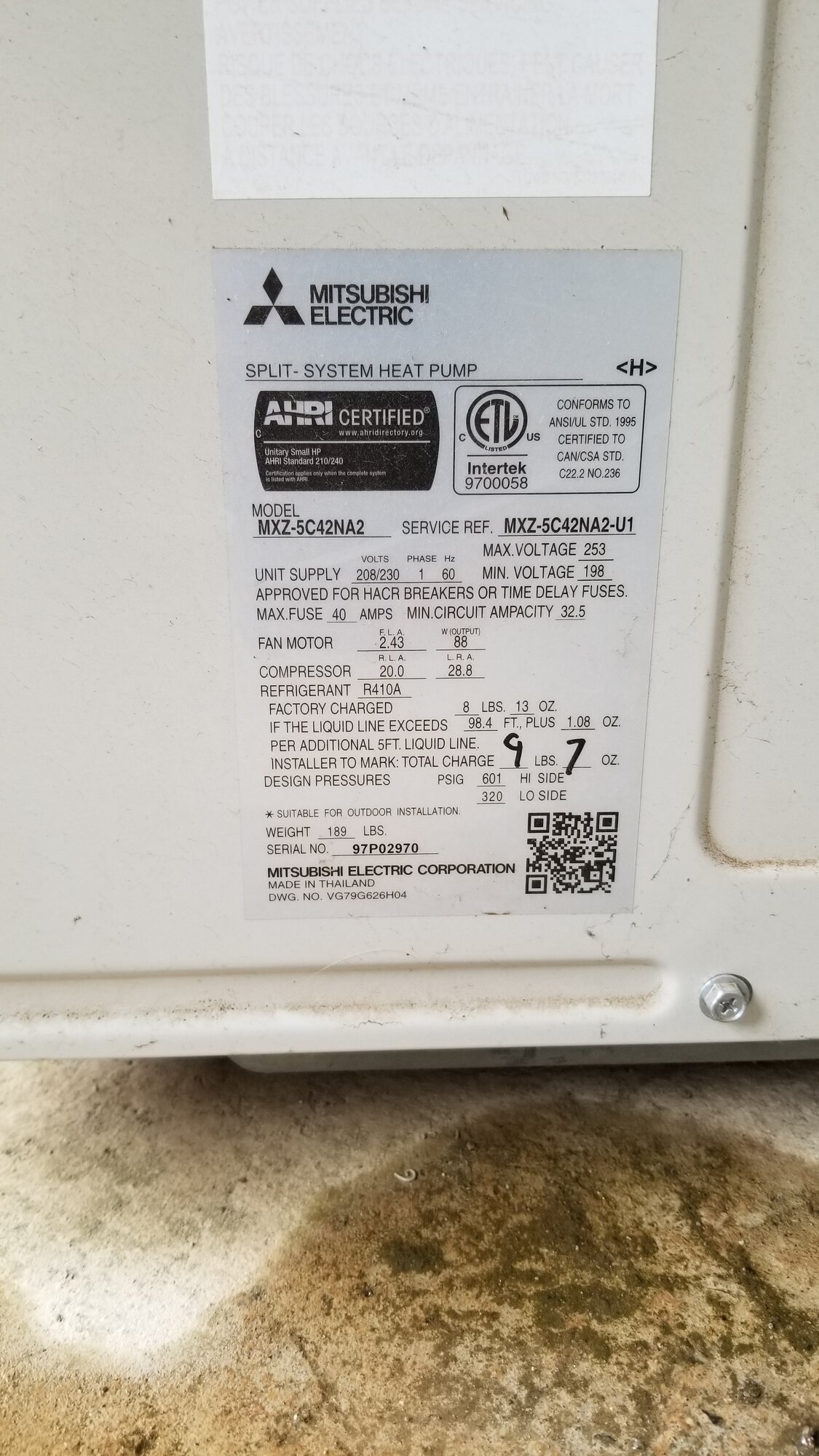

I believe your plate tells you exactly what you need for a breaker, right?

MCA 32.5 amps. As a HVAC product this is subject to the 125 continuous use specification. Which is why the recommended breaker is 40 amp.

Load? Running or startup? Startup, as in what you'd need from a generator, can be significant. That's LRA (locker rotor amps) plus fan. RLA is roughly running amps, and you'd total the compressor and fan.

BTW, I run a very large home, complete w/6 ton Geothermal, on 200 amp and have never had an issue (20 years now).

What's this "meet code spec for 200A" thing? When I build my house nobody gave a hooka. I picked out what service I thought I could live with (been right so far), and nobody cared. BTW, we once tested my total current demand in my house. With every possible thing running, and I mean right down to sump pump on, disposal, toaters, and two vacuams, (you get the idea) I was pulling something like 330 amps over a 200 amp service. And it didn't blow.

Back then a ton of that was lighting (lots of light in house). Now, with LED in everything, I doubt I could break 200 if I tried.

I can say this: Long-term I'm pretty sure we'll all be charging our cars at work. Short-term most folks aren't pulling enough power at night to matter. Someplace in the middle there will be some dual EV's homes trying to take something like 130 amps during the night. I know my power loads pretty well. I would be reluctant to allocate less than 60 amps (12kva) to running my home at night (5,200 sq'). During the day I would need at least 100 amps. But I don't use electric dryers either, so..

So in my home, my size, my build, 200 amp could, maybe, get tight someday but even then would still be viable.