There is a lot of sorcery in the answer to that question that I don't understand. It isn't just the imbalance - it is the behavior of the imbalance. When the BMS detects a brick that starts to behave differently than its neighbors, it will throw the 029 code if it passes a certain threshold. Tesla seems to have tightened this tolerance already and will probably do it again in the future. When accused of planned-obsolescence, they will stand on the table and shout the S word as loud and long as they need to to drown out the complaints. The S word is SAFETY by the way.Do I understand correctly that an imbalance of more than 30 millivolts will not allow the machine to start anymore?

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2014 P85d High Voltage Failure

- Thread starter mr_hyde

- Start date

Here I see that the error bms_f107 appears after an imbalance of 35 mV. I also have a problem at the moment.

Tesla model s 2013 P85 not start drive.

Hello everyone. The problem with the 2013 Tesla model s. The car won't start. A lot of errors DI_u014 BMS_u008 BMS_w107 BMS_f107 GTW_w018. I was opening the battery. There was a little moisture. And also the wire from the BMB board on two blocks is torn off. I fixed it. The insulation is...

My car just didn't start. Then she stood there in the cold and the error bms_f107 fell out.

I had a wire torn off on two modules. I fixed it. I thought the machine would be able to start itself and rebalance the module. I bought access to toolbox 3 but the error is not reset. Contractors do not close.

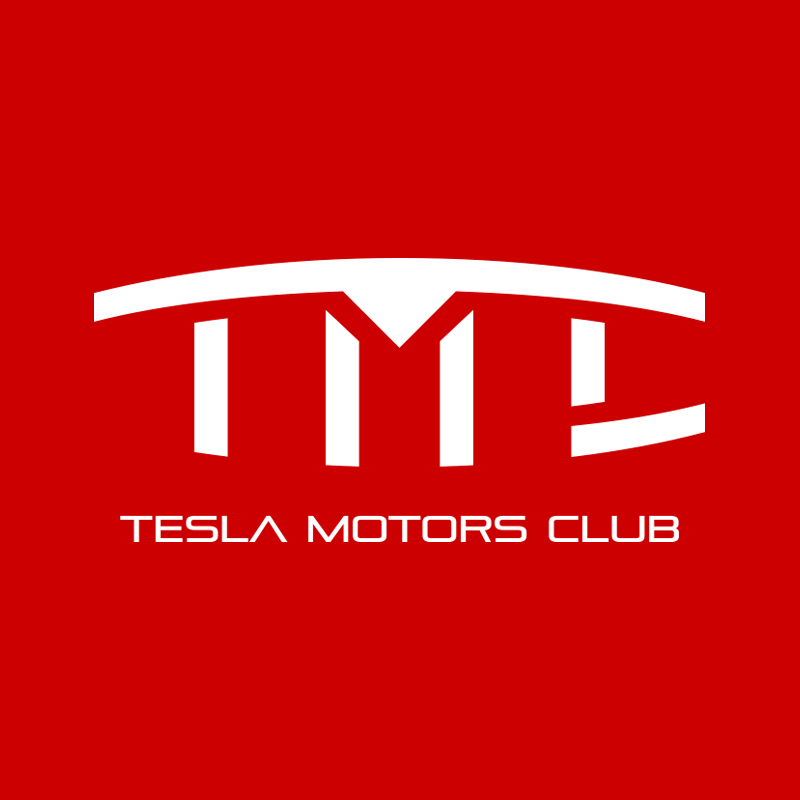

Now I have an imbalance of 96 mv. After reading your article, it seems to me that I need to rebalance the module first and then buy access again and reset the error.

Also in the Scan of my tesla, I have no data about the DC DC converter. Perhaps no one has them with the contractors turned off. But I do not know if this is the case and I think that the problem may be in the DC DC converter.

This is an example of a photo where there is data about DCDC

In toolbox 3, I tried to ping DC DC over the CAN bus and it didn't respond.

Here I see that the error bms_f107 appears after an imbalance of 35 mV. I also have a problem at the moment.

Tesla model s 2013 P85 not start drive.

Hello everyone. The problem with the 2013 Tesla model s. The car won't start. A lot of errors DI_u014 BMS_u008 BMS_w107 BMS_f107 GTW_w018. I was opening the battery. There was a little moisture. And also the wire from the BMB board on two blocks is torn off. I fixed it. The insulation is...teslamotorsclub.com

My car just didn't start. Then she stood there in the cold and the error bms_f107 fell out.

I had a wire torn off on two modules. I fixed it.

If the voltage sensor wire fell off, imbalance would be much higher than 35mV. Can you clarify?

I thought the machine would be able to start itself and rebalance the module. I bought access to toolbox 3 but the error is not reset. Contractors do not close.

Now I have an imbalance of 96 mv. After reading your article, it seems to me that I need to rebalance the module first and then buy access again and reset the error.

Maybe 96mV imbalance force trigger f107 but this is only a guess.

There is also a BMS reset button in service mode on MCU. Don't know what that does. But I guess BMS must keep some history which maybe need clearing after repair?

Also 35mV to 96mV change is significant. Do you know which module/brick changed significantly and why? If voltage sensor wire connection wasn't good. Maybe can't trust the readings.

Also in the Scan of my tesla, I have no data about the DC DC converter. Perhaps no one has them with the contractors turned off. But I do not know if this is the case and I think that the problem may be in the DC DC converter.

In toolbox 3, I tried to ping DC DC over the CAN bus and it didn't respond.

DCDC1 receive HV with contactors closed. Maybe diagnostics have problems without contactor closing? Again, just a guess.

Last edited:

It was slightly pinned down by the plastic lid and had poor contact. That's probably why BMB can't balance it properly.If the voltage sensor wire fell off, imbalance would be much higher than 35mV. Can you clarify?

I will try to rebalance this module tomorrow. And I will inspect the bmb for corrosion or poor soldering

Since you reported moisture in the pack ( post ) Check BMBs carefully with magnifying glass. @mr_hyde HV pack had 4 corroded BMBs towards front of pack (inspected all 16). Only 1 corroded BMB had 1 voltage sensor circuit completely fail and triggered F107 ( post ) But the other 3 corroded BMBs likely will fail in the near future.

@mr_hyde also added additional conformal coating (BMB conformal coating sprayed on unevenly) and added more gap to prevent plastic tub from touching BMB components to rub off conformal coating ( link )

Last edited:

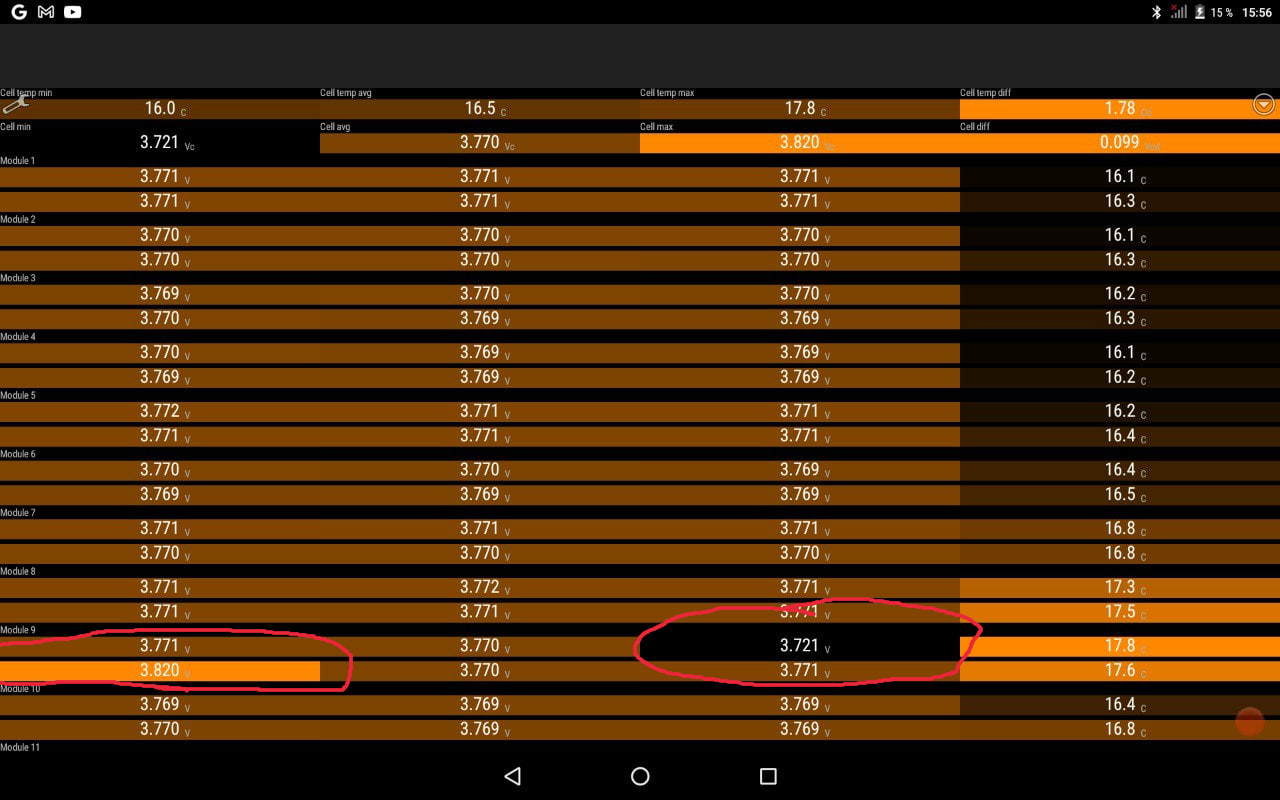

Today I measured the voltage - everything is fine. I moved the bmb board to another module. The problem has moved to another module. It looks like I have a problem with the bmb board. Can I buy a bmb board of another revision? And will it be necessary to program it?

The BMB board looks intact. Without corrosion.

The BMB board looks intact. Without corrosion.

Mack, those voltage readings certainly look bogus. When I was doing mine, someone said to match the part number. My BMB looked just like that and also said Rev01 but I was told it was actually Rev 1.5. I think the difference is that ours have a socket for the sensor wires instead of being soldered to the board (which is a big improvement in terms of workability). I got mine on eBay by searching the part number. In your case 1050951-00-A.

Mack,

Since you have the pack open, I would recommend checking all of the modules carefully. There are 112 sensor wire connections plus the BMB boards to check. I poked all of mine with a plastic tool, cleaned each with 200 proof alcohol and recoated each with another layer of conformal coating to help insure no moisture gets in. I did the same with the capacitors on each BMB. It took a lot of time (10 hours?), but when one thing fails in these, there are a LOT of similar connections/components that could be right behind.

Since you have the pack open, I would recommend checking all of the modules carefully. There are 112 sensor wire connections plus the BMB boards to check. I poked all of mine with a plastic tool, cleaned each with 200 proof alcohol and recoated each with another layer of conformal coating to help insure no moisture gets in. I did the same with the capacitors on each BMB. It took a lot of time (10 hours?), but when one thing fails in these, there are a LOT of similar connections/components that could be right behind.

It's a varnish. I rewired the fuse today. The BMB board started working correctly. Now the imbalance is 0.008. Reset the error using toolbox 3. The contactors started clicking, but now the error bms_f150 bms_w150 crashes. I'll deal with her tomorrow.Your C27 looks like it might have a crack in it. SMD (Surface Mount Devices) caps usually fail with such minute cracks and best seen under microscope.

Great news! I haven't seen the 150 error. Hopefully that isn't too much trouble. As you were inspecting your caps, did you notice the bottom half of the plastic shield making contact with the BMB - specifically C27 and C26? Several of my plastic covers were making contact which was slowly rubbing the coating off those caps. One failed completely causing my battery to stop but 4 others were showing significant signs of wear. I replaced those boards preemptively, modified the shield, added spacers to keep the shield off the board components and recoated everything on all 16 boards in that area.

Incidentally, I just checked eBay (USA) and I don't see any 1050951-00-A boards available which is the exact board I have. Someone more knowedgable should be able to tell you if any other part numbers are compatible. Anything with the same form-factor and connections might work but I'm not sure. The good news is there is no programming to do...

Gtech

Active Member

I had the w150 and f150 (Precharge too long) because of a shorted PTC but it could be any component off course but strange that it happened after you fixed the HV batteryIt's a varnish. I rewired the fuse today. The BMB board started working correctly. Now the imbalance is 0.008. Reset the error using toolbox 3. The contactors started clicking, but now the error bms_f150 bms_w150 crashes. I'll deal with her tomorrow.

View attachment 1005830

I had the w150 and f150 (Precharge too long) because of a shorted PTC but it could be any component off course but strange that it happened after you fixed the HV battery

BTW, when I had the car(HV) disabled for 2-3 months during LDU rebuild. HVIL failed after reassembly + driving the car a few times in a week + 1 hand car wash. Eventually found was just corrosion on HV plugs for DCDC1. One of the HV devices connector contacts must have gathered some corrosion during 2+ mo idle and failed soon after my car wash (which dumps water onto DCDC1 + its plugs through windshield run off) All I did to fix it was unplug and replug DCDC1 connectors and contactors closed and car was working again. I decided to spray it with contact cleaner and plan on doing it perhaps annually.

So I wonder if having the HV system idle for long periods will promote issues like I encountered. I suppose it could just be random bad luck from the car wash of an aging car in rainy pacific northwest (car does park indoor at home + work)

brainhouston

Active Member

More details would be useful...Solved the problem. I just assembled the dc dc incorrectly. Everything is working now.

Similar threads

- Replies

- 13

- Views

- 521

- Replies

- 23

- Views

- 1K

- Replies

- 17

- Views

- 2K

- Replies

- 31

- Views

- 6K