I agree. This is true for 4680 Gen I currently produced at Kato Road in a dry/wet process (capacity target 10 GWh/a). The current Model Y AWD uses these Gen I batteries. The Gen II 4680 factories in Austin and later in Nevada will be Gen II in a dry/dry process and the targeted capacity in Austin is 40 GWh. To reach this capacity I expect the catode plant also in Austin is a pre-requisite.

Gen II 4680 is a prerequisite for a meaningful production of the Cybertruck. For Model Y in Austin and in Berlin, 2170 was the fallback option. For the Cybertruck there is no fallback option, the project will just be delayed until everything is ready.

The

Battery Day presentation, there stated 5 major goals.

View attachment 939382

Of these goals, Gen I 4680 includes

- “cell design” (the tabless cell enables the increase of the diameter).

- “cell factory”

- “cathode materials” (with nickel so far)

- “cell vehicle integration” (structural pack combined with front and rear casting)

Gen II 4680 includes the “anode materials” according to slides 41 to 45 of the Battery Day presentation.

“Silicon stores 9x more lithium than graphite” but involves the challenge “volume expansion” which Tesla intends to solve by using a design which can cope with this expansion. Benefits of ”anode materials” are a 20 % range increase (page 44) and a 37 % $/kWh reduction.

I honestly have no idea if the silicon - lithium anode will enable a faster charging rate in 4680 Gen II. We will figure out after the frist Cybertrucks are handed out to customers.

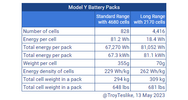

Now I would to look further to the consequences to the model Y and the model 3. Troy Teslike explained with

this table that the energy density (Wh/kg) of the Model Y AWD (range 279 miles) is 13 % lower than of the Model Y LR with Panasonic 2170 batteries (range 330 miles)

As stated above, (Gen II cells) with silicon/lithium anodes will offer a 20 % range increase: 279 miles + 20 % is 334.8 miles for the Model Y with 4680 Gen II. So with a small software limit, the range is the same as today.

Therefore, Tesla is currently able to use 4680 Gen II batteries as soon as they are ready instead of 4680 Gen I batteries at their Austin plant and rebadge the Model Y AWD as a Model Y LR. Benefit of this strategy is that Tesla will have a lot of real world experience for the Cybertruck battery system, so there is little to worry about in this regard.

When I watched Munro Live’s Teardown of the 4680 Model Y battery pack I saw that there is about 10-15 % unused space left in the pack. By making the modules wider, a model Y extended range configuration with about 370 miles would be quite easy to build with Gen II 4680 batteries. However, I don’t expect this range increase as long as Tesla is 4680 batteries constrained, so until 2025 or 2026.

For the model 3, there will be simply no space left in the battery pack to further increase the range by adding additional cells. I expect the same Gen II battery pack of the model to fit into the model 3. 4680 Gen II offers a 4 % range advantage over Panasonic 2170 batteries. But in the meantime Tesla has switched to 2170 Batteries from LG which offer a slightly lower range (and as a benefit are eligible at least for a partial IRA credit). So when the switch to 4680 Batteries happens in January 2024 at the earliest imho, the range increase will look a bit more substantial than it actually is. So all together, yes I think at some point we will see a model 3 highland with 400 miles range at some time. But Tesla is for now seriously 4680 battery constrained (Model Y Austin, Cybertruck), so I would not be surprised to not see this configuration for another two years. Another issue of this rumored Ludicrous Model Y configuration with more range is that it can only be produced in Fremont which increases shipping costs for Europe and Asia. Also this version will be more expensive than the limit of 55’000 USD of the IRA credit. Another issue is a further cannibalizing of the Model S which is already low in demand. So the Model 3 Ludicrious could be the suscessor of the Model S, but only after the Roadster 2 as a new halo product is out in 2025 as we learned at the annual meeting.

Last, it makes no sense to ship 2170 batteries from Nevada to Austin since this invovles additional logistics cost of about 1 $ per kWh according to my estimation due to the longer trip. Lowering costs is a current top priority at Tesla. So the Model 3 Highland made in Fremont will use 2170 batteries as soon as the IRA credit expires end of December 2023 and therefore not offer a range real increase compared to the old model 3 LR with 2170 Panasonic batteries. I expect the price to go up a bit again due to the higher range. Of course also a configuration with a lower range will be available. I expect the Model 3 highland will be first handed out to customers in February and March 2024. This makes also sense since this is the quarter with the lowest demand, therefore a demand boost due to a model 3 relaunch is welcome from a business point of view.

In summary it appears that Tesla has a sophisticated plan and is constantly adapting the plan as soon as issues and opportunities arise.

www.youtube.com

www.youtube.com