I used to love sneaking up on Porsches with my 66 vw sun roof bus and passing them. I am pretty sure that at least a few of them chased me down to pass me even if it meant going out of their way.That new 2020 Corvette is some amazing car. With a V8 and two seats it is only 4/10 of a second slower accelerating to 60 mph than the 5 seat Tesla Model S performance sedan that has been available for a while already and will be replaced next year by the plaid Model S that will be much faster.

Good thing that a soccer mom with 4 kids and a couple dogs (plus a cat for @Krugerrand ) in a Model S didn't pass the new Corvette during the video filming. THAT would have been embarrassing.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

Unfortunately this shows you only have a surface knowledge of the topic. A battery pack is a system that’s safety and density characteristics are only partially defined by the chemistry. The packaging (including but not limited to the choice of cell housing) can make a NCA cell safer then a NMC cell packaged in a different manner.

In the end, real world statistics show Tesla is literally the safest sedan on the road , validating Tesla’s choices.

All three packaging type has improved to the point where cooling and so aging is not an issue any more. To be more precise pouch cell has the best geometry for cooling as it is a rectangle prism shape so its thickness can be sized arbitrarily and can have a large cooling surface if needed. Porsche Taycan uses pouch cells from LG chem for example and has no cooling or performance problems. I will show the longevity below. Prismatic cells have no issues as well, BMW i3 from 2014 was able to take 2C charge which Tesla wasn't able to achieve until the Model 3 v3 charging.

Tesla cars aren't the safest on the road, but this isn't the topic now. (look up Mazda 3 on EuroNCAP and compare them)

At purely the cell level, using generic NMC and NCA cells from some random battery supplier, in a figurative (not literal) vacuum, these points may be valid.

However, everyone else continues to struggle and/or give up developing the necessary surrounding methods and technologies to take advantage of the supposed NMC advantages, piling inefficiency on inefficiency (packaging, thermal, production, materials costs, etc) to come out far behind what Tesla can achieve with the "inferior" NCA batteries. And that is ignoring the advances in chemistry Tesla has achieved, which nullify most of those supposed NMC advantages on their own ...

If you compare the fully integrated Tesla battery system to any other battery system, for essentially any metric nobody surpasses Tesla (or if they do, it comes at a significant cost or compromise - whether it be more expensive subsystems, reduced longevity, etc).

In theory, if Tesla decided to apply everything they know to using NMC cells, they could make a "superior" (based on your claims) battery system, but having already achieved being able to go a million miles with NCA the "longer lasting" is moot, and as for safer, Tesla has thus far shown that engineering can "solve" the thermal runaway issue (even with some older vehicles having had fires they are far slower and less deadly than equivalent ICE fires, with nearly everyone walking away from accidents they shouldn't have in an ICE, so NMC lasting just a few degrees longer before self igniting is moot - in most cases, they would have still burned if they were NMC, and especially comparing prismatic cells to cylindrical the difference in effective cooling might make a NMC prismatic more problematic than NCA cylindrical)

I don't see everyone else struggling. BMW had no issues with their prismatic desing since 2014 for example. When you say efficiency. Most car makers have efficient batteries. That's not the showstopper. The efficiency of the pouch cells can easily be increased by using thicker copper layers. (the volume of the cylindrical cell would increase faster with thicker copper). Look at the internal resistance of the following batteries: pouch has lower energy density but the internal resistance is 40 times less compared to the cylindrical.The density and internal resistance can be scaled by design inverse proportionally.

Source: Accelerated Internal Resistance Measurements of Lithium-Ion Cells to Support Future End-of-Life Strategies for Electric Vehicles

Yeah, and the big disadvantage of prismatic cells is the lack of protection against swelling - which all cell chemistries are exposed to.

Cylindrical cells have strong protection against swelling, in form of a strong metallic, cylindrical casing.

Prismatic and pouch cells, not so much:

View attachment 478228

Most non-Tesla car manufacturers are using pouch or prismatic cells not because it's superior, but because they don't know how to make battery packs with cylindrical cells economically.

You are refering to consumer electronics.

Automotive pouch/prismatic cells are sealed in a metalic box. There is no such issue.

It is not meaningful to discuss cell chemistry safety without discussing how the cell design and Battery Management System deals with this.

The three key advantages of Tesla's cell strategy are 1) ability to use stripped back simplified cylindrical cells, 2) ability to safely use the in principle more dangerous NCA chemistry and 3) economies of scale (including standardized cell size unlike prismatic cell sizes which vary with battery pack design).

The core of 1 & 2 is that Tesla is able to use simplified cylindrical cells (with no safety systems) and NCA chemistry because it has far superior battery management software (including fleet learning benefit) and hardware – it shifts cell costs into battery pack IP (and no ICE OEMs are even attempting to catch up on this path).

Cylindrical battery cells

Advantages:

Cheaper to manufacture.

Has the least components and simplest manufacturing process (8 components vs up to 30 for prismatic cells which are now mostly being adopted by the industry).

Cylindrical is the most mature technology and has the most automated manufacturing process with highest utilization rates in manufacturing steps.

Tesla’s NCA cylindrical cells have by far the highest volumetric energy density, I think in part due to tighter cathode winding in cylindrical structures. This should reduce pack size and hence pack (non cell) weight.

One cell design can fit multiple different battery packs and vehicle programs. Pouch/Prismatic generally have to be designed differently for each program so get much less economies of scale. For example CATL makes 34 different shapes of cell while BYD makes 10.

Cylindrical cells generally need less safety specific components, but Tesla’s cells are able to strip these back further - Tesla's cells lack a CID (vent ) and a positive temperature coefficient device. They can do this in part due to the pack design and software.

Mechanical stability against internal swelling.

Smaller cells can allow better thermal management.

The winding process can be done faster than stacking for other cell types, they can also be wound tighter.

Disadvantages :

Limitation in cell size means a huge number of cells per car which makes module assembly much more difficult and makes cell balancing much more difficult. Model 3 has c.4000 cells vs c.300 pouch cells in the Bolt.

More cells per car also means more chance for something to go wrong.

Cylindrical cells have lower gravimetric energy density (for equal chemistry) I think mostly because smaller cylindrical cells need more housing material. This is largely compensated because it is easier to use higher cathode energy density chemistries in cylindrical cells.

Cell testing is more expensive because more cells need to be connected and tested.

Tesla’s NCA chemistry has the highest nickel cathode content and the highest cathode energy density of any EV. It has much less cobalt than NCM designs which reduces raw material prices and reduces supply risk. Its disadvantage is the chemistry is less stable relative to lower Nickel content/lower cathode energy density cells – this is another reason Tesla uses cylindrical cells – the smaller canned cylindrical format helps limit this instability.

Tesla's BMS software delivers:

High useable capacity of the battery cells.

High and safe charge rates.

High safety despite the less stable high energy density chemistry. (The software limits flammability risks - it ensures temperature is not allowed to rise and prevents metals deposits forming)

High safety despite simplified cells without in-built safety features.

Limited degradation and long life (in miles) of Tesla’s batteries relative to the competition. This benefits from Tesla’s precise cell balancing.

Resilience to a certain failure/error rate of cells (many competitor’s designs require perfection to operate safely or at all).

Together with the better software, Tesla limits (as far as we know eliminates) the dangers of high Nickel cathodes by using pack materials with low heat conductivity and using inbuilt thermometers.

I explain Tesla's Powertrain and Battery strategy in more detail below:

Battery management is not rocket science. The researchers, or better, the cell testers give characteristic maps to the software developer who runs optimization algorythms to make the best use of the battery. It is the cell testing that has to be done correctly, software is easy.

Economics: Why does the Audi E-tron with ~93kWh battery cost less than the Model X with 100kWh yet is has more features and finer material? I'm not sure there is a big cost advantage to Tesla regarding the battery. VW claims it’s buying a $100 kWh battery. Cylindrical is cheaper to manufacture but not much fun to build the pack. Complicated cooling system.

(BMW i3 has a carbon fibre chassis and a factory with fully renewable energy so that hard to compare to Tesla)

As for energy density Jack Rickard measured 243 Wh/kg for the Model 3 cells. (I don't have the volumetric energy density for the Tesla cell though. If I use 24.25mm^3 for cell volume and 17.3Wh/cell, the volumetric density comes to 713 Wh/L) Compare this to CATL:

CATL’s NCM 523 battery cells (available since 2017):

Prismatic format: 235 Wh/kg and 570 Wh/L

Pouch format: 250 Wh/kg and 530 Wh/L

CATL’s NCM 811 battery cells, since 2019:

Prismatic format: 270 Wh/kg and 660 Wh/L

Pouch format: 300 Wh/kg and 700 Wh/L

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Additionally the cobalt content of the NMC 811 is similar to Tesla's NCA.

One more thing: battery degradation.

Tesla batteries have the cycle life of around 800. NCM usually has much higher cycle life, around 1500.

This article says about Tesla:

"Well, according to lithium-ion battery cells studies, after 500-800 charging cycles and 100,000 to 150.000 miles a battery’s charging capacity drops to around 70%. "

Tesla Batteries Last Forever (Basically)

https://www.quora.com/What-is-the-charge-discharge-cycle-durability-of-Teslas-2170-cells

Compare that to CATL's 1800 charge cycle with the capacity drop to 80%:

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Attachments

All three packaging type has improved to the point where cooling and so aging is not an issue any more. To be more precise pouch cell has the best geometry for cooling as it is a rectangle prism shape so its thickness can be sized arbitrarily and can have a large cooling surface if needed. Porsche Taycan uses pouch cells from LG chem for example and has no cooling or performance problems. I will show the longevity below. Prismatic cells have no issues as well, BMW i3 from 2014 was able to take 2C charge which Tesla wasn't able to achieve until the Model 3 v3 charging.

Tesla cars aren't the safest on the road, but this isn't the topic now. (look up Mazda 3 on EuroNCAP and compare them)

I don't see everyone else struggling. BMW had no issues with their prismatic desing since 2014 for example. When you say efficiency. Most car makers have efficient batteries. That's not the showstopper. The efficiency of the pouch cells can easily be increased by using thicker copper layers. (the volume of the cylindrical cell would increase faster with thicker copper). Look at the internal resistance of the following batteries: pouch has lower energy density but the internal resistance is 40 times less compared to the cylindrical.The density and internal resistance can be scaled by design inverse proportionally.

View attachment 478601

Source: Accelerated Internal Resistance Measurements of Lithium-Ion Cells to Support Future End-of-Life Strategies for Electric Vehicles

You are refering to consumer electronics.

Automotive pouch/prismatic cells are sealed in a metalic box. There is no such issue.

Battery management is not rocket science. The researchers, or better, the cell testers give characteristic maps to the software developer who runs optimization algorythms to make the best use of the battery. It is the cell testing that has to be done correctly, software is easy.

Economics: Why does the Audi E-tron with ~93kWh battery cost less than the Model X with 100kWh yet is has more features and finer material? I'm not sure there is a big cost advantage to Tesla regarding the battery. VW claims it’s buying a $100 kWh battery. Cylindrical is cheaper to manufacture but not much fun to build the pack. Complicated cooling system.

(BMW i3 has a carbon fibre chassis and a factory with fully renewable energy so that hard to compare to Tesla)

As for energy density Jack Rickard measured 243 Wh/kg for the Model 3 cells. (I don't have the volumetric energy density for the Tesla cell though. If I use 24.25mm^3 for cell volume and 17.3Wh/cell, the volumetric density comes to 713 Wh/L) Compare this to CATL:

CATL’s NCM 523 battery cells (available since 2017):

Prismatic format: 235 Wh/kg and 570 Wh/L

Pouch format: 250 Wh/kg and 530 Wh/L

CATL’s NCM 811 battery cells, since 2019:

Prismatic format: 270 Wh/kg and 660 Wh/L

Pouch format: 300 Wh/kg and 700 Wh/L

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Additionally the cobalt content of the NMC 811 is similar to Tesla's NCA.

One more thing: battery degradation.

Tesla batteries have the cycle life of around 800. NCM usually has much higher cycle life, around 1500.

This article says about Tesla:

"Well, according to lithium-ion battery cells studies, after 500-800 charging cycles and 100,000 to 150.000 miles a battery’s charging capacity drops to around 70%. "

Tesla Batteries Last Forever (Basically)

What is the charge/discharge cycle durability of Tesla's 2170 cells? - Quora

Compare that to CATL's 1800 charge cycle with the capacity drop to 80%:

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Battery degradation of 30% in 150k miles? Nonsense

Tesla Model S battery life: what the data show so far

"But, overall, the data offer some basis for confidence that a Tesla Model S will lose—on average—less than 15 percent of its battery capacity over the average 150,000-mile (250,000-km) life of a vehicle."

There is so much miss information in the comment above... Pouch batteries in comparison to cylindrical batteries... Cost of competitors batteries etc.

Last edited:

You are making the major mistake of trying to extrapolate Tesla's vision network based 3D object distance detection ability from academic papers.

In reality Tesla's neural networks are way ahead, which is obvious if you look at annotated videos of Autopilot object detection:

In that (older and HW2 based) video there are several examples of accurate tracking of cars 100-150m away - and consistent tracking of 50m+ cars. The HW3 networks will likely be significantly better.

So your claim is simply false - not to mention that the angular resolution and field of view of $10k LIDAR units is much poorer than that of $50k+ Velodyne units.

So Tesla Autopilot object detection is getting better with time - while LIDARs are getting significantly worse as they are trying to reduce costs - and that doesn't even address poor LIDAR performance in common driving scenarios that @KarenRei outlined (winter, rain).

There's also the point @MarcusMaximus made:

"Teslas have 3 forward-facing cameras, with different FOV’s simulating multiple vantage points, and correctly identify objects and distances >100m away."

You are mixing up 3D object detection with 2D neural network image recognition.

I'm not, the Autopilot video I cited shows that Autopilot is perfectly aware of the 3D object location of detected cars: the position and distance labels are 3D coordinates in essence, and Autopilot uses this 3D object data to estimate relative velocities as well.

(Anyway, futures markets open soon so this is getting very OT.)

Yes, you are.

This is a depth map from 3D object detection using stereo cameras. Notice it doesn't have to recognize the shape of an object to know how far it is within a certain distance. Image recognition however can't measure the distance if it doesn't know the size of the object.

In your video above with the boxes. Boxes are the results of image recognition and the distance/speed information comes from the radar. You misunderstood that video.

Here is a better representation from a recent video from verygreen:

green on Twitter

notice how the camera failed at 0:46. It thought the police car is stationary because it had issues with connecting the radar impulses with the image. Here is another one similar to that police car:

Elon Musk did mention in the recent interview with Lex Fridman that object localization is very difficult.

Huskyf

Member

Whaou check this article on cnbc

https://seekingalpha.com/article/4307615-tesla-analysis-demand-established-markets

https://seekingalpha.com/article/4307615-tesla-analysis-demand-established-markets

The conclusion may be right, but the methodology is flawed in a production-constrained environment.Whaou check this article on cnbc

https://seekingalpha.com/article/4307615-tesla-analysis-demand-established-markets

Phil LeBeau described the Ford Mustang Mach-E as a Tesla competitor, before Tim Seymour spent much time trying to explain his Tesla short position.

CNBC Fast Money - video half hour ago: The electric car wars are gaining speed as Ford unveils New Mustang MU

That interview is painful... not from watching Tim Seymour squirm, but because of the long stream of misinformation from Phil at the beginning. Just in a couple sentences:

- The Mach-E's price is $44k for 300 miles range (no, that's two completely different trims with very different range and price points)

- That said $44k, 300 mile range vehicle comes to market late next year (neither $44k nor 300 miles comes late next year)

- Model Y is expected to come out late next year, around the same time as the Mach-E (no, it's expected out in Q2)

Tesla cars aren't the safest on the road, but this isn't the topic now. (look up Mazda 3 on EuroNCAP and compare them)

Adult Occupant: About equal (98% vs. 96%)

Child occupant: About equal (87% vs 86%)

Vulnerable road users: win Mazda (81% vs. 74%)

Safety assist: blowout Model 3 (73% vs. 94%)

You have some weird takes on things.

Interesting article about Tesla and Berlin:

https://cleantechnica.com/2019/11/17/a-gigafactory-for-berlin/

https://cleantechnica.com/2019/11/17/a-gigafactory-for-berlin/

ReflexFunds

Active Member

All three packaging type has improved to the point where cooling and so aging is not an issue any more. To be more precise pouch cell has the best geometry for cooling as it is a rectangle prism shape so its thickness can be sized arbitrarily and can have a large cooling surface if needed. Porsche Taycan uses pouch cells from LG chem for example and has no cooling or performance problems. I will show the longevity below. Prismatic cells have no issues as well, BMW i3 from 2014 was able to take 2C charge which Tesla wasn't able to achieve until the Model 3 v3 charging.

Tesla cars aren't the safest on the road, but this isn't the topic now. (look up Mazda 3 on EuroNCAP and compare them)

I don't see everyone else struggling. BMW had no issues with their prismatic desing since 2014 for example. When you say efficiency. Most car makers have efficient batteries. That's not the showstopper. The efficiency of the pouch cells can easily be increased by using thicker copper layers. (the volume of the cylindrical cell would increase faster with thicker copper). Look at the internal resistance of the following batteries: pouch has lower energy density but the internal resistance is 40 times less compared to the cylindrical.The density and internal resistance can be scaled by design inverse proportionally.

View attachment 478601

Source: Accelerated Internal Resistance Measurements of Lithium-Ion Cells to Support Future End-of-Life Strategies for Electric Vehicles

You are refering to consumer electronics.

Automotive pouch/prismatic cells are sealed in a metalic box. There is no such issue.

Battery management is not rocket science. The researchers, or better, the cell testers give characteristic maps to the software developer who runs optimization algorythms to make the best use of the battery. It is the cell testing that has to be done correctly, software is easy.

Economics: Why does the Audi E-tron with ~93kWh battery cost less than the Model X with 100kWh yet is has more features and finer material? I'm not sure there is a big cost advantage to Tesla regarding the battery. VW claims it’s buying a $100 kWh battery. Cylindrical is cheaper to manufacture but not much fun to build the pack. Complicated cooling system.

(BMW i3 has a carbon fibre chassis and a factory with fully renewable energy so that hard to compare to Tesla)

As for energy density Jack Rickard measured 243 Wh/kg for the Model 3 cells. (I don't have the volumetric energy density for the Tesla cell though. If I use 24.25mm^3 for cell volume and 17.3Wh/cell, the volumetric density comes to 713 Wh/L) Compare this to CATL:

CATL’s NCM 523 battery cells (available since 2017):

Prismatic format: 235 Wh/kg and 570 Wh/L

Pouch format: 250 Wh/kg and 530 Wh/L

CATL’s NCM 811 battery cells, since 2019:

Prismatic format: 270 Wh/kg and 660 Wh/L

Pouch format: 300 Wh/kg and 700 Wh/L

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Additionally the cobalt content of the NMC 811 is similar to Tesla's NCA.

One more thing: battery degradation.

Tesla batteries have the cycle life of around 800. NCM usually has much higher cycle life, around 1500.

This article says about Tesla:

"Well, according to lithium-ion battery cells studies, after 500-800 charging cycles and 100,000 to 150.000 miles a battery’s charging capacity drops to around 70%. "

Tesla Batteries Last Forever (Basically)

What is the charge/discharge cycle durability of Tesla's 2170 cells? - Quora

Compare that to CATL's 1800 charge cycle with the capacity drop to 80%:

CATL achieves 304 Wh/kg in new battery cells - PushEVs

Sorry there is so much wrong or completely missing the point here that I'm sceptical it is just misunderstanding.

Among your various claims you are honestly trying to claim E-tron has better powertrain tech than Model X because the only relevant data point is base $ price of the car (and not powertrain performance, efficiency and production cost), battery management software is easy, battery/powertrain efficiency, size and cost are irrelevant, Tesla customers are all lying about their limited degredation and cycle life, NHTSA comprehensive crash fatality data and government safety test data are fake etc.

Much of the rest including cobalt content is addressed in the prior post i linked to which i doubt you read.

Regarding CATL's lab based energy density - this is not relevant until they can get costs to the point where the cell is competitive for mass production.

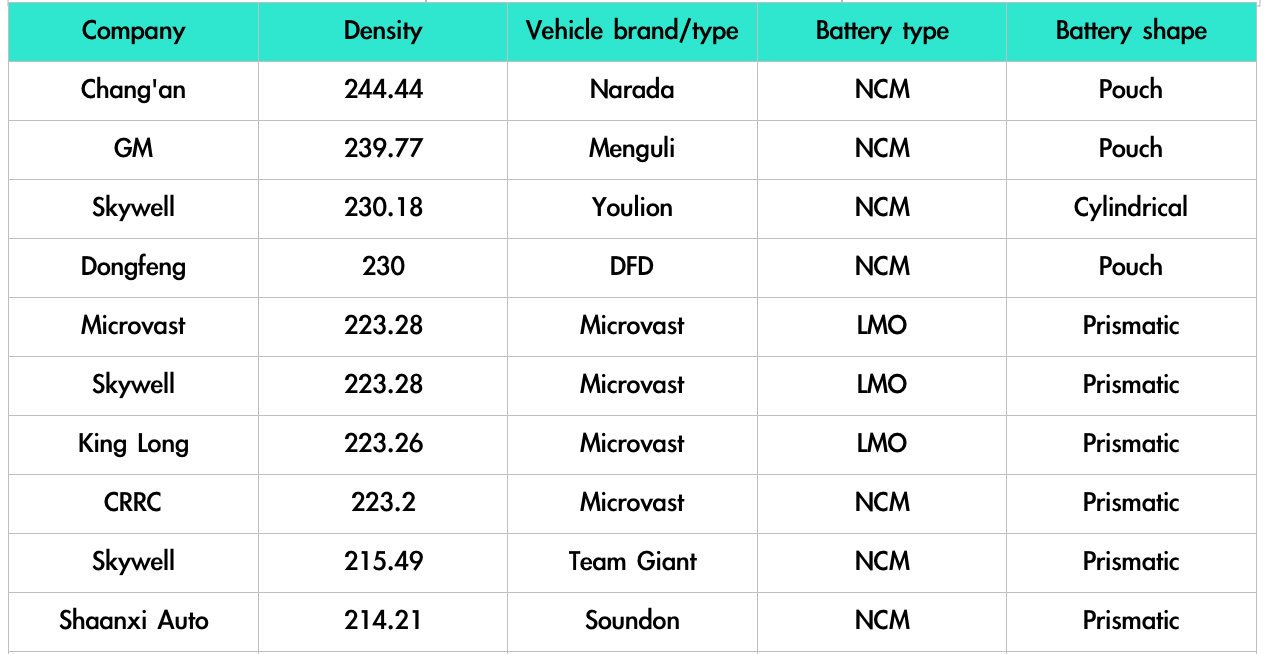

These are the actual leading cell energy densities in production in China as at September 2019. But volumetric volume density where cylindrical has the advantage also makes a lot of difference for reducing pack costs. And ultimately what really matters is production cost per KWh:

Can't wait for the Cybrtrk reveal. Finally no more Mach-E talk

Going back to the thread - anyone knows what happened with the Insideevs monthly EV sales estimate? We are mid November and there is no October estimate yet.

InsideEVs lost their most important datasources. The US is increasingly a black box based on anecdotes. It'd also be meaningless because it's been abnormally supply-starved this quarter.

Wait two weeks - we'll have good EU data at least (QoQ November numbers, plus the three realtime countries).

Last edited:

2virgule5

Member

Production delays for the Taycan’t apparently...

Tek.no - Tester, guider, teknologi

What happened to experienced OEM ?

?

Tek.no - Tester, guider, teknologi

What happened to experienced OEM

Man it seems we have a new member that is full of ...um..." Facts" that under examination are actually bullsugar.

Why do these same type of posters keep showing up?

Almost like they come from some type of farm.

A bot farm....maybe from some other country?

Why do these same type of posters keep showing up?

Almost like they come from some type of farm.

A bot farm....maybe from some other country?

Re-ran my OpenNY processing script for estimating the state's pricing and trim mix (pricing only accounts for trim and colour, not other options). The results:

07/2019: 417

Model 3: 317 / 76.0% :: ASP: $46744

LR AWD/P: 201 / 63.4% :: ASP: $50650

LR RWD: 7 / 2.2% :: ASP: $44714

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 109 / 34.4% :: ASP: $39673

Model S: 43 / 10.3%

--: 7 / 16.3%

LR: 31 / 72.1%

P: 5 / 11.6%

Model X: 57 / 13.7%

--: 11 / 19.3%

LR: 36 / 63.2%

P: 10 / 17.5%

08/2019: 534

Model 3: 401 / 75.1% :: ASP: $46485

LR AWD/P: 247 / 61.6% :: ASP: $50640

LR RWD: 8 / 2.0% :: ASP: $44593

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 146 / 36.4% :: ASP: $39558

Model S: 61 / 11.4%

--: 5 / 8.2%

LR: 47 / 77.0%

P: 9 / 14.8%

Model X: 72 / 13.5%

--: 11 / 15.3%

LR: 54 / 75.0%

P: 7 / 9.7%

09/2019: 809

Model 3: 624 / 77.1% :: ASP: $47684

LR AWD/P: 429 / 68.8% :: ASP: $51146

LR RWD: 6 / 1.0% :: ASP: $44666

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 189 / 30.3% :: ASP: $39921

Model S: 53 / 6.6%

--: 10 / 18.9%

LR: 31 / 58.5%

P: 12 / 22.6%

Model X: 132 / 16.3%

--: 12 / 9.1%

LR: 99 / 75.0%

P: 21 / 15.9%

10/2019: 200

Model 3: 172 / 86.0% :: ASP: $46842

LR AWD/P: 106 / 61.6% :: ASP: $51141

LR RWD: 0 / 0.0% :: ASP: N/A

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 66 / 38.4% :: ASP: $39936

Model S: 12 / 6.0%

--: 2 / 16.7%

LR: 8 / 66.7%

P: 2 / 16.7%

Model X: 16 / 8.0%

--: 7 / 43.8%

LR: 8 / 50.0%

P: 1 / 6.2%

So no shock that it's down QoQ. I'm surprised that there was enough supply to support that many sales. I almost hesitate posting this just because I fully expect people to deliberately conflate supply limitations with demand, as they bloody always do.

Note that these are just estimates; the OpenNY data is really messy (full of errors) and you have to try to use logic to figure out what's what based on date, weight, VIN, and drive. And there's no way at all to separate AWD from P for Model 3 (you can get it from the VIN for S/X). "--" on S/X can be from either an unexpectedly low listed weight (<4800lbs for S, <5300 for X), or a drive category in the VIN other than 2 or 4. Probably either older inventory, or (common) registration errors.

07/2019: 417

Model 3: 317 / 76.0% :: ASP: $46744

LR AWD/P: 201 / 63.4% :: ASP: $50650

LR RWD: 7 / 2.2% :: ASP: $44714

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 109 / 34.4% :: ASP: $39673

Model S: 43 / 10.3%

--: 7 / 16.3%

LR: 31 / 72.1%

P: 5 / 11.6%

Model X: 57 / 13.7%

--: 11 / 19.3%

LR: 36 / 63.2%

P: 10 / 17.5%

08/2019: 534

Model 3: 401 / 75.1% :: ASP: $46485

LR AWD/P: 247 / 61.6% :: ASP: $50640

LR RWD: 8 / 2.0% :: ASP: $44593

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 146 / 36.4% :: ASP: $39558

Model S: 61 / 11.4%

--: 5 / 8.2%

LR: 47 / 77.0%

P: 9 / 14.8%

Model X: 72 / 13.5%

--: 11 / 15.3%

LR: 54 / 75.0%

P: 7 / 9.7%

09/2019: 809

Model 3: 624 / 77.1% :: ASP: $47684

LR AWD/P: 429 / 68.8% :: ASP: $51146

LR RWD: 6 / 1.0% :: ASP: $44666

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 189 / 30.3% :: ASP: $39921

Model S: 53 / 6.6%

--: 10 / 18.9%

LR: 31 / 58.5%

P: 12 / 22.6%

Model X: 132 / 16.3%

--: 12 / 9.1%

LR: 99 / 75.0%

P: 21 / 15.9%

10/2019: 200

Model 3: 172 / 86.0% :: ASP: $46842

LR AWD/P: 106 / 61.6% :: ASP: $51141

LR RWD: 0 / 0.0% :: ASP: N/A

MR: 0 / 0.0% :: ASP: N/A

SR-/+: 66 / 38.4% :: ASP: $39936

Model S: 12 / 6.0%

--: 2 / 16.7%

LR: 8 / 66.7%

P: 2 / 16.7%

Model X: 16 / 8.0%

--: 7 / 43.8%

LR: 8 / 50.0%

P: 1 / 6.2%

So no shock that it's down QoQ. I'm surprised that there was enough supply to support that many sales. I almost hesitate posting this just because I fully expect people to deliberately conflate supply limitations with demand, as they bloody always do.

Note that these are just estimates; the OpenNY data is really messy (full of errors) and you have to try to use logic to figure out what's what based on date, weight, VIN, and drive. And there's no way at all to separate AWD from P for Model 3 (you can get it from the VIN for S/X). "--" on S/X can be from either an unexpectedly low listed weight (<4800lbs for S, <5300 for X), or a drive category in the VIN other than 2 or 4. Probably either older inventory, or (common) registration errors.

Last edited:

JRP3

Hyperactive Member

ook at the internal resistance of the following batteries: pouch has lower energy density but the internal resistance is 40 times less compared to the cylindrical

You're comparing power cells to energy cells, it has nothing to do with the cell format.

Garbage. Real world has shown Tesla NCA cells hold capacity much better than that at over 300,000 miles. You aren't arguing with the dummies at Seeking Alpha here, you'll need to do much better.One more thing: battery degradation.

Tesla batteries have the cycle life of around 800. NCM usually has much higher cycle life, around 1500.

This article says about Tesla:

"Well, according to lithium-ion battery cells studies, after 500-800 charging cycles and 100,000 to 150.000 miles a battery’s charging capacity drops to around 70%. "

Last edited:

Sean Wagner

Member

Can't wait for the Cybrtrk reveal. Finally no more Mach-E talk

And now, for something completely different.

A little factoid concerning the market for convertible bonds in China that I wanted to post here.

It cought my eye because the example in question relates directly to GF3's Chinese location. Viz:

China’s $1tn scramble for convertible bonds reflects hot market | Nov 12 2019

Bidding for new deals including Shanghai Pudong Development Bank stuns investors

...

But when investors last month placed more than $1tn worth of orders for a convertible bond issued by Shanghai Pudong Development Bank, about 140 times the $7bn raised, it was enough to shock even the most seasoned China investor.

...

Subscribe to read | Financial Times

It pays to read the article concerning specifics of the Chinese market for such bond offerings. But [my take] the result does look like the same story as everywhere: oodles of cash chasing limited opportunities.

Krugerrand

Meow

Color me shocked! The Chevy Corvette wins COTY!

The Chevrolet Corvette is the 2020 MotorTrend Car of the Year - Motor Trend

"Sometimes, a car comes along that leaves the automotive landscape different than before. In today's Silicon Valley parlance, we'd be tempted to term such a car a "disrupter." The last car to so radically shift the car world was the Tesla Model S, our 2013 Car of the Year.

This time around, our 2020 MotorTrend Car of the Year, the Chevrolet Corvette, fully scrambles the order of things. Simply put, never before has so much four-wheeled exoticism been attainable for so little money. Or I should say, so much good exoticism.

Chevrolet Performance did not phone in the first-ever production mid-engine Corvette. It dialed it, massaged it, honed it, crafted the new 'Vette to the point of the nearly impossible. The eighth-generation car will bring people into dealerships who previously would never have come in. The mid-engine Corvette is a game changer, an inflection point, and a reminder that when Americans truly set our minds to a task, look out. For soon you'll be standing on the moon—or driving the sports car equivalent thereof.

What the —?

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M