Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

But there is that mystery cover hanging under the back - could be covering an extended range battery option?

Unfortunately, no. That area gets crushed in a rear end collision, so for crash worthiness you don't want to put batteries there. It would be a big fire risk.

EVs all have the battery located as centrally as possible with as much crumple space around them as possible.

(Pic for reference)

I think you didn't hear/see what I saw/heard in the CT rollout. The unique thing about the CT was the Stainless steel structural exoskeleton (not just cosmetic or aerodynamic panels - structure). The idea was that this structural design would, similar to unibody construction, enable a lot more strength with a lot less mass as is needed to carry enough battery weight to enable long enough range while towing or hauling. So many people (Musk included) seemed to get caught up in the Cyberpunk aspects, steel shot, and sledge hammer that they missed that key element.anything new. Air suspension on a pickup? Been around for decades now. Electronic bed covers? Been around for many years. EV pickups? Several already on the market today with a bunch more coming over the next few years. Stainless steel panels?

The challenges were many:

- Can they work the stainless steel to create the necessary shape?

- Will imperfections on the folding look bad on the final product?

- Can this design carry enough battery mass and still have sufficient payload mass to meet the market needs?

- Can it be done cheaply enough to provide a viable sell price?

- Will it really be better than the traditional body-on-frame or uni-body construction?

- Were there unknown issues that arose as they went down the path?

Whether it worked or not is the big question that we may learn more about Thursday.

Just like the Starship launches: Musk can't promise success but he can promise it will be exciting.

I tend to see the above as "Market Research", while "Marketing"(at least in the real world as opposed to the academic B-school) tends to be more about selling things as I described. You're probably right about that 101 course aspect. I was thinking more about what the industries I've been around call "Marketing".Just FYI - Marketing 101 has nothing to do with selling goods and services people don't need. In fact, it's the exact opposite - determining what the market needs - through real world research and market analysis - determining the TAM for that market - and then designing and building a product that meets those needs at a price the average consumer is willing to actually pay for that good or service. Put another way, it's all about solving real world market problems.

You're probably also right that, as a technology company, Tesla is more interested, initially at least, in whether the technology works than whether it meets a particular understood market. The assumption in this case is that, if the technology proves superior, it can be applied in different areas to meet different market needs, just as the body-on-frame and uni-body techniques did.

Since when is bending stainless steel any more difficult than any other steel or metal? Its not like its infinitely strong or anything. Its pretty much the same as any other high strength steel Sure, if its hardened, it can be brittle and crack if bent too sharply, but this is all well known in the realm of sheet metal fabrication techniques and limitations.I think you didn't hear/see what I saw/heard in the CT rollout. The unique thing about the CT was the Stainless steel structural exoskeleton (not just cosmetic or aerodynamic panels - structure). The idea was that this structural design would, similar to unibody construction, enable a lot more strength with a lot less mass as is needed to carry enough battery weight to enable long enough range while towing or hauling. So many people (Musk included) seemed to get caught up in the Cyberpunk aspects, steel shot, and sledge hammer that they missed that key element.

The challenges were many:

- Can they work the stainless steel to create the necessary shape?

- Will imperfections on the folding look bad on the final product?

My refrigerator has stainless front door panels on it. Wanna know why? Its not that stainless is some magic material from which to build the best appliances, no. And its not that I need a bullet proof refrigerator. It is stainless because stainless is shiny and attracts buyers. Just like birds and fish are attracted to shiny things.

Xenoilphobe

Well-Known Member

We don't seem to have any of those problems here on the east coast. When I got my first Tesla there were zero charging stations on the east coast, now on my fourth with over 400K of Tesla driving (my wife is on her second S too) they are everywhere. I would like 500, but in reality the way I drive, I can make a gas car only get 200 miles of range.Not of it takes Forever to charge, or you can’t find a charging station, or they are full of vehicles not Tesla’s, and now you will charged an idle fee too? Range is King.

lowtek

Active Member

Same.We don't seem to have any of those problems here on the east coast. When I got my first Tesla there were zero charging stations on the east coast, now on my fourth with over 400K of Tesla driving (my wife is on her second S too) they are everywhere. I would like 500, but in reality the way I drive, I can make a gas car only get 200 miles of range.

I'd love a 500 mile truck for the same reason I want a < 3s truck and the same reason I want a 1100hp Plaid ... but I'm not towing every day nor do I hit the track with the S.

HitchHiker71

Member

They are SS panels over a high strength steel unibody design, here are several pics of the CT assembly line. Munro Associates did a deep dive on these pics and came right out and said these are panels over a unibody assembly - the first pic is of an early mock-up design that was hand built where the guy on the assembly line is actually attaching the SS panels by hand:I think you didn't hear/see what I saw/heard in the CT rollout. The unique thing about the CT was the Stainless steel structural exoskeleton (not just cosmetic or aerodynamic panels - structure).

lowtek

Active Member

The first pic is clearly a fake.They are SS panels over a high strength steel unibody design, here are several pics of the CT assembly line. Munro Associates did a deep dive on these pics and came right out and said these are panels over a unibody assembly - the first pic is of an early mock-up design that was hand built where the guy on the assembly line is actually attaching the SS panels by hand:

View attachment 994400

View attachment 994401

View attachment 994402

But it was always going to be exoskeleton over unibody, we knew that from the beginning. The stainless steel exoskeleton is there to add strength to the unibody. Without it, the truck won't be able to do truck things. Traditional trucks have a ladder frame for strength. The Cybertruck doesn't have a ladder frame, just a structural pack, so it takes both the unibody and exoskeleton to give it the strength it needs to do truck things.

Simple search reveal that the rest of the planet understands that stainless is not just plain steel.Since when is bending stainless steel any more difficult than any other steel or metal? Its not like its infinitely strong or anything. Its pretty much the same as any other high strength steel Sure, if its hardened, it can be brittle and crack if bent too sharply, but this is all well known in the realm of sheet metal fabrication techniques and limitations.

My refrigerator has stainless front door panels on it. Wanna know why? Its not that stainless is some magic material from which to build the best appliances, no. And its not that I need a bullet proof refrigerator. It is stainless because stainless is shiny and attracts buyers. Just like birds and fish are attracted to shiny things.

Does Stainless Steel Bend Easily? Exploring Material Properties And ...

or

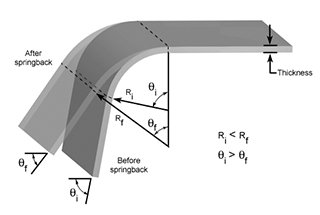

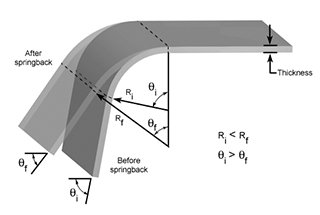

Bending Stainless Steel Sheet: Strategies to Conquer Springback | MachineMFG

Get the key points and analysis you need to bend stainless steel like a pro! Learn how to avoid springback and get flawless results. Get expert tips now.

or how about why use stainless in a kitchen

Strong & Durable: Why We Use Stainless Steel in the Kitchen

Stainless steel is absolutely everywhere in the kitchen. If you don’t have sleek stainless steel appliances or kitchen islandsSteel is fantastic stuff. It’s an iron alloy and strong as all get-out. It doesn’t chip, bend, or crack easily (though it does scratch), and it stays shiny over years of...

Growing Popularity of Stainless Steel in the Kitchen; 11 Reasons why:

Stainless steel- you've seen it, heard of it and likely already use it. Stainless steel is not new. In fact it has been well adored for centuries in commercial, industrial and household kitchens around the world. The early '70s saw a surge in plastic use in kitchens and has grown exponentially...

dalcinistainless.com

dalcinistainless.com

Stainless Steel Use in the Food Service Industry - Unified Alloys

Since the earliest days of its existence, people have seen stainless steel’s potential to help make food preparation safer and easier. From high-end consumer items to the largest commercial kitchens, stainless steel surfaces, equipment,...

Sure, but that's why most reasonable manufacturers don't take orders when the car is still in the prototype stageyeah the SS are just panels over a more traditional body, sacrifices had to be made to get it to production.

HitchHiker71

Member

Other than Musk's pleadings - please show me one engineering analysis that clearly states that this is an exoskeleton over a unibody. A unibody does not require anything to add strength to it - that would be a horrible design approach from a safety standpoint. The unibody is the frame. There can also be subframes attached to the unibody for design purposes. The CT is not a body on frame design as you're attempting to say here. It's a unibody design with steel panels. I'll believe Sandy Munro, who has been in the automotive design business for decades, over anyone on this forum, without question.The first pic is clearly a fake.

But it was always going to be exoskeleton over unibody, we knew that from the beginning. The stainless steel exoskeleton is there to add strength to the unibody. Without it, the truck won't be able to do truck things. Traditional trucks have a ladder frame for strength. The Cybertruck doesn't have a ladder frame, just a structural pack, so it takes both the unibody and exoskeleton to give it the strength it needs to do truck things.

Refundable 100$ interests are not Orders nor commitments to final design. It costed no one anything to show an interest. Big difference.Sure, but that's why most reasonable manufacturers don't take orders when the car is still in the prototype stage

I think you proved my point when your simple search on the internet reveals that the knowledge necessary for bending stainless is readily available and well known.Simple search reveal that the rest of the planet understands that stainless is not just plain steel.

Does Stainless Steel Bend Easily? Exploring Material Properties And ...

or

Bending Stainless Steel Sheet: Strategies to Conquer Springback | MachineMFG

Get the key points and analysis you need to bend stainless steel like a pro! Learn how to avoid springback and get flawless results. Get expert tips now.www.machinemfg.com

or how about why use stainless in a kitchen

Strong & Durable: Why We Use Stainless Steel in the Kitchen

Stainless steel is absolutely everywhere in the kitchen. If you don’t have sleek stainless steel appliances or kitchen islandsSteel is fantastic stuff. It’s an iron alloy and strong as all get-out. It doesn’t chip, bend, or crack easily (though it does scratch), and it stays shiny over years of...www.thekitchn.com

Growing Popularity of Stainless Steel in the Kitchen; 11 Reasons why:

Stainless steel- you've seen it, heard of it and likely already use it. Stainless steel is not new. In fact it has been well adored for centuries in commercial, industrial and household kitchens around the world. The early '70s saw a surge in plastic use in kitchens and has grown exponentially...dalcinistainless.com

Stainless Steel Use in the Food Service Industry - Unified Alloys

Since the earliest days of its existence, people have seen stainless steel’s potential to help make food preparation safer and easier. From high-end consumer items to the largest commercial kitchens, stainless steel surfaces, equipment,...www.unifiedalloys.com

Why are you even here other than to complain to anyone who says anything positive, fortunately TMC has a remedy, I'm done bothering with you - goodbyeI think you proved my point when your simple search on the internet reveals that the knowledge necessary for bending stainless is readily available and well known.

legendsk

Member

I have good confidence in 500 miles. There may be some caveats, such as all down hill, with greater than 30 mph tail wind, temperature between 68ºF and 72ºF and no passengers, driver or cargo, but those could all happen - most likely failure to meet spec would be if it requires V12 in order to reach 500?

I always assumed SS was waiting for a reason to exist. Thank goodness for the CT exosekelton.Since when is bending stainless steel any more difficult than any other steel or metal? Its not like its infinitely strong or anything. Its pretty much the same as any other high strength steel Sure, if its hardened, it can be brittle and crack if bent too sharply, but this is all well known in the realm of sheet metal fabrication techniques and limitations.

My refrigerator has stainless front door panels on it. Wanna know why? Its not that stainless is some magic material from which to build the best appliances, no. And its not that I need a bullet proof refrigerator. It is stainless because stainless is shiny and attracts buyers. Just like birds and fish are attracted to shiny things.

ThomasD

Active Member

I always assumed that an exoskeleton meant that the panels would be load bearing. It seams to me that the Sheetmetal attached to the inner structure is not load bearing. The Skeleton of the Truck does the load bearing because everything attaches to it and it must support the weight of the Body panels and Glass roof. The Battery seems to also be load bearing because it holds the weight of everything above it like the Seats of the Truck. Without a strong shell the Truck wouldn't be able to support the weight of all of the external items attached to it.

Mrbrock

Active Member

They go for short term gains from these speculations about future products and hope stock owners forget about the when the products come in underperforming and/or the resultant price drop will be less than the initial gain.Unfortunately Elon seems prone to violating marketing 101 principles. Provide conservative estimates and then come in ahead of said estimates - which always converts into happy customers/consumers. Aim high but promise low, and then beat expectations when you come to market. Aiming high and coming in low and not meeting expectations (11k vs 14k towing, 500 miles vs ??? miles, 2500 vs 3500 payload rating, etc.), doesn't bode well in the eyes of most consumers. I'm a stockholder and therefore obviously believe in the long term vision and mission of Tesla, but the company could learn a thing or two on how to better market their products and services, at least to otherwise normative consumers outside of the worshipping fanboy base.

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 17

- Views

- 680

- Replies

- 18

- Views

- 799