Aluminum wire is prone to oxide buildup, which provides a higher resistance and risk of fire. It also expands and contracts more with heat than copper and can lead to loose connections, arcing and risk of fire.thanks for the reply. I'll have to check back my HPWC gen 1 manual. I fairly certain aluminum was ok but that being 10 years ago, I might be wrong obviously. In any case, for any electrical number, a smaller number is bigger guage.If I recall properly we used size 0 or 1.

Howerver, just to understand, what issues could arise?

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Tesla Universal Wall Connector

- Thread starter MP3Mike

- Start date

Note:...

Love that box, though. "Made on Earth for Humans." So, they threw that "lbf" in there to handle the use case on Mars?

Their printing on the outside of the box -

Got you to thinking outside of the box.

Here’s the cable. It’s evening and dark so I’ll wait for tomorrow to read the sizeAluminum wire is prone to oxide buildup, which provides a higher resistance and risk of fire. It also expands and contracts more with heat than copper and can lead to loose connections, arcing and risk of fire.

Attachments

The two Universal Wall Connectors are Installed! In background, charging the Model X; on left, ready to charge the Model S

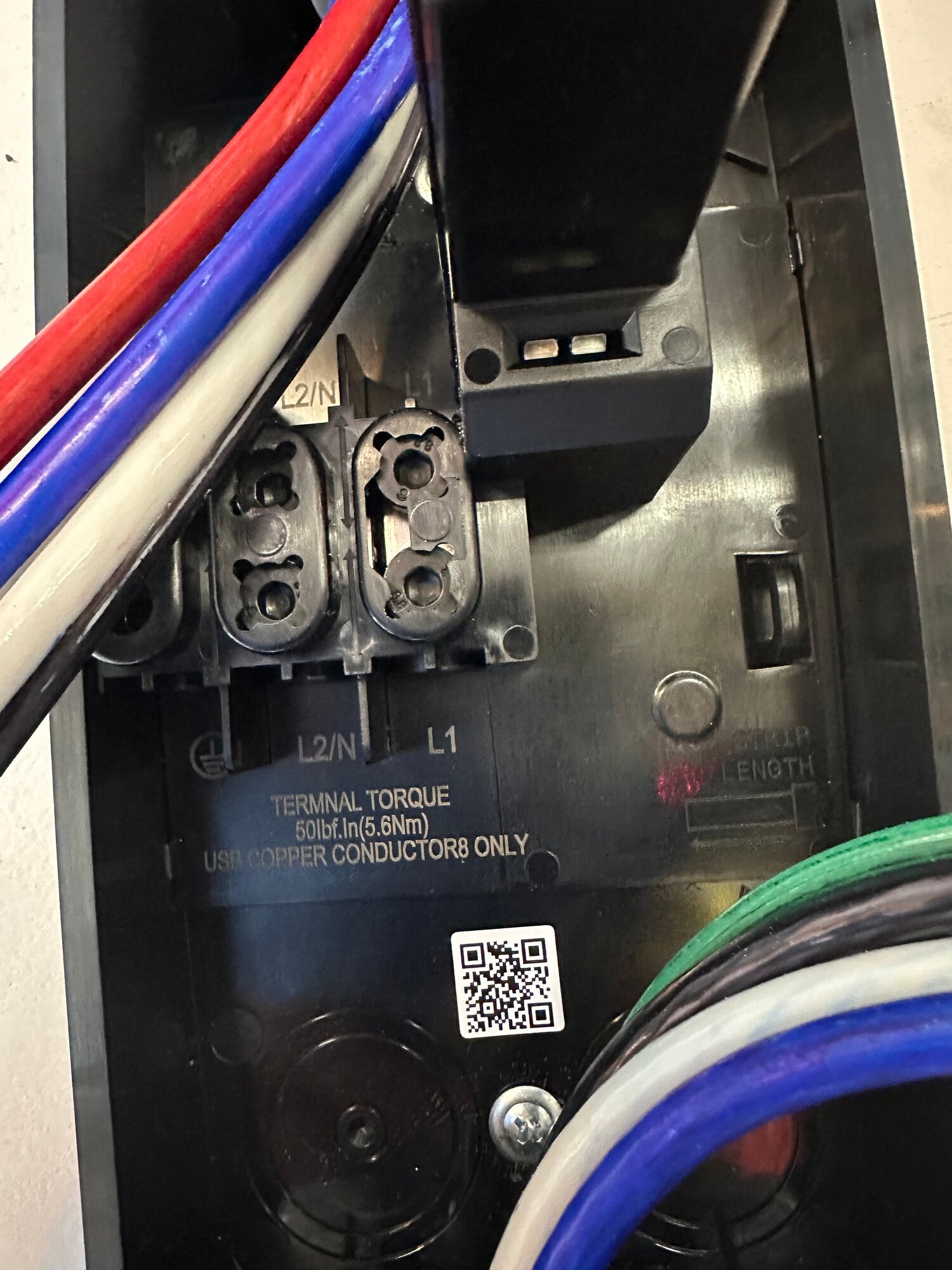

That "USB" and "Conductor8" in their ignominy, and the "lbf.in" remains there. BUT: my electrician did a "Whoa!" upon seeing the lug nomenclature, as shown in the photo below. He said that that is contrary to all standard siting; that the uniform placement for 240V always is (left to right) Ground - L1 - L2, as opposed to this G-2-1. He bopped his apprentice for having switched the wires....until Junior showed him he was indeed following Tesla's map!

That "USB" and "Conductor8" in their ignominy, and the "lbf.in" remains there. BUT: my electrician did a "Whoa!" upon seeing the lug nomenclature, as shown in the photo below. He said that that is contrary to all standard siting; that the uniform placement for 240V always is (left to right) Ground - L1 - L2, as opposed to this G-2-1. He bopped his apprentice for having switched the wires....until Junior showed him he was indeed following Tesla's map!

Last edited:

tivoboy

Active Member

Not sure where the country of manufacture is, but it would seem that the copy got garbled in transmission somewhere, either engineering spec or printing. and it should read “USE COPPER CONDUCTORS ONLY”The two Universal Wall Connectors are Installed! In background, charging the Model X; on left, ready to charge the Model S

View attachment 980296View attachment 980297

That "USB" and "Conductor8" in their ignominy, and the "lbf.in" remains there. BUT: my electrician did a "Whoa!" upon seeing the lug nomenclature, as shown in the photo below. He said that that is contrary to all standard siting; that the uniform placement for 240V always is (left to right) Ground - L1 - L2, as opposed to this G-2-1. He bopped his apprentice for having switched the wires....until Junior showed him he was indeed following Tesla's map!View attachment 980298

So confused...BUT: my electrician did a "Whoa!" upon seeing the lug nomenclature, as shown in the photo below. He said that that is contrary to all standard siting; that the uniform placement for 240V always is (left to right) Ground - L1 - L2, as opposed to this G-2-1. He bopped his apprentice for having switched the wires....until Junior showed him he was indeed following Tesla's map!View attachment 980298

L1 and L2 are interchangeable on a split phase 240V system. Tesla has that order because it could be on a non-split phase circuit like 208V Wye where there is a neutral.

Why 5 wires? The wall connector doesn't use neutral, what is blue for (usually 3 phase)? Did they run wires in the top and bottom and use the UWC as a junction box?

Is power sharing configured or did you have lots of spare capacity?

Some of those wires run to the second charger; this way I didn’t need a junction box. There is just enough room on the right-hand side for that.

And when you’re power sharing/ganging up more than one of these, you and your assistant had better keep L1 and L2 not crossed!

And when you’re power sharing/ganging up more than one of these, you and your assistant had better keep L1 and L2 not crossed!

Last edited:

Oh...Some of those wires run to the second charger; this way I didn’t need a junction box. There is just enough room on the right-hand side for that.

So white is hot and green is spliced in the wall connector?

Two of white, black, red, blue feed one UWC, 2 feed the other?

Wire size seems good

1 inch is max conduit size, so current carrying conductors are probably 6 AWG

There are 4 current carrying conductors in the conduit so they get derated 80%

6 AWG is rated at 75A at 90C

75 * 80% (4 conductor derating) = 60 Amp, lower than the 65A @ 75C value

60 * 80% (continuous load) = 48 Amp charge rate which is max for the UWC

1 inch is max conduit size, so current carrying conductors are probably 6 AWG

There are 4 current carrying conductors in the conduit so they get derated 80%

6 AWG is rated at 75A at 90C

75 * 80% (4 conductor derating) = 60 Amp, lower than the 65A @ 75C value

60 * 80% (continuous load) = 48 Amp charge rate which is max for the UWC

davewill

Active Member

It sounds like that's what they did. I'd be worried that the extra connections would generate more heat at the connectors than the wall connector was designed for.... Did they run wires in the top and bottom and use the UWC as a junction box?

...

Um. I'm not quite sure what the current NEC standards and building codes are; but at one time, in the mid 1970's or 1980's when the price of copper skyrocketed (and there were people getting serious $$ by hauling out their sacks of pennies so they could be melted down), there was this crazy to use aluminum wiring in new construction.“Howerver, just to understand, what issues could arise?”

Copper and aluminum don’t play well together where they meet, different rates of expansion leads to loose connections, increased resistance and heat.

After a couple of years, there was an epidemic of Al-wired houses burning down. Some of that was electricians Not Reading The Rules about Aluminum wiring and playing mix-and-match when dissimilar metals Don't Let One Do That; and some of that is just that, frankly, Al2O3 is a pretty darn good, very tough insulator, that forms almost instantly when Al is exposed to the atmosphere. CuO, by comparison, is a much softer substance that's easy to get a gas-tight connection with.

As the epidemic wore on, it became Forbidden to use Al to wire houses. I don't know how current building standards are arranged, but I'm actually mildly surprised, given the above history, that Al wire is still in use. Outside of repairs on those older, Al-wired homes, that is.

It's not forbidden. There are some conditions and techniques that have to be followed when applying aluminum wire to deal with that oxidation problem.As the epidemic wore on, it became Forbidden to use Al to wire houses. I don't know how current building standards are arranged, but I'm actually mildly surprised, given the above history, that Al wire is still in use.

This article has a lot of useful information: Aluminum Wiring - Code CheckUm. I'm not quite sure what the current NEC standards and building codes are; but at one time, in the mid 1970's or 1980's when the price of copper skyrocketed (and there were people getting serious $$ by hauling out their sacks of pennies so they could be melted down), there was this crazy to use aluminum wiring in new construction.

After a couple of years, there was an epidemic of Al-wired houses burning down. Some of that was electricians Not Reading The Rules about Aluminum wiring and playing mix-and-match when dissimilar metals Don't Let One Do That; and some of that is just that, frankly, Al2O3 is a pretty darn good, very tough insulator, that forms almost instantly when Al is exposed to the atmosphere. CuO, by comparison, is a much softer substance that's easy to get a gas-tight connection with.

As the epidemic wore on, it became Forbidden to use Al to wire houses. I don't know how current building standards are arranged, but I'm actually mildly surprised, given the above history, that Al wire is still in use. Outside of repairs on those older, Al-wired homes, that is.

15 or 20A branch circuits should definitely not be done in Al. But Al service entrances and sub panel feeders are fine, safe, and legal, when installed correctly. I've never seen a home that used copper on the service entrance, and I've been in a bunch of breaker panels. I've only seen one subpanel done in copper. Every home I've lived in (wired as late as 2021) has had Al for the service entrance and sub panel feeders.

My current house (1972) has Al service entrance and subpanel feeders (installed in 2018/20). The range outlet was wired with 6ga Al SEU to a 10-50. When I remodel the kitchen, I'll convert to copper NM-B and a 14-50.

Interesting. So, and this is the important point: Is it legal to use aluminum for a 50A "branch" circuit to connect a NEMA14-50 to a breaker box? This wouldn't be a sub-panel, natch, but a, well, 240 VAC, 50A outlet in, say, a garage. I presume that the duplex breaker in the panel has to be compatible with aluminum, as well as the NEMA14-50 being used.This article has a lot of useful information: Aluminum Wiring - Code Check

15 or 20A branch circuits should definitely not be done in Al. But Al service entrances and sub panel feeders are fine, safe, and legal, when installed correctly. I've never seen a home that used copper on the service entrance, and I've been in a bunch of breaker panels. I've only seen one subpanel done in copper. Every home I've lived in (wired as late as 2021) has had Al for the service entrance and sub panel feeders.

My current house (1972) has Al service entrance and subpanel feeders (installed in 2018/20). The range outlet was wired with 6ga Al SEU to a 10-50. When I remodel the kitchen, I'll convert to copper NM-B and a 14-50.

It might have been this thread or another, but there was some mention by the poster that, "The electrician used aluminum wire since it was cheaper." Which (probably incorrectly) raised the hairs on the back of my neck.

If both sets of terminals are rated for aluminum, it's fine.Interesting. So, and this is the important point: Is it legal to use aluminum for a 50A "branch" circuit to connect a NEMA14-50 to a breaker box? This wouldn't be a sub-panel, natch, but a, well, 240 VAC, 50A outlet in, say, a garage. I presume that the duplex breaker in the panel has to be compatible with aluminum, as well as the NEMA14-50 being used.

It might have been this thread or another, but there was some mention by the poster that, "The electrician used aluminum wire since it was cheaper." Which (probably incorrectly) raised the hairs on the back of my neck.

Breakers are mostly CU-AL and some outlets are also:

https://www.gordonelectricsupply.com/p/Cooper-5754N-Fl-Sgl-Rcpt-N14-50R/6347037

Quite an eye opener of an article. And it's flat-out weird that the article states, multiple times, that rigorous tests to check Al/Cu connections haven't been done. Wowsers.This article has a lot of useful information: Aluminum Wiring - Code Check

15 or 20A branch circuits should definitely not be done in Al. But Al service entrances and sub panel feeders are fine, safe, and legal, when installed correctly. I've never seen a home that used copper on the service entrance, and I've been in a bunch of breaker panels. I've only seen one subpanel done in copper. Every home I've lived in (wired as late as 2021) has had Al for the service entrance and sub panel feeders.

My current house (1972) has Al service entrance and subpanel feeders (installed in 2018/20). The range outlet was wired with 6ga Al SEU to a 10-50. When I remodel the kitchen, I'll convert to copper NM-B and a 14-50.

After reading All The Different Ways Branch Circuits Made out of Al can fail... Now we know why most electricians (outside of the service entrance stuff) stick to copper.

^ but why were more than 3 wires used for this installation? 1 ground, L1 and L2 is all that is needed. What were the extra conductors used for?The two Universal Wall Connectors are Installed! In background, charging the Model X; on left, ready to charge the Model S

View attachment 980296View attachment 980297

That "USB" and "Conductor8" in their ignominy, and the "lbf.in" remains there. BUT: my electrician did a "Whoa!" upon seeing the lug nomenclature, as shown in the photo below. He said that that is contrary to all standard siting; that the uniform placement for 240V always is (left to right) Ground - L1 - L2, as opposed to this G-2-1. He bopped his apprentice for having switched the wires....until Junior showed him he was indeed following Tesla's map!View attachment 980298

They ran the wires for the second Wall Connector through the first one.^ but why were more than 3 wires used for this installation? 1 ground, L1 and L2 is all that is needed. What were the extra conductors used for?

Some of those wires run to the second charger; this way I didn’t need a junction box. There is just enough room on the right-hand side for that.

And when you’re power sharing/ganging up more than one of these, you and your assistant had better keep L1 and L2 not crossed!

Right. Although these units can be linked, with smart circuitry controlling the voltage to each one, for other reasons I kept them on separate circuits and what you see with the additional wires is my using that first one as the j-box.

PM me if anyone needs details or ideas.

PM me if anyone needs details or ideas.

Similar threads

- Replies

- 5

- Views

- 248

- Replies

- 0

- Views

- 125

- Replies

- 8

- Views

- 4K

- Replies

- 3

- Views

- 758