It’s this rush to get the job done and leave a barely acceptable finish rather than an excellent one that caused me to pull in my own cable, routed exactly how I wanted, hidden behind skirting and buried under the stone flagstones in my back garden. Even so, it only took me an afternoon to do without professional tools (although I’d have given my right arm for a decent SDS drill)

With a bit of thought and planning, the need for ugly plastic trunking and shoddy cable clipping is removed and the job itself takes no longer. This smash ‘n’ grab approach just leaves a bad taste. Some of the shoddy installs on YouTube and other sites like this one make my teeth itch.

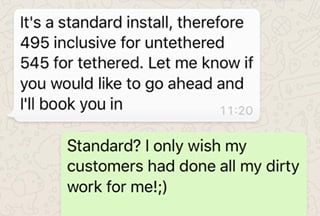

If you do go to the trouble I did though, don’t expect any discount.. EO for instance, on witnessing the fact that I had provided them with a cable end clipped to the wall next to the consumer unit, with the other cable end clipped to the wall outside at the charging point and an earth rod already installed with earth wire run in, merely demoted the cost to a ‘standard install’. I’ve saved them the cost of the cable, the clips, the earth rod, the earth rod junction box, the earth clamp, the screws, plugs an fasteners, the earthing wire and all the labour of fitting it all. All they have to do is finish the job;

With a bit of thought and planning, the need for ugly plastic trunking and shoddy cable clipping is removed and the job itself takes no longer. This smash ‘n’ grab approach just leaves a bad taste. Some of the shoddy installs on YouTube and other sites like this one make my teeth itch.

If you do go to the trouble I did though, don’t expect any discount.. EO for instance, on witnessing the fact that I had provided them with a cable end clipped to the wall next to the consumer unit, with the other cable end clipped to the wall outside at the charging point and an earth rod already installed with earth wire run in, merely demoted the cost to a ‘standard install’. I’ve saved them the cost of the cable, the clips, the earth rod, the earth rod junction box, the earth clamp, the screws, plugs an fasteners, the earthing wire and all the labour of fitting it all. All they have to do is finish the job;