On second thought: my guidance was probably too harsh, so go ahead and discuss the Cyberquad. But don't go overboard.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

Krugerrand

Meow

No need to ask any questions. If he’s a friend simply tell him he does not own enough TSLA.In an amazing coincidence, I am going to be chatting today with a battery research engineer friend who happens to work for, wait for it...

VW

What should I ask this person?

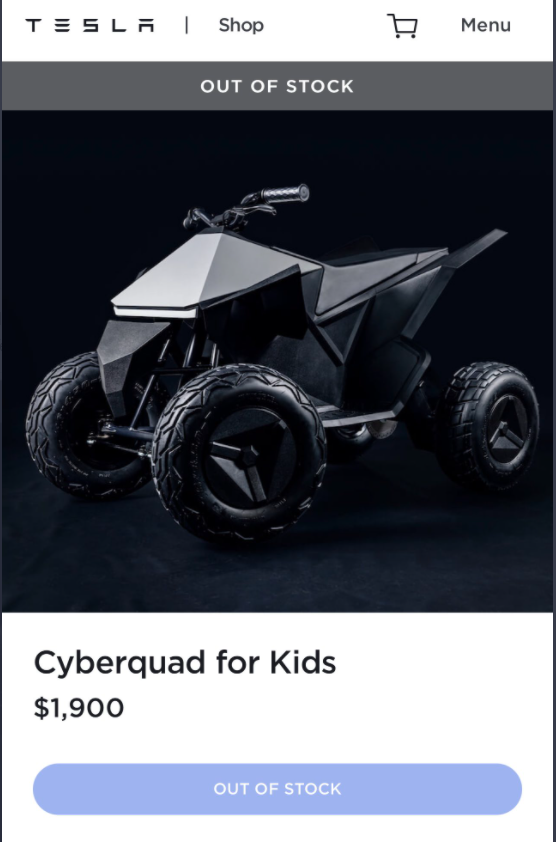

On second thought: my guidance was probably too harsh, so go ahead and discuss the Cyberquad. But don't go overboard.

It's sold out already, we waited too long to discuss it!

Good, cuz I wasn't sure where I could park it.It's sold out already, we waited too long to discuss it!

Looks like a good bounce off that levelTime to re-test the 1060 support...

SOLD OUTOn second thought: my guidance was probably too harsh, so go ahead and discuss the Cyberquad. But don't go overboard.

All of this Cybertruck swag was probably meant to roll out along with the start of deliveries. I give it a small chance though that we either get word of when production starts or perhaps that production has just started.

Regardless, I expect the final design to be unveiled very soon.

Regardless, I expect the final design to be unveiled very soon.

Just piecing some information together.

Tesla rejected a $1B+ incentive in Berlin, for which part of the conditions was that the factory must be the first to utilize 4680 cell.

Now we are bombarded with CT merchandises and hints that something big may happen on 12/9. Could it be Elon decided to use the current 4680 cells in production on limited CT production, which would prevent them from going to Berlin?

Tesla rejected a $1B+ incentive in Berlin, for which part of the conditions was that the factory must be the first to utilize 4680 cell.

Now we are bombarded with CT merchandises and hints that something big may happen on 12/9. Could it be Elon decided to use the current 4680 cells in production on limited CT production, which would prevent them from going to Berlin?

BrownOuttaSpec

Active Member

It's a toy, not made/produced by Tesla. It is made by Radio Flyer (same people who made the mini Model S and Model Y), I feel very confident in saying that there is zero Tesla tech in this product: Ride-On Tesla Toys for Kids | Radio FlyerOn second thought: my guidance was probably too harsh, so go ahead and discuss the Cyberquad. But don't go overboard.

I think you were correct in your original guidance of moving it to its own thread. If not, why dont we add the Hot Wheels RC Cybertruck and the Lego Cybertruck.

SOLD OUT

.. since we are now allowed to discuss

Tesla Toys needs it's own SPAC and IPO

The quad goes uphill as well .. Nikola

Even just getting it started in very low production would be huge. Tesla does have a history of seeding the market with low numbers to get buzz going (see model Y shipments to Europe).Just piecing some information together.

Tesla rejected a $1B+ incentive in Berlin, for which part of the conditions was that the factory must be the first to utilize 4680 cell.

Now we are bombarded with CT merchandises and hints that something big may happen on 12/9. Could it be Elon decided to use the current 4680 cells in production on limited CT production, which would prevent them from going to Berlin?

Um. That's a little odd.There might be something to the Porsche battery story.

For what it is worth, analog voltage measurements have to be converted to digital format to process them in a computer. The device used to do this is an analog to digital converter.

The digital output has a finite number of discrete steps. The number of steps that the device is capable of are typically smeared over the measurement range.

If you use the same device to measure 800V as is used for 400V, the step size will be twice as large - perhaps too coarse for ideal operation.

ADC's come in various "bit" sizes: 8 bit, 12 bit, 16 bit, etc. They'll typically have a precision reference voltage (band-gap diode reference or something) hooked up to the top of a resistor chain and ground or something at the bottom of said chain. An 8-bit ADC can measure 256 possible values, plus or minus the usual inaccuracy. But 8-bit ADCs are relatively uncommon; the cost difference between an 8-bit, 12-bit, or 16-bit ADC is minimal, so people usually go for the 12-bit (4096 values) or 16-bit (65536 values). The bigger bits are slower, typically, than the smaller bit types, but we're talking typical sample rates of 1 MSa/s and up for the cheapies, and I'm pretty sure that a BMS doesn't need to know state of charge on a microsecond-by-microsecond basis. (Now, if you want to sample along at 10 GSa/s, then you might be restricted to an 8-bit ADC, but that's a different story.)

Further, I suspect you're not going to find very many people willing to sell you an ADC that takes in 800V directly; that's a good way to end up with silicon vapor. Typically, one uses a resistor divider so the maximum input voltage to the ADC is 80% of the maximum for the ADC. (And the accuracy of the measurement is directly related to the accuracy of the resistors; in an application like this, one would need to use matched resistors, built on the same substrate, around .1% accuracy, typically, without spending too much money.)

So, to measure 800 V, we'd divide this down to 80% of the maximum of the ADC, then measure. So, using a 12-bit ADC, we'd have 800/(4096*0.8) = 244 mV/step; with a 16-bit ADC, that'd be 800/(65536*0.8) = 15 mV/step.

First off: in my extremely uneducated BMS opinion, 244 mV or 122 mV (for a 400V system) seems too large to keep track of the voltage on a battery chain; for sure, if one was monitoring the overall battery voltage, 16-bit and 15mV (or 7.5 mV for a 400V system) seems to be the way to go. Now, if I can figure this out without an envelope, so can anybody else.

Second: I dunno if Porsche (or Tesla, or whomever) is running every single battery cell in series (unlikely in the extreme) or all in parallel (impossible if one wants high voltage), or some combination of series and parallel (a lot more likely), the individual voltages that the BMS would be monitoring would be individual cell voltages or smaller groups of cells, then do some math to add it up to the overall battery pack voltage (if desired). Remember: They're trying for the amount of charge on cells, I would think. But that means that the voltages they're measuring would be, for the Porsche, 800/N, where N is the number of series groups.

Which means that my step sizes up above would also be divided by N. So, for example, there's 10 bunches of cells in series, with 80V across each bunch, then a 12-bit ADC on that bunch would have 244/10 = 24.4 mV/step. Which is probably getting down to the point where a 12-bit ADC would be doable.

Conclusion: This ain't rocket science, at least not for a practicing EE. So, while it sounds like a nifty idea (ADC mistake!), it's probably not that. Sorry.

Last edited:

StarFoxisDown!

Well-Known Member

Amazing number considering how many more boats left Shanghai so far this quarter. Aug (2nd month of quarter was like 31k), so I’m expecting at least 35k exports minimum but I think 40k is more likely

No hail Marys needed here. I sold a chunk of TQQQ to make room for a June '23 call.Elon, forgive me.

I sold 5% of my stock and bought options.

I will wax my car as penance.

Hock1

Member

How about exports? Are they broken out, or included?

Um. I agree with you about cutting blocks of cells in/out of a group in parallel. But I have a quibble about voltages and such and where they come from.I'm not seeing an issue:

Gruber cuts out cells on Roadster blades to repair packs.

Roadster - ESS Main Battery Pack Services 2 | Gruber Motors

Electrically, cells within a group charge in parallel. Linguistically, all cells charge simultaneously which is synonymous with 'in parallel' as opposed to sequentially (or half of the 800V pack at a time to match 400V chargers which is not how this system works)

As to the process: Taycan is a 2p setup so they can cut out the problem cell and its mate, then jumper around them. If the pack is under rated in terms of capacity, then this mod can be hidden by a software calibration tweak.

As to the potential root cause: When a pack is nearing full charge, the key parameter is the voltage on the highest SOC cell. The charger must throttle back current to ensure this cell does not exceed design spec. If the charger output exceeds the BMS balance capability, then the cells will be overcharged.

Possibly, the charger does not regulate current output well enough (inherent issue or poor regulation from mains fluctuations).

A current reading of less than its actual output would be my guess. Resolution of measurement (precision) is less critical than accuracy (or at least the correct bias of accuracy). Better for the output to be undercurrent/ undervoltage than over.

I've formed an opinion (probably wrong, but who knows?) that the actual battery charger in all these BEVs is some form of DC-DC converter, running at $DIETY's own switching frequency. Input side would be DC from the car's on-board AC->DC converter or direct DC from a charger. Output side would be the DC voltage and current used to charge the battery. These things are highly efficient in their power conversion, especially with relatively high voltages on input and output.

I mess with these things from time to time at work on a regular basis, although admittedly the outputs are used to power up silicon, not batteries. Having said that, though: I haven't run into one of these in the past decade or two that doesn't have the capability of measuring both its output voltage and current; and, even if one had some kind of home-brew circuit that didn't have the output V and I monitoring built in, it's truly trivial to add that after the fact; Hall-effect current sensors are out there and are cheap, not to mention just measuring the voltage across a low-value resistor.

In principle, then, an electron shouldn't be able to fall in the woods without somebody/something noticing.

I suspect that the problem with Porsche's BMS, assuming the whistleblower is onto something, has nothing to do with basic monitoring. Since I got the Tesla, I've been reading the odd papers here and there posted online about different battery chemistries, longevities, anode and cathode structures, and all that. I'm not an expert, by any means, but the algorithms used to charge/discharge the batteries in a BEV look to be very, very challenging, and, if one gets those wrong, then, yeah, the whistleblower may be onto something.

CLK350

Member

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M