I am curious about some of the design choices of the Semi from a first principles‘ lens. So now I am going to nerd out and list questions and what I think the answers are. What do you think  are these the answers or do you have another interpretation?

are these the answers or do you have another interpretation?

1) Why are there continuous frame rails instead of a load bearing battery pack? As any engineer will tell you, a large tube (e.g. structural pack) is much much stronger than two small C sections by mass, so this choice added mass.

-answer: Tesla is working on a structural 4680-pack and doesn‘t want to expend energy on a temporary structural 2170 pack. So went with the proven design of old school frame rails that the other semis have. This might be why it turned out a little heavier than planned and not listing tractor weight yet.

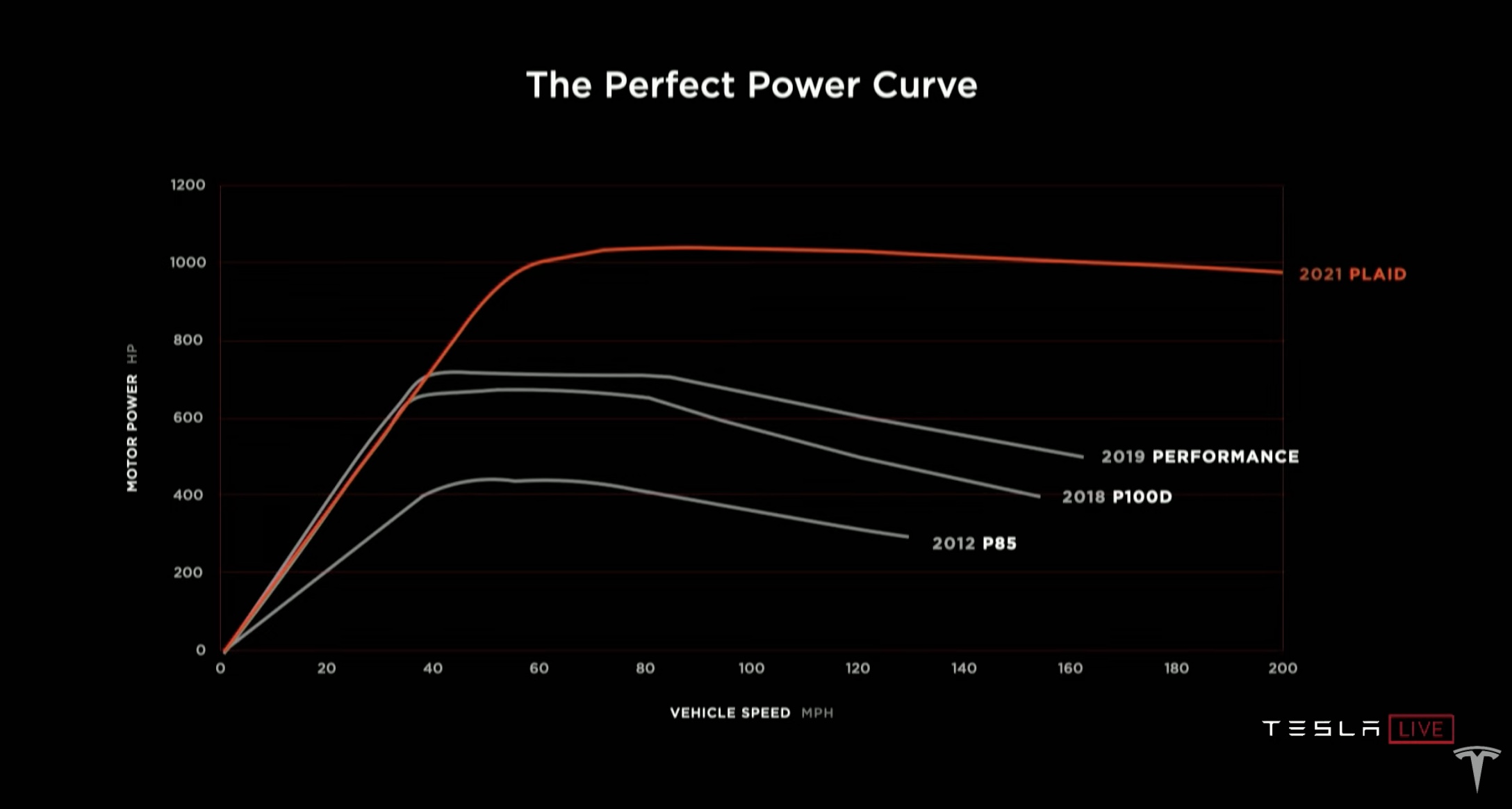

2) Why did they go from four M3-motors to there Plaid motors? and lost half of the coveted anti jack knifing torque vectoring that was previously advertised? And possibly increasing cost if 3 plaid motors would cost more than 4 M3 ditto?

-answer: I think it’s a consequence of point 1. With the chassis turning out a little heavier than planned they needed to hunt through the truck for other weight savings. Side benefit; with one motor and gearbox instead of two powering cruise, there is a tiny bit of lowered energy consumption, enabling the shedding of a few lbs of batteries. The exciting point is that if they keep this configuration when the structural pack comes, the truck will be even more badass. Maybe that’s where the 650 mile statement comes from?

3) Why 1000 V charging?

Answer: -thinner cables and fewer FETs save a few pounds. not much bit all little savings add up. Then you have thinner charge cables as a side benefit.

4) No AC charging. This is my guess. Haven’t seen the spec yet.

Resons: -with a battery 10 times the size of a Tesla car, think of your most powerful your AC outlet And divide your charge speed by 10. That’s one. The other is mass and cost of onboard charger.

5) No 400V DC Charging This is my guess too.

Reasons: Mass of DC-DC converter would defeat the purpose of going with 1000 V, which was to save a tiny bit of mass. Cost: if a customer had a route through a 400 V SC that was already truck sized (highly unlikely) would be cheaper to install a 1000 V stall there rather than putting a dc-dc converter in all the trucks. Likely will never be an issue bec there are almost no truck SC. So they’ll build 1000 V truck SC.

6) why did they lose the aero side skirts?

answer: -to have less Prius vibe and look more bad ass

1) Why are there continuous frame rails instead of a load bearing battery pack? As any engineer will tell you, a large tube (e.g. structural pack) is much much stronger than two small C sections by mass, so this choice added mass.

-answer: Tesla is working on a structural 4680-pack and doesn‘t want to expend energy on a temporary structural 2170 pack. So went with the proven design of old school frame rails that the other semis have. This might be why it turned out a little heavier than planned and not listing tractor weight yet.

2) Why did they go from four M3-motors to there Plaid motors? and lost half of the coveted anti jack knifing torque vectoring that was previously advertised? And possibly increasing cost if 3 plaid motors would cost more than 4 M3 ditto?

-answer: I think it’s a consequence of point 1. With the chassis turning out a little heavier than planned they needed to hunt through the truck for other weight savings. Side benefit; with one motor and gearbox instead of two powering cruise, there is a tiny bit of lowered energy consumption, enabling the shedding of a few lbs of batteries. The exciting point is that if they keep this configuration when the structural pack comes, the truck will be even more badass. Maybe that’s where the 650 mile statement comes from?

3) Why 1000 V charging?

Answer: -thinner cables and fewer FETs save a few pounds. not much bit all little savings add up. Then you have thinner charge cables as a side benefit.

4) No AC charging. This is my guess. Haven’t seen the spec yet.

Resons: -with a battery 10 times the size of a Tesla car, think of your most powerful your AC outlet And divide your charge speed by 10. That’s one. The other is mass and cost of onboard charger.

5) No 400V DC Charging This is my guess too.

Reasons: Mass of DC-DC converter would defeat the purpose of going with 1000 V, which was to save a tiny bit of mass. Cost: if a customer had a route through a 400 V SC that was already truck sized (highly unlikely) would be cheaper to install a 1000 V stall there rather than putting a dc-dc converter in all the trucks. Likely will never be an issue bec there are almost no truck SC. So they’ll build 1000 V truck SC.

6) why did they lose the aero side skirts?

answer: -to have less Prius vibe and look more bad ass

Last edited: