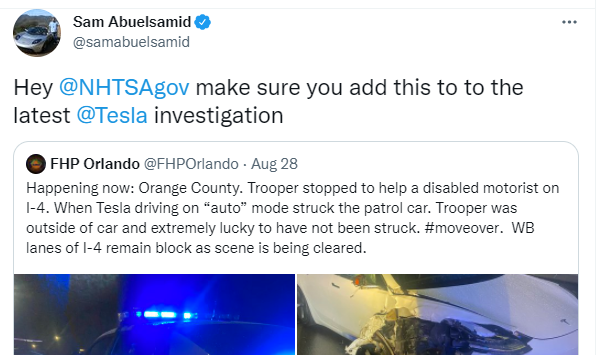

So it turns out that the folks from Navigant/Guidehouse that rank Tesla last in autonomy actually just hate Tesla. Numerous examples exist.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

henchman24

Active Member

I'm certainly not an expert in batteries. From my readings it seems the core of the issue is dendrites and overcharging, but the form factor allows more deformation which increases the chances of failure.

ChefBoyardee

Member

We all agree that the Bolt thing is bad for EVs, but what I find interesting is how GM is handling it with regard to their battery supplier, LG. For starters, they are trying to get them to pay a good chunk of the ~$1.8B recall.

Then the GM spokesman, Dan Flores, says, “Because we are not confident that LG has the capability to build defect-free products, we’ve put the repairs on hold and we are not building new Bolts. We’re not going to start recall repairs or start building new Bolts until we’re confident LG will build defect-free products.”

I thought this was interesting (and relevant): It's near impossible to produce 100% defect-free batteries 100% of the time, so Tesla designed the risk out of the system:

"Days later, a small group of battery consultants were gathered with what at first seemed like a manageable message: Yes, even the best battery manufacturers produced a random cell that would have a defect, causing it to short and catch fire. But the odds were remote. “It happens really, really infrequently,” one of the consultants said. “I mean like between one in a million and one in ten million cells.”

But Tesla planned to put about 7,000 cells in a single car. Sitting near Straubel, Berdichevsky pulled out his calculator and computed the likelihood that a cell in one of their cars might catch fire by chance. “Guys, that’s like between one in 150 and one in 1,500 cars,” he said.

And not only would they be churning out cars with defective batteries that, if ignited, could set off a chain reaction, but their cars could be detonating in the garages of the richest of the rich—burning down mansions and lighting up local TV news. The mood in the room shifted. The questions became more urgent: Was there anything that could be done to avoid defective cells?

Nope. Random cells were always going to get too hot and spark thermal runaway — basically an explosion sparked by overheating.

... A solution to thermal runaway could amount to a true breakthrough, one that would set Tesla apart from the auto industry for years to come. ...

... Eventually, Straubel began to narrow in on a solution. If they couldn’t keep a cell from warming, maybe they could keep it from reaching the point where it set off a chain reaction. Through trial and error, the team realized that if they had each cell lined up a few millimeters from its neighbor, snaked a tube of liquid between them, and dumped a brownie-batter-like mixture of minerals into the resulting battery pack, they could create a system that contained overheating. If a defective cell within began to overheat, its energy would dissipate to its neighboring cells, with no individual cell ever reaching combustibility."

- Power Play by Tim Higgins

So basically, GM is barking up the wrong tree by blaming suppliers, while TSLA already solved the problem years ago

TheTalkingMule

Distributed Energy Enthusiast

So to be clear.....I should be putting my commentary around what TSLA options look appealing within the Intraday $TSLA Analysis thread, and this thread is reserved for discussion of non-Tesla battery tech?

Some pretty bad PMI and consumer confidence numbers should keep macros down today and slow TSLA buying pressure enough to put MM's back in the driver's seat.

Let's see if they can manage $720 by tomorrow.

Some pretty bad PMI and consumer confidence numbers should keep macros down today and slow TSLA buying pressure enough to put MM's back in the driver's seat.

Let's see if they can manage $720 by tomorrow.

JRP3

Hyperactive Member

Evidence suggests otherwise:It's got nothing to due with the battery cell form factor. It's all about forming dendrites due to overcharging (c.f. BMS firmware), which eventually pierce the separator membrane causing an electrical short curcuit and spontaneous combustion. That's why these GM Bolts burst into flames at random times.

GM’s investigation into the problems with its batteries found battery cell defects like a torn anode tab and folded separator.

GM says it will seek reimbursement from LG Chem for $1B Chevy Bolt recall losses | TechCrunch

American automaker General Motors expanded its recall of Chevrolet Bolt electric vehicles on Friday due to fire risks from battery manufacturing defects.

Don't mind me I'm just whale watching over here

TheTalkingMule

Distributed Energy Enthusiast

Or not! This has been quite a bullish 24hrs.Some pretty bad PMI and consumer confidence numbers should keep macros down today and slow TSLA buying pressure enough to put MM's back in the driver's seat.

In the case of the LG cells, the failure is a manufacturing issue and occurs when both the anode tab is torn and the separator is out of position resulting in the anode tab directly contacting the cathode tab. Not a dendrite nor GM BMS issue,It's got nothing to due with the battery cell form factor. It's all about forming dendrites due to overcharging (c.f. BMS firmware), which eventually pierce the separator membrane causing an electrical short curcuit and spontaneous combustion. That's why these GM Bolts burst into flames at random times.

Dr. Jeff Dahn at Dalhousie U. has spent over 6 years researching battery cells, and has identified the correct blend of electrolyte additives to reduce the risk of dendrite formation. As I said, the rest is BMS firmware, which amounts to not overcharging the cells (too fast, or too high).

BTW, this issue in NOT new. Read this article from Oct 14, 2014:

Scientists pinpoint cause of harmful dendrites and whiskers in lithium batteries

Scientists have uncovered a root cause of the growth of needle-like structures -- known as dendrites and whiskers -- that plague lithium batteries, sometimes causing a short circuit, failure, or even a fire. Such defects are a major factor holding back the batteries from even more widespread use...www.sciencedaily.com

Cells in GM, Hyundai EV battery fires linked to several LG plants

Documents filed by GM and Hyundai with the U.S. safety regulator show how the two automakers separately identified the same cause of battery fires in their newest electric vehicles, tracing them to similar manufacturing defects in battery cells made at at least two plants operated by a unit of LG Chem.

GM identified the defects as a torn anode tab and a folded separator, and said the defective cells were produced at LG’s plant in Ochang, Korea.

Hyundai said its investigators determined that a battery fire in a Kona EV - one of more than 15 such incidents in Korea, Europe and Canada - was caused by an internal short circuit in a battery cell. Hyundai traced the issue to a “folded anode tab.”

@JRP3 types faster.

TheTalkingMule

Distributed Energy Enthusiast

I wonder what it feels like to buy a million shares of something in 6 minutes?

Artful Dodger

"Neko no me"

Get ready for Tesla traffic-proximity audio-warnings to get a lot smarter:

Cheers!

Cheers!

Artful Dodger

"Neko no me"

@JRP3 types faster.

So basically a QA issue in manufacturing, and nothing to do with the form-factor of the defective cells.

It's got nothing to due with the battery cell form factor. It's all about forming dendrites due to overcharging (c.f. BMS firmware), which eventually pierce the separator membrane causing an electrical short curcuit and spontaneous combustion. That's why these GM Bolts burst into flames at random times.

Dr. Jeff Dahn at Dalhousie U. has spent over 6 years researching battery cells, and has identified the correct blend of electrolyte additives to reduce the risk of dendrite formation. As I said, the rest is BMS firmware, which amounts to not overcharging the cells (too fast, or too high).

BTW, this issue in NOT new. Read this article from Oct 14, 2014:

Scientists pinpoint cause of harmful dendrites and whiskers in lithium batteries

Scientists have uncovered a root cause of the growth of needle-like structures -- known as dendrites and whiskers -- that plague lithium batteries, sometimes causing a short circuit, failure, or even a fire. Such defects are a major factor holding back the batteries from even more widespread use...www.sciencedaily.com

Pouch cells inevitably have a more flexible outer case than cylindrical. That in turn means there will be mechanical movement going on to a greater extent than in cylindrical. Combine that wth dendrites, add in poor BMS, and voila, bang.

(as many laptop and cell phone owners find out when they take off their bulging cover plates.

(At least that is the way I see it - am I wrong)

(Surely, to an extent the same is the case with prismatics. Both the bend radius at the corner curves are a greater issue than the corresponding cylindtrical spiral roll, and the mechanical rigidity of the casing is less than the cylinder's rigidity for the same casing thickness (pure hoop stress) - again, am I wrong ?)

(Add in that cylindrical/spiral roll-forming production machinery is generally better/faster/cheaper/more repeatable for these sorts of processes and that volumetric fill is not that different, plus opportunity to load-share/function-share and it seems generally preferable to go down the cylindrical can route. It is not that the others can't succeed, but that they might not be preferable. So we may one day see Teslas with these form factors, never say never.)

I'm certainly not an expert in batteries. From my readings it seems the core of the issue is dendrites and overcharging, but the form factor allows more deformation which increases the chances of failure.

Guess I'm late to this party. From very limited knowledge (and I'm not from Barcelona; Fawlty Towers ref) form factor does play a role also. Tesla solved this; "competitors" saved on pennies to lose all the pounds.Evidence suggests otherwise:

GM says it will seek reimbursement from LG Chem for $1B Chevy Bolt recall losses | TechCrunch

American automaker General Motors expanded its recall of Chevrolet Bolt electric vehicles on Friday due to fire risks from battery manufacturing defects.techcrunch.com

In short: Agree with most here.

Artful Dodger

"Neko no me"

From very limited knowledge (and I'm not from Barcelona; Faulty Towers ref) form factor does play a role also. Tesla solved this; "competitors" saved on pennies to lose all the pounds.

Although its yet to be confirmed via a teardown, its very likely that the LFP packs that Tesla purchases from CATL use cells with a hard-case pouch, or a prismatic form-factor (but not cylindrical).

This shouldn't be a issue at all, since LFP chemistry is much less prone to thermal runaway.

TL;dr I trust Tesla Engineering.

Cheers!

I'm thinking the TSLA Summer Sales Event ends today...

Phobi

Member

Meanwhile market maker battlestations…

the fight for $740 is on…

the fight for $740 is on…

TheTalkingMule

Distributed Energy Enthusiast

I'm thinking the TSLA Summer Sales Event ends today...

The LEAP sale is certainly over. I really missed the boat on closing out a few covered calls yesterday.

dhanson865

Well-Known Member

It's almost as if they put fire retardant in every pack. I swear I've heard that somewhere before.I thought this was interesting (and relevant): It's near impossible to produce 100% defect-free batteries 100% of the time, so Tesla designed the risk out of the system:

"Days later, a small group of battery consultants were gathered with what at first seemed like a manageable message: Yes, even the best battery manufacturers produced a random cell that would have a defect, causing it to short and catch fire. But the odds were remote. “It happens really, really infrequently,” one of the consultants said. “I mean like between one in a million and one in ten million cells.”

But Tesla planned to put about 7,000 cells in a single car. Sitting near Straubel, Berdichevsky pulled out his calculator and computed the likelihood that a cell in one of their cars might catch fire by chance. “Guys, that’s like between one in 150 and one in 1,500 cars,” he said.

And not only would they be churning out cars with defective batteries that, if ignited, could set off a chain reaction, but their cars could be detonating in the garages of the richest of the rich—burning down mansions and lighting up local TV news. The mood in the room shifted. The questions became more urgent: Was there anything that could be done to avoid defective cells?

Nope. Random cells were always going to get too hot and spark thermal runaway — basically an explosion sparked by overheating.

... A solution to thermal runaway could amount to a true breakthrough, one that would set Tesla apart from the auto industry for years to come. ...

... Eventually, Straubel began to narrow in on a solution. If they couldn’t keep a cell from warming, maybe they could keep it from reaching the point where it set off a chain reaction. Through trial and error, the team realized that if they had each cell lined up a few millimeters from its neighbor, snaked a tube of liquid between them, and dumped a brownie-batter-like mixture of minerals into the resulting battery pack, they could create a system that contained overheating. If a defective cell within began to overheat, its energy would dissipate to its neighboring cells, with no individual cell ever reaching combustibility."

- Power Play by Tim Higgins

So basically, GM is barking up the wrong tree by blaming suppliers, while TSLA already solved the problem years ago

Great synopsis and I laughed out-loud so many times while listening to this. Kudos to @avoigt ! I was outside at my driving range with headphones and if someone had seen me shaking my head and then laughing they'd thought I'd lost my mind.The entire interview felt like an embodiment of why the German car industry is doomed:

A: Tesla are growing fast and eating our lunch, should we not have been doing OTA 8 years ago like Tesla? Are you not worried?

P: Jaja. But there is this startup I am investing in, which in a few years will have a product that does something nobody needs or wants.

A: How about the giga casting and structural battery packs, that will make the cars better and cheaper?

P: I would not be worried. The most important thing is not automation but material cost. Also German companies cannot take risks like Tesla. If we did we would go to jail. *cough*

A: How about AI day, will not all talent go to Tesla now?

P: Haha didn’t watch. The robot is stupid.

A: How about Dojo and vector space neural nets and neural planning?

P: The most important thing will be simulations. Also the leader is Waymo, they have more driven miles.

A: It was nice talking with you

What made me laugh is many of your points above, but the gist of it is that this guy doesn't even know or realize what is actually happening. He seemed so proud of his company that is making something that Tesla considered tablestakes 12 years ago and folks like me in the software/service industry have done for nearly 20+ years. And it is so super easy that it is basically a line item on the feature spec with a few dev weeks of work to tie in the sub-components. And if this guy is a thought leader in the German auto industry then it is sooooo much worse than I thought. Even the progressive thinkers, like this guy, can't see how unbelievably behind they are and WILL NOT catch up as what is being talked about is infinitesimal progress relative to Tesla innovation.

TL;DR - Auto execs simply do not understand software AT ALL. The gap will continue to widen and seems to be accelerating based on this interview.

Similar threads

- Locked

- Replies

- 0

- Views

- 4K

- Locked

- Replies

- 0

- Views

- 6K

- Locked

- Replies

- 11

- Views

- 10K

- Replies

- 6

- Views

- 5K

- Locked

- Poll

- Replies

- 1

- Views

- 12K