Sorry about having the equipment and not being able to use it. That hurts.

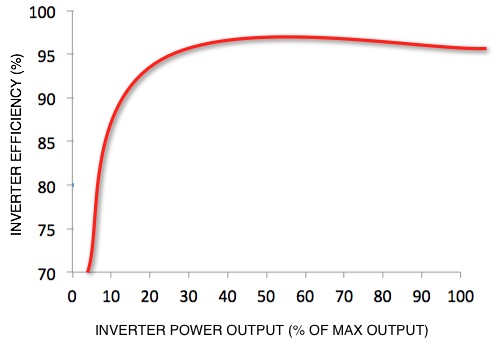

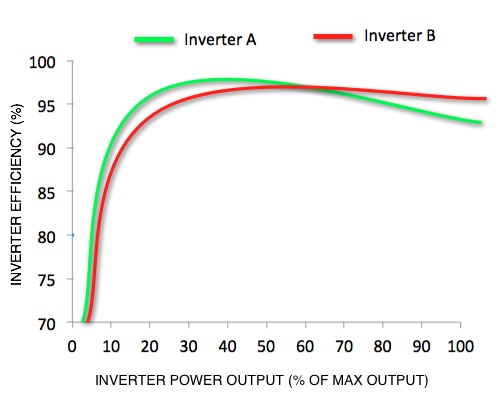

Just to clear up the "more efficient" claims, we are talking about a few percent difference from something like 40% to 100% loading of an inverter. Not a lot.

e.g.

Two Reasons You Must Look At Efficiency Curves When Choosing Your Solar Inverter with two great figures;

and more importantly;

Just because you are getting "the most efficient" inverter says nothing about whether that inverter will produce the most power on your panels over a year. (Above the green version is "more efficient", but it will produce less overall power than the red version over normal load conditions.)

The bit that does not get enough air time, in my opinion, is that all inverters become less efficient as they heat up. That alone argues for having your standalone inverter spend more time at less than 100%. Again, the temperature effect amounts are a few percent to ten percent or so. The effect is much less pronounced for microinverters which are designed for much higher operating temperatures. (But it is still a real effect.)

If you are sweating efficiency, it normally requires a deep dive into the efficacy plots for a given inverter model by power, and by temperature. Different designs lose efficiency in different ways, and I think that modeling the efficiency effects at any given site is not straightforward. I would say that at some point, one pretty rapidly hits the point of diminishing ROI, especially with standalone inverters where the capital cost is high.

I think that if I were dependent upon a stand alone inverter, I would own a spare. The old adage that for critical items one equals zero, and two equals one applies to standalone inverters in my book. Or have a standby generator to be able to step in and cover for you.

All the best,

BG