Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

artsci, have you tried glass beading. sandblasting, solvent wipes, etc. on edges to try to help disrupt the linear light transmission?

Yes all the above. I'm using mirrored Plexi, which I now realize is part of the problem. I'm now having some T's make out of translucent plexi, a kind of milky white, and based on some early tests that should make for much more even lighting.

Now returning from several days in the San Jose/Palo Alto area and a factory tour during which I was able to inspect up close key parts of the car as they were being assembled. A tram is used for the tour and it accommodates several dozen people I would guess. At a few key points the tram stops and all of the passengers can get off for a closer look. At one of those points, where the final assembly was being completed, I was looking carefully at the rear hatch lid and a worker approached me to ask if I had any questions. I chatted with him for a few minutes about the car and told him how much I appreciated the great job they are doing building the car.

If you've not done the tour it's worth going to California just for that. It's an amazing experience.

Also visited the Fremont factory service center and was able to obtain a number of key parts I need for my various mods. The service there was exceptionally good and the staff extremely helpful as I described what I needed. One member of the staff spent an hour with me and actually went into the factory to look for some parts and ask for some advice.

I also had time to perfect the PCB design for the lighted T as well as the placement of the LEDs, so tomorrow I'll begin working on the modified version. It will be a few days before I'll be able to show the new version. In the meantime I'll mount the current beta version on my car so I can post some photos tomorrow night.

If you've not done the tour it's worth going to California just for that. It's an amazing experience.

Also visited the Fremont factory service center and was able to obtain a number of key parts I need for my various mods. The service there was exceptionally good and the staff extremely helpful as I described what I needed. One member of the staff spent an hour with me and actually went into the factory to look for some parts and ask for some advice.

I also had time to perfect the PCB design for the lighted T as well as the placement of the LEDs, so tomorrow I'll begin working on the modified version. It will be a few days before I'll be able to show the new version. In the meantime I'll mount the current beta version on my car so I can post some photos tomorrow night.

Last edited:

The lighted T on my spare nose cone is now installed on my car. The install went very well. I've taken dozens of photos of the steps but I'm waiting until it gets dark to take more photos of the T lit up. Then I'll post the results.

Last edited:

The Fury

Member

I installed my spare nose cone with the lighted T. Here’s how it was done.

First, the nose cone with the lighted T was prepared and tested on my workbench. It was in ready-to-install condition. All of the wiring has spade connectors for easy plug and play connections.

My carbon fiber wrapped cone was removed following standard procedures: loosen one of the upper right or left corners with a plastic pry tool and the rest pops out. Easy to do.

The all of the black plastic trim around the frunk has to be removed to provide easy access to parts and ways to hide the wiring once it’s all connected. All of this stuff just snaps out.

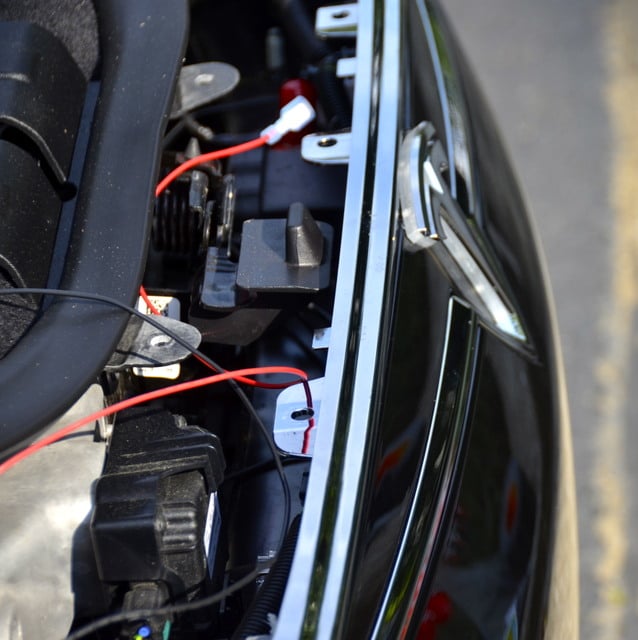

Here's what I have behind the nose cone. The radar detector receiver is to the left on the cross beam, my EZPass license plate transponder is on the front center of the cross beam, and plug in RJ 45 connections are on the right and left top of the cross beam to connect the laser jammer transponders. The GPS receiver for the radar detector is to the left of the EZPass transponder.

The most critical step is removing the space around the center clip receiver for the spring clip in the top center of the nose cone. I thought this was metal but it’s actually chromed plastic, which makes it easy to cut with a Dremel tool with a cut off tool attached, as shown. The rough red lines represent the area to be cut out. This is essential so that the printed circuit board connecting all the LEDs and system wiring will fit. Without cutting this out the nose cone would not fit flush at the top.

Here’s the backside of the nose cone before it was attached.

You can see that all of the wiring was already in place an taped down. The only connections to be made were for power (from the TAP-A-FUSE lead) and ground. As I had attached spade connectors to both ends of the appropriate wiring this was just a matter of pushing the leads together. I used a calk gun to pump in black silicone calk to waterproof all of the holes in the nose cone for the LED leads. I also taped the back of the PCM to cover all the solder connections so there would be no risk of a short.

For power I tapped into a fuse with TAP-A-FUSE, as shown, and ran the lead to the nose cone under the Frunk plastic trim. I loosened one of the many 10mm bolts attached to the frame to make the connection for ground.

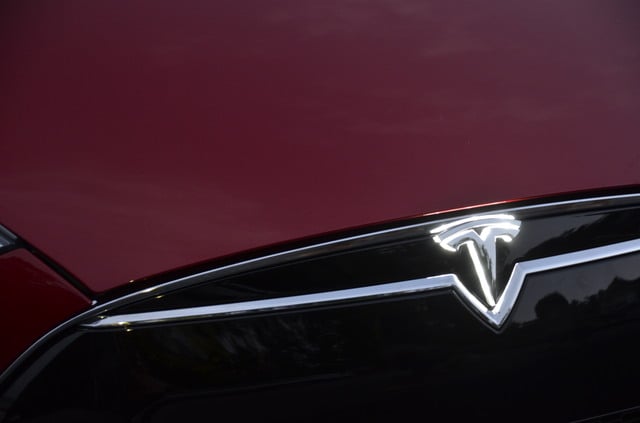

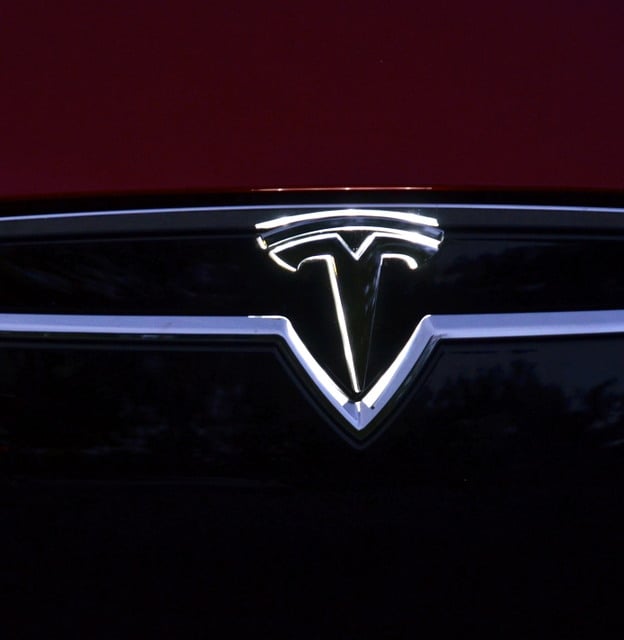

After making the ground and power connections I snapped the nose cone in place and use the remote to turn on the T. Voila! It looks much better in person than in the photos. In fact it’s quite striking. The reflection off the V under the T is not nearly as bothersome as it was in my bench tests a few weeks ago.

Here a number of photos of the T under varying light conditions, from full daylight to near-darkness. I didn’t have time to shoot a video, so I’ll do that tomorrow night.

My next version will use translucent white Plexi, which will reduce the hot spots (although these are not as big an issue as I thought they’d be). I should have that version ready next weekend.

First, the nose cone with the lighted T was prepared and tested on my workbench. It was in ready-to-install condition. All of the wiring has spade connectors for easy plug and play connections.

My carbon fiber wrapped cone was removed following standard procedures: loosen one of the upper right or left corners with a plastic pry tool and the rest pops out. Easy to do.

The all of the black plastic trim around the frunk has to be removed to provide easy access to parts and ways to hide the wiring once it’s all connected. All of this stuff just snaps out.

Here's what I have behind the nose cone. The radar detector receiver is to the left on the cross beam, my EZPass license plate transponder is on the front center of the cross beam, and plug in RJ 45 connections are on the right and left top of the cross beam to connect the laser jammer transponders. The GPS receiver for the radar detector is to the left of the EZPass transponder.

The most critical step is removing the space around the center clip receiver for the spring clip in the top center of the nose cone. I thought this was metal but it’s actually chromed plastic, which makes it easy to cut with a Dremel tool with a cut off tool attached, as shown. The rough red lines represent the area to be cut out. This is essential so that the printed circuit board connecting all the LEDs and system wiring will fit. Without cutting this out the nose cone would not fit flush at the top.

Here’s the backside of the nose cone before it was attached.

You can see that all of the wiring was already in place an taped down. The only connections to be made were for power (from the TAP-A-FUSE lead) and ground. As I had attached spade connectors to both ends of the appropriate wiring this was just a matter of pushing the leads together. I used a calk gun to pump in black silicone calk to waterproof all of the holes in the nose cone for the LED leads. I also taped the back of the PCM to cover all the solder connections so there would be no risk of a short.

For power I tapped into a fuse with TAP-A-FUSE, as shown, and ran the lead to the nose cone under the Frunk plastic trim. I loosened one of the many 10mm bolts attached to the frame to make the connection for ground.

After making the ground and power connections I snapped the nose cone in place and use the remote to turn on the T. Voila! It looks much better in person than in the photos. In fact it’s quite striking. The reflection off the V under the T is not nearly as bothersome as it was in my bench tests a few weeks ago.

Here a number of photos of the T under varying light conditions, from full daylight to near-darkness. I didn’t have time to shoot a video, so I’ll do that tomorrow night.

My next version will use translucent white Plexi, which will reduce the hot spots (although these are not as big an issue as I thought they’d be). I should have that version ready next weekend.

Last edited:

SCW-Greg

Active Member

The Fury

Member

zax123

CDN Model S 100D

That looks awesome! I don't see hot spots but maybe they just don't show through the pictures.

Doesn't look like a very difficult install once it's already installed on the cone.

I'm guessing this is just a test install and your final version (using the final approved version of plexi) will be on your CF-wrapped cone?

Looking forward to the final product and a test kit so I can play too!

Doesn't look like a very difficult install once it's already installed on the cone.

I'm guessing this is just a test install and your final version (using the final approved version of plexi) will be on your CF-wrapped cone?

Looking forward to the final product and a test kit so I can play too!

I'm guessing this is just a test install and your final version (using the final approved version of plexi) will be on your CF-wrapped cone?

For sure, working on that now. My CF-wrapped nose cone is now on my workbench waiting for the installation. Once I have that done and I'm sure all the parts are right, I'll begin shipping the kits to the five testers.

BTW, I left the T on all night and in my parking garage at work today. No appreciable drain on the 12v battery.

It looks very cool and sets the car off even more as something quite special. And not bling at all -- looks very elegant, is if it was meant to be.

Last edited:

The Fury

Member

The Fury

Member

hans

P631

MrIanB

Member

Artcsi:

you are a god to this car and I don't even own one yet. This will be my first mod.

Ian B

you are a god to this car and I don't even own one yet. This will be my first mod.

Ian B

...

My next version will use translucent white Plexi, which will reduce the hot spots (although these are not as big an issue as I thought they’d be). I should have that version ready next weekend.

Along with the milk plex you might consider color changing LEDs. That way an owner can "light color match" to their S's paint if they want.

zax123

CDN Model S 100D

Rick, this is looking awesome!! I love the pulsating glow too.

I had a question. With the control unit you're using (which I've ordered) is there a way to tell it to automatically "go to last setting" when it gets power on the red wire? Meaning when I turn off the car with it at a certain setting, it will automatically resume that setting when the car comes back on/it gets power again? That would be awesome! (Assuming of course you tap a fuse which is on only when the car is on)

Thanks for all your hardwork which I'm sure a lot of us will benefit from!!

I had a question. With the control unit you're using (which I've ordered) is there a way to tell it to automatically "go to last setting" when it gets power on the red wire? Meaning when I turn off the car with it at a certain setting, it will automatically resume that setting when the car comes back on/it gets power again? That would be awesome! (Assuming of course you tap a fuse which is on only when the car is on)

Thanks for all your hardwork which I'm sure a lot of us will benefit from!!

Last edited:

Watching that logo "breath" like a Apple Laptop gets me every time.

The breathing glow effect is very Apple-esque indeed... Artsci, this is a very, very cool mod

Similar threads

- Replies

- 203

- Views

- 8K

- Replies

- 0

- Views

- 763

- Replies

- 13

- Views

- 6K

- Replies

- 11

- Views

- 5K

- Replies

- 3

- Views

- 1K