ken830

Model S 85, Model 3 Performance, Model X LongRange

WhiteP85... I'll admit that I don't know how far this will lead or whether or not we'll hit a solid wall, but here's what I'm thinking... The four lines in the cable only carry power and ground to the camera model, and a serial differential pair for the video stream from the camera module to the touchscreen CPU. I don't believe there is any communication from the touchscreen CPU to the camera module. Having said that, the Omnivision OV10630 default value on the TIMING_CTRL1D register is 0x40 (assuming the same as the OV10633) which means the mirror bits (bits [1:0]) are both 0 -- mirroring is disabled by default. This means that something in the camera module is setting that register -- and my guess was an onboard microcontroller.... Which brings me to this....

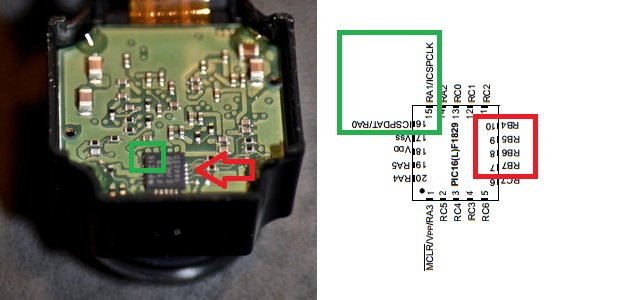

Artsci.. Thanks for the photos! At a quick glance, I see a Microchip PIC microcontroller (PIC16F1829) in a 20-pin QFN package. This microcontroller can be configured with up to two I2C ports on Port B:

SCL1 on pin 8 (RB6)

SDA1 on pin 10 (RB4)

SCL2 on pin 7 (RB7)

SDA2 on pin 9 (RB5)

I've highlighted these in red. Can you visually trace to see which pair goes to the OV10630?

The PIC microcontroller has program and data memory protection. If this is enabled, then, I'm afraid there's not much we can do short of replacing the PIC, but we'll have to somehow duplicate all of the other functions that it serves, which could be nothing or could be many. Before we can even consider that, we should see if the programming pins are broken-out to a connector footprint somewhere.. These are pins 15 and 16, which I've highlighted in green. From the photo, it looks like those two signals go straight to the back-side of the board. Any way to see the back-side of the board to follow those signals?

Artsci.. Thanks for the photos! At a quick glance, I see a Microchip PIC microcontroller (PIC16F1829) in a 20-pin QFN package. This microcontroller can be configured with up to two I2C ports on Port B:

SCL1 on pin 8 (RB6)

SDA1 on pin 10 (RB4)

SCL2 on pin 7 (RB7)

SDA2 on pin 9 (RB5)

I've highlighted these in red. Can you visually trace to see which pair goes to the OV10630?

The PIC microcontroller has program and data memory protection. If this is enabled, then, I'm afraid there's not much we can do short of replacing the PIC, but we'll have to somehow duplicate all of the other functions that it serves, which could be nothing or could be many. Before we can even consider that, we should see if the programming pins are broken-out to a connector footprint somewhere.. These are pins 15 and 16, which I've highlighted in green. From the photo, it looks like those two signals go straight to the back-side of the board. Any way to see the back-side of the board to follow those signals?