Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model S Performance vs BMW M5

- Thread starter CapitalistOppressor

- Start date

eledille

TMS 85 owner :)

I just have to write one more post on electric motors and transmissions, I hope it's not too far off topic.

There is another, incredibly elegant way of achieving constant power: Field weakening.

Back emf is caused by the interaction of the magnetic field of the rotor with the stator windings. Torque and back emf depend linearly on the field strength of the rotor (or the stator in a DC motor). Back emf also depends linearly on rotational speed. The result is that if voltage and current are held constant (at max, say), a reduction in rotor field strength will cause a proportional torque reduction and an increase of effective voltage. Speed will then increase automatically.

So if you can control the magnetic field of the rotor, you effectively have a continuously variable transmission without having to increase the voltage.

With a wound-rotor, synchronous machine this is easy to do, since the rotor field is energized separately. But this motor type has the drawback of requiring slip rings, which are expensive and increase maintenance. Permanent magnet and induction motors are simpler, they don't need any electrical connections to the rotor. But is it possible to control their rotor fields?

In a permanent magnet synchronous motor, the stator field rotates at the same speed as the rotor, but leads the rotor by some degrees in order to pull it forwards. They are locked together as if through springs by the magnetic fields. If a second signal is added to the stator input to set up two superimposed fields rotating at the same frequency, where the second field is aligned with the rotor field, but in the opposite direction, then the field of the permanent magnet can be partially cancelled out. The stator field that weakens the rotor field can be controlled at whatever fineness the power electronics is capable of already, and as the forces involved are perpendicular to the direction of movement, there is no power requirement except for small losses.

Voila, an ultra efficient CVT without voltage conversion or moving parts.

This does not work in an induction motor because the field of its rotor is created through interaction with the stator field. It is actually a rotating transformer, and the stator and rotor fields can't be varied independently. To control the rotor field, you would have to tap power from the rotor through slip rings and feed it back to the battery, which probably does not make sense.

I have no clue as to which motor type is the "best", and different manufacturers choose different motors: Zoe - wound-rotor synchronous, Leaf - permanent magnet synchronous, Tesla - induction. Advantages of the induction motor include that it packs a lot of punch for its size and weight, is simple and efficient, and does not require any exotic materials.

I think the electric motor is the best machine mankind could ever hope to create. The Ultimate Machine. What else includes a near-lossless CVT for free and can be made 99% efficient? The only problem is how to store the energy it needs. To me, the only attractive feature of the internal combustion engine is the capacity of its fuel tank.

I'm waiting for the electric M-series...

More on field weakening in permanent magnet AC motors here. Yes, it's for washing machines, but if you can make it work well in a mass produced, cheap motor, then you can do it in an expensive motor too.

There is another, incredibly elegant way of achieving constant power: Field weakening.

Back emf is caused by the interaction of the magnetic field of the rotor with the stator windings. Torque and back emf depend linearly on the field strength of the rotor (or the stator in a DC motor). Back emf also depends linearly on rotational speed. The result is that if voltage and current are held constant (at max, say), a reduction in rotor field strength will cause a proportional torque reduction and an increase of effective voltage. Speed will then increase automatically.

So if you can control the magnetic field of the rotor, you effectively have a continuously variable transmission without having to increase the voltage.

With a wound-rotor, synchronous machine this is easy to do, since the rotor field is energized separately. But this motor type has the drawback of requiring slip rings, which are expensive and increase maintenance. Permanent magnet and induction motors are simpler, they don't need any electrical connections to the rotor. But is it possible to control their rotor fields?

In a permanent magnet synchronous motor, the stator field rotates at the same speed as the rotor, but leads the rotor by some degrees in order to pull it forwards. They are locked together as if through springs by the magnetic fields. If a second signal is added to the stator input to set up two superimposed fields rotating at the same frequency, where the second field is aligned with the rotor field, but in the opposite direction, then the field of the permanent magnet can be partially cancelled out. The stator field that weakens the rotor field can be controlled at whatever fineness the power electronics is capable of already, and as the forces involved are perpendicular to the direction of movement, there is no power requirement except for small losses.

Voila, an ultra efficient CVT without voltage conversion or moving parts.

This does not work in an induction motor because the field of its rotor is created through interaction with the stator field. It is actually a rotating transformer, and the stator and rotor fields can't be varied independently. To control the rotor field, you would have to tap power from the rotor through slip rings and feed it back to the battery, which probably does not make sense.

I have no clue as to which motor type is the "best", and different manufacturers choose different motors: Zoe - wound-rotor synchronous, Leaf - permanent magnet synchronous, Tesla - induction. Advantages of the induction motor include that it packs a lot of punch for its size and weight, is simple and efficient, and does not require any exotic materials.

I think the electric motor is the best machine mankind could ever hope to create. The Ultimate Machine. What else includes a near-lossless CVT for free and can be made 99% efficient? The only problem is how to store the energy it needs. To me, the only attractive feature of the internal combustion engine is the capacity of its fuel tank.

I'm waiting for the electric M-series...

More on field weakening in permanent magnet AC motors here. Yes, it's for washing machines, but if you can make it work well in a mass produced, cheap motor, then you can do it in an expensive motor too.

Last edited:

Johan

Ex got M3 in the divorce, waiting for EU Model Y!

I just have to write one more post on electric motors and transmissions, I hope it's not too far off topic.

There is another, incredibly elegant way of achieving constant power: Field weakening.

[...]

Sorry to continue the somewhat off-topic discussion here...

What you are suggesting is very interesting since, IMO, the so far only weakness of cars with electric motors has been the "one fixed gear" which limits top speed. In everyday use cars like the Model S (performance) has more than enough top speed. However, if you want to make a supercar you'll need that increased top speed and the other perks of having gears. Now, with the massive torque from 0 rpm that you get with an electric motor it has been shown that mechanical gearboxes just won't hold up that well (Roadster 1.0) and it also gives mechanical/heat losses and still has fixed (albeit multiple) gearing ratios. A CVT or other form of dynamic gearing mechanism, especially the "non-mechanical" type that you are proposing is much more elegant. I have asked Mate Rimac in the thread about their Rimac Automobili - Concept_One supercar if they propse to use some kind of CVT mechanism but I think he would not answer since this is something of a trade secret. The Concept_One uses a permanent magnet synchronous motor (see this link for confirmation) which, in theory, would make your described method with field weakening/multiple inputs to partially cancel out the main one, a real possibility. If this indeed turns out to be a technology used in the Concept_One then remember where you heard it first

--Update--

One thing to consider though - the concept of field weakening allows you to spin the motor/rotor at >100% of the rated speed, however this of course is at the expence of reduced torque. (You move from the "constant (full) torque range" to the "constant power range" (where torque diminishes with ever increasing speed). As described in the article you reference this is not much of a problem with at washingmachine since a lot of momentum has been built up during acceleration and once you cross into the constant power range the loss of torque really doesn't matter that much since the drum is loaded with motion energy. In a car going at high speed this might be different: air resistance increases exponentially with increased speed. At the high speeds where this mechanism would be of most use, you will still need to provide a lot of torque to be able to further accelerate the car (and also to keep it moving at a constant high speed since we're not driving i vacuum) - it's not all about allowing the rotor to spin faster than it's rated speed (rpm).

Last edited:

eledille

TMS 85 owner :)

132: I'm envious...

Johan: What you are forgetting now is that if there is an upper limit to power, then as soon as this limit is hit, torque and speed are inversely proportional. Power in watts = torque in Nm * 2 pi * rotational speed in revolutions per second. Wikipedia article on torque, speed and power. You simply cannot continue to increase speed at constant torque, because that will necessarily require more power, which you don't have when you're already at max. No matter what type of motor and gear system you have, as soon as you hit maximum power, the best you can possibly do is reduce torque inversely proportionally to speed.

This is exactly what you do when you change up through the gears of a conventional transmission, except with higher losses and in steps instead of continuously. Those steps and the shape of the power curve of an ICE also imply that the engine is never exactly at the power peak (infinitely close to never, to be precise), which implies lower average acceleration than theoretically possible with a perfect CVT. For maximum acceleration, you want to hit max power as soon as possible and stay exactly there.

The power curve can never be flat, though - infinite torque would have unfortunate medical side effects... Jokes aside, the amount of torque the tires can handle is a limit to achievable power.

Jokes aside, the amount of torque the tires can handle is a limit to achievable power.

An example of a constant torque machine is the turbojet (thrust is the same thing except linear). An F-16 has a relatively low thrust to weight ratio compared to a supercar in second gear. But its thrust does not drop as speed increases. At 100 m/s (i.e. supercar speeds) it's developing about 13 000 kW, and at mach 2, the thing is producing around 85 000 kW, enough to power a smallish aircraft carrier. Its fuel economy in city driving isn't all that great, though...

Johan: What you are forgetting now is that if there is an upper limit to power, then as soon as this limit is hit, torque and speed are inversely proportional. Power in watts = torque in Nm * 2 pi * rotational speed in revolutions per second. Wikipedia article on torque, speed and power. You simply cannot continue to increase speed at constant torque, because that will necessarily require more power, which you don't have when you're already at max. No matter what type of motor and gear system you have, as soon as you hit maximum power, the best you can possibly do is reduce torque inversely proportionally to speed.

This is exactly what you do when you change up through the gears of a conventional transmission, except with higher losses and in steps instead of continuously. Those steps and the shape of the power curve of an ICE also imply that the engine is never exactly at the power peak (infinitely close to never, to be precise), which implies lower average acceleration than theoretically possible with a perfect CVT. For maximum acceleration, you want to hit max power as soon as possible and stay exactly there.

The power curve can never be flat, though - infinite torque would have unfortunate medical side effects...

An example of a constant torque machine is the turbojet (thrust is the same thing except linear). An F-16 has a relatively low thrust to weight ratio compared to a supercar in second gear. But its thrust does not drop as speed increases. At 100 m/s (i.e. supercar speeds) it's developing about 13 000 kW, and at mach 2, the thing is producing around 85 000 kW, enough to power a smallish aircraft carrier. Its fuel economy in city driving isn't all that great, though...

Last edited:

Johan

Ex got M3 in the divorce, waiting for EU Model Y!

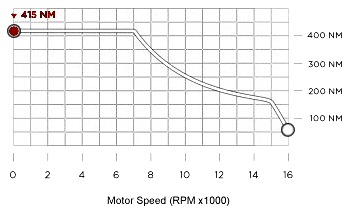

You are right of course about how a traditional gearbox is the same, just in steps. But you also have to consider that the electric motor has a different torque-rpm curve than an ICE. Here is the one fir Model S:

This curve suggests that it would be wise to start applying field weakening = "changing the gear ratio" already around 7000 rpm. How to do that in a Model S which has an induction motor (no permanent magnet) is the big question I guess?

This curve suggests that it would be wise to start applying field weakening = "changing the gear ratio" already around 7000 rpm. How to do that in a Model S which has an induction motor (no permanent magnet) is the big question I guess?

eledille

TMS 85 owner :)

That looks just like the best possible curve except for the part from 15 to 16k rpm. It suggests that it hits max power at 7k and that it's able to keep power nearly constant up to 15k rpm. At that point they hit some difficulty and had to let power drop off. I'm a bit surprised that max power doesn't occur earlier than 7k, though.

See my first post in this thread for a possible solution (voltage conversion).

See my first post in this thread for a possible solution (voltage conversion).

smorgasbord

Active Member

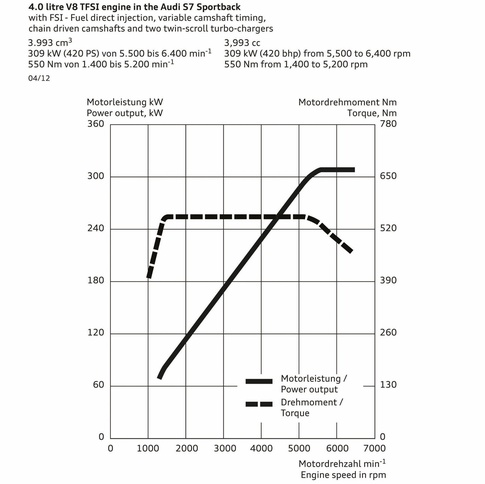

Just for comparison, here's the HP and Torque curves from the 2013 Audi S6/S7 (Twin-Turbo V6):

Note that it produces 550 Nm from 1400 rpm to 5200 rpm, which is very very good for an ICE.

Max HP is 420 at 5500 rpm.

The S6 is reported to do 0-60 in Roadster Sport time.

Note that it produces 550 Nm from 1400 rpm to 5200 rpm, which is very very good for an ICE.

Max HP is 420 at 5500 rpm.

The S6 is reported to do 0-60 in Roadster Sport time.

eledille

TMS 85 owner :)

Note that it produces 550 Nm from 1400 rpm to 5200 rpm, which is very very good for an ICE.

Wow. Yes, that's extremely good. They had to use two twin-scroll turbos and variable valve timing to get there, but still. I had no idea that an ICE could possibly have such a flat torque curve. That really is an impressive achievement.

Thanks.

Last edited:

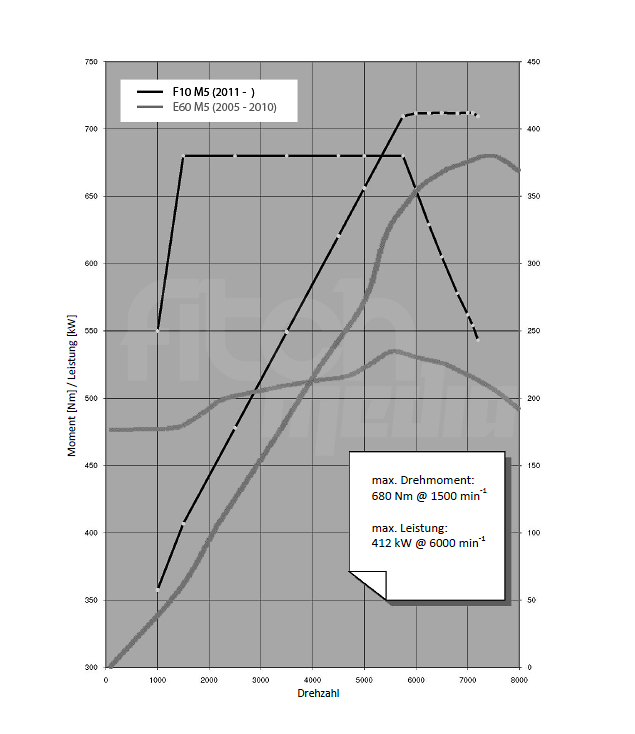

Just bringing back to M5 for a second, I am including the F10 M5 TQ curve (compared to prior M5 model (the E60)). You'll see that it produces a flat 680nm from 1500 to 5700 RPM. I actually think that most modern high-end turbo cars have basically flat TQ curves.

Best this is engine torque in a *single* gear, so not comparable to the cool science fiction discussed above of a virtual CVT.

Best this is engine torque in a *single* gear, so not comparable to the cool science fiction discussed above of a virtual CVT.

spatterso911

P100DL - Raven

I don't have my MSP yet, so sadly I won't be there. Please post your numbers when you get back. I'm very interested in the M5.

Flash results: 1:47 best lap so far after two sessions. I have video and telemetry. Anyone know MSP times?

I am running with traction/stability in track "MDM" mode and it is kicking in under wot, but I am chicken to turn off.

Last edited:

mnx

2018 M3P

Model S will do a 1:51...

Tesla Model S smokes the Tesla Roadster at REFUEL 2012 electric car race

Tesla Model S smokes the Tesla Roadster at REFUEL 2012 electric car race

Flash results: 1:47 best lap so far after two sessions. I have video and telemetry. Anyone know MSP times?

I am running with traction/stability in track "MDM" mode and it is kicking in under wot, but I am chicken to turn off.

With a pro driver (i assume) which, ahem, I am NOT.

DaveN007

Member

Here are a couple of those laps:

I am following in my Cayman R to document. Full disclosure: We are brothers and own 2 Civic Hybrids and Volt between us.

The S is an amazing vehicle for the road, but just like the Roadster, its capabilities on the track are greatly exaggerated. That is fine. It is revolutionary technology. And OMG what a beautiful car. My neighbor has an S in a rich maroon-ish color that is to die for. It drips quality and luxury. Awesome for folks who can afford a $100k car. Anyone know if Tesla will have an exemption carved out for it to avoid the proposed 3x vehicle licensing fees in CA?

I am following in my Cayman R to document. Full disclosure: We are brothers and own 2 Civic Hybrids and Volt between us.

The S is an amazing vehicle for the road, but just like the Roadster, its capabilities on the track are greatly exaggerated. That is fine. It is revolutionary technology. And OMG what a beautiful car. My neighbor has an S in a rich maroon-ish color that is to die for. It drips quality and luxury. Awesome for folks who can afford a $100k car. Anyone know if Tesla will have an exemption carved out for it to avoid the proposed 3x vehicle licensing fees in CA?

Last edited by a moderator:

DaveN007

Member

Numbers mean nothing and you can argue until the cows come home. What matters is real world performance. I think it's time Tesla put the model S through some laps on a track to compare - like Laguna Seca.

I'm thinking the Model S performance should be able to pull more Gs in the corner than the M5 thanks to the weight distribution. But the M5 probably has better brakes, and the lower weight will help. Who has the stiffer chassis? Does the M5 have double wishbone suspension? What are the wheel dimensions on the M5 compared to the S performance wheels? There are just an incredible number of factors that can decide whether a car is fast or slow. The only numbers that can give a true measure of performance are lap times, everything else like 0-60 are just parts of the equation. The torque levels are so different between the two cars that even that doesn't make too much sense.

A couple of novice drivers have run 1:47s in the M5. See video above. AFAIK there has not been a pro in an MSP that has posted anything under 1:51. The M5 can do this lap after lap after lap. I am not sure if the MSP is at the point in it's development where it can withstand the rigors of track driving for extended periods of time. Nothing wrong with that, since even folks who occasionally hit the track will drive their cars on the road 99 percent of the time. But it is relevant for the purposes of this discussion, which is a bit academic when you are cruising past gas stations in your MSP ;-)

The "fuel your car at home" then do a lap test would leave the M5 at a bit of a disadvantage when it came time to refine crude oil in your garage. LOL.

DaveN007

Member

Drag strip is great and yes, 1/4 mile would have been better, but faster to 100 is cool too! And I'm sure they used launch control, but it wasn't apparent from the sound of the M5 at take off.

And yes, there are still questions to be answered, but it seems more and more likely that MSP will beat the 2013 M5 around any given track. Just has too many pro's going for it. It is a great day indeed!

Apparently not Laguna Seca where we ran some 1:48s and a 1:47 for fun to show that a novice driver in an M5 can beat the Pro time of 1:51 in an MSP.

Last edited by a moderator:

strider

Active Member

We should note that those were engineering mules and not production cars that Tesla brought to Laguna last July. Of course that could to go either way. Either those cars were still lacking final suspension tuning and software tweaks such that production cars are even faster or it could mean that those cars had secret suspension/power tweaks that would mean a production car would be even slower. I suck at driving cars (can turn 1:40's at Laguna on my motorcycle though) but hope to make it out for REFUEL next year.Apparently not Laguna Seca where we ran some 1:48s and a 1:47 for fun to show that a novice driver in an M5 can beat the Pro time of 1:51 in an MSP.

DaveN007

Member

We should note that those were engineering mules and not production cars that Tesla brought to Laguna last July. Of course that could to go either way. Either those cars were still lacking final suspension tuning and software tweaks such that production cars are even faster or it could mean that those cars had secret suspension/power tweaks that would mean a production car would be even slower. I suck at driving cars (can turn 1:40's at Laguna on my motorcycle though) but hope to make it out for REFUEL next year.

I am going out on a limb and speculating that they were pushing the internals of those cars harder than they will let a production car run. My brother and I happened to be at Ferrari event at Thunderhill where Tesla brought a pair of Roadsters. They consistently went into a "degraded performance mode" after a lap or two. Tracks are really hard on cars, and my understanding is that both cars were air cooled...which is fine for the street, but not up to snuff on he track. The Model S is water cooled? Even so, I would guess that heat and resistance are an issue on the track. (I am relying on my RC car knowledge...LOL) It is pretty easy to figure this one out. A Tesla Model S owner just needs to sign up for a track day and see what happens.

Don't misunderstand my fascination with the Tesla S as "hating' or "bashing". I hope to earn my way past recent...ahem...government imposed additions to my family's budget LOL...and own one of these awesome machines one day. Frankly, I think it is a bit silly to focus on the "high performance driving" characteristics of the Model S. But as long as people make assertions, it is worth exploring them.:smile:

Looking forward to having someone do a fun comparo with my brother's M5. In the past we have had lot's of fun comparing Porsche's with the Nissan GT-R. We still have an off the line race between his Volt and my Cayman R to do. They have near identical max torque numbers. Of course, my R delivers zero torque at zero rpm.

Similar threads

- Replies

- 11

- Views

- 667

- Replies

- 75

- Views

- 4K

- Replies

- 1

- Views

- 2K

- Replies

- 183

- Views

- 16K