I had a Volvo 240 wagon with that 2.4L diesel VW/Audi lump. I think it made a whopping 70 HP. That Peugeot/Renault/Volvo motor in your 740 was also what powered the futuristic DeLorean. Volvo made much better engines on their own.Volvo used to sell a diesel 740 with a VW engine- said VW right on the valve cover. My 740 had an engine made by Renault. Almost everybody except the Japanese use the ZF 8 speed in at least one model.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

Fact Czeching

Member

New S/X with HW4 not only don't have ultrasound sensors, but no autopilot / TACC.

How long can this go on for? Is V11 coming this week, month, or?

How long can this go on for? Is V11 coming this week, month, or?

powertoold

Active Member

New S/X with HW4 not only don't have ultrasound sensors, but no autopilot / TACC.

How long can this go on for? Is V11 coming this week, month, or?

KBF

Model X owner (formerly Cdn Signature Model S)

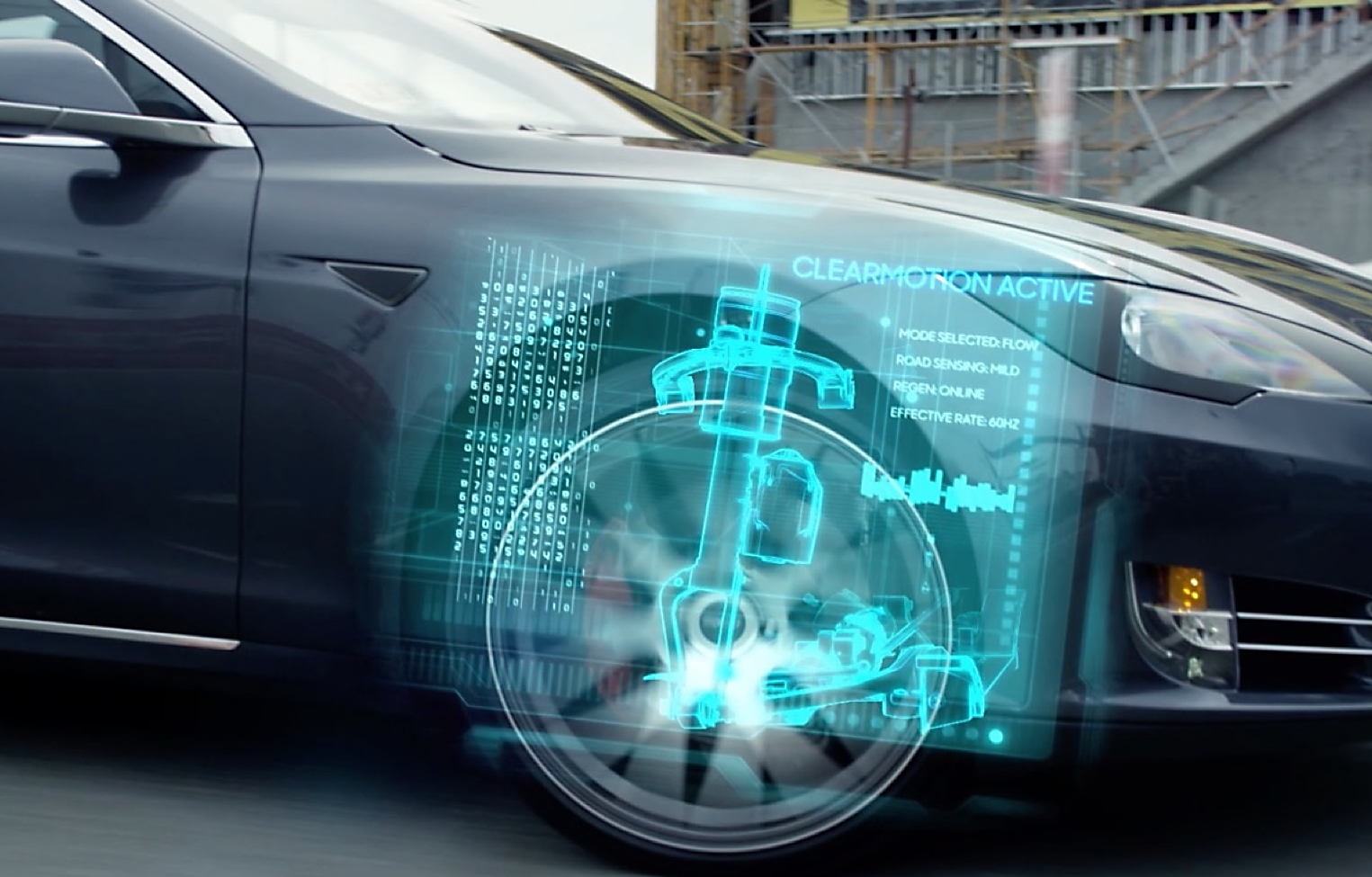

The ClearMotion website has no press release notifications since 2020 - it looks pretty cool, but I guess no auto manufacturer has any deals with them. Is it still an active company?So kinda acting like the Bose system did years ago, eh? Too bad that wasn't implemented back then, it looked pretty slick. If Tesla could accomplish something like that, but using that sensor, that would be much less expensive.

Edit: Here's a great description of the Bose system that apparently was purchased in 2018, although I haven't seen it implemented on a production auto yet. Nice vehicle they chose to show their version off on though!

After 30 years, Bose-developed suspension tech will go into production

Thirty years ago the audio-minded the folks at Bose decided to dive into the world of automotive suspensions. The goal was to create a dynamic driving experience that improved on-road comfort. Using a Lexus LS400 as the testbed, Bose showed off the technical advantages of its suspension...www.motorauthority.com

Doubt they would still have a webpage if they weren't active somehow. I did notice they had no open positions listed however, even though their site says they'll make lunch for you ;-)The ClearMotion website has no press release notifications since 2020 - it looks pretty cool, but I guess no auto manufacturer has any deals with them. Is it still an active company?

willow_hiller

Well-Known Member

New S/X with HW4 not only don't have ultrasound sensors, but no autopilot / TACC.

Try to keep up, buddy. Autopilot, TACC, and NoA have already been rolled out to HW4 on firmware version 2023.2.201:

insaneoctane

Well-Known Member

I think the choice to use "model years" compounded the lethargy. Should I fix this problem? Nah, I'll get to it later on the next model year....or next refresh even. Gotta keep something for next time! I'll go chit-chat at the water cooler instead....The more I learn about Tesla, the more I confirm my suspicions as I looked at technology growth and pondered as to why legacy automakers seemed to always lag decades behind, failing to implement widely used technologies we saw appear in so many other consumer products.

It was frustrating for me owning cars over the years and being so consistently disappointed, while working in tech industries and knowing they could do this or that much better. Granted, finally, they began including many up-charge items, like cruise control, AC, power locks/windows, etc. as standard features. They could have done so much earlier, and brought more innovation to their products as well. Seeing Tesla do this as a matter of course is the proof that it can happen in the auto sector as easily as it did in computers, entertainment products, etc.

Looking back with a perspective now based upon what Tesla has done, and is doing, in regard to actually keeping their product on the cutting edge of tech it seems almost disrespectful to a consumer the way the legacy OEMs have dragged their feet, unable to innovate and improve both the product and the manufacturing process.

Tesla has demonstrated that not only can it be done, but, it can be done quickly enough to completely disrupt the entire sector. In doing so they have pulled back the curtain on the "wizards" of legacy auto to show how they only made improvements when they had to, rather than doing so as a matter of pride in their work. They have been resting on their laurels since sometime shortly after the transition from horse and buggy. Is it any wonder that so many of them, and the ideology from top management down to union workers on the line, will at best struggle to remain relevant in the least degree if they don't go away completely.

I say bring the MM's up and downs, the shorties plays, and lay down the FUD as thick as possible, Tesla has already reached escape velocity and is comfortably in orbit looking down upon all the players so desperate to maintain their status quo. Whatever they are trying to preserve from the past, whether it be fossil fuels, century-old manufacturing processes, or playing fast and loose within the bounds of a rigged stock market, the effects upon Tesla have been minimal and temporary.

"Unassailable lead" is the term SMR has used for years, and it really does best describe the situation.

Bring on more of these shenanigans.

I ain't skeered. I hold shares of TSLA.

lafrisbee

Active Member

I typically don't downvote a post without providing my perspective.Something that has been rattling around in my head since investor day is what tesla’s next generation “unboxed” production process might mean for the potential for smaller assembly locations around the world where some level of localized production would make sense due to logistics, import taxes and/or production incentives/subsidies, free trade treaties etc.

View attachment 914998

For instance some markets that are large but low income (Brazil/Indonesia), or resource rich but smaller populations (Australia) or a mix of both (Argentina/Chile) where a full size gigafactory might be seen as inappropriate, but where some level of component production makes sense, either for export or for serving the local market with a lower cost structure.

For instance looking at the unboxed process gives you 3 major pieces of the car: The Front and Rear assemblies containing the gigacastings and the motors, and the structural battery pack (Duh). The rest of the components being relatively simple stamped metal parts.

So for example could we eventually see some assembly factories in lithium rich countries where the structural packs could be manufactured locally, while the front and rear assemblies, along with stamped parts, are imported from Mexico or China? How much cheaper would a factory be if you didn’t need to have Gigacastings, stamping presses or paint shops to start initial production? In return, complete structural packs could be exported to other Gigafactories and/or complete cars to other markets, and over time more production of parts could be localized (Seats, wheels, glass etc), and eventually if the market proves itself it could be expanded to a full size gigafactory.

I have no idea if any of the above makes financial sense for Tesla right now, but thought it might be possible in some circumstances down the road thanks to the new production process.

Tesla is known for everyone engineering together at the same time at the same place. On that alone your view would not be teslanian. But also it would create logistic nightmares not solvable by the mothership.

Thekiwi

Active Member

There is some precedence with the Netherlands tesla setup where they shipped knock down kits there for final assembly of S/X units, IIRC. More recently of course Tesla builds power trains in Nevada and ships to California, so your assertion that “Tesla is known for everyone engineering together at the same time at the same place” doesn't really hold up.I typically don't downvote a post without providing my perspective.

Tesla is known for everyone engineering together at the same time at the same place. On that alone your view would not be teslanian. But also it would create logistic nightmares not solvable by the mothership.

navguy12

Active Member

No TACC? Does that mean good old fashioned “dumb” cruise control where I can relax knowing that there will be no phantom braking under any circumstances thus not risk getting rear ended by the tailgaters in my world? Where do I sign up?New S/X with HW4 not only don't have ultrasound sensors, but no autopilot / TACC.

How long can this go on for? Is V11 coming this week, month, or?

Edit: Guess TACC is back, I missed out…

MC3OZ

Active Member

This kind of final assembly kit may work for a place like India with import restrictions.There is some precedence with the Netherlands tesla setup where they shipped knock down kits there for final assembly of S/X units, IIRC. More recently of course Tesla builds power trains in Nevada and ships to California, so your assertion that “Tesla is known for everyone engineering together at the same time at the same place” doesn't really hold up.

The problem is an assembled car without a battery pack can't be moved,

Packaging up and shipping all of the preassembled modules might be bulky, we would need to know if that kind of shipping was cheaper than shipping finished cars. But is is a lot more hassle when all of the bits to assemble the car already exist at the factory that is making it.

The assembly part which puts the car together is likely to require a lot of robots and will probably require a fair amount of capex.

They did say that the Lathrop Megapack factory was low capex and was built quickly.

There is a good case for local 4680 LFP production in Australia and India and a factory to make Megapacks and Powerwalls, These are products that sell well in the local market all of the raw battery materials are available locally.

If Powerwalls require high nickel cells then making them in Indonesia and exporting to Australia and India might be a good idea.

It is also possible that a lot of the battery pack cases, and some of the other components can be made locally.

The main thing they would need to import are the power electronics and similar modules, these components are not heavy or bulky and single container load would probably support building lots of batteries.

Energy storage batteries are lower capex, fewer parts, and easier to make. They are also heavy and bulky.

Fishy Fish

Member

I haven't seen this mentioned in reply to this post yet, but the creator of the feed and video that attended the investors day was seated with employees of 10 years instead of with other retail investors so could ask questions, and also spoke at length with Tom Zhu and he'll be posting another thread and video in the next day with details of the Cybertruck including dimensions and tire sizes I believe he said at the end of the video. He's been seeking questions from his followers the last couple days to be answered if he can in the upcoming thread/video.New Semi Video:

And this is the twitter link with most of the information:

This guy has had some great insights from Investor Day (he was there) where he spoke to Tom Zhu! He's interviewed Franz before, if I remember correctly. Cybertruck info is tomorrow...

Last edited:

Electroman

Well-Known Member

Interviewer: "So the amazing speed with how the factory was built and how fast the plant came to operation and how fast the cars are being made here with very high quality.... <few more things> ..... you are proud of all that right?"Was just watching this Shanghai GF walkthrough video made by Chinese state media, and at 19:35 the news anchor just said “now we are seeing Giga 2, not just the Giga 1”, when she was boasting “Shanghai had helped Tesla in many ways…”

EXCLUSIVE: Experiencing "Tesla speed" at Shanghai gigafactory

EXCLUSIVE: How fast do Tesla models roll off the production line at its Shanghai gigafactoryï¼Join Xinhua's Zhou Rui to experience the "Tesla speed" at the U....www.youtube.com

Wait, have we confirmed the SECOND GF in Shanghai?

What will that be making?

Has Tesla officially announced that?

Where exactly is it?

When are they building it and when will it start production?

I have so many questions…

Tesla employee: "Yes, I am proud".

Damn, shoulda put some money into WW... up 79% just today. I guess losing pounds makes dollars eh?

Oveeus

Member

For those not fluent in Spanish, I will try to give a summary.There is plenty of positive Tesla media coverage! Just not in English …

It's an interview with Nuevo Leon's governor to discuss the behind the scene and/or reasons why Tesla decided to put a Giga there.

He went on to discuss that Tesla had formed the decision back in November. With that decision, he went to discuss the proposal with the Mexican Federal government. He emphasized the reason behind putting a Giga there had to do with everything from water, power, insecurity management, and geolocation... etc that attracted Tesla there.

One of the reasons that he singled out as well was the tension between US and China. Tesla knows it and wants to diversify its next Giga location. I believe this relates to the rumor that surfaced a while back about a second Giga in China.

All in all, an interesting insider perspective on how Giga Monterey materialized.

Electroman

Well-Known Member

I find these stats a little disingenuous. FSD by the very nature that it is still iffy means, not many are turning in on, and those who are using it are doing it with extra caution and taking control when it makes a mistake (which is good). So these stats are not a reflection of how good FSD is, rather how much attention it needs.This looks promising from an InsideEvs article(taken from a twitter post):

"According to Tesla, cars with FSD Beta engaged experienced a crash that resulted in airbag deployment every 3.2 million miles. Meanwhile, Tesla says the US average based on the most recent police-reported stats is an airbag-deployed accident every 600,000 miles."

Check Out Tesla's FSD Beta Crash Stats: Should We Be Impressed?

Advanced driver-assist systems like Tesla's FSD Beta aren't yet meant to replace human drivers, but to keep them safer. Per Tesla's stats, it may be working.insideevs.com

The same reason why there are few accidents on the L2 driving tech from other makers compared to Tesla. Because they all suck, very few use them and those who use do them only in very safe places, whereas Tesla drivers use Autopilot anywhere and everywhere and are completely lulled because it is so damn good.

Webeevdrivers

Active Member

Pretty good point. Honestly I think we are probably a decade away from any kind of autonomous driving car but it’s very true. We use FSD every single day in some pretty tough circumstances. It fails regularly which we don’t mind because it’s still fun to watch the tech grow and intervening is easy if one is paying attention. But yah, we know lots of people with other makes of vehicles with ADA systems and they NEVER use them.I find these stats a little disingenuous. FSD by the very nature that it is still iffy means, not many are turning in on, and those who are using it are doing it with extra caution and taking control when it makes a mistake (which is good). So these stats are not a reflection of how good FSD is, rather how much attention it needs.

The same reason why there are few accidents on the L2 driving tech from other makers compared to Tesla. Because they all suck, very few use them and those who use do them only in very safe places, whereas Tesla drivers use Autopilot anywhere and everywhere and are completely lulled because it is so damn good.

Good observation.

TN Mtn Man

Member

I'm not sure how true that is. I have a Telluride with highway drive assist and adaptive cruise control and use it almost everywhere. Rural 2-lane roads, city streets and of course highway driving. It of course isn't any kind of FSD, doesn't stop for traffic signals (unless cars are stopped ahead) and of course no navigation. But for what it is, it works very well. Can't speak for other makes or other drivers.I find these stats a little disingenuous. FSD by the very nature that it is still iffy means, not many are turning in on, and those who are using it are doing it with extra caution and taking control when it makes a mistake (which is good). So these stats are not a reflection of how good FSD is, rather how much attention it needs.

The same reason why there are few accidents on the L2 driving tech from other makers compared to Tesla. Because they all suck, very few use them and those who use do them only in very safe places, whereas Tesla drivers use Autopilot anywhere and everywhere and are completely lulled because it is so damn good.

Idiotic that FSD is still classified as level II, when it does so much more than a level II system (HDA and adaptive cruise). HDA/AA are in no way and no path towards autonomy, instead simply aids. FSD is true autonomy that just needs a little supervision at the current time.

Last edited:

The fact that people can actually use the feature is what sets Teslas autonomous features apart from the competition. Tesla has data for many millions of miles of FSD driving compared to orders of magnitude less from the competition. Attribute that to whatever you like; the bottom line is that the feature is useful enough that people use it…and it makes them less likely to crash.I find these stats a little disingenuous. FSD by the very nature that it is still iffy means, not many are turning in on, and those who are using it are doing it with extra caution and taking control when it makes a mistake (which is good). So these stats are not a reflection of how good FSD is, rather how much attention it needs.

The same reason why there are few accidents on the L2 driving tech from other makers compared to Tesla. Because they all suck, very few use them and those who use do them only in very safe places, whereas Tesla drivers use Autopilot anywhere and everywhere and are completely lulled because it is so damn good.

If people are crashing less and that’s captured in the data; then I’m not sure what’s disingenuous…it’s working as designed. Ideally future designs require

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M