Some perspective: in 2016 I sold 200 pre-split shares (now 1000) to for a downpayment on my model s. This year it is going to become a million dollar car. HODLI need someone to talk me off the ledge.

My finger is poised over the order button for a new MS.

Not the plaid but the long range...it is faster than my 2017MS...but I don't need faster than my current.."are you freaking kidding me"

It has longer range...but do I need the extra hundred miles??

Tesla is offering 2.49 interest rate...so no need to sell any sweet sweet shares.

OT because I MIGHT sell some chairs to put more down.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

RobStark

Well-Known Member

Remember when BMW was the car all the iPhone owners drove around? BMW was closely aligned to Apple, so much so that BMW actually put the proprietary iPod/iPhone connectors in their cars so you could plug your Apple device right into the car.

Now, Apple is supposedly partnering with Hyundai/Kia for the Apple Car. BMW isn't even on their radar anymore. The days when people thought BMW was cool are long gone.

Apple talked to all the German automakers a year ago, including BMW.

They are said Nein to becoming Foxconn of cars. They wanted a share of software/subscription revenue to make the Apple car.

According to reports there are senior executives within Kia that don't want to become the Foxconn of cars.

We’ve already been at $900. Don’t question krugerrand’s mom.Hmm, I believe her last PT was $900. How reliable is she? Anyone know what the 52-week high is?

Been thinking about production in Shanghai. Rumor says 700 Model Y/day(something). Video that is out looks really good:

This was much faster than I though they would get it up and running. But it is their second line in Shanghai and lots of parts are shared so maybe it was easier to ramp than Model 3. But is this really enough to explain the increased ramp? A quote came to mind:

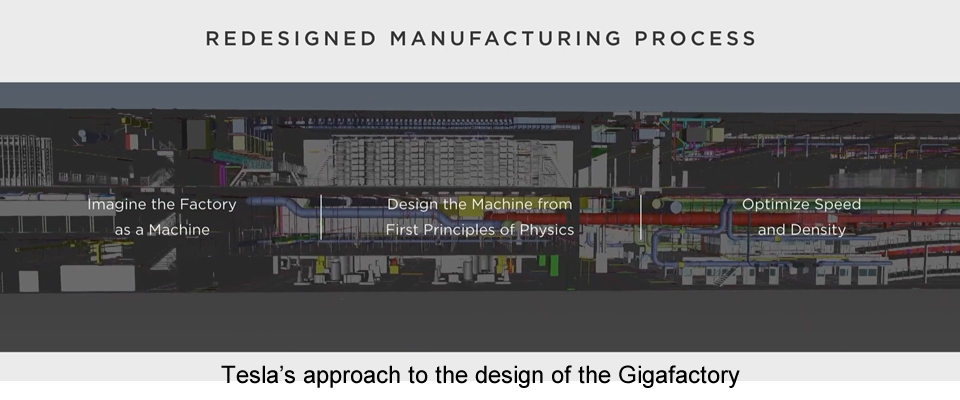

Manufacturing Leadership Journal - October 2016 - page10

I think Tesla is the first automotive company that is thinking that way. I’ve never seen that before. I believe if you have a machine that makes a machine — if you have a smart machine that makes a machine — you can create more throughput, more quality.

This from the former Audi execture now Tesla Vehicle Production VP. And I remember Gigafactory Nevada’s detailed plan:

I assume they had similar CADs for Shanghai, Berlin and Austin.

Making Model 3 MIC line was their first attempt of designing and building a production line from scratch. I guess they learnt a lot from this. Maybe enough to make Model Y MIC work well from start. And if this is the case then maybe we can expect to have Berlin Model Y line ramping almost as fast.

So maybe 700/day is actually not a misquote. It would be in line with the 550k 2021 target rumor that has been going around.

Tesla Gigafactory Shanghai is aiming to produce 550K vehicles next year: report

I am starting to believe these rumors actually add up.

This was much faster than I though they would get it up and running. But it is their second line in Shanghai and lots of parts are shared so maybe it was easier to ramp than Model 3. But is this really enough to explain the increased ramp? A quote came to mind:

Manufacturing Leadership Journal - October 2016 - page10

I think Tesla is the first automotive company that is thinking that way. I’ve never seen that before. I believe if you have a machine that makes a machine — if you have a smart machine that makes a machine — you can create more throughput, more quality.

This from the former Audi execture now Tesla Vehicle Production VP. And I remember Gigafactory Nevada’s detailed plan:

I assume they had similar CADs for Shanghai, Berlin and Austin.

Making Model 3 MIC line was their first attempt of designing and building a production line from scratch. I guess they learnt a lot from this. Maybe enough to make Model Y MIC work well from start. And if this is the case then maybe we can expect to have Berlin Model Y line ramping almost as fast.

So maybe 700/day is actually not a misquote. It would be in line with the 550k 2021 target rumor that has been going around.

Tesla Gigafactory Shanghai is aiming to produce 550K vehicles next year: report

I am starting to believe these rumors actually add up.

On the flip side, you can now make 5G calls without a phone.Second dose hit me hard, I think the implanted microchip is not 5nm technology.... frickin’ Gates

Been thinking about production in Shanghai. Rumor says 700 Model Y/day(something). Video that is out looks really good:

This was much faster than I though they would get it up and running. But it is their second line in Shanghai and lots of parts are shared so maybe it was easier to ramp than Model 3. But is this really enough to explain the increased ramp? A quote came to mind:

Manufacturing Leadership Journal - October 2016 - page10

I think Tesla is the first automotive company that is thinking that way. I’ve never seen that before. I believe if you have a machine that makes a machine — if you have a smart machine that makes a machine — you can create more throughput, more quality.

This from the former Audi execture now Tesla Vehicle Production VP. And I remember Gigafactory Nevada’s detailed plan:

View attachment 634398

I assume they had similar CADs for Shanghai, Berlin and Austin.

Making Model 3 MIC line was their first attempt of designing and building a production line from scratch. I guess they learnt a lot from this. Maybe enough to make Model Y MIC work well from start. And if this is the case then maybe we can expect to have Berlin Model Y line ramping almost as fast.

So maybe 700/day is actually not a misquote. It would be in line with the 550k 2021 target rumor that has been going around.

Tesla Gigafactory Shanghai is aiming to produce 550K vehicles next year: report

I am starting to believe these rumors actually add up.

Another argument for a daily build rate of 700 cars: it was said that there were 100,000 orders within a short period of time and that anyone ordering after that would only get their car somewhere in Q2. A build rate of 700 cars makes for about 60,000 cars in three months, probably less with the New Year break. If the build rate were much lower it would be impossible for cars that are ordered now to be delivered in Q2. Unless ofcourse the number 100,000 was incorrect.

How do you mean?Making Model 3 MIC line was their first attempt of designing and building a production line from scratch. I guess they learnt a lot from this. Maybe enough to make Model Y MIC work well from start. And if this is the case then maybe we can expect to have Berlin Model Y line ramping almost as fast.

Fremont had the stamping, paint, and receiving locations pre defined, but the S assembly line was from scratch (low volume). The X had new body and assembly lines (low volume. ) The Fremont 3 line was the first volume assembly line from scratch (again with the Fremont base).

Shanghai was the first vehicle factory from scratch, but the lessons from Fremont went into the line which allowed it to go from watermelons to mass production in under 18 months (built in 168 days).

Then Fremont added the Y with castings. Onluh after that did Y Shanghai came on line. So it was around the fourth from scratch line (not to forget the GA variants at Fremont).

With Y commonality, plus the gigacastings, plus the local pretrained workforce, Y ramp up could reasonably be expected to be the smoothest/ fastest yet.

When Tesla makes the machine that makes the machine (and many of the machines that go into the both machines) as a product, this increase in speed continues each generation.

Berlin and Austin will be amazing!

JohnnyEnglish

Member

It is difficult to know the original information with these rumours but from the Teslarati article it seems that the 'measured' figure is 29 vehicles per hour:Another argument for a daily build rate of 700 cars: it was said that there were 100,000 orders within a short period of time and that anyone ordering after that would only get their car somewhere in Q2. A build rate of 700 cars makes for about 60,000 cars in three months, probably less with the New Year break. If the build rate were much lower it would be impossible for cars that are ordered now to be delivered in Q2. Unless of course the number 100,000 was incorrect.

According to the media outlet, the Model Y line in the Shanghai-based plant currently has a converted production cycle of 29 jobs per hour. This means that Tesla China, despite only producing the all-electric crossover for a few months, is already capable of building one Model Y every two minutes. That’s an impressive milestone, especially considering that this translates to an annual run-rate of about 250,000 vehicles.

This would be be 700/day (and 250,000/year) IF they are working 24/7. Do we have confirmation of the 24/7? IIRC they ramped the Model 3 line to 28/day before moving to multiple shifts.

Getting to 29 vehicles per hour in this short timeframe is hugely impressive. Looking good for Shanghai 3/Y production to exceed Fremont later this year (Q2?) provided the logistics chain can ramp that fast.

JohnnyEnglish

Member

Berlin has a lot of new technology (4680, front casting, structural battery, advanced paintshop) and will be a new workforce and local logistics so we might need some patience on that ramp. Austin should be able to take advantage of the technology learnings from Berlin, some key workforce from Fremont and existing logistics so has everything going for it.Berlin and Austin will be amazing!

Apple talked to all the German automakers a year ago, including BMW.

They are said Nein to becoming Foxconn of cars. They wanted a share of software/subscription revenue to make the Apple car.

According to reports there are senior executives within Kia that don't want to become the Foxconn of cars.

But they were always Foxconn of cars. Produce ICE engine and transmission internally while buying every other thing from somebody else including software. Assemble the car and sell it to a dealer.

This is the current business model of any legacy auto.

Plus a BEV does not need an ICE engine and transmission.

Now they want a part of software/subscription revenues? Hilarious.

That might be the reason why the Foxconn of cars don’t be wants to have 2 levels of Foxconning. Apple at least have enough introspection to understand they should never try to manufacture a car, they have been trying to subcontract OEM to make the Apple car happen since a couple years ago. Once the OEMs profits go down dramatically due to multiple interesting EV sales growing in the next few years, they might give a second thought to build it and let Apple take their 39% margin on every iCar.But they were always Foxconn of cars. Produce ICE engine and transmission internally while buying every other thing from somebody else including software. Assemble the car and sell it to a dealer.

This is the current business model of any legacy auto.

Plus a BEV does not need an ICE engine and transmission.

Now they want a part of software/subscription revenues? Hilarious.

Your Mom TSLA price targets seems to be consistantly more reliable than wallstreet analysts. I’m changing my PT from $1200 to $1300 because of your mom lol.Mom has received her second Covid vaccine, but more importantly she’s talking to me again about TSLA. She has upped her PT to $1300 and claimed she’s a good friend of Dionne.

Even transmissions are mostly purchased from third parties.But they were always Foxconn of cars. Produce ICE engine and transmission internally while buying every other thing from somebody else including software. Assemble the car and sell it to a dealer.

This is the current business model of any legacy auto.

Plus a BEV does not need an ICE engine and transmission.

Now they want a part of software/subscription revenues? Hilarious.

I’m still intrigued by that central, indoor roadway that runs the length of the Austin factory. Elon described it when construction was just getting started, and at it was visible during site prep, but now seems to have disappeared. If it is still in the plan, it would seem logical that only electric vehicles (i.e., Tesla Semi) could operate there.Berlin has a lot of new technology (4680, front casting, structural battery, advanced paintshop) and will be a new workforce and local logistics so we might need some patience on that ramp. Austin should be able to take advantage of the technology learnings from Berlin, some key workforce from Fremont and existing logistics so has everything going for it.

2daMoon

Mostly Harmless

I’m still intrigued by that central, indoor roadway that runs the length of the Austin factory. Elon described it when construction was just getting started, and at it was visible during site prep, but now seems to have disappeared. If it is still in the plan, it would seem logical that only electric vehicles (i.e., Tesla Semi) could operate there.

I seem to remember him later saying they won't be doing that internal roadway.

Great video! I watched it through google translate, just use the app, select camera and point it at the screen. Didn’t learn too much useful information, it seemed like a great team from all over the country. They use networked torque wrenches and record every torque, not sure if that is standard in the industry, they said the wrench costs 10x more than normal wrenches if I understood it correctly. People seemed very hardworking and happy to be there, some came there because they had family there so I assume word of mouth is good.14 minutes of GigaShanghai MY factory tour - mostly about the factory workers rather than the production itself. The food looks tasty.

With the number of workers present, it gives more support to the high volume manufacturing rumours.

微博

From Kelvin

View attachment 634406

I wonder if it will be as easy to hire skilled staff in Austin and Berlin as it seemed to have been in Shanghai. Berlin has 4M people, Austin 1M, Shanghai 24M. And I assume it was pretty easy to find people willing to relocate to Shanghai to work at the factory, will it be as easy in US/EU?

Too bad, if true. I always thought internal loading docks would be a great way to load the cars/trucks onto the semis without exposing them to the elements. In fact, if Tesla could come up with an enclosed carrier trailer, the cars would never be exposed to the elements until they arrive at the destination. That might reduce a lot of the pre-delivery cleanup/repairs.I seem to remember him later saying they won't be doing that internal roadway.

nativewolf

Active Member

Great video! I watched it through google translate, just use the app, select camera and point it at the screen. Didn’t learn too much useful information, it seemed like a great team from all over the country. They use networked torque wrenches and record every torque, not sure if that is standard in the industry, they said the wrench costs 10x more than normal wrenches if I understood it correctly. People seemed very hardworking and happy to be there, some came there because they had family there so I assume word of mouth is good.

I wonder if it will be as easy to hire skilled staff in Austin and Berlin as it seemed to have been in Shanghai. Berlin has 4M people, Austin 1M, Shanghai 24M. And I assume it was pretty easy to find people willing to relocate to Shanghai to work at the factory, will it be as easy in US/EU?

Well Austin metro area is 2.5 million or so, Berlin metro area is a about 6.1 and much of the Shanghai sprawl means that someone on one side of the city might as well be from another metro region. The real question is how many people live within an hour commute of the factory. I can't answer that for any of them but I would guess that the Austin facility it is 100% . Austin is just not that big. I would think they are going to be relocating lots of people there. Eventually Tesla gets heavily burned in China. For my planning and forecast I'd discount China long term. They are letting Tesla run because it is good to push the local companies along, give it 4 years and then the interference will start and then they will get the google treatment and be cut off at the balls.

So the day that Tesla gets it’s first regulatory approval for its robotaxi service, it will stop selling cars to the public, right? Why bother putting a precious battery into a vehicle that sells for less than $100k when Tesla can use it in a service worth more than double that?

Or, the selling price of the Model S goes to something like $200,000, and it only makes economic sense for an individual to buy it if you include it in the robotaxi service when you’re not driving it.

Enjoy buying and exclusively using your Tesla car while you can. Those days are numbered.

On the other hand, used non-Tesla cars will be super cheap, which you might have in your garage as a collectible or to go on sentimental road trips, much like you might now have a record turntable and LPs.

Or, the selling price of the Model S goes to something like $200,000, and it only makes economic sense for an individual to buy it if you include it in the robotaxi service when you’re not driving it.

Enjoy buying and exclusively using your Tesla car while you can. Those days are numbered.

On the other hand, used non-Tesla cars will be super cheap, which you might have in your garage as a collectible or to go on sentimental road trips, much like you might now have a record turntable and LPs.

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M