People obsessing about body panel gaps are missing the whole point about driving a Tesla. If it looks good and performs well the car should be accepted. Elon has mentioned that panel gaps should get better as they introduce more large castings instead of many smaller parts that need to be welded together.

There is no published spec for body parts gaps, just to put them together as well as you can in the time allotted. Some manufacturers are better at this than others. Tesla must deal with a millennial California workforce. Perhaps in Germany they have more precision oriented workers.

I think you’ve pivoted this into some generational or cultural work ethic thing.

Let’s just focus on why panel gap is important. As doors get opened and closed and hatches get slammed, they start to move. At severe levels, this wear causes rain to be pulled into the cabin, air to leak in causing noise and whistles, and also looks terrible. Eventually parts will “kiss” and cause damage.

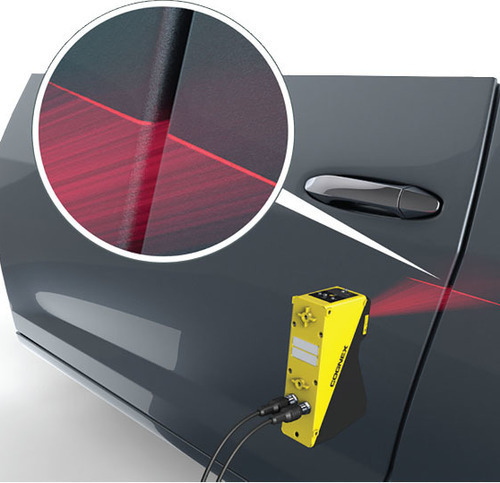

Automakers not named Tesla shoot for +/- 1mm around a 4 or 5 mm baseline spec when new. This means a door can drift to 2mm and probably be fine.

If the car is new and starts at 1mm that is a problem. Especially if the buyer is expecting to own the car instead of lease.

Automakers will not honor warranty claims on issues caused by gaps over time because they view this as a wear item. Since every automaker not named Tesla ships new cars that are in spec for these “minor things”, millions of normal car buyers don’t care about gaps because they didn’t have to care.

Since Tesla has proven they are fine shipping poorly aligned panels, anyone who buys the car and wants to keep it a while needs to take it upon themselves to get measurements. Paying someone to fix a leak at 20,000 miles is not cool, and is preventable.

So yeah, Tesla’s apathy unfortunately means someone needs to do seemingly idiotic steps to address issues that Tesla should be addressing before the product lands in dealerships. I hope this P3 I’m expecting is “normal” for an average budget automaker…