Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

Why should it be for free or automated?

Do it for the same price as aftermarket, but on the production line.

With the Cybertrucks simpler geometry, everyone of the fewer parts can be precicely pre-cut.

You pull the BiW of the line and apply the wrap there. Likewise for other subassemblies.

Compared to aftermarket you save the disassembly/reassembly-cost, but add exact matching of parts and VIN and possibly some protection measures during assembly.

Assuming it's popular, even done manually, by the hundreds it could scale really well with a small team .

honestly? Why bother with offering it? Let the aftermarket flourish in offering thousands of possible custom designs. Some even suggested of special heat-treatments to discolor the steel.

No paint: faster output, more environmentally friendly, weighs less (...), more robust/futuristic feeling, less/no risk of scratching during transport/shipping to customer (just buff them out if they would happen during it out), no YT-videos how bad the paint/wrap job is. Overall: less risk for Tesla.

-=buzz=-

Member

Just for reference regarding the cost discussion, I seem to remember that Musk once told someone that the incremental cost for one more Model S was in the $30k range. I don't remember whether that's including labor costs and I think it was for the original 2012 Design.This “new” member is very informed.

Are you by chance reincarnated from the beaches of Rio de Janeiro?

StealthP3D

Well-Known Member

The points you make (heavy, inefficient, expensive to build) seems to counter your first point, in that the problem IS the actual product. Having said that, I agree with your overall sentiment, but I don't think it finishes the thought process.

I see your point, and I agree with your overall sentiment too, but I was responding directly to the claim we need to wait for the Munro teardown to make up our mind. I'm essentially saying we know enough about the vehicle, we don't need to know the nitty-gritty details, and, if they could manufacture it cheaply enough, the specs are good enough and will improve gradually with time. Not great, but good enough to sell in large numbers and help Tesla revolutionize the light truck industry, if only they could make it cheaply enough. Yes, it's inferior, we know that, it's the cost to make them and the low volume they can make that is the problem. We don't need Munro's teardown to know that already. Tesla has a huge advantage in being able to produce EV's at compelling prices because they want to produce EV's at compelling prices. If Ford does that, it kills their profitable ICE vehicles. Thus, they don't want to, regardless of how much posturing that says they do.

My understanding is that Lightning is not designed as an EV from the ground up, rather it's based on a standard F-150 with the engine/driveline removed and electric motors and a battery pack bolted on. (I'd like to see a comparison of the frame between the two vehicles.) Now, I'm sure Ford knew it wouldn't be efficient. But IMO they were trying to do specific things.

1) Get an EV truck out quickly to establish their name in the market, with modest development costs.

2) Get a EV truck out to see how well the market accepts it, what features buyers want and what they don't, and get a feel for demand.

3) Buy time with a vehicle in the market so they can do a proper, ground-up design, building on what they learn with Lightning and Mach E and what the competition does. I recall reading that Ford was working on a successor model before Lightning went on the market.

I think the fact that Ford unveiled the battery electric F-150 in 2008 at SEMA Las Vegas and they have had 14 years to test market demand, develop and release it pretty much negates all 3 points:

14 years is a long time to get ready. The electric F-150 unveiled in 2008 had 4 electric motors, produced 600 hp and had a 40 kWh battery with a claimed range of 100 miles. It looks like all Ford did in 14 years was triple the battery size and range and eliminate two of the four motors. The obvious deduction is Ford doesn't want to make electric pickups, they want to keep selling ICE pickups.

I'd also speculate that an additional concern was to build a truck that looks as much like a traditional pickup as possible to not alienate the traditional P/U buyer. I love Cybertrucks styling and packaging, and the fact that it loses the long, high hood of a conventional P/U, resulting in a much more compact overall vehicle. But it's anything but traditional and not something many P/U buyers will accept initially. This is a way to transition buyers to new technology without alienating them.

That's fine. I'm sure Ford is convinced a traditional look is necessary as well. That doesn't mean they are not wrong. There is a cost to making them look traditional, namely, it jacks the price way up to get comparable freeway range. That makes the truck harder to sell in volume. But that's Ford's choice, I'm not going to try to get them to change their mind, I'm just going to watch them go bankrupt. I'm certainly not buying any of their stock.

By 2032 we will see how important that "traditional" pickup look really was. Traditional pickup aesthetics have very little going for it beyond the fact that it's been the standard for a long time. That's why they are considered "traditional". People will learn how quickly things change when change happens. There's no compelling reason why a pickup should continue to look so dated and frumpy. The narrative that buyers won't change is a narrative based on looking in the rearview mirror. The same people also said truck buyers would never adopt automatic transmissions. I could go on and on.

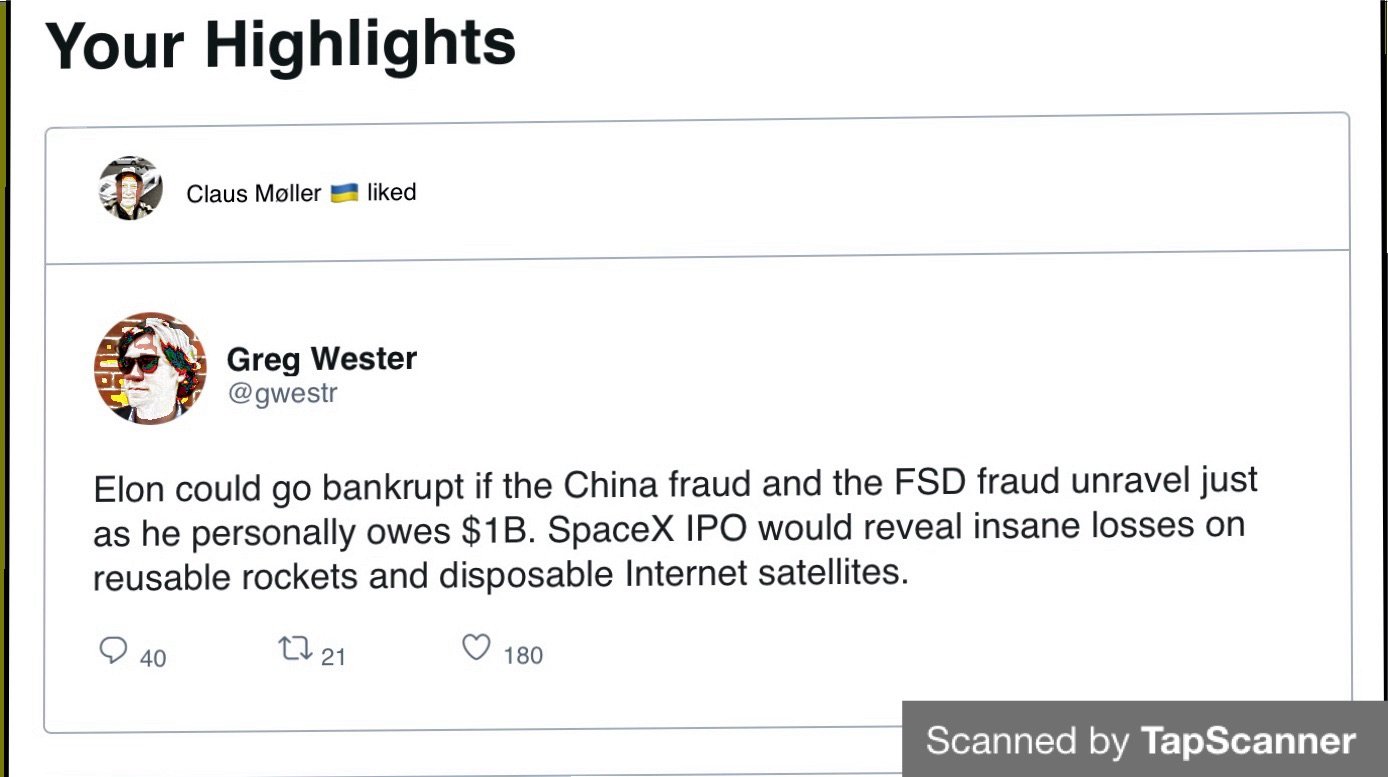

Woke up this morning with this email from Twitter. Never received FUD email. Who is this Greg Wester guy? Have algos turned against Elon because of the breakup that I am getting this in my Twitter feed? (I don’t believe in coincidences)

Remember that production cost excludes every cost that happens after a vehicle leaves the production line. I would be shocked if Model Y Austin 4680 with dual mega castings were to be very much higher than that right now. Typical post production delivery, documentation and preparation is usually ~15% of costs, (excluding dealer markups for the non-Tesla ones). Tesla is obviously learning how to reduce those costs with some fairly exotic steps, such as two story charging. Further between gigacastings, structural battery pack and new paint shop there are hundreds of robots and humans no longer needed in production. All those reduce materials, labor, preparation, etc.

We all know we cannot quantify these very well right now and we also know each new factory is a major advance on the last one. It's obvious that more factory space efficiency is happening.

When we consider all that for every model we see production costs reducing, warranty costs reducing, transportation costs and needs reducing as factories are becoming more efficiently located, customer delivery costs are plummeting with more self-delivery. These lists go on and on.

As all of this happens most of us are not understanding how huge the efficiencies are becoming. That is natural...they've been happening steadily for some years, and we usually miss them.

So, rather than date specific details, how about examining Tesla gross margins over the last four years? Once one does that the virtuous trend becomes clear. No car company other than RACE (i.e. Ferrari) has consistently higher margins than does Tesla. Some like Porsche have stellar margins in some years, but those examples are technically subsidiaries of larger companies that can easily alter transfer pricing.

Just spitballing here, but I expect we'll learn that Tesla's current production cost for the 4680 Model Y is in the $35k-40k range. That should drop as production ramps and economies of scale accrue.

So am I. It is a bit getting used to but I like the white on black!Browsing the forum on the iOS app for the first time. Pretty snazzy

If you did get invited, or if you attended Tesla Shareholders meetings in the past, please head to the following thread for further discussion:

2022 shareholder meeting in-person

I entered the lottery for the in-person ticket to the 2022 shareholder meeting at the Austin gigafactory. I got the email yesterday that I was picked. I’ve never been to one of these and had a few questions. How long do they last ? None of the Tesla online product announcements ever seem to...

-=buzz=-

Member

Well, the one reason I could see is as a high margin option.honestly? Why bother with offering it? Let the aftermarket flourish in offering thousands of possible custom designs. Some even suggested of special heat-treatments to discolor the steel.

No paint: faster output, more environmentally friendly, weighs less (...), more robust/futuristic feeling, less/no risk of scratching during transport/shipping to customer (just buff them out if they would happen during it out), no YT-videos how bad the paint/wrap job is. Overall: less risk for Tesla.

It sells cars and it finances additional EV production lines. Why leave this revenue to the aftermarket?

Whether it actually is high margin and worth the headaches I don't know.

jkirkwood001

Active Member

...Rational GenX folks like myself are hitting 45-50 and realizing we've been killing ourselves on behalf of corporations for no reason.

And Millennials never really started. They knew burning out and corporate allegiance was pointless.

Well, not exactly "no reason" and "pointless". There's a certain company called Tesla that works its employees extremely hard - and they continue to have a line-up of potential new employees - and yet the result has been beneficial to the employees, and really REALLY beneficial for some, in particular, TSLA investors.

So don't ridicule those who continue to work extra hard (i.e. don't look a gift horse in the mouth). We're lucky they do.

Because the Model Y is a much more premium vehicle, made with more premium components/materials. Guess what Subaru's official sales slogan was when they first appeared in the US market- "Cheap and ugly". I think Tesla could very well manufacture the cheapest to produce vehicle on the US market at some point, but it won't be the Model Y or Cybertruck.

That's a decent point, but I don't think it's enough to make the case.

We may never get to see a Munro analysis, but I bet any difference in materials cost is not nearly enough to make up for the fact that it will take a lot less labor to build a 4680 Model Y than a Subaru Impreza.

I know there is no good way to settle this, but I'd love to hear other ideas about why the unit cost for 4680 Model Y can't beat every other car made in the US.

D

dm28997

Guest

"Although there are many reasons why two Tesla Semis would be driving behind each other, one of the most interesting is the testing of FSD. During the presentation of Semi, Elon Musk mentioned “Convoy Mode,” a feature that would allow multiple trucks to move close together, optimizing battery power and range. Convoy Mode's main trick is that it also allows one piloted Semi to drive multiple unmanned trucks along a route."

www.tesmanian.com

www.tesmanian.com

Two Tesla Semis Spotted in California Possibly Testing Convoy Mode

Two Tesla Semis were spotted in California heading west. Since the two trucks were following one another, there is a possibility that they tested the Convoy Mode.

Me, too. Likey.Browsing the forum on the iOS app for the first time. Pretty snazzy

It's a tough balancing act for sure. Ford might not make it without government help.The problem is that each F-150 Lightning Ford sells replaces a high margin ICE F-150 (more or less). That business model will NOT keep Ford solvent.

CLK350

Member

Must be something else - bold still happens in all browsers - tho maybe because of adblockers? - not - suddenly all good now -CSS leak from top banner ad again. Close banner to unbold posts.

I think I'm starting to understand. Even though I've been following Tesla closely for quite awhile, seeing the current Munro teardown of the 4680 Model Y has flipped a switch for me mentally.As all of this happens most of us are not understanding how huge the efficiencies are becoming. That is natural...they've been happening steadily for some years, and we usually miss them.

99.99% of folks could watch the structural pack lowered from the vehicle with the seats attached and think nothing of it. But at Munro, they said this event drew a huge crowd. People who understand manufacturing know what this all means.

That's why I've asked about the cost comparison of 4680 Model Y to all other cars made in the US. Even though I'm a raging Tesla bull, I had not really grasped the significance until now.

UkNorthampton

TSLA - 12+ startups in 1

Refresh page after closing banner worked for me.Must be something else - bold still happens in all browsers - tho maybe because of adblockers? - not - suddenly all good now -

StealthP3D

Well-Known Member

Woke up this morning with this email from Twitter. Never received FUD email. Who is this Greg Wester guy? Have algos turned against Elon because of the breakup that I am getting this in my Twitter feed? (I don’t believe in coincidences)

View attachment 827104

Are you sure it's e-mailed by Twitter? If so, that's pretty bad, especially considering the timing. I'm interested to know if other Twitter members are getting similar e-mails.

D

dm28997

Guest

“This is something a human driver can easily miss… now we have the technology to put an AI-powered second set of eyes in every car at all times. It’s a game-changer.”

I may not drive or own a car, but I have seen Tesla’s FSD Beta in action. When I was in Austin earlier this month, Gail Alfar was using FSD Beta. The artificially intelligent powered software uses remarkable speed to avoid disasters."

www.teslarati.com

www.teslarati.com

I may not drive or own a car, but I have seen Tesla’s FSD Beta in action. When I was in Austin earlier this month, Gail Alfar was using FSD Beta. The artificially intelligent powered software uses remarkable speed to avoid disasters."

Tesla's FSD Beta quickly reacts to a pedestrian exiting their car

Tesla's Full Self-Driving Beta quickly reacted to a pedestrian exiting their car. In a video posted by @WholeMarsBlog

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M