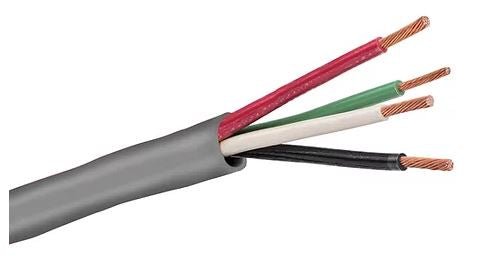

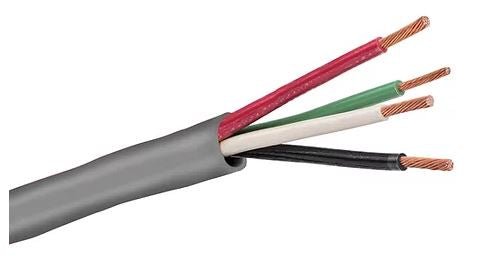

IN preparation for my EV Charger install, I have spent the last 2+ hours reading forums regarding the use of 6/2 NM-B and I'm convinced that I should use #4 NM-B for a 48A load with a 60A CB. As we all know 4/2 NM-B is not available so i would have to buy 4/3. Of course #4 has a larger bending radius so it is harder to work with. I want to revisit a topic brought up briefly at the beginning of this thread regarding TCERJP. It still has 4 conductors, but AWG6 would be easier to install. The question is whether this cable can use the 75C column (65A) or the 60C Column (55A) for ampacity. The datasheet gives an exception for "permanently installed generator applications" but I don't know if that would apply to EV chargers. This is the cable I'm talking about:

www.zillerelectric.com

www.zillerelectric.com

The cable description sounds perfect. "EV Charger Installation Wire #6 x 3 + #8 Ground Copper TCERJP (Trable)

EV Charger Installation Wire #6 x 3 + #8 Ground Copper TCERJP (Trable) – Ziller Electric

INSTALLING YOUR EV (ELECTRIC VEHICLE) CHARGING STATION IS NOW QUICK AND EASY! OUR EV INSTALLATION WIRE (TRABLE) IS JUST WHAT YOU NEED! STARTING AT $9.01 THE PRICE PER FOOT DECREASES AS LENGTH INCREASES. CHOOSE LENGTH TO SEE YOUR TOTAL SHIPPED PRICE **This 4 Conductor EV Cable includes the...

The cable description sounds perfect. "EV Charger Installation Wire #6 x 3 + #8 Ground Copper TCERJP (Trable)