Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

There is a company in Morro Bay called Goofy Graphics that will produce a sticky graphic of your plate that does not require drilling. Not sure about legality. I have one but have not installed it yet.

dsmith2189

Active Member

I love the upside down mount. Do you have any pics you could post of the completed job with the nosecone in place from the front and from the side? Thanks!

Ddruz, I took what brainman did with teh Zip-ties and what Tommy did

with the Toilet flange bolts

Experimenting with mounting ideas, I took the common toilet to flange bolt and filed it down to just fit between the honeycomb openings. I used the larger diameter 5/16" bolt as I found the bolt itself just cleared the opening and made for a nice snug fit with no up/down slop.

I secured the bolt to the honeycomb structure by rotating the bolt 90 degrees which allowed the "ears" on the bolt to overlap the plastic; it seems very secure just finger tight, though I would use a locking nut to keep the bolt from rotating. Believe it or not, the bolts hit the lower corners of the mounting frame nearly perfect. The honeycomb openings are staggered so with a bit of trial and error (2 attempts) I found the right slot openings to mount the bolts to the plate holder.

The length of the bolt is 2 1/4" which is about a 1/4" short of meeting up with the bottom portion of the plastic license plate holder. A longer bolt would permit a sleeve to be placed over the bolt that would backstop the license place holder and allow for a threaded flat nut to secure the front. Lots of different ways to capture and secure the frame to this setup. Leaving it to the group's collective ideas to come up with a "best".

This is on the GP nose cone and probably would work best for those wanting a "permanent" mount that doesn't drill into the nose cone.

Bolts mounted on the honeycomb; bottom of plate holder would attach to these bolts.

Purcase parts from Home Depot

View attachment 15781

Parts actually used, use file or Dremel tool to narrow the "wings" on the bolt to fit through honeycomb grill openings.

View attachment 15782

As assembled on Tesla supplied plate bracket

View attachment 15783

Side View mounted on car

View attachment 15784

Front View mounted on Car

View attachment 15785

- - - Updated - - -

Here is another option that I came up with using a Blind Fastener Well nut.

Parts:

Blind Fastener Well nut 1/4"-20 X 1 (From West Marine)

Pan head Mach Screw 1/4"-20 X 3 1/2"

Nylock Nut 1/4"-20

Nut 1/4"-20

Flat Washer 1/4"

Press the Well nut into the Grille

mount the bolt and nuts to the license plate frame.

use the nylock nut behind the license plate frame. Tighten enough that you can still turn the bolt.

use the regular nut as a jam nut againtst the well nut. start all three bolts before tightening down all the way.

Last edited:

badgerlake

Member

I love the upside down mount. Do you have any pics you could post of the completed job with the nosecone in place from the front and from the side? Thanks!

Sorry it took so long to get the pics, but here ya go.

Tommy

Member

No Holes Drilled License Plate Holder Project

It's been mentioned before by other posters of using MAGNETS to attach the license plate holder to the nose of the car. Over the last several weeks I have been working on a way to accomplish this and have a working solution that involves attaching a set of magnets to the license plate holder as well as the inside of the nose cone. Naturally, various "engineering" problems presented themselves as I proceeded with the project, so some Edison trial and error method came into play. I am not that evolved to have used the Tesla (the man) method.

This attachment solution is for those that are ok with the factory look of the license plate holder mounted to the nose cone. It's for those that do not want the nose cone drilled into, however they may occasionally want to take the plate off for displaying at car shows. Also, those that like to drive"naked"with no front plate and want a quick means to attach the license plate such as when traveling or parking in the big city to avoid a "fix it" ticket. If you want the look of a below the nose cone mount this attachment method is not for you.

I need to emphasize an important safety point if you want to proceed with this project: These magnets are very powerful and can pinch your fingers and will literally fly and strike with force if brought near another magnet or ferrous material. Always treat these magnets with proper respect and care; they are not the wimpy magnets found on the refrigerator door. Also, if you know you will NOT be moving the car with the license plate holder attached and will only be attaching the holder to a stationary car, than using magnets on the inside of the nose cone can probably be skipped and only the ferrous metal knockouts need to be attached. These will provide enough pull force to keep the license plate holder's magnets attached on a stationary car, however I would not feel comfortable with this being a secure enough attachment with the car moving. I am working on possibly adding more magnets to the plate holder itself and that may eliminate the need for magnets on the inside of the nose cone altogether.

I used K&J Magnetics KJ Magnetics - Strong Neodymium Magnets, Rare Earth Magnets

to gather information to determine if using magnets to secure the license plate holder to the nose cone was even feasible. They have a great FAQ section and technical charts of most all the magnets they sell that graph the forces these magnets generate; be it attached to metal, to each other or by distance between each other. After mulling over the FAQ, the graphs and the various magnets available, I thought "yep, this just might work" and proceeded to order what I thought would be the necessary magnets to complete the project. It turned out, that some revisions were necessary and I had to reorder a second and third time. I am mostly happy with the results. However I know if I was working for the late Steve Jobs it would be back to the drawing board; it's not "perfect". I am satisfied enough however, that the project is ready for scrutiny and should see the light of the day through TMC eyes. Other than the magnets, I used off the shelf parts that are readily available at a hardware store. Some grinding/filing was needed on the screws and star washers. There may be more suitable parts, so please feel free to tweak and share on improvements.

The first challenge I faced was how to reliably fasten a magnet to plastic. The plastic Tesla uses to form the nose cone is called PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene). It is ID stamped on the inside of the cone; the license plate holder is probably also the same material, however it not being ID stamped, is a guess on my part. The significance of using PC/ABS is it forms well in molds because it is a medium to low surface energy material. What this means is glue/adhesives do not bond well to it. Not good if one is trying to attach a magnet and want a secure bond that can also flex. I tried to glue a magnet to the license plate holder using an epoxy specific for plastic, unfortunately the bond failed when I "pulled" on the magnet with another magnet. I also tried 3M's VHB tape and that also did not bond well to my satisfaction. Although 3M has a plethora of choices regarding adhesives, many are only available for jobbers and not readily available on the retail side. I definitely wanted a retail available adhesive so the project could be duplicated by others. I also realized after my failed attempt to bond the magnet directly to the plastic that permanently bonding the magnet directly to the plastic wasn't such a good idea especially inside the nose cone. An attachment method that permitted the magnet to be easily removed was better and I found a solution for that as well.

So first design criteria is magnet needs to be mechanically fastened to license plate holder as it offers the most secure bond and able to endure the stress of flexing as the holder is attached and removed from the nose cone.

Here are the other design criteria I came up with:

License plate needs to mount flush to the front of license plate holder; no protruding bolts or screw heads.

License plate holder needs to mount flush to nose cone; must look factory installed.

Magnet surface touching nose cone must be smooth, no protruding bolt or screw head to dent nose cone. Turns out the magnets don't appear to touch at all.

Magnets mounted onto nose cone need to be removable.

Magnets mounted onto nose cone need to be protected if struck by mechanic's tools when nose cone is removed.

The constraints of the above criteria meant the magnet's physical dimensions could be no larger than 1/4" x 1" diameter. The 1/4"limitation is the depth of the license plate holder. The 1" diameter was dictated by the available space between the grid ribs of the license plate holder.

Here is my parts list:

4) 1" od x 3/16" thick with countersunk hole for #10 screw magnets KJ Magnetics - Products

(to be attached to license plate holder)

4) 1" od x 1/4"thick magnet KJ Magnetics - Products

(for inside of nose cone)

4) 8-32x1/4" Brad Hole T-Nuts; be sure to get the flat face ones and out of ferrous metal not stainless steel. (Lowes carries in their separate parts drawers hardware section)

4) 8/32x3/8" flat head stainless steel machine screw (ACE local hardware store); will need to be filed down, a 8/32x1/4" would be better as no filing would be needed, but couldn't find at local stores.

4) 1" dia. od x 3/16"id fender washer (used as spacer) Fender washers are thinner than regular washers and have the correct id dia.

4) Star washers for 8/32 screw or other suitable washer (points may need to be filed down)

4) 3/4" electrical knockouts (KO); obtained from single gang electrical box. The KO's actually measure a little over 1" dia.

1) Industrial strength Velcro strip (comes in 4' pair available at Home Depot) GET VELCRO BRAND

4) Soda bottle caps (water bottle caps won't work as they have a raised relief inside cap)

1) Rubbing alcohol ( for cleaning plastic and metal parts before applying velcro or epoxy)

1) 220 grit sandpaper (for ruffing up plastic and metal)

1) Blue painter's tape

1) Loctite plastic epoxy bonder (other adhesives may work as well; I had success and happy how this bonded the metal KO to the velcro; it doesn't adhere very well to PC/ABS plastic thou)

Tools needed:

Drill and 13/64" drill bit; using a 3/16" drill bit you will have to ream a little bit.

Philips screw driver

Small cloth covered putty knife (to assist removing the nose cone)

File and or grinder (to file down screws and possibly star washers)

Scissors (to cut velcro)

Mixing sticks for epoxy

Ice pick or equivalent sharp point for marking where to drill holes in license plate holder

Prepping the license plate holder:

On the back you will notice the license plate holder has a grid work of supporting ribs; we will be using the outer left and right upper most quadrants and the lower left and right quadrants adjacent to the pre-drilled holes. The reason not to use the existing holes is the nose cone has raised areas were these holes are to provide more grip to the fasteners Tesla uses to attach the holder to the nose cone. We need the magnets to be as close as possible to their "mates" to provide the most grip. The upper magnets I placed about 1/8" from the lower and inside interior ribs. The lower holes, the magnet needs to be as close to both the outer circle of the pre-holes and the straight vertical rib centered to the circle. I used an ice pick to mark the hole so my drill bit wouldn't drift.

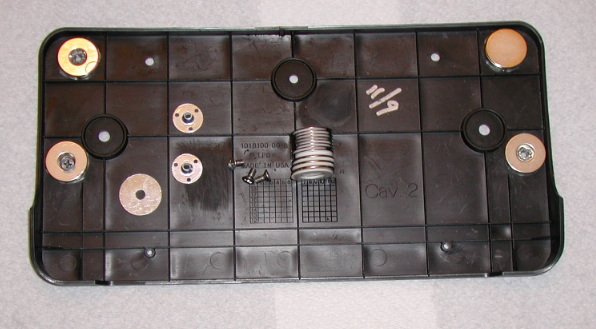

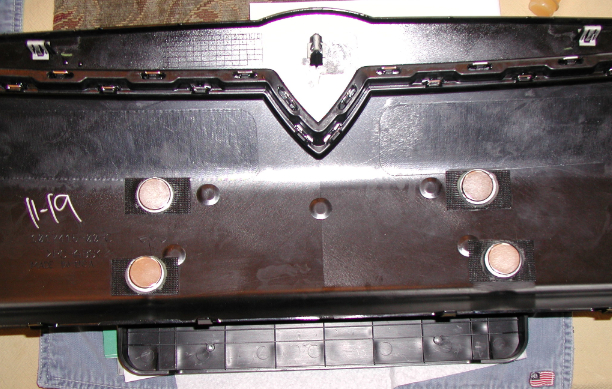

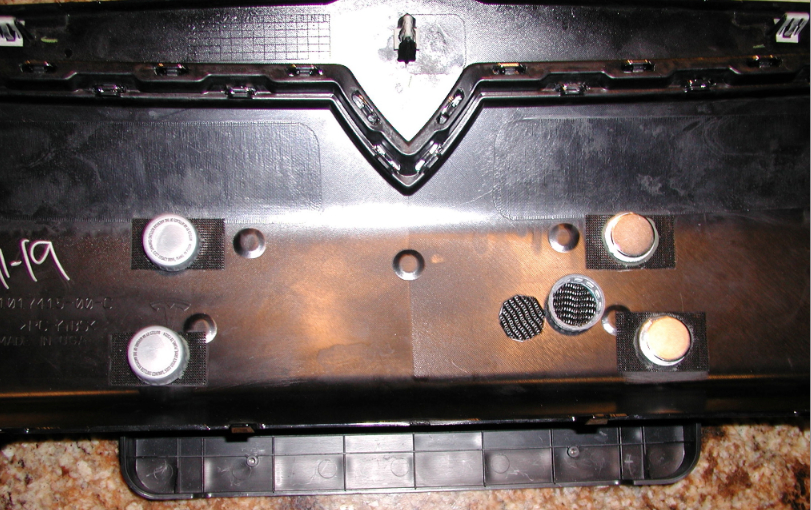

Position of the magnets and the various parts I used; T-nuts, fender washer, flat head screws and star washers. Some extra magnets in stack that were not used.

Drill the holes.

Insert the T-nuts through the holes from the front. The T-nut provides a flat surface so the license plate itself will lay flat against the plate holder. If there is a bump in the plastic after the T-nut is inserted that will need to be sanded flat.

On the back side, place the fender washer over the protruding T-nut shaft; this washer acts as a shim since the magnet thickness is not enough to fully cover the T-nut shaft. Some filing of the T-nut shaft will need to be done if the star washer isn't used as the shaft is just a bit too long.

Carefully place the magnet with countersunk hole over the T-nut shaft. The magnet will want to pull so hold on tight!

I had to use a star washer placed in the countersunk opening to fully tighten between the T-nut and magnet. That particular magnet was the best option because the inner opening diameter fits onto the T-nut's shaft. The points on the star washer will need to be removed to get the flat head screw to be flush with the magnet top. The star washer was used as it easily conforms to the cone shape of the flat head screw. Another way of doing this perhaps is to use an o-ring.

Insert the 8/32 flat headed machine screw and hand tighten. The protruding thread will need to be filed flush with the T-nut.

License plate holder is done and now ready to be the template for mounting the metal knockouts( KO) on the inside of the nose cone.

Completed license plate holder with Velcro, epoxy and electrical Box knockouts removed

Front side of license plate holder

Getting the KO's ready to mount in the nose cone:

As good fortune would have it, I discovered that industrial strength velcro adheres to PC/ABS plastic excellent on another project I did. So I know velcro will adhere to the nose cone inside, and confirmed on a sample that indeed it does. The idea is the velcro bonds to the nose cone; the ferrous metal KO bonds to the velcro via epoxy and the magnet sticks to the nose cone because it is attracted to the ferrous metal KO. The magnet is very powerful and will stay attached to the nose cone and yet can be removed if need be by sliding to one side or the other to remove. I used the hook side of the velcro to bond the KO to the velcro. The tiny hooks act as little attachment points as the epoxy flows around them. I tried 3M's Dual Lock brand version of velcro, too thick and the adhesive didn't bond very well to the plastic; use Velcro branded Industrial Strength Velcro.

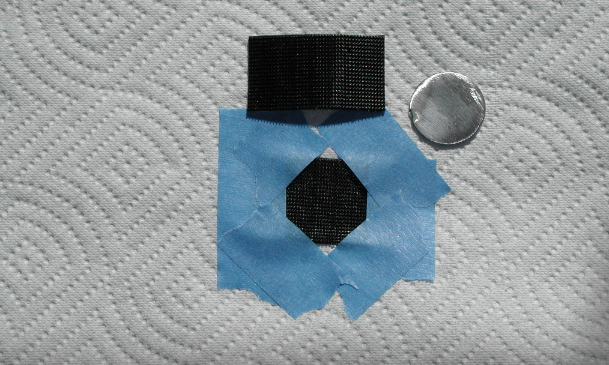

Ready for epoxy; KO sanded and wiped with rubbing alcohol

Epoxy applied to both surfaces to get epoxy in between velcro hooks

I used one of the magnets to act as a clamp on my 4 epoxied pieces each stacked atop one another, a weight would work as well.

Tip on getting the most accurate placement of KO assembly inside the nose cone:

The velcro is 2" in width which will be the "length" of each piece. Cut 4 pieces, cut them all identical in size and when gluing the KO to the velcro, glue so each piece is a "clone" of the other. You will be placing the magnet on the nose cone by itself first to get it to line up" to where the magnetic field is best due to the strong attraction to the magnet on the license plate holder. By having all pieces identical, this will facilitate placing the KO/Velcro Assembly in the correct position as you will need to remove the magnet from its temporary placement to adhere the KO/Velcro assembly to the plastic.

To answer why I choose an electrical knockout vs a washer; simply because it is solid whereas the washer has a hole. I don't know magnetic theory well enough (not at all really) to account for the effect of the hole so I went the safe route. The KO is slightly larger in diameter than the magnet which is also a good thing.

Remember to lightly sand with 220 grit and wipe down with rubbing alcohol any metal or plastic getting attached by either epoxy or velcro.

Removing the nose cone:

I started on the passengers side just below the hood line where the straight horizontal chrome trim comes to a point with the oval shaped chrome trim. I used a cloth covered putty knife to gently pry the nose cone away from it's attachment point. There are 5 attachment points across the front and 1 on each lower side (7 total). There are an additional 6 tabs along the bottom which have barbs on them. Once you get the nose cone out enough to grab onto you can use your hands to free it from all of the attachment points. I advise being gentle, however Tesla has removed my nose cone twice and they literally grabbed the corner with their bare hands and pulled the piece right off. Personally, I like the slow hand approach.

Nose cone attachment points; the bottom tab's attachment points are not ID'ed in photo

Using a cloth covered small putty knife to get started removing the nose cone

Attaching the KO/Velcro Assembly:

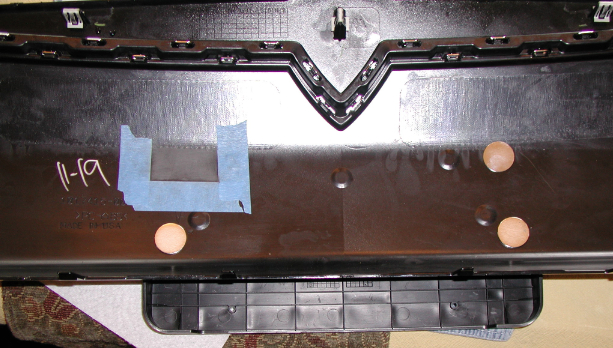

You will need to position the license plate holder with its attached magnets in its normal mounted position: The center hole is centered with the Tesla "T" and the curved bottom portion of the holder is against the bottom of the nose cone. Now use the 4 1" dia.x1/4" magnets to hold the license plate holder in place. The magnets will self align themselves as you move them about their final position. You will work on one corner at a time while the other three magnets hold the license plate holder in place. A couple of different ways you can be sure the KO/Velcro assembly gets put in the exact position it needs to be: One is simply center the KO over the magnet and align the Velcro strip by rotating; another is to take the backing off of the velcro strip and center over the magnet and align. What ever method you use you will need to outline the area the velcro strip covers with blue masking tape. This is so when you remove the magnet for placement of the KO/Velcro Assembly you will be able to get the exact placement right. The other reason is it defines the area that needs to be sanded (220 grit) and cleaned with rubbing alcohol. After the area has been prepped, now attach the KO/Velcro Assembly in place by pressing down firmly to establish the bond. It takes 24 hours to reach full strength, however after a 1/2 hour I had difficulty removing the velcro from the plastic. Next place the magnet onto the attached assembly making sure the North/South orientation is correct. The magnet will be attracted to the KO in either orientation, however it will repeal the license plate holder if not orientated correctly.

First magnet area prepped for KO/Velcro Assembly; other 3 magnets firmly holding the license plate holder in place

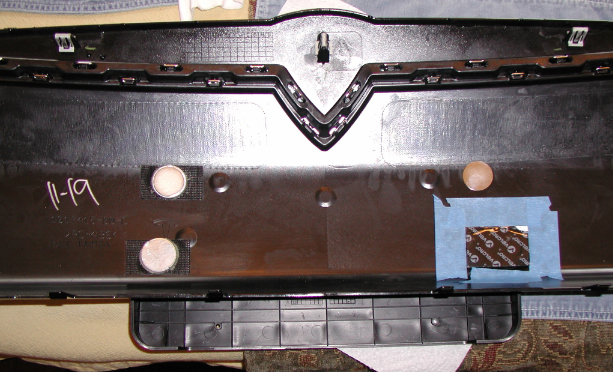

Do the remaining three magnets using the same method

All four magnets attached to the KO/Velcro Assembly

Protective Cap Placement:

After having a few tools getting very cozy with my magnets I realized it would be a good idea to provide a protective cover over the magnets at the least to prevent them being hit hard and breaking. I found soda bottle caps fit just about perfect and cut circles of velcro to fit inside the caps and onto the top of the magnets. The picture depicts 3M's Dual Lock product which does not stick, so Velcro to the rescue again.

Two caps in place; getting ready to install third cap

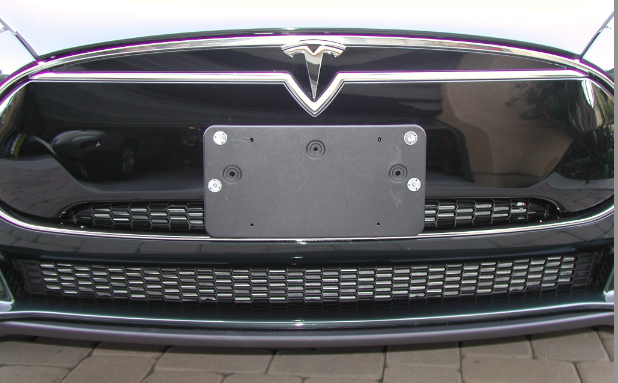

Installed License Plate Holder, it fits flush and the magnets do not seem to even touch the nose cone. I have paint armor, so in the event of marring an easy fix.

Front license plate holder installed and held in place by magnets alone

Installing and removing License Plate Holder:

To install, at an approximate 45 degree angle place the center of the license plate holder centered to the "T" on the nose cone; the top of the license plate holder will be at the ridge line of the nose cone. Swing the bottom portion down into place. The pull force of the magnets will help direct the proper placement. To remove, grab the bottom back side of the license plate holder with your fingers while positioning your thumbs over the two bottom magnet attachment points. Swing the holder up and away as if the upper top of the holder was mounted on a hinge. Be sure to hold on securely when attaching and removing, the magnets are very strong.

Some final thoughts

To wrap up and put a bow on this post: The Tesla supplied screws will work to secure the bottom of your license plate to the holder. However, I think the top screws will need to be changed to shorter machine screws otherwise the supplied screws will be going into the nose cone. I haven't checked for sure but eye balling it, it looks to be the case. Second, K&J Magnetics have a $5 off discount on orders over $35 for February using code FIVE213 Also, the tabs on the bottom nose cone have their own individual slot they fit into. It's real easy to have them slip into the honeycomb opening just below the dedicated slot. So get on your hands and knees to double check everything is back together ok. And finally, I speed checked at speeds up to 75mph over the last few days so anything over that it's YMMV.

It's been mentioned before by other posters of using MAGNETS to attach the license plate holder to the nose of the car. Over the last several weeks I have been working on a way to accomplish this and have a working solution that involves attaching a set of magnets to the license plate holder as well as the inside of the nose cone. Naturally, various "engineering" problems presented themselves as I proceeded with the project, so some Edison trial and error method came into play. I am not that evolved to have used the Tesla (the man) method.

This attachment solution is for those that are ok with the factory look of the license plate holder mounted to the nose cone. It's for those that do not want the nose cone drilled into, however they may occasionally want to take the plate off for displaying at car shows. Also, those that like to drive"naked"with no front plate and want a quick means to attach the license plate such as when traveling or parking in the big city to avoid a "fix it" ticket. If you want the look of a below the nose cone mount this attachment method is not for you.

I need to emphasize an important safety point if you want to proceed with this project: These magnets are very powerful and can pinch your fingers and will literally fly and strike with force if brought near another magnet or ferrous material. Always treat these magnets with proper respect and care; they are not the wimpy magnets found on the refrigerator door. Also, if you know you will NOT be moving the car with the license plate holder attached and will only be attaching the holder to a stationary car, than using magnets on the inside of the nose cone can probably be skipped and only the ferrous metal knockouts need to be attached. These will provide enough pull force to keep the license plate holder's magnets attached on a stationary car, however I would not feel comfortable with this being a secure enough attachment with the car moving. I am working on possibly adding more magnets to the plate holder itself and that may eliminate the need for magnets on the inside of the nose cone altogether.

I used K&J Magnetics KJ Magnetics - Strong Neodymium Magnets, Rare Earth Magnets

to gather information to determine if using magnets to secure the license plate holder to the nose cone was even feasible. They have a great FAQ section and technical charts of most all the magnets they sell that graph the forces these magnets generate; be it attached to metal, to each other or by distance between each other. After mulling over the FAQ, the graphs and the various magnets available, I thought "yep, this just might work" and proceeded to order what I thought would be the necessary magnets to complete the project. It turned out, that some revisions were necessary and I had to reorder a second and third time. I am mostly happy with the results. However I know if I was working for the late Steve Jobs it would be back to the drawing board; it's not "perfect". I am satisfied enough however, that the project is ready for scrutiny and should see the light of the day through TMC eyes. Other than the magnets, I used off the shelf parts that are readily available at a hardware store. Some grinding/filing was needed on the screws and star washers. There may be more suitable parts, so please feel free to tweak and share on improvements.

The first challenge I faced was how to reliably fasten a magnet to plastic. The plastic Tesla uses to form the nose cone is called PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene). It is ID stamped on the inside of the cone; the license plate holder is probably also the same material, however it not being ID stamped, is a guess on my part. The significance of using PC/ABS is it forms well in molds because it is a medium to low surface energy material. What this means is glue/adhesives do not bond well to it. Not good if one is trying to attach a magnet and want a secure bond that can also flex. I tried to glue a magnet to the license plate holder using an epoxy specific for plastic, unfortunately the bond failed when I "pulled" on the magnet with another magnet. I also tried 3M's VHB tape and that also did not bond well to my satisfaction. Although 3M has a plethora of choices regarding adhesives, many are only available for jobbers and not readily available on the retail side. I definitely wanted a retail available adhesive so the project could be duplicated by others. I also realized after my failed attempt to bond the magnet directly to the plastic that permanently bonding the magnet directly to the plastic wasn't such a good idea especially inside the nose cone. An attachment method that permitted the magnet to be easily removed was better and I found a solution for that as well.

So first design criteria is magnet needs to be mechanically fastened to license plate holder as it offers the most secure bond and able to endure the stress of flexing as the holder is attached and removed from the nose cone.

Here are the other design criteria I came up with:

License plate needs to mount flush to the front of license plate holder; no protruding bolts or screw heads.

License plate holder needs to mount flush to nose cone; must look factory installed.

Magnet surface touching nose cone must be smooth, no protruding bolt or screw head to dent nose cone. Turns out the magnets don't appear to touch at all.

Magnets mounted onto nose cone need to be removable.

Magnets mounted onto nose cone need to be protected if struck by mechanic's tools when nose cone is removed.

The constraints of the above criteria meant the magnet's physical dimensions could be no larger than 1/4" x 1" diameter. The 1/4"limitation is the depth of the license plate holder. The 1" diameter was dictated by the available space between the grid ribs of the license plate holder.

Here is my parts list:

4) 1" od x 3/16" thick with countersunk hole for #10 screw magnets KJ Magnetics - Products

(to be attached to license plate holder)

4) 1" od x 1/4"thick magnet KJ Magnetics - Products

(for inside of nose cone)

4) 8-32x1/4" Brad Hole T-Nuts; be sure to get the flat face ones and out of ferrous metal not stainless steel. (Lowes carries in their separate parts drawers hardware section)

4) 8/32x3/8" flat head stainless steel machine screw (ACE local hardware store); will need to be filed down, a 8/32x1/4" would be better as no filing would be needed, but couldn't find at local stores.

4) 1" dia. od x 3/16"id fender washer (used as spacer) Fender washers are thinner than regular washers and have the correct id dia.

4) Star washers for 8/32 screw or other suitable washer (points may need to be filed down)

4) 3/4" electrical knockouts (KO); obtained from single gang electrical box. The KO's actually measure a little over 1" dia.

1) Industrial strength Velcro strip (comes in 4' pair available at Home Depot) GET VELCRO BRAND

4) Soda bottle caps (water bottle caps won't work as they have a raised relief inside cap)

1) Rubbing alcohol ( for cleaning plastic and metal parts before applying velcro or epoxy)

1) 220 grit sandpaper (for ruffing up plastic and metal)

1) Blue painter's tape

1) Loctite plastic epoxy bonder (other adhesives may work as well; I had success and happy how this bonded the metal KO to the velcro; it doesn't adhere very well to PC/ABS plastic thou)

Tools needed:

Drill and 13/64" drill bit; using a 3/16" drill bit you will have to ream a little bit.

Philips screw driver

Small cloth covered putty knife (to assist removing the nose cone)

File and or grinder (to file down screws and possibly star washers)

Scissors (to cut velcro)

Mixing sticks for epoxy

Ice pick or equivalent sharp point for marking where to drill holes in license plate holder

Prepping the license plate holder:

On the back you will notice the license plate holder has a grid work of supporting ribs; we will be using the outer left and right upper most quadrants and the lower left and right quadrants adjacent to the pre-drilled holes. The reason not to use the existing holes is the nose cone has raised areas were these holes are to provide more grip to the fasteners Tesla uses to attach the holder to the nose cone. We need the magnets to be as close as possible to their "mates" to provide the most grip. The upper magnets I placed about 1/8" from the lower and inside interior ribs. The lower holes, the magnet needs to be as close to both the outer circle of the pre-holes and the straight vertical rib centered to the circle. I used an ice pick to mark the hole so my drill bit wouldn't drift.

Position of the magnets and the various parts I used; T-nuts, fender washer, flat head screws and star washers. Some extra magnets in stack that were not used.

Drill the holes.

Insert the T-nuts through the holes from the front. The T-nut provides a flat surface so the license plate itself will lay flat against the plate holder. If there is a bump in the plastic after the T-nut is inserted that will need to be sanded flat.

On the back side, place the fender washer over the protruding T-nut shaft; this washer acts as a shim since the magnet thickness is not enough to fully cover the T-nut shaft. Some filing of the T-nut shaft will need to be done if the star washer isn't used as the shaft is just a bit too long.

Carefully place the magnet with countersunk hole over the T-nut shaft. The magnet will want to pull so hold on tight!

I had to use a star washer placed in the countersunk opening to fully tighten between the T-nut and magnet. That particular magnet was the best option because the inner opening diameter fits onto the T-nut's shaft. The points on the star washer will need to be removed to get the flat head screw to be flush with the magnet top. The star washer was used as it easily conforms to the cone shape of the flat head screw. Another way of doing this perhaps is to use an o-ring.

Insert the 8/32 flat headed machine screw and hand tighten. The protruding thread will need to be filed flush with the T-nut.

License plate holder is done and now ready to be the template for mounting the metal knockouts( KO) on the inside of the nose cone.

Completed license plate holder with Velcro, epoxy and electrical Box knockouts removed

Front side of license plate holder

Getting the KO's ready to mount in the nose cone:

As good fortune would have it, I discovered that industrial strength velcro adheres to PC/ABS plastic excellent on another project I did. So I know velcro will adhere to the nose cone inside, and confirmed on a sample that indeed it does. The idea is the velcro bonds to the nose cone; the ferrous metal KO bonds to the velcro via epoxy and the magnet sticks to the nose cone because it is attracted to the ferrous metal KO. The magnet is very powerful and will stay attached to the nose cone and yet can be removed if need be by sliding to one side or the other to remove. I used the hook side of the velcro to bond the KO to the velcro. The tiny hooks act as little attachment points as the epoxy flows around them. I tried 3M's Dual Lock brand version of velcro, too thick and the adhesive didn't bond very well to the plastic; use Velcro branded Industrial Strength Velcro.

Ready for epoxy; KO sanded and wiped with rubbing alcohol

Epoxy applied to both surfaces to get epoxy in between velcro hooks

I used one of the magnets to act as a clamp on my 4 epoxied pieces each stacked atop one another, a weight would work as well.

Tip on getting the most accurate placement of KO assembly inside the nose cone:

The velcro is 2" in width which will be the "length" of each piece. Cut 4 pieces, cut them all identical in size and when gluing the KO to the velcro, glue so each piece is a "clone" of the other. You will be placing the magnet on the nose cone by itself first to get it to line up" to where the magnetic field is best due to the strong attraction to the magnet on the license plate holder. By having all pieces identical, this will facilitate placing the KO/Velcro Assembly in the correct position as you will need to remove the magnet from its temporary placement to adhere the KO/Velcro assembly to the plastic.

To answer why I choose an electrical knockout vs a washer; simply because it is solid whereas the washer has a hole. I don't know magnetic theory well enough (not at all really) to account for the effect of the hole so I went the safe route. The KO is slightly larger in diameter than the magnet which is also a good thing.

Remember to lightly sand with 220 grit and wipe down with rubbing alcohol any metal or plastic getting attached by either epoxy or velcro.

Removing the nose cone:

I started on the passengers side just below the hood line where the straight horizontal chrome trim comes to a point with the oval shaped chrome trim. I used a cloth covered putty knife to gently pry the nose cone away from it's attachment point. There are 5 attachment points across the front and 1 on each lower side (7 total). There are an additional 6 tabs along the bottom which have barbs on them. Once you get the nose cone out enough to grab onto you can use your hands to free it from all of the attachment points. I advise being gentle, however Tesla has removed my nose cone twice and they literally grabbed the corner with their bare hands and pulled the piece right off. Personally, I like the slow hand approach.

Nose cone attachment points; the bottom tab's attachment points are not ID'ed in photo

Using a cloth covered small putty knife to get started removing the nose cone

Attaching the KO/Velcro Assembly:

You will need to position the license plate holder with its attached magnets in its normal mounted position: The center hole is centered with the Tesla "T" and the curved bottom portion of the holder is against the bottom of the nose cone. Now use the 4 1" dia.x1/4" magnets to hold the license plate holder in place. The magnets will self align themselves as you move them about their final position. You will work on one corner at a time while the other three magnets hold the license plate holder in place. A couple of different ways you can be sure the KO/Velcro assembly gets put in the exact position it needs to be: One is simply center the KO over the magnet and align the Velcro strip by rotating; another is to take the backing off of the velcro strip and center over the magnet and align. What ever method you use you will need to outline the area the velcro strip covers with blue masking tape. This is so when you remove the magnet for placement of the KO/Velcro Assembly you will be able to get the exact placement right. The other reason is it defines the area that needs to be sanded (220 grit) and cleaned with rubbing alcohol. After the area has been prepped, now attach the KO/Velcro Assembly in place by pressing down firmly to establish the bond. It takes 24 hours to reach full strength, however after a 1/2 hour I had difficulty removing the velcro from the plastic. Next place the magnet onto the attached assembly making sure the North/South orientation is correct. The magnet will be attracted to the KO in either orientation, however it will repeal the license plate holder if not orientated correctly.

First magnet area prepped for KO/Velcro Assembly; other 3 magnets firmly holding the license plate holder in place

Do the remaining three magnets using the same method

All four magnets attached to the KO/Velcro Assembly

Protective Cap Placement:

After having a few tools getting very cozy with my magnets I realized it would be a good idea to provide a protective cover over the magnets at the least to prevent them being hit hard and breaking. I found soda bottle caps fit just about perfect and cut circles of velcro to fit inside the caps and onto the top of the magnets. The picture depicts 3M's Dual Lock product which does not stick, so Velcro to the rescue again.

Two caps in place; getting ready to install third cap

Installed License Plate Holder, it fits flush and the magnets do not seem to even touch the nose cone. I have paint armor, so in the event of marring an easy fix.

Front license plate holder installed and held in place by magnets alone

Installing and removing License Plate Holder:

To install, at an approximate 45 degree angle place the center of the license plate holder centered to the "T" on the nose cone; the top of the license plate holder will be at the ridge line of the nose cone. Swing the bottom portion down into place. The pull force of the magnets will help direct the proper placement. To remove, grab the bottom back side of the license plate holder with your fingers while positioning your thumbs over the two bottom magnet attachment points. Swing the holder up and away as if the upper top of the holder was mounted on a hinge. Be sure to hold on securely when attaching and removing, the magnets are very strong.

Some final thoughts

To wrap up and put a bow on this post: The Tesla supplied screws will work to secure the bottom of your license plate to the holder. However, I think the top screws will need to be changed to shorter machine screws otherwise the supplied screws will be going into the nose cone. I haven't checked for sure but eye balling it, it looks to be the case. Second, K&J Magnetics have a $5 off discount on orders over $35 for February using code FIVE213 Also, the tabs on the bottom nose cone have their own individual slot they fit into. It's real easy to have them slip into the honeycomb opening just below the dedicated slot. So get on your hands and knees to double check everything is back together ok. And finally, I speed checked at speeds up to 75mph over the last few days so anything over that it's YMMV.

Last edited:

GREAT write-up Tommy. I was thinking of going the magnet route with my car too, and this pretty much settles it for me... I might try one tweak to your approach, though - use hot glue instead of Velcro on the inside of the nose cone; you'd still need to prep (sand) the plastic to get it to bond properly, but hot glue holds quite well once set, and would be a simple approach to adding the protective bottle-cap covers. I'll try this when I get my car and report back...

Todd Burch

14-Year Member

Awesome Tommy, I think I'm going to go this route too! Great job!

BTW, I like EKoS's suggestion of hot glue. Also, what do you think about the idea of gluing or taping a thin piece of fabric to each of the magnets on the back of the license plate holder? Unless I'm reading it incorrectly, it seems like the design you've got has the magnets directly in contact with the nose cone. Seems like this would cause scratching and marring.

BTW, I like EKoS's suggestion of hot glue. Also, what do you think about the idea of gluing or taping a thin piece of fabric to each of the magnets on the back of the license plate holder? Unless I'm reading it incorrectly, it seems like the design you've got has the magnets directly in contact with the nose cone. Seems like this would cause scratching and marring.

Tommy

Member

Awesome Tommy, I think I'm going to go this route too! Great job!

BTW, I like EKoS's suggestion of hot glue. Also, what do you think about the idea of gluing or taping a thin piece of fabric to each of the magnets on the back of the license plate holder? Unless I'm reading it incorrectly, it seems like the design you've got has the magnets directly in contact with the nose cone. Seems like this would cause scratching and marring.

I would be surprised if the hot glue bonded to the PC/ABS. Although there is specific "welding" equipment specifically for bonding this type of plastic that uses heat to melt special plastic sticks; I am assuming EKos's is referring to the generic type of hot glue. Also I am not fond of not having the magnets be readily removable, personal preference. An easy experiment would be to see if the hot glue could bond metal to the back side of the license plate and hold it. Regarding the magnets touching the nose cone, I think there is an air gap between the magnets and the nose cone. The magnets sit ever so slightly below the outer frame of the holder and the frame is flush against the nose cone with no gap so I can't be sure if they are touching or not. Removing the shim would lower the magnets so they do not touch however the T-nut really needs to be trimmed down to do that as well as the flat headed screw. I have paint armor on my nose cone so I am not as concerned about marring as someone who does not have this protection. An option would be to get just the nose done with paint armor to provide peace of mind.

Lastly, I am in the camp that's driving "naked" with no front plate. My intended use hopefully will be limited to my visits to the big city. I did have the holder in place for a few days and didn't notice any marring, but that doesn't provide enough info for how it will wear attached long term. Good to get other ideas on how best to fasten. Thanks.

- - - Updated - - -

GREAT write-up Tommy. I was thinking of going the magnet route with my car too, and this pretty much settles it for me... I might try one tweak to your approach, though - use hot glue instead of Velcro on the inside of the nose cone; you'd still need to prep (sand) the plastic to get it to bond properly, but hot glue holds quite well once set, and would be a simple approach to adding the protective bottle-cap covers. I'll try this when I get my car and report back...

I just answered Todd's post and realized I may have misunderstood your hot glue suggestion. If you are suggesting just hot gluing the bottle caps than yes I agree that would be a great alternative if not better. However if the hot glue is to attach the KO's to the PC/ABS I have my reservations.

Last edited:

This?3M double sided auto tape.

3M Scotch 06376 Automotive Attachment Tape, 30 mil : Amazon.com : Automotive

Trnsl8r

S85 2012-2018, X90 since 2016, 3 since 2018

Perfect! Why couldn't TM do that? That setup I would actually use...

Perfect! Why couldn't TM do that? That setup I would actually use...

It partially blocks the airflow to the heat exchangers. Now this might not be a problem in some areas, but when it's 40C or 45C, it's a big issue.

sp4rk

Banned

Did anyone get this electric front licence plate holder after all yet?

Show N Go License Plate Holder - Fully Powered w/Remote : Amazon.com : Automotive

Although I ordered mine with front holder, it was delivered without. So seriously considering this option instead now.

Show N Go License Plate Holder - Fully Powered w/Remote : Amazon.com : Automotive

Although I ordered mine with front holder, it was delivered without. So seriously considering this option instead now.

fizzazle

Member

Did anyone get this electric front licence plate holder after all yet?

Show N Go License Plate Holder - Fully Powered w/Remote : Amazon.com : Automotive

Although I ordered mine with front holder, it was delivered without. So seriously considering this option instead now.

Saw it but I read the reviews and changed my mind. Most said it was cheap quality and wasn't meant to be used daily ...mostly just occasionally (like for a car show...)

please let us know how your experience is with this product! If you think it's great quality and works as advertised then it may be worth the $120!

Francis Lau

P-1456

Here are photos of my front plate with the Skene brackets. Each bracket mounts with a single screw highlighted in red box

joepruitt

Seattle Sig Red #497

Francis, did you really screw into the lower fender below the grill? That's almost worse than the nose cone. I got a skene but was planning on screwing it up in on the underside of the nose-cone so it wouldn't be visible if I wanted it to be removed.

Francis Lau

P-1456

Francis, did you really screw into the lower fender below the grill? That's almost worse than the nose cone. I got a skene but was planning on screwing it up in on the underside of the nose-cone so it wouldn't be visible if I wanted it to be removed.

I did

Do you not have plates yet? Or are driving with just rear plates?

joepruitt

Seattle Sig Red #497

Francis, I do have my plates but am running with just the rears on. If/when I get pulled over, I'll look at installing it. For now, I'm going to see how it goes.

Similar threads

- Question

- Replies

- 4

- Views

- 81

- Replies

- 10

- Views

- 767

- Replies

- 0

- Views

- 214

- Locked

- Marketplace listing

- Replies

- 5

- Views

- 1K