Hmm, the Wall street worries about the quarter-to-quarter numbers. But either you make a mad rush at the last one month of the quarter, OR make a steady increasing pace for each of the 3 months; the numbers for the entire quarter would be the SAME either way. No matter how I look at it, I still don't understand why Tesla only work super-hard at the last month of the quarter, but not the first two months.Because once you've done it once, Wall St makes it hard to get off the roundabout. Tesla do some amount of batching because of the logistics of shipping and country homologation, but it would be surprising to me if this naturally coincided with quarter boundaries. But the first quarter where they don't do anything special will have less deliveries. Now, I think at some point, Elon will just have to say out loud that at some future quarter, they will go into steady state mode, and incorporate that into projections. The analysts will hit TSLA hard for ever saying something like that, because they're all about Q-on-Q numbers. So maybe Elon will never say that. Anyway, he seems to like the internal pressure generated too.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hmm, the Wall street worries about the quarter-to-quarter numbers. But either you make a mad rush at the last one month of the quarter, OR make a steady increasing pace for each of the 3 months; the numbers for the entire quarter would be the SAME either way. No matter how I look at it, I still don't understand why Tesla only work super-hard at the last month of the quarter, but not the first two months.

That's a complete misread. Examine the factory to delivery timelines and model the delivery logistics. The numbers are not the same either way. Take the exact same production and compare the resulting deliveries if you do no regional batching and allocation versus extreme regional batching and allocation. The resulting numbers would be vastly different.

Plotted the spreadsheet data for Model S (from Model S Order & Delivery 2016).

...

Still have to do this for the X, I´ll see when I find time.

View attachment 208180

Can´t find the same spreadsheet for the X. In one place around TMC I read there is none

dc_h

Active Member

They produce at a steady pace all quarter, but deliver long supply chain regions at the start of the quarter and deliver the closest locations last. China would be first, followed by Europe and then Eastern US and Canada and finally west coast of US. This maximizes deliveries each quarter and also minimizes inventory held at the end of the quarter, which affects free cash flow. The result is maximized sales, minimized inventory, max cash, minimum liabilities.Hmm, the Wall street worries about the quarter-to-quarter numbers. But either you make a mad rush at the last one month of the quarter, OR make a steady increasing pace for each of the 3 months; the numbers for the entire quarter would be the SAME either way. No matter how I look at it, I still don't understand why Tesla only work super-hard at the last month of the quarter, but not the first two months.

Here is a poll that Teslarati is running on Facebook, curious to see how the results differ from TMC's poll (given the broader audience)

POLL LINK

Didn't we conclude all polls are meaningless since Trump win?

I will say that reviewing some of the data cryptyk provided - gave some interesting findings. Inventory through the summer ramped up substantially and we know from his work that a good majority of inventory is not put up on the web for folks to see. I guess if all inventory was online, fewer orders would be made for full-priced cars and some folks would go with inventory buying.

I logged 540 inventory, meaning non-Customer orders, (only US and Euro - can't see China) for Vin # set 168xxx alone.

That lines up with 10/10 and AP 2.0 introduction. Also, lots of inventory vin # series of substance leading up to the September sell-off, so we know that was well planned ahead of time. Cool graphs and I wish I could show them for democratic review. Will wait until sales numbers are out next week. You don't want to see the Model X Vin # trend going into 2017. One thing about cryptyk's work - the ev-cpo.com seems to have always been well low on the actual inventory availability and as others have said, go into a local store to talk about the "real inventory list".

The two substantial pushes using Inventory bulk deployment were "September Sales" and "AP 2.0 intro-push" for year end. Of course, real customer orders had to wait while these inventory blocks were built and shipped. But that's the industry - that's what you do.

I logged 540 inventory, meaning non-Customer orders, (only US and Euro - can't see China) for Vin # set 168xxx alone.

That lines up with 10/10 and AP 2.0 introduction. Also, lots of inventory vin # series of substance leading up to the September sell-off, so we know that was well planned ahead of time. Cool graphs and I wish I could show them for democratic review. Will wait until sales numbers are out next week. You don't want to see the Model X Vin # trend going into 2017. One thing about cryptyk's work - the ev-cpo.com seems to have always been well low on the actual inventory availability and as others have said, go into a local store to talk about the "real inventory list".

The two substantial pushes using Inventory bulk deployment were "September Sales" and "AP 2.0 intro-push" for year end. Of course, real customer orders had to wait while these inventory blocks were built and shipped. But that's the industry - that's what you do.

Last edited:

schonelucht

Well-Known Member

I logged 540 inventory, meaning non-Customer orders, (only US and Euro - can't see China) for Vin # set 168xxx alone.

That lines up with 10/10 and AP 2.0 introduction.

I still don't exactly understand how the Model S production/delivery went this year. For example if you look at the Norway Model S VIN deliveries they are well over 15 000 VINS behind (delivering 165xxx cars when 181xxx VINS are handed out). Yet the Model X they are delivering 27xxx which means they are only 6 000 or so VINS behind. Since both models have the same transportation chain, I'd expect them to run behind at approximately the same rate.

how does rotating delivery region in various months minimize inventory?? You are talking about the same car/design for vast majority of the market, except the small right-hand drive market where there are changes of design/parts.They produce at a steady pace all quarter, but deliver long supply chain regions at the start of the quarter and deliver the closest locations last. China would be first, followed by Europe and then Eastern US and Canada and finally west coast of US. This maximizes deliveries each quarter and also minimizes inventory held at the end of the quarter, which affects free cash flow. The result is maximized sales, minimized inventory, max cash, minimum liabilities.

If you are talking about car inventory instead of part inventory, I don't see how car inventory would be lower either. As long as the transport logistics keep shipping cars out to all region every single month, I don't think car inventory is an issue at all. Massive pile up of inventory only happens if there is a bottle-neck anywhere in the entire production-to-delivery process.

how does rotating delivery region in various months minimize inventory?? You are talking about the same car/design for vast majority of the market, except the small right-hand drive market where there are changes of design/parts.

If you are talking about car inventory instead of part inventory, I don't see how car inventory would be lower either. As long as the transport logistics keep shipping cars out to all region every single month, I don't think car inventory is an issue at all. Massive pile up of inventory only happens if there is a bottle-neck anywhere in the entire production-to-delivery process.

The EU receives car parts, not whole cars. They are assembled in Tilburg. Considering that they've only delivered less than 4k, spreading that out over 3 months means only ~1k cars worth of parts per shipment. On a container ship that can fit over 36k cars, 1k is peanuts and probably doesn't get as good of a discount on shipping that 4k would've gotten.

Based on the detail data about European deliveries (shown below), it is also similar to North American market where majority of deliveries happens on the last month of each quarter. Probably not the best to operate the company where the company is absolutely slammed on the last month.

Tesla Europe Registration Stats

Tesla Europe Registration Stats

By the way, this chart from (see below) would be helpful for people who wants to look at the historical numbers.

Tesla Europe Registration Stats

Tesla Europe Registration Stats

Chart above says that the US/Canada are highly favored now. Couple years ago, the "split" was supposed to grow with N. America being 40% and Europe/Asia being 30% each. US was high in Q3 due to the prevalence of both the Model X deliveries growing and the 2-year lease deals and discounting as well. 30K discounted P90DL units were offered on 2-year lease and were quite active in the sales cycle - as were MS 60 to Model 3 reservation holders who were called and offered 2-year lease deals to get one and not wait on the Model 3 for their first Tesla.

geneclean55

Active Member

Lets see how China looks this quarterChart above says that the US/Canada are highly favored now. Couple years ago, the "split" was supposed to grow with N. America being 40% and Europe/Asia being 30% each. US was high in Q3 due to the prevalence of both the Model X deliveries growing and the 2-year lease deals and discounting as well. 30K discounted P90DL units were offered on 2-year lease and were quite active in the sales cycle - as were MS 60 to Model 3 reservation holders who were called and offered 2-year lease deals to get one and not wait on the Model 3 for their first Tesla.

dc_h

Active Member

Without regional bundling their in transit inventory of cars would be close to 30% of quarterly deliveries. Averaging 3 weeks of N American in transit and 50% of international shipments would be inventory. It may not be optimal for logistics, but financially it is probably necessary.how does rotating delivery region in various months minimize inventory?? You are talking about the same car/design for vast majority of the market, except the small right-hand drive market where there are changes of design/parts.

If you are talking about car inventory instead of part inventory, I don't see how car inventory would be lower either. As long as the transport logistics keep shipping cars out to all region every single month, I don't think car inventory is an issue at all. Massive pile up of inventory only happens if there is a bottle-neck anywhere in the entire production-to-delivery process.

Dedicated shipping with model 3 could improve logistics without the regional bundling. They will be able to fill a cargo container every week at full production.

Model X, S combine production 32,500

delivery 27,500

Hi Ratanpara,

Welcome to TMC! For your first posting, you've laid down quite an impressive prediction (and way out of range of factory production guidance). I am curious as to how you came up with it?

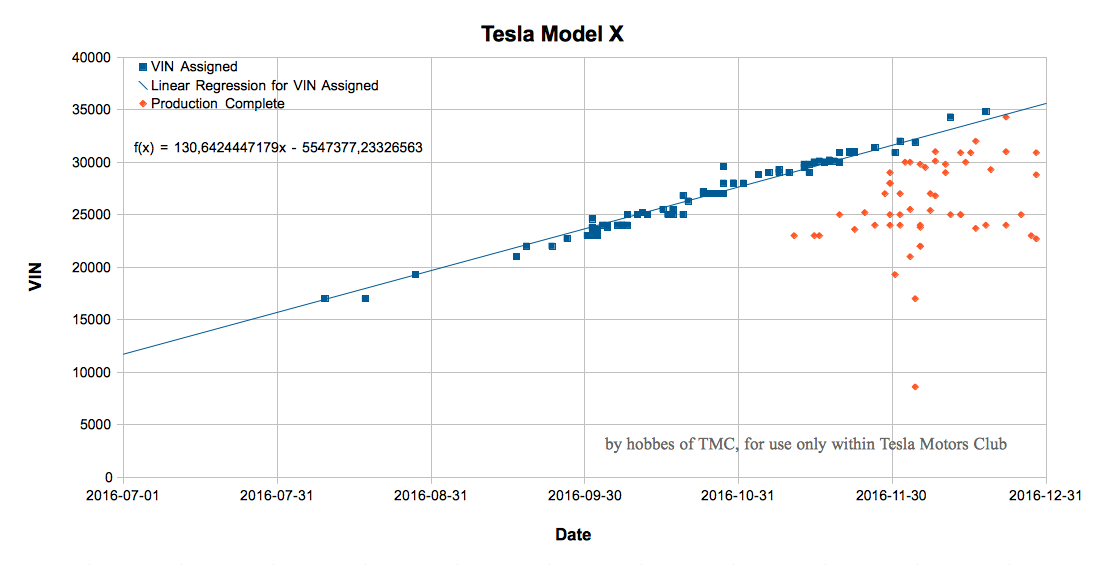

Did the same graph for the limited X data from Model S Order & Delivery 2016 . Also added a trend line. Calculating from the slope, Q4 should have approximately 12,000 VINs assigned. Doing the same for the Model S plot I posted above, I get approx.15,800 VINs assigned.

This assumes the trend the data shows continued through the last two weeks of 2016 (and not did not slow down as @bonair suggested for the X). Using this for predicting deliveries one must also take into account how VIN assignments correlate into deliveries (there might still be part shortages or delivery problems after a VIN is assigned).

All I would definitely conclude: not more than 27,800 cars produced and delivered . However, you could use data posted @bonair here: It shows how VIN assignment and actual deliveries have differed over the quarters. With a filled delivery queue (5000 at end of last Q), I think assuming 2000 cars less delivered than VINs is a moderately conservative estimate, so the 23,000 to 26,000 bin in this poll seems about right IMHO.

. However, you could use data posted @bonair here: It shows how VIN assignment and actual deliveries have differed over the quarters. With a filled delivery queue (5000 at end of last Q), I think assuming 2000 cars less delivered than VINs is a moderately conservative estimate, so the 23,000 to 26,000 bin in this poll seems about right IMHO.

This assumes the trend the data shows continued through the last two weeks of 2016 (and not did not slow down as @bonair suggested for the X). Using this for predicting deliveries one must also take into account how VIN assignments correlate into deliveries (there might still be part shortages or delivery problems after a VIN is assigned).

All I would definitely conclude: not more than 27,800 cars produced and delivered

Trying to come up with a good number here makes me wonder how long does it actually take to deliver a car?(Side thought: will they just self drive it to your house eventually?) I'm guessing it could be almost same day if it's Bay Area, but how long to make delivery in Europe or China?

The reason I ask is if they could batch the deliveries to send out the longer shipments earlier in Dec, and then maybe do easier deliveries the week before Christmas, and then I assume last week was down for the Holidays, that would open up the possibility of getting the in-transit number down which IIRC is what happened last year. If they were able to deliver everything produced the delivery number could get close to 30k IMO.

The reason I ask is if they could batch the deliveries to send out the longer shipments earlier in Dec, and then maybe do easier deliveries the week before Christmas, and then I assume last week was down for the Holidays, that would open up the possibility of getting the in-transit number down which IIRC is what happened last year. If they were able to deliver everything produced the delivery number could get close to 30k IMO.

Similar threads

- Replies

- 45

- Views

- 4K

- Replies

- 18

- Views

- 1K

- Replies

- 1

- Views

- 466

- Question

- Replies

- 4

- Views

- 792

- Replies

- 15

- Views

- 1K