I discussed parts of this briefly the other day, but I thought I’d write in a bit more detail.

One (of many) of Tesla’s key competitive advantages is its huge battery and powertrain cost advantage. (I’ll go into its other advantages another day)

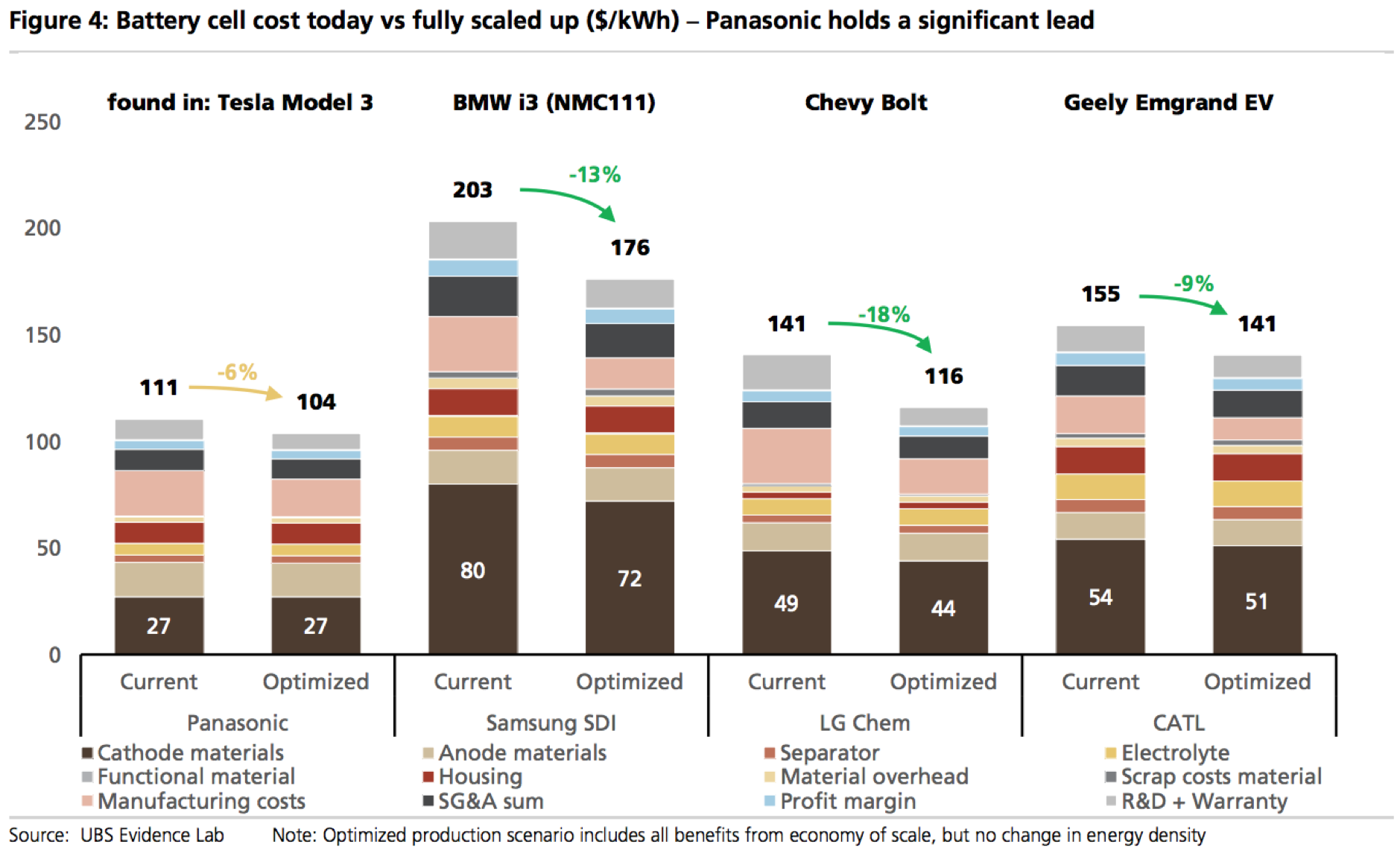

Sandy Munro’s car teardown and P3’s cell teardown reports (arranged by UBS) put Tesla’s cell costs at $111/KWh, pack costs (for SR) at $35/KWh and other powertrain costs at $4.5k. For SR+ this totals $12.5k ($8k for battery pack, $4.5k for other powertrain).

For Chevy Bolt total Powertrain costs were estimated at $16.6k ($12.3k battery pack, $4.3k other powertrain).

Sandy Munro estimated mass market ICE powertrain costs at $6.5k and Luxury ICE powertrain costs at $8.5k (BMW 330i).

So this gave Tesla a $4.1k cost advantage vs Chevy Bolt on its Powertrain. However Model 3 specs are equivalent to a luxury ICE while Chevy Bolt specs are closer to a mass market car. So really Tesla’s cost advantage vs the bolt relative to their equivalent ICE Powertrain is $6.1k. Relative to the BMW 330i, Model 3’s powertrain costs are c.$4k more expensive. So Model 3 costs are significantly closer to the ICE equivalent and they are to its EV competition.

It’s worth noting that the Chevy Bolt powertrain was $4.6k cheaper than UBS’s previous estimates when UBS/Munro’s first teardown study came out in May 2017. So together this $4.6k Chevy beat plus Model 3’s $6.1k beat puts Tesla’s EV vs ICE powertrain cost premium $10.7k lower than UBS (and much of the auto industry) was estimating for EV tech as recently as 2017. Just $4k further to go for powertrain upfront cost parity, ignoring Tesla’s other cost advantages and other total costs of ownership advantages.

So just a reminder, Tesla’s SR+ Powertrain is $4k cheaper than the Bolt despite vastly superior specs on every metric. How do the specs compare?

· Range: Model 3 240 miles. Bolt 238 miles.

· 0-60 Acceleration: Model 3 5.3 seconds. Bolt 6.5 seconds.

· Max charging: Model 3 250KW. Bolt 50KW.

· Powertrain Life: Model 3 battery 500k miles, other powertrain 1,000k miles. Bolt 200k miles?

· Power: Model 3 306 HP. Bolt 200 HP.

· Torque: Model 3 415 lb-ft. Bolt 266 lb-ft.

· Battery fires: No known fires for either? Vastly better than ICE cars.

The Bolt is not a special case. As far as we know Model 3’s powertrain costs also beat the Audi E-tron and Jaguar I-pace by a similar if not greater margin.

How does Tesla have such a lead?

Five reasons: 1) Cheaper battery cells, 2) Cheaper battery packs, 3) Better battery to wheel efficiency, 4) Better weight (including battery pack capacity/kg and motor power/kg) and 5) Better drag coefficient.

Before I start a very long post on exactly how I think Tesla is winning in EV powertrain costs, just a reminder how significant Tesla’s $4-6k cost advantage is. ICE OEMs normally make around $1k EBIT per car, while luxury cars can be $2-3k. If an ICE OEM had the same cost advantage vs other ICE OEMs for ICE cars their profit per car would be 5x higher. And Tesla’s $4-6k cost advantage here is on powertrain alone – they have other significant savings including from not advertising, not using dealerships, using an online first sales model, higher vertical integration of non-powertrain auto manufacturing and higher non-powertrain manufacturing innovation.

Relative to the Chevy Bolt I estimate Tesla Model 3’s $4.1k powertrain cost advantage comes from roughly: 1) $1.6k lower cell costs, 2) $1.4k lower pack (non cell) costs 3) $1.2k better wheel to wheel efficiency (mostly this), weight & drag. On top of this Tesla’s powertrain performance, longevity and likely safety advantage all come for free.

How does Tesla beat ICE OEMs efforts in each of these categories?

Cheaper battery cells.

Tesla’s three key advantages are 1) ability to use stripped back simplified cylindrical cells, 2) ability to safely use the in principle more dangerous NCA chemistry and 3) economies of scale (including standardized cell size unlike prismatic cell sizes which vary with battery pack design).

The core of 1 & 2 is that Tesla is able to use simplified cylindrical cells (with no safety systems) and NCA chemistry because it has far superior battery management software (including fleet learning benefit) and hardware – it shifts cell costs into battery pack IP (and no ICE OEMs are even attempting to catch up on this path).

Cylindrical battery cells

Advantages:

- Cheaper to manufacture.

- Has the least components and simplest manufacturing process (8 components vs up to 30 for prismatic cells which are now mostly being adopted by the industry).

- Cylindrical is the most mature technology and has the most automated manufacturing process with highest utilization rates in manufacturing steps.

- Tesla’s NCA cylindrical cells have by far the highest volumetric energy density, I think in part due to tighter cathode winding in cylindrical structures. This should reduce pack size and hence pack (non cell) weight.

- One cell design can fit multiple different battery packs and vehicle programs. Pouch/Prismatic generally have to be designed differently for each program so get much less economies of scale. For example CATL makes 34 different shapes of cell while BYD makes 10.

- Cylindrical cells generally need less safety specific components, but Tesla’s cells are able to strip these back further - Tesla's cells lack a CID (vent ) and a positive temperature coefficient device. They can do this in part due to the pack design and software.

- Mechanical stability against internal swelling.

- Smaller cells can allow better thermal management.

- The winding process can be done faster than stacking for other cell types, they can also be wound tighter.

Disadvantages :

- Limitation in cell size means a huge number of cells per car which makes module assembly much more difficult and makes cell balancing much more difficult. Model 3 has c.4000 cells vs c.300 pouch cells in the Bolt.

- More cells per car also means more chance for something to go wrong.

- Cylindrical cells have lower gravimetric energy density (for equal chemistry) I think mostly because smaller cylindrical cells need more housing material. This is largely compensated because it is easier to use higher cathode energy density chemistries in cylindrical cells.

- Cell testing is more expensive because more cells need to be connected and tested.

Tesla’s NCA chemistry has the highest nickel cathode content and the highest cathode energy density of any EV. It has much less cobalt than NCM designs which reduces raw material prices and reduces supply risk. Its disadvantage is the chemistry is less stable relative to lower Nickel content/lower cathode energy density cells – this is another reason Tesla uses cylindrical cells – the smaller canned cylindrical format helps limit this instability.

I think Tesla's current NCA cathode chemistry is Nickel 93% Cobalt 5% and Aluminium 2%. This compares to most common NMC 532 at 50% Nickel, 30% Manganese and 20% Cobalt.

The rest of the industry is starting to transition to higher Nickel NMC 811 (now c.7% of China cathode production) which is closer to NCA. However this chemistry will face increased manufacturing costs and increased safety challenges, particularly given the industry does not have the battery pack expertise to use smaller cylindrical cells which limit the chemical instability.

Is anyone copying Tesla’s cell approach?

No Auto OEM is trying currently. For example in China in July just 5% of battery KWh in EVs was cylindrical cells (and this was still mostly 18650) and NCA is only around 3% of total cells. Model 3 cells are 257WH/kg. CATL’s highest energy density cell is 236WH/kg and BYD doesn’t have any >220WH/kg. They both largely make prismatic cells.

Some startups such as Rivian say they will be using cylindrical cells, but exactly what chemistry they use and whether they use the same extremely stripped back cell design as Tesla is unclear.

Cheaper battery packs

Tesla’s battery pack strategy is very similar to its Autopilot strategy. It is all about vertical integration, software and fleet learning. Tesla’s pack costs benefit from a lean and high tech design as well as from the high volumetric energy density of its cells, but also because it has shifted cell/pack hardware complexity into better (likely neural net based) software. The Munro teardown found Model 3 pack cost at $30/kWh, half of the $60/kWh in the Chevy Bolt, despite Model 3 pack’s ability to use higher energy density cathode chemistries and much simpler and cheaper battery cell designs.

Tesla is the only automaker that can continuously collect data from its customer fleet, it is also the only automaker that has designed its own software, semiconductors and other pack components in-house (normally these are outsourced to multiple suppliers). For the battery it can collect information on driving style, charging, battery temperature, battery capacity changes, voltage, degradation etc. This statistical data is fed into Tesla’s BMS to precisely manage tiny differences in each cylindrical cell’s performances and provide equilibrium for the overall system. Tesla’s BMS software use multiple in-house designed ASIC chips called batman and robin for cell balancing. I think it is highly likely Tesla’s BMS is neural net based with data fed into a neural net to optimize management and balancing across the 4,000+ cells.

The BMS software delivers:

- High useable capacity of the battery cells.

- High and safe charge rates.

- High safety despite the less stable high energy density chemistry. (The software limits flammability risks - it ensures temperature is not allowed to rise and prevents metals deposits forming)

- High safety despite simplified cells without in-built safety features.

- Limited degradation and long life (in miles) of Tesla’s batteries relative to the competition. This benefits from Tesla’s precise cell balancing.

- Resilience to a certain failure/error rate of cells (many competitor’s designs require perfection to operate safely or at all).

Together with the better software, Tesla limits (as far as we know eliminates) the dangers of high Nickel cathodes by using pack materials with low heat conductivity and using inbuilt thermometers.

Moving so much of the cell/pack tech/management into software rather than hardware means Tesla can use the same hardware designs for multiple different products - semi/storage/performance cars/pickup/Model 3 etc, giving better economies of scale.

Tesla’s reliance on fleet learning, vertical integration and software as the core of its battery strategy gives it a huge advantage against ICE OEMs and as far as I know Tesla is now so far ahead nobody is even trying to copy their approach. ICE OEMs do not have the vertical integration to design a harmonized overall system. They do not have ability to collect data from their fleet. They do not have software or AI expertise to move to a software first approach. Unlike Tesla they do not have 10 years of data to feed into their system to enable use of cheaper cells and higher risks chemistries. Given the bad publicity surrounding EV fires, it is extremely high risk to roll out a new high risk battery chemistry/pack design without first having the fleet data to optimize the software to ensure safety – I just think it is extremely difficult for anyone to risk following Tesla at this stage. As Tesla bears UBS write: “Despite Panasonic's cost advantage we expect to see limited adoption by other OEMs. A sophisticated battery management system (Tesla produces in-house) is required for the format and we do not think this is easily replicable.”

Better battery to wheel efficiency

All Tesla cars again significantly beat all the competition on this key metric. The cost savings from better powertrain efficiency can easily be higher than savings on cheaper battery cells. More efficiency means lower battery size for the same range which means lower battery costs – this can be worth as much as $4k relative to cars such as the I-Pace.

Tesla wins here for 2 main reasons: 1) It has the most experience and best engineers with the best hardware designs and 2) It has the most vertical integration and best software talent which allows design of a harmonious powertrain.

Some specific hardware breakthroughs Tesla has made include the use of a high efficiency silicon carbide inverter, a breakthrough permanent magnet motor design (willing to pivot from its previous expertise in induction motors), high tech cooling design, reduced cabling and combination of multiple hardware components into the same housing with a modular and compact design.

On the software side again, the vertical integration and fleet learning across the entire EV powertrain has allowed continuous improvements and efficiencies. Overall, including battery and other powertrain, software has driven around half of the 40% improvement in Tesla’s powertrain over the past 5-6 years.

Tesla’s battery pack capacity/kg beats the competition I think in part due to the better volumetric energy density of its cells – which requires less pack casing. E-tron and EQC battery packs are about 2kg/kWh heavier than Model 3, which can add up to around 200kg on the car which has a negative impact on range, acceleration and handling.

Model 3 also has the best power-to-weight ratio of its electric drive unit (motor and gearbox) of any electric vehicle in the market.

Model 3's drag coefficient is just 0.23 which is the best of all cars in its segment. Tesla obviously has extremely smart engineers and designers working to minimise drag co-efficient while maintaining aesthetics. ICE OEMs are often handicapped here, partially because their vehicles and brand has a distinctive “look” which they are trying to maintain despite the shift to EVs. ICE OEMs are also handicapped because many have decided to build flexible platforms (to avoid properly committing to EVs) which can be used for ICEs, EVs or PHEVs, rather than being designed specifically towards EVs.