Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

I think that’s Elon in the painting slaying the shorts!!

Trump administration has made several signals this weekend that they now realize how important it is that some sort of stimulus / unemployment benefits enhancement / eviction moratorium be continued, even suggesting that it be done ASAP so as to prevent a lapse.

Incompetence of the late realization aside, this could buoy macros if there is real movement towards the quick passage of a relief package.

Headwinds remain, however; Republicans want to pass something piecemeal, including a liability shield for businesses, which is a nonstarter for Democrats, whereas Democrats want something comprehensive to retain leverage. Also, it is unclear what type of payments Republicans want to offer Americans; there is talk of another round of direct stimulus in addition to unemployment enhancements, and the amount of the latter, expiring at $600 week, is also not known. Republicans want to bring that number down ($200 a week has been floated), a suggestion at which Democrats might also balk.

Incompetence of the late realization aside, this could buoy macros if there is real movement towards the quick passage of a relief package.

Headwinds remain, however; Republicans want to pass something piecemeal, including a liability shield for businesses, which is a nonstarter for Democrats, whereas Democrats want something comprehensive to retain leverage. Also, it is unclear what type of payments Republicans want to offer Americans; there is talk of another round of direct stimulus in addition to unemployment enhancements, and the amount of the latter, expiring at $600 week, is also not known. Republicans want to bring that number down ($200 a week has been floated), a suggestion at which Democrats might also balk.

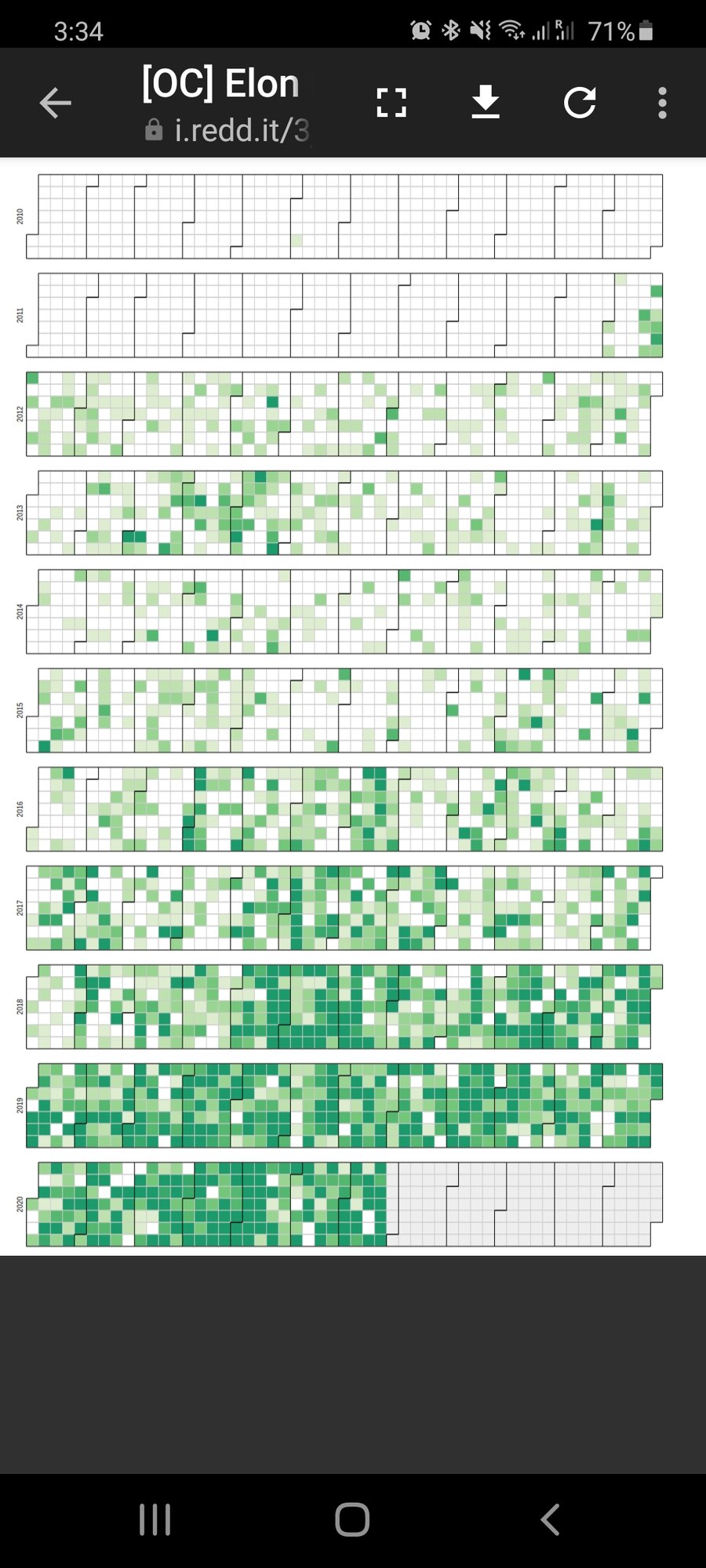

Weekend OT. Here's Elon's tweet frequency.

Source

[OC] Elon Musk daily number of tweets : dataisbeautiful

Source

[OC] Elon Musk daily number of tweets : dataisbeautiful

“The Seige of the Alamo” by Lajos MarkosI think that’s Elon in the painting slaying the shorts!!

"You may all go to hell and I will go to Texas".

- Davy Crockett to Tennessee, 1835

- Elon Musk to California, 2020

Last edited:

Too bad it’s racist.The nerd in me want the phrase to be:

"Pulling on All Poles"

An electric motor has multiple poles which are pulled by magnetic forces. Accurate phrase, but not familiar enough to catch on with the general public.

https://twitter.com/firstsquawk/status/1287381690705489921?s=21

Kudlow says coronavirus relief will include $1,200 checks and extension of eviction moratorium

Should lift macros Monday. (And gold).

Kudlow says coronavirus relief will include $1,200 checks and extension of eviction moratorium

Should lift macros Monday. (And gold).

More funds coming to RobinHood

ZachF

Active Member

I have nothing to add but this image on the twitter thread was funny.

We've had this brainstorming session before: Tesla, TSLA & the Investment World: the 2019-2020 Investors' Roundtable

And if those aren't good enough, how about:

- flux fields to the max

- reaching maximum flux

- she's gonna blow

I prefer “fluxing on all capacitors”

UkNorthampton

TSLA - 12+ startups in 1

Tesla, "Daily dividends of driving pleasure"

Daily dividends of driving DELIGHT - more D

or

driving DELIGHT Daily dividends

JusRelax

Active Member

A pretty compelling youtube video by Sovling the Money Problem on how Tesla and Tencent's partnership will facilitate domination in China:

Weekend OT.No, I’m not. This is my area of knowledge and I’ve been researching a bit on how it could be done.

It is not easier or even necessarily faster to laser cut, bend bulletproof stainless steel from a huge, heavy sheet into a vehicle body and just weld other parts to it than to stamp body panels and assemble the old fashion way.

The laser cutting machineS and bending machinesS/brakes pressES will have to be specially designed/adapted, robotS programmed, new racking designed and developed, new end of arm tooling designed and developed and several other things.

Never mind that the stainless steel is not an ‘off the shelf’ metal produced in large quantities as required for volume vehicle production. This basically means you have to find someone to add to/start a new business to make massive quantities of a new material (or do it themselves - *insert maniacal laugh*).

Never mind that any welding creates burn marks, some of which are highly likely to show on the exterior (ie, door seams) so now instead of painting you have to have some kind of ‘cleaning’ process (sand blasting? polishing?) to be done unless you’re going to leave it (for the OCD among us to complain).

All processes for this vehicle have never been done before. That means trial and error, time and money inefficiencies, mega multiple iterations and so on.

A body panel takes seconds to produce from coil to final piece. I guarantee the main truck panel will take minutes to produce. And they still have to produce the doors, tailgate and other individual parts. Those parts can’t be stamped because the material they’re intending to use is too hard and will wear out/break dies sets. Laser cutting a blank takes A LOT longer than stamping a blank.

Where time can be saved is ‘I think’ on assembly - eventually. But there isn’t enough information available yet to determine that. I’ve got a lot of ‘inside the panels’ questions.

I’m confident in the end they’ll revolutionize the whole process but they are quite literally starting from ‘I have an idea’ and not from ‘Let’s make a few changes to make this process better’.

Mark my words, we’ll be hearing about how hard it was to make CYBRTRCK in a future earnings call.

I'm no expert in stainless steel manufacturing, but I think Tesla could use multi-layer metals instead of 301 stainless steel. Look at the way stainless steel cookware is manufactured. Round shapes are not a problem.

All-Clad D5 vs. Copper Core: Differences, Similarities, Pros, Cons - Prudent Reviews

Some multi-ply cookware is 4 times harder than stainless steel, and is manufactured using titanium nanolayers NanoBond Story - Hestan Culinary.

You do realize your dividend payments, which are what you say add value to a stock, are also are just database entries?You do realize those are physical commodities that are used in electronics, jewellery, and other cases right? They have physical utility. My tesla stock isnt even printed on sheets of paper. its just a database entry.

If gold looked like dirt and had no physical uses at all, then yup, it would be worth sod all.

1. It’s not 301 steel.Weekend OT.

I'm no expert in stainless steel manufacturing, but I think Tesla could use multi-layer metals instead of 301 stainless steel. Look at the way stainless steel cookware is manufactured. Round shapes are not a problem.

All-Clad D5 vs. Copper Core: Differences, Similarities, Pros, Cons - Prudent Reviews

Some multi-ply cookware is 4 times harder than stainless steel, and is manufactured using titanium nanolayers NanoBond Story - Hestan Culinary.

2. Stamping equipment would be required.

Jack6591

Active Member

This was Lutz. Here is the article. Last 3 paragraphs.

Bob Lutz Talks Panel Gaps, Tesla, and Why Every Detail Matters

During the 1980s I was a Field Service Engineer working on IBM mainframe computers. Many of my associates derided the personal computers that IBM was developing for terminal emulation — kid stuff they would say. In reflection, it amazes me that obviously intelligent people could be so short sighted.

The pace of transition from mainframe computers to PCs and local area networks and finally to servers and the Internet was historic. I failed to envision the impact on mankind. However, it left an indelible impression on me; I would never again underestimate the evolution of technology.

Today, I work at an electric utility, surrounded by those that deride solar power. I always think, I’ve got a mainframe computer I could sell you.

Rivian to begin deliveries of electric pickup truck in June 2021 – TechCrunch

Rivian has started to run a pilot production line at its factory in Normal, Illinois, as the electric vehicle startup prepares to bring its pickup truck and SUV to market in summer 2021.

In an email sent to prospective customers, Rivian said deliveries of its R1T electric pickup truck will begin in June 2021. Deliveries of the R1S electric SUV will start in August 2021.

Rivian said in May that deliveries of the R1T and R1S would be pushed to 2021. It wasn’t clear — until today’s email — exactly when deliveries would begin.

Rivian has started to run a pilot production line at its factory in Normal, Illinois, as the electric vehicle startup prepares to bring its pickup truck and SUV to market in summer 2021.

In an email sent to prospective customers, Rivian said deliveries of its R1T electric pickup truck will begin in June 2021. Deliveries of the R1S electric SUV will start in August 2021.

Rivian said in May that deliveries of the R1T and R1S would be pushed to 2021. It wasn’t clear — until today’s email — exactly when deliveries would begin.

Krugerrand

Meow

Agree with most of what you say, especially that 2nd paragraph is very true.

But you know, they could've built Model 3 and Model Y concurrently in Shanghai, but didn't, and they could build 3+Y out concurrently in Berlin, but they're not doing that. If they built out both at the same time in Texas, ofc the Y should go up faster, but we don't really know the official plan.

My reason for having reservations about Y being built in Texas in 2021 is because I think the only ways to do so are:

- Build out Cybertruck and Y concurrently, which we haven't seen before.

- Miss the Cybertruck target.

I’m not understanding the resistance to the logical.

They didn’t build simultaneously 3 and Y in China for at least the very basic reason, you don’t build a new vehicle for the first time on foreign soil. You need to build what you KNOW first there so that you can make money asap and not be dealing with all the unknowns of a new vehicle manufacturing from thousands of miles away. That’s suicide. You do the new stuff at ‘home’ first. They couldn’t possibly improve/iterate for Y production in China when they hadn’t even made the vehicle.

Now that they’ve worked a lot of kinks out in Y on Fremont, it becomes copy and paste in China with various efficiency iterations.

Second reason the ever important money issue; efficient spending of limited capital.

In Texas logically the first building should be with Y in mind so they can print money. Then when the groundwork of that is well on its way they can think about/integrate CYBRTRCK stuffs.

When I say simultaneously I don’t mean that to be exactly timed but rather staggered simultaneously. So before Y is completely done they start CYBRTRCK stuffs. And technically that’s what they’re doing in China. They started building for Y long before Model 3 lines were optimal. Model 3 in China still isn’t at full production capacity but the equipment for Y is going in. That’s what I mean and what I fully expect in Texas purely from a logical business standpoint.

JRP3

Hyperactive Member

So, we might as well keep 'firing on all cylinders

Tesla motive power still comes from cylinders, (cylindrical cells).

The nerd in me want the phrase to be:

"Pulling on All Poles"

An electric motor has multiple poles which are pulled by magnetic forces. Accurate phrase, but not familiar enough to catch on with the general public.

The general public may come up with completely different imagery than what you're imagining

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Locked

- Replies

- 11

- Views

- 10K

- Replies

- 6

- Views

- 5K

- Locked

- Poll

- Replies

- 1

- Views

- 12K