How much of a gap is there between the plastic well cover and the body? I'm thinking on covering the inside of the plastic with Resonix barrier sheets.I went back for work on the front wheel wells, wanted to share pictures. Am going back in a couple weeks for sound measurements (aiming same time and day of week as before measurements we already took), will share those as well.

Layperson's experience is that the front deadening helped with road noise and a resonant boominess. Am very pleased with the results so far, and am also going to try enemji's sound absorption mods next!

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MYLR7 Sound Deadening

- Thread starter dupeks

- Start date

GreenCoffee

Member

A 1db increase in sound level is usually the smallest increment that most people can hear a discernible difference, A 3db level increase is very noticeable, with a loudspeaker a 3db increase takes double the power to produce, there are many areas in this chart that average 3 to 6db decrease in sound levels, 6db increase used to be the level people would say that the sound level has doubled, I believe some are still using that figure while others argue a 10db level is a perceived doubling of the sound levels.ehh don't really see that much of a difference in the readings chart.

GreenCoffee

Member

I am getting ready to build a 2 story 2,400 sq ft. duplex with a 1,200 sq. ft. 3 bed 2 bath downstairs and an exact copy stacked on top, the owners want extensive sound proofing as they are both musicians who make their living playing the Viola with hours of daily practice.

I have been researching how to get the most bang for their buck (or least bang transmitting!)

4 things that one can do to mitigate sound transmission,

1. Decouple, this one yields a lot but not sure how you can incorporate this in a vehicle.

2. Mass, this is one of the most important things to do as the more mass an item has the less it can pass sound (except the lower frequencies)

3. Damping, works very well in reducing transmission of sound through the absorption of vibration energy that would turn a surface into a transducer

4. Absorption, works best with mid to higher frequencies and is a very important part of an entire system to mitigate sound transmission.

The sound deadening mats typically used in automotive work well because they address 2 of the 4 items very well, they add mass with their composite of a thin metal sheet and the layer of vinyl, this property also adds damping.

There are few cavities you can fill with absorptive materials (doors being the only ones that come to mind without losing space) and i'm not sure you can get enough in to make a difference but I don't know?

I have been researching how to get the most bang for their buck (or least bang transmitting!)

4 things that one can do to mitigate sound transmission,

1. Decouple, this one yields a lot but not sure how you can incorporate this in a vehicle.

2. Mass, this is one of the most important things to do as the more mass an item has the less it can pass sound (except the lower frequencies)

3. Damping, works very well in reducing transmission of sound through the absorption of vibration energy that would turn a surface into a transducer

4. Absorption, works best with mid to higher frequencies and is a very important part of an entire system to mitigate sound transmission.

The sound deadening mats typically used in automotive work well because they address 2 of the 4 items very well, they add mass with their composite of a thin metal sheet and the layer of vinyl, this property also adds damping.

There are few cavities you can fill with absorptive materials (doors being the only ones that come to mind without losing space) and i'm not sure you can get enough in to make a difference but I don't know?

Rockwool is what I heard would do a great job to absorb sound when filled in the space between the top floor and lower ceiling. Of course decoupling the floor and the ceiling is the first step.I am getting ready to build a 2 story 2,400 sq ft. duplex with a 1,200 sq. ft. 3 bed 2 bath downstairs and an exact copy stacked on top, the owners want extensive sound proofing as they are both musicians who make their living playing the Viola with hours of daily practice.

I have been researching how to get the most bang for their buck (or least bang transmitting!)

4 things that one can do to mitigate sound transmission,

1. Decouple, this one yields a lot but not sure how you can incorporate this in a vehicle.

2. Mass, this is one of the most important things to do as the more mass an item has the less it can pass sound (except the lower frequencies)

3. Damping, works very well in reducing transmission of sound through the absorption of vibration energy that would turn a surface into a transducer

4. Absorption, works best with mid to higher frequencies and is a very important part of an entire system to mitigate sound transmission.

The sound deadening mats typically used in automotive work well because they address 2 of the 4 items very well, they add mass with their composite of a thin metal sheet and the layer of vinyl, this property also adds damping.

There are few cavities you can fill with absorptive materials (doors being the only ones that come to mind without losing space) and i'm not sure you can get enough in to make a difference but I don't know?

Given how flat the underbody is, I wonder if it would practical or valuable to cover it in a layer of MLV, with a foam layer in between to decouple from the metal. I'd be willing to try it if there were no warranty concerns but I doubt that would be the case.

GreenCoffee

Member

I have a plan that is extensive starting with a double 3/4" subfloor on top with green glue in between, rock wool insulation, under that drywall hat channel with isolation clips and 2 layers of 5/8" drywall, green glue in between, dropping in a 2 x 10 second ceiling below that with an air gap as we are starting with a 10' ceiling downstairs, will fill with more rock wool and finish the whole thing off in 5/8" drywall, should take care of the foot fall noise and most everything else as well, looking for plus 70 stc when done.Rockwool is what I heard would do a great job to absorb sound when filled in the space between the top floor and lower ceiling. Of course decoupling the floor and the ceiling is the first step.

When I asked about foam and rockwool they noted that both can help (adding basically anything helps with absorption). In their typical approach they seldom add rockwool because there isn't a huge amount of open space and the end result is cleaner with layered MLV and foam. Rather than spend time adding rockwool they suggested spending more time covering a larger surface of the car (in the order: trunk/rear wheel wells, front wheel wells, floor).Ask them about my Mod. Definitely would love to hear their opinion on what I did from someone who actually does this for a living.

My personal take -- I got the sense they believed most of the benefit was from the "mass" effect of the carefully installed MLV layered with foam for dampening. It's possible given the minimalistic upholstery on Tesla vehicles that adding rockwool etc. would help with certain frequencies.

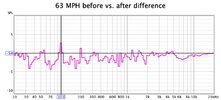

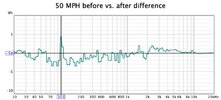

Came back for measurements after the front-end work. See attached for SPL C-weighted charts + SPL-A weighted average dB reading (in the box)

Impact was not as big as initial trunk+back wheel well work, but it was noticeable. Very happy with the result

Impact was not as big as initial trunk+back wheel well work, but it was noticeable. Very happy with the result

Attachments

No, it didn't eliminate it but the combined effort helped a good amount. I would say that 5/6" OD vinyl tubing + 3d printed hatch stops + hatch stop adjustment solved most of the "booming" problem for me. It's possible sound deadening the trunk and wheel wells also helped by reducing sound transmission. I still experience occasional booming when riding over certain rough road surfaces at approx 30mph, but it's pretty minor compared to how it was originally.@dupeks Does this eliminate that "booming" noise?

Sound deadening the wheel wells and trunk primarily lessened road/outside noise and perhaps helped reduce resonance/reflections.

REX88

Member

For booming sound. I used Dyanpad bought Amazon. Cover it all over the wheel well on both sides & some left over for the Truck tub. It reduces the noise overall level by 2db on avg on a 75MPH on an unsmooth highway. $120 and 1 hr of your time. I bought this for the boomy sound when driving 30-40MPH, and it reduces it.@dupeks Does this eliminate that "booming" noise?

I was surprise that even the electric motor high pitch when you step on the accesslrator is reduce significantly (becomes very faint)

Have tried other ways, and the dynapd was the most noticeable success to absorb the low frequency (it was design for that)

FYI the STC number is derived from sound attenuation values tested at sixteen standard frequencies from 125 Hz to 4000 Hz. That means that low bass, which has the longest waveform and is the most penetrative of walls, is NOT covered by STC measurements. By "low bass", I mean 20Hz to about 120 HZ.I have a plan that is extensive starting with a double 3/4" subfloor on top with green glue in between, rock wool insulation, under that drywall hat channel with isolation clips and 2 layers of 5/8" drywall, green glue in between, dropping in a 2 x 10 second ceiling below that with an air gap as we are starting with a 10' ceiling downstairs, will fill with more rock wool and finish the whole thing off in 5/8" drywall, should take care of the foot fall noise and most everything else as well, looking for plus 70 stc when done.

All those low frequencies requires more than 2” thick sound absorption and deadening. That is why large limousines are quiter as that can be included in the extra spaceFYI the STC number is derived from sound attenuation values tested at sixteen standard frequencies from 125 Hz to 4000 Hz. That means that low bass, which has the longest waveform and is the most penetrative of walls, is NOT covered by STC measurements. By "low bass", I mean 20Hz to about 120 HZ.

GreenCoffee

Member

The second drop ceiling will serve best to decouple the foot fall noises which is the hardest to control, it will also allow all mechanical/electrical/plumbing to be routed so as no penetrations will be made to the actual ceiling/floor structure in between units, now when one of them fires up the pipe organ all bets are off!FYI the STC number is derived from sound attenuation values tested at sixteen standard frequencies from 125 Hz to 4000 Hz. That means that low bass, which has the longest waveform and is the most penetrative of walls, is NOT covered by STC measurements. By "low bass", I mean 20Hz to about 120 HZ.

Yes, having double walls (or ceilings) is generally the best way to attenuate those long waveforms. Mass Loaded Vinyl, heavy dense products, and air gaps - they all help.The second drop ceiling will serve best to decouple the foot fall noises which is the hardest to control, it will also allow all mechanical/electrical/plumbing to be routed so as no penetrations will be made to the actual ceiling/floor structure in between units, now when one of them fires up the pipe organ all bets are off!

I chose to use this old thread since my case is close enough.

Also my plan was to reduce annoying road/tire noise in my MYLR -22 cabin. Step one was to concentrate on trunk, rear wheel wells (inside) and doors. For the trunk I used 3mm butyl-aluminum -sheets on bottom and 8mm multi layer absorption sheets on top. For the doors I used 2mm butyl-aluminum sheets on bottom and 6,5mm multi layer absorption sheets on top. In addition, for the door plastic covers I used some pieces of 2mm butyl-aluminum sheets and whole inner part of the plastic was covered with profiled PU-foam.

The whole project took me two (12h) days but the results are not yet satisfying. Doors feel really solid and they close nice 'thud', also the overall feeling of panels is solid. At least they won't resonate anymore. Total weight of insulation and absorption material was around 90 lbs. I still have plans to do at least wheel wells on outside because the effect was not big enough.

Also my plan was to reduce annoying road/tire noise in my MYLR -22 cabin. Step one was to concentrate on trunk, rear wheel wells (inside) and doors. For the trunk I used 3mm butyl-aluminum -sheets on bottom and 8mm multi layer absorption sheets on top. For the doors I used 2mm butyl-aluminum sheets on bottom and 6,5mm multi layer absorption sheets on top. In addition, for the door plastic covers I used some pieces of 2mm butyl-aluminum sheets and whole inner part of the plastic was covered with profiled PU-foam.

The whole project took me two (12h) days but the results are not yet satisfying. Doors feel really solid and they close nice 'thud', also the overall feeling of panels is solid. At least they won't resonate anymore. Total weight of insulation and absorption material was around 90 lbs. I still have plans to do at least wheel wells on outside because the effect was not big enough.

Attachments

-

IMG_20230917_180815.jpg244.3 KB · Views: 87

IMG_20230917_180815.jpg244.3 KB · Views: 87 -

IMG_20230917_161928.jpg641.6 KB · Views: 89

IMG_20230917_161928.jpg641.6 KB · Views: 89 -

IMG_20230917_152817.jpg482.3 KB · Views: 80

IMG_20230917_152817.jpg482.3 KB · Views: 80 -

IMG_20230917_150800.jpg342.7 KB · Views: 87

IMG_20230917_150800.jpg342.7 KB · Views: 87 -

IMG_20230917_133338.jpg386 KB · Views: 82

IMG_20230917_133338.jpg386 KB · Views: 82 -

IMG_20230917_122252.jpg378.9 KB · Views: 79

IMG_20230917_122252.jpg378.9 KB · Views: 79 -

IMG_20230917_120005.jpg452.4 KB · Views: 84

IMG_20230917_120005.jpg452.4 KB · Views: 84 -

IMG_20230917_112443.jpg434.4 KB · Views: 90

IMG_20230917_112443.jpg434.4 KB · Views: 90 -

IMG_20230916_223305.jpg446.5 KB · Views: 87

IMG_20230916_223305.jpg446.5 KB · Views: 87 -

IMG_20230916_115820.jpg360.5 KB · Views: 96

IMG_20230916_115820.jpg360.5 KB · Views: 96

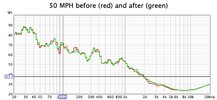

Here are the measurements before and after.

I used Room EQ Wizard + UMIK-1 + laptop for measurements. The microphone is calibrated but I still checked the levels by playing pink noise through my Tesla sound system (volume level was selected the same in both cases). This is not necessary, but I just wanted to make sure that the mic was recording same levels both times.

I attached the mic on the front passenger seat at ear level and recorded the SPL on 50MPH (80KMPH) and 63MPH (100KMPH). One measurement took about 30s (system made around 50 averaging). I chose the same locations on freeway in both measurements. Some reduction in noise levels (2-3dB) can be seen in graphs but I would still prefer more damping. These effects were quite small. Strange is the boost peak at 50mph graph, it was also present when I measured multiple 50MPH locations, for 63MPH peak is smaller but still there. However, it's not probably so loud in real life since human hearing sensitivity is much lower on lower frequencies.

I could have done measurements also on back seat, maybe the trunk deadening is stronger there. Well, that's too late now

Last graph could be the goal when making sound deadening against road noise. This graph tells the noise difference between old rough asphalt and new smooth one which were measured one after the other. In real life the difference was HUGE and in the future I'm hoping to get close to this kind of effects. Maybe I'm dreaming

I used Room EQ Wizard + UMIK-1 + laptop for measurements. The microphone is calibrated but I still checked the levels by playing pink noise through my Tesla sound system (volume level was selected the same in both cases). This is not necessary, but I just wanted to make sure that the mic was recording same levels both times.

I attached the mic on the front passenger seat at ear level and recorded the SPL on 50MPH (80KMPH) and 63MPH (100KMPH). One measurement took about 30s (system made around 50 averaging). I chose the same locations on freeway in both measurements. Some reduction in noise levels (2-3dB) can be seen in graphs but I would still prefer more damping. These effects were quite small. Strange is the boost peak at 50mph graph, it was also present when I measured multiple 50MPH locations, for 63MPH peak is smaller but still there. However, it's not probably so loud in real life since human hearing sensitivity is much lower on lower frequencies.

I could have done measurements also on back seat, maybe the trunk deadening is stronger there. Well, that's too late now

Last graph could be the goal when making sound deadening against road noise. This graph tells the noise difference between old rough asphalt and new smooth one which were measured one after the other. In real life the difference was HUGE and in the future I'm hoping to get close to this kind of effects. Maybe I'm dreaming

Attachments

ilovecoffee

Member

I chose to use this old thread since my case is close enough.

Also my plan was to reduce annoying road/tire noise in my MYLR -22 cabin. Step one was to concentrate on trunk, rear wheel wells (inside) and doors. For the trunk I used 3mm butyl-aluminum -sheets on bottom and 8mm multi layer absorption sheets on top. For the doors I used 2mm butyl-aluminum sheets on bottom and 6,5mm multi layer absorption sheets on top. In addition, for the door plastic covers I used some pieces of 2mm butyl-aluminum sheets and whole inner part of the plastic was covered with profiled PU-foam.

The whole project took me two (12h) days but the results are not yet satisfying. Doors feel really solid and they close nice 'thud', also the overall feeling of panels is solid. At least they won't resonate anymore. Total weight of insulation and absorption material was around 90 lbs. I still have plans to do at least wheel wells on outside because the effect was not big enough.

Wow that's quite the undertaking. Good job.

If it were me I wouldn't focus on the doors. The resonance in this car I feel all starts at the suspension and then is worsened by the rigidity of the structure because of the battery.

I've seen people apply deadening material to the exterior of the wheel wells (behind the covers) in some Chinese forums (but I don't know much more because Google Translate only goes so far) and I think someone here has also. I don't know what effect weather has on butyl but that to me seems like a logical next step if you want to take it further.

Just as an aside did you ever modify the hatch door with vinyl tubing or make rigid hatch stops? It's uncanny how much that hatch door flex adds to low frequency resonance inside.

Including also the doors improve the quality of the sound system so that's another reason for door deadening.

The exterior wheel wells is surely my next step but let's see when I have time. Butyl is commonly used in exterior of wheel wells here in Finland where the temperatures vary between -30C to +30 and snow and moisture are present.

I haven't used the vinyl tubing since the low noises haven't disturbed me yet. Road noise frequencies that bother me most are somewhere 600Hz and up.

The exterior wheel wells is surely my next step but let's see when I have time. Butyl is commonly used in exterior of wheel wells here in Finland where the temperatures vary between -30C to +30 and snow and moisture are present.

I haven't used the vinyl tubing since the low noises haven't disturbed me yet. Road noise frequencies that bother me most are somewhere 600Hz and up.

ilovecoffee

Member

Including also the doors improve the quality of the sound system so that's another reason for door deadening.

The exterior wheel wells is surely my next step but let's see when I have time. Butyl is commonly used in exterior of wheel wells here in Finland where the temperatures vary between -30C to +30 and snow and moisture are present.

I haven't used the vinyl tubing since the low noises haven't disturbed me yet. Road noise frequencies that bother me most are somewhere 600Hz and up.

Ah ok, interesting to know. I'm in Canada so similar weather conditions. I may do the exterior of the wheel wells as well.

Regarding the vinyl tubing, since it's such a minor modification and you went this far, I would still suggest trying it since it only takes 10 minutes to put ~8mm tubing in the gasket seal. 600hz sounds mostly like wind noise or engine whine, it's quite a high frequency are you sure that's what you mean? Online Tone Generator - generate pure tones of any frequency

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 13

- Views

- 5K

- Replies

- 58

- Views

- 8K

- Replies

- 7

- Views

- 2K