Last night I plugged in my Model 3 around 50% battery like I do each day (charge to 80% daily).

Went to go to work this morning and I notice I'm at 28% battery. I see the HPWC has no power. Breaker is on but nothing from the HPWC. So I take my Jeep to work and deal with it later.

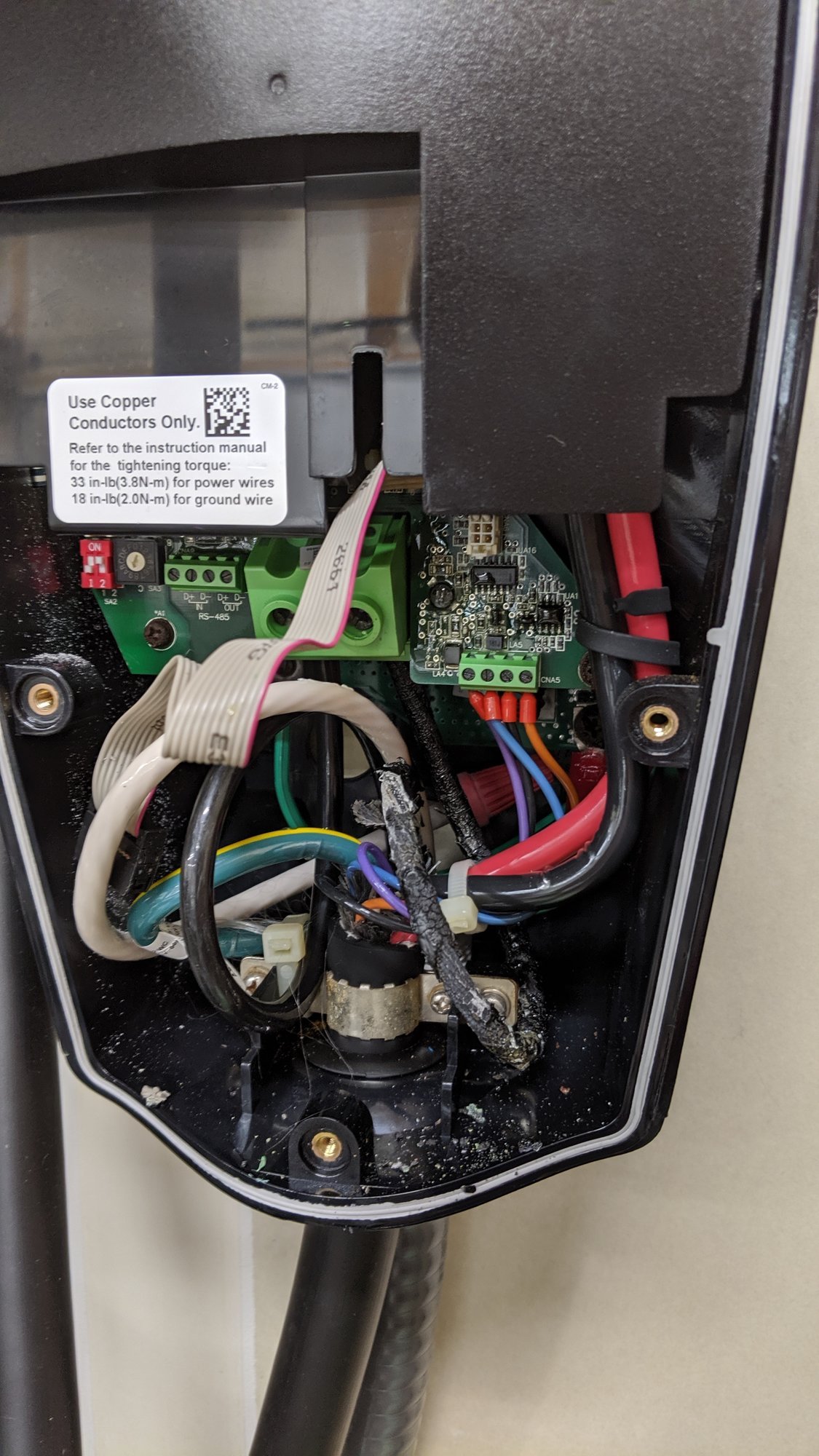

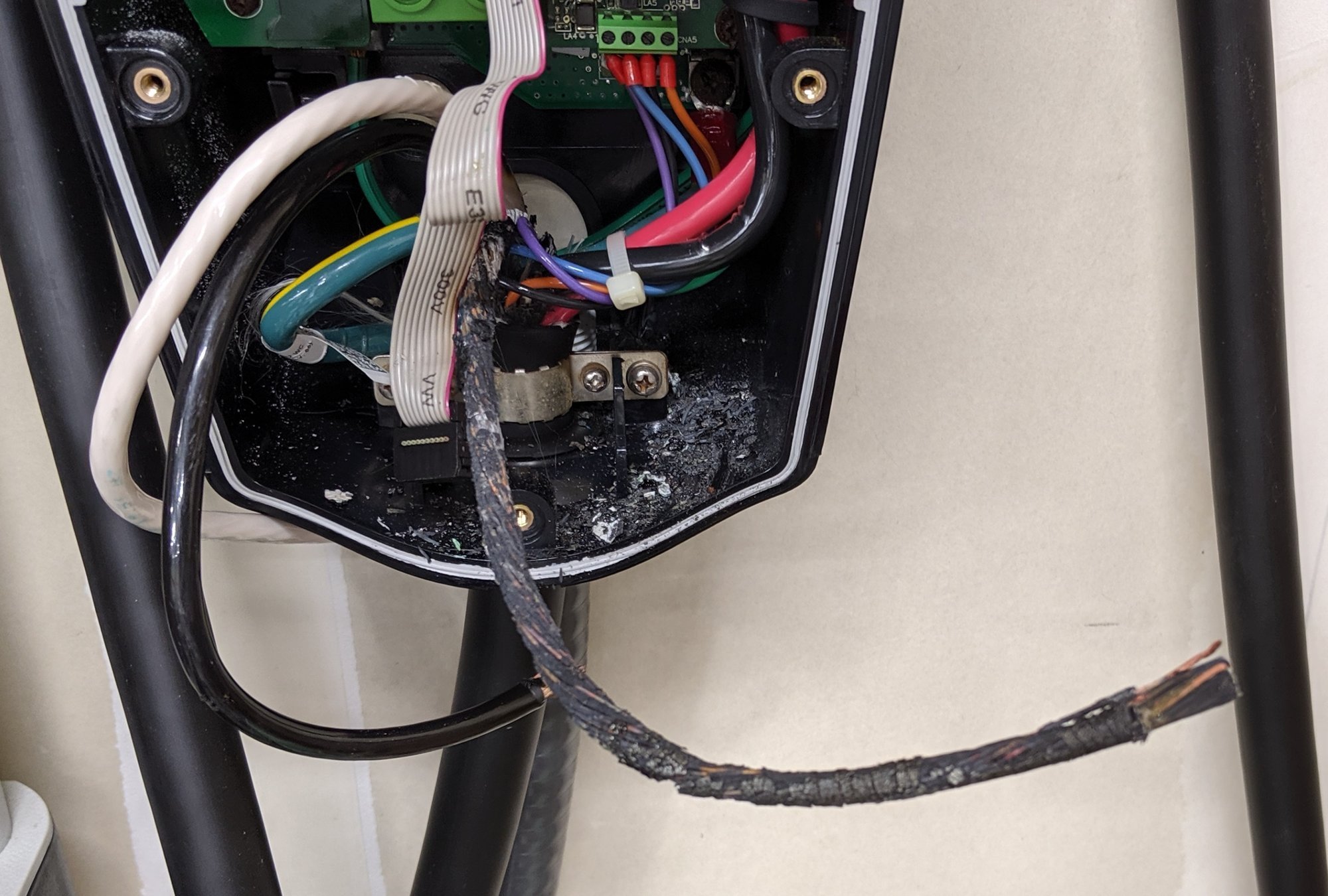

Tonight I open up the HPWC to see that one of the hot wires is completed melted through the jacked all the way to where the wires enter the HPWC. The breaker never tripped at the panel and the wire seems to be ok just inside the conduit and at the panel side.

Wire is THHN 6 Awg and 25 feet from the panel. I charge at 48 amps each day and the HPWC was installed in May.

Anyone else see this before? Any thoughts to what might have caused this?

Car seems ok, but I haven't driven it yet. I've been charging on 120v 12amp mobile connector.

Went to go to work this morning and I notice I'm at 28% battery. I see the HPWC has no power. Breaker is on but nothing from the HPWC. So I take my Jeep to work and deal with it later.

Tonight I open up the HPWC to see that one of the hot wires is completed melted through the jacked all the way to where the wires enter the HPWC. The breaker never tripped at the panel and the wire seems to be ok just inside the conduit and at the panel side.

Wire is THHN 6 Awg and 25 feet from the panel. I charge at 48 amps each day and the HPWC was installed in May.

Anyone else see this before? Any thoughts to what might have caused this?

Car seems ok, but I haven't driven it yet. I've been charging on 120v 12amp mobile connector.