Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I was brainstorming options for this and I thought of this:

Peel and Stick Laminate - Clear | Duck® Brand

It is a giant sheet of peel and stick clear duct tape, essentially.

What if you just cut a 19" circle and stuck it on the face of the rim? I know that it would not last for a really long time, but maybe for just one use or for a road trip.

One problem is that the area that is not in contact with the rim would be sticky and gather crud, but probably not more than a dusting.

There is no danger associated with them falling off or failing, other than litter.

The wind forces are way to strong for that solution. In my experience, there is quite some pressure from the air and also think about the fact that the wheels are following the road's every little bump. So there is also some serious vibration going on.

mgdurand

Member

If there's a concern with one of these things killing somebody, maybe you should use gluten-free pizza pans?

Quick update. After driving with them for several thousand miles I was able to see a noticeable difference in energy usage. I never had the time to do a controlled test. I tried but it isn't easy to do two identical test runs with and without the disks to be able to measure the actual difference very accurately. But on the other hand, covered wheels aren't a new concept and many tests have been done before. There is a lot of data out there indicating the difference at highway speeds is between 4-6%.

I decided to take them off and have a professional company manufacture new ones for me including a better mounting system. Hopefully one that allows the disks to be removed quickly. That was the biggest drawback of my solution. I will update when I have the new disks installed.

I decided to take them off and have a professional company manufacture new ones for me including a better mounting system. Hopefully one that allows the disks to be removed quickly. That was the biggest drawback of my solution. I will update when I have the new disks installed.

Last edited:

JJMc

Member

David99, what about Moon's snap-on discs? I didn't see their hardware, but that would be a quick solution to fastening.

islandbayy

Active Member

Quick update. After driving with them for several thousand miles I was able to see a noticeable difference in energy usage. I never had the time to do a controlled test. I tried but it isn't easy to do two identical test runs with and without the disks to be able to measure the actual difference very accurately. But on the other hand, covered wheels aren't a new concept and many tests have been done before. There is a lot of data out there indicating the difference at highway speeds is between 4-6%.

I decided to take them off and have a professional company manufacture new ones for me including a better mounting system. Hopefully one that allows the disks to be removed quickly. That was the biggest drawback of my solution. I will update when I have the new disks installed.

Who is manufacturing them for you? Sign me up for a set!

ERP

Ludicrous Member

I am concerned some of you are so comfortable drilling into your wheels. Is it possible to do it safely? Yes, with a properly fixtured wheel on a mill with repeatable control of the hole depth, and testing to determine it does not cause fracturing. But doing it by hand in a garage is very risky.

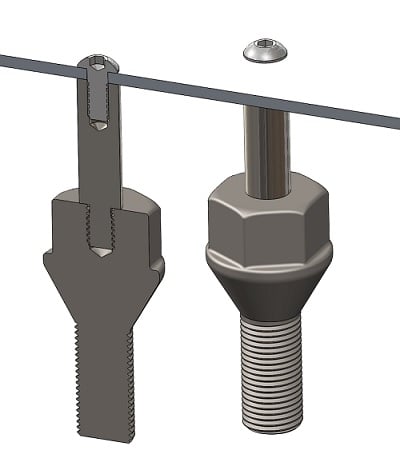

A much safer and simpler solution is to add a tapped hole to the end of the lug nuts. Then use a spacer bolt to bring the surface flush to the disc which is secured with a small button head screw. I've put together a quick assembly and rendering of this setup. It's easy to install and much less obvious when the disc is off.

A much safer and simpler solution is to add a tapped hole to the end of the lug nuts. Then use a spacer bolt to bring the surface flush to the disc which is secured with a small button head screw. I've put together a quick assembly and rendering of this setup. It's easy to install and much less obvious when the disc is off.

Thumper

Active Member

RC plane builders use a product called Monocoat. It is available at hobby shops in fairly large sheets. It comes in colors, is adhesive when heated and shrinks to tautness. I have used it to build recumbent bicycle aero tail boxes which last for years. I think it would work well directly on the wheel but it might be difficult to remove without paint damage. It might not be difficult to remove.

JRP3

Hyperactive Member

I had an idea for attaching the pans without drilling the rims, drill and tap the tops of the lug nuts.

A much safer and simpler solution is to add a tapped hole to the end of the lug nuts. Then use a spacer bolt to bring the surface flush to the disc which is secured with a small button head screw. I've put together a quick assembly and rendering of this setup. It's easy to install and much less obvious when the disc is off.

View attachment 80243

Exactly what I was talking about, though the spacer could just be a hollow tube and use a longer bolt.

ERP

Ludicrous Member

Exactly what I was talking about, though the spacer could just be a hollow tube and use a longer bolt.

While that would work, I would not want to go that route. It would be much more difficult to install the disc. Everything would have to be preassembled on the disc then blindly lined up with the lug nuts.

JRP3

Hyperactive Member

Good point, though I could think of a few ways around that issue, but your way is probably the easiest.

MarcG

Active Member

David, any updates on your new set of pans?

The company that said they would make them is totally dropping the ball. They kept saying 'soon' but nothing happened. Now they don't even answer my emails.

Quick update.

The shop has finished the disks and custom lug nuts. It all looks great, but unfortunately the lug nuts aren't deep enough so they have to be redone. But we put them on just for a few photos. I think they will have the kit ready in about 4 weeks hopefully.

The shop has finished the disks and custom lug nuts. It all looks great, but unfortunately the lug nuts aren't deep enough so they have to be redone. But we put them on just for a few photos. I think they will have the kit ready in about 4 weeks hopefully.

JRP3

Hyperactive Member

ratsbew

Active Member

Awesome! So you've partnered with a shop to manufacture these? I can't wait to see a scientific test of these!

Awesome! So you've partnered with a shop to manufacture these? I can't wait to see a scientific test of these!

I didn't really partner with them, I just brought the idea to them and they are using me as a test mule. I let them borrow a wheel so they could prototype. They are not a huge shop but they are known for their custom made disks. Their idea is to offer a kit for Tesla owners. I won't get any commission for any of their sales.

BTW, the disks are really well done and light (aluminum). They are clear painted so they are easy to keep clean.

FlatSix911

Porsche 918 Hybrid

FlatSix911

Porsche 918 Hybrid

Similar threads

- Replies

- 86

- Views

- 7K

- Replies

- 20

- Views

- 3K

- Replies

- 10

- Views

- 2K