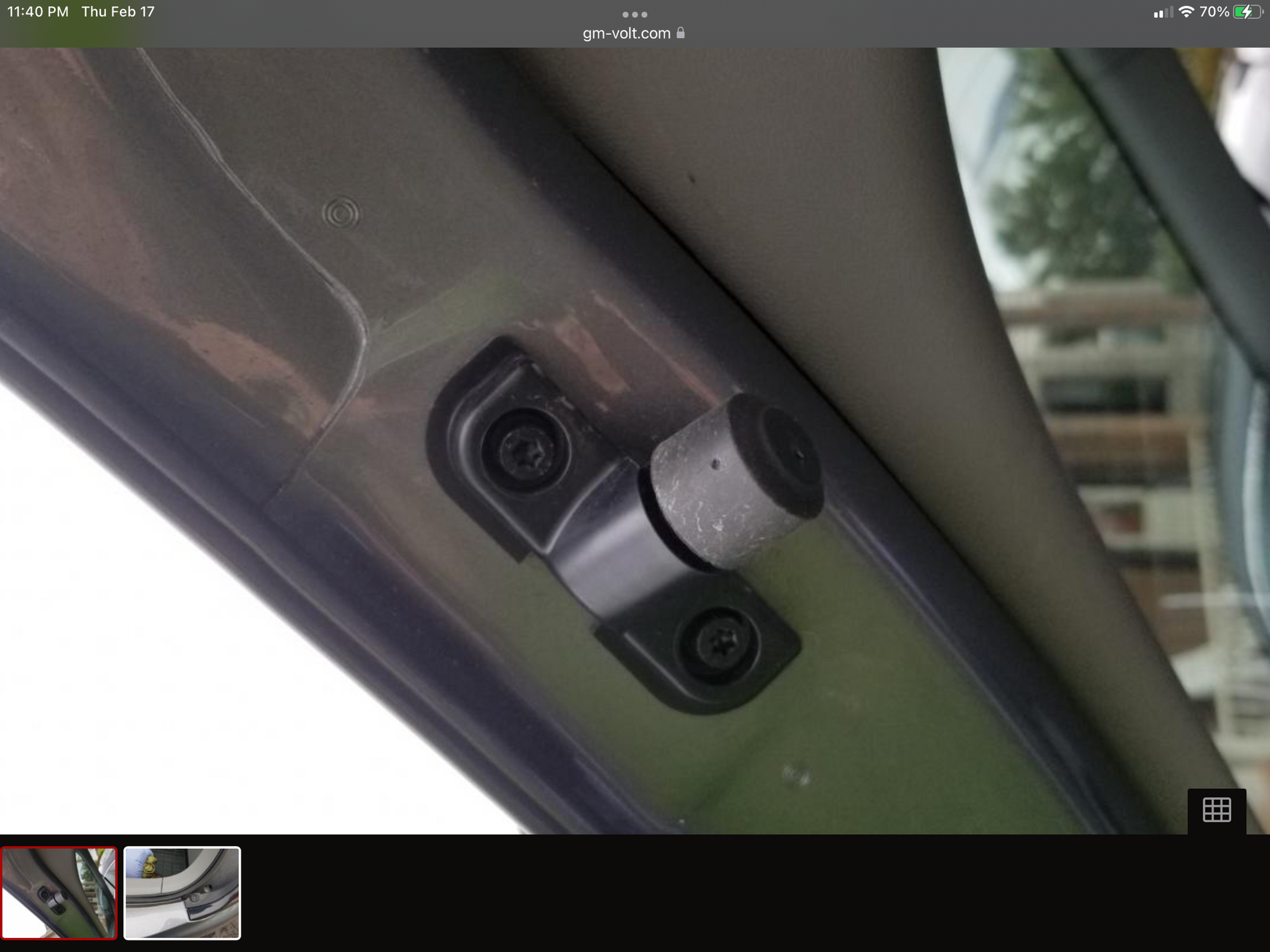

I suspect your rigid stops are too short. They should hit fairly hard without the pad. Try 1/4" longer. If the hatch won't close, sand 1/16" off and try again. They should hit firmly when the hatch closes. If there is any play, they won't work.lol... and for good measure - here's my rigid hatch stops that did nothing - with and without padding

View attachment 851295

View attachment 851296

The hatch is effectively a huge speaker cone. It doesn't have to move much to be loud.

I was concerned about stressing the mechanism that pulls the hatch closed without play in the stops. It does thump when it closes and I suspect the electric catch pull mechanism is flexing the steel in the hatch a bit. For me, this hasn't caused any issue.

The good news is you can experiment with this for only a few bucks.

Last edited:

So I had my trunk hatch seal replaced because I ripped it with a too large tube. The replacement part was different and the Tesla technician also noted that. It has some extra bits of rubber on the bottom that sit on the inside. There is no foam/tubing inserted as some have seen it before, but almost as if there is a thicker rim that interfaces with the body at some points. I asked why there is a difference and the tech didn't know. Maybe this has something to do with this.

Chaucerino

Member

Just added the tubing and it has made a significant difference. Going to try the butyl and foam next.

Thanks guys!

Already a world of difference.

Thanks guys!

Already a world of difference.

Interesting. Does it help? How much did it cost you? I tore mine up as well.So I had my trunk hatch seal replaced because I ripped it with a too large tube. The replacement part was different and the Tesla technician also noted that. It has some extra bits of rubber on the bottom that sit on the inside. There is no foam/tubing inserted as some have seen it before, but almost as if there is a thicker rim that interfaces with the body at some points. I asked why there is a difference and the tech didn't know. Maybe this has something to do with this.

I still don't know if the new seal was improving the issue, but one thing I noticed is that the trunk has a significantly harder time to close with the tube inserted into it.

With the old seal, it took only a few hard closes to make the trunk close reliably. With the new seal and tube it still doesn't close without extra help after a day and maybe 30+ hard closes. So the new seal is probably thicker. I might have to remove the tube altogether.

For context, the new seal is different than the one in my late July built MiC Model Y and I had it installed because I ripped the old seal.

With the old seal, it took only a few hard closes to make the trunk close reliably. With the new seal and tube it still doesn't close without extra help after a day and maybe 30+ hard closes. So the new seal is probably thicker. I might have to remove the tube altogether.

For context, the new seal is different than the one in my late July built MiC Model Y and I had it installed because I ripped the old seal.

ilovecoffee

Member

I still don't know if the new seal was improving the issue, but one thing I noticed is that the trunk has a significantly harder time to close with the tube inserted into it.

With the old seal, it took only a few hard closes to make the trunk close reliably. With the new seal and tube it still doesn't close without extra help after a day and maybe 30+ hard closes. So the new seal is probably thicker. I might have to remove the tube altogether.

For context, the new seal is different than the one in my late July built MiC Model Y and I had it installed because I ripped the old seal.

You mentioned the previous time the tubing was too big which is what led you to rip it somehow

Was it the same tubing you used this time? I think you should go smaller if you still want to attempt it. 5/16" OD is just under 8mm. So you should stay under that. The Tesla version of the tubing if I had to guess after seeing it, was probably 6 to 7mm.

If you ripped it because of sharp edges of the tube while pushing it through you should make sure it's covered in electrical tape, and push it in parallel with the gasket so as to not widen the air hole more than you need to. That's my advice

Similar threads

- Replies

- 0

- Views

- 188

- Replies

- 3

- Views

- 4K

- Replies

- 2

- Views

- 1K