I installed a weeding/peeling board. It's a 4'x8' sheet of eucatile HDF thrifty white from home depot for $17. It has the look and feel of a white board. It is moisture resistant and will be perfect for this one time project.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY PPF on 2022 Blue Model S

- Thread starter zoomer0056

- Start date

SBDPlaid

Member

If you can get this done and it look professional, more power to you! I’ve only done easy items like the headlights and fog lights, and after those I’d never try anything major lol

Something with no curves, edges, etc isn’t bad, but anything more is very difficult to come out with a professional looking install

Something with no curves, edges, etc isn’t bad, but anything more is very difficult to come out with a professional looking install

I'm gonna give it my best try. I have all the tools. Drive Protected and Renoson have been two of my YouTube teachers. I have head and fog lights, wear and tear and rocker panel kits from Renoson.com. These are good starter pieces. Headlights are simple curves. The other kits have some right angles and long runs and are out of direct line of sight. I'll then do (in order) doors with trim removed, hood, front fenders with camera bumps removed, rear fenders, mirrors, pillars, lower part of hatch and then front bumper. With all that experience on cut patterns I'll attack the top part of the hatch with a bulk application. The cut pattern for that part would leave a long seam along the top. My wife is getting impatient. I'm a guy who likes to work with his hands. She says why don't you just get a guy (some guy besides me) to do it for you. She will never understand. I've been working on vehicles since my first bike at age six ... now 60 years later I'm working on PPFing an all electric vehicle!If you can get this done and it look professional, more power to you! I’ve only done easy items like the headlights and fog lights, and after those I’d never try anything major lol

Something with no curves, edges, etc isn’t bad, but anything more is very difficult to come out with a professional looking install

Last edited:

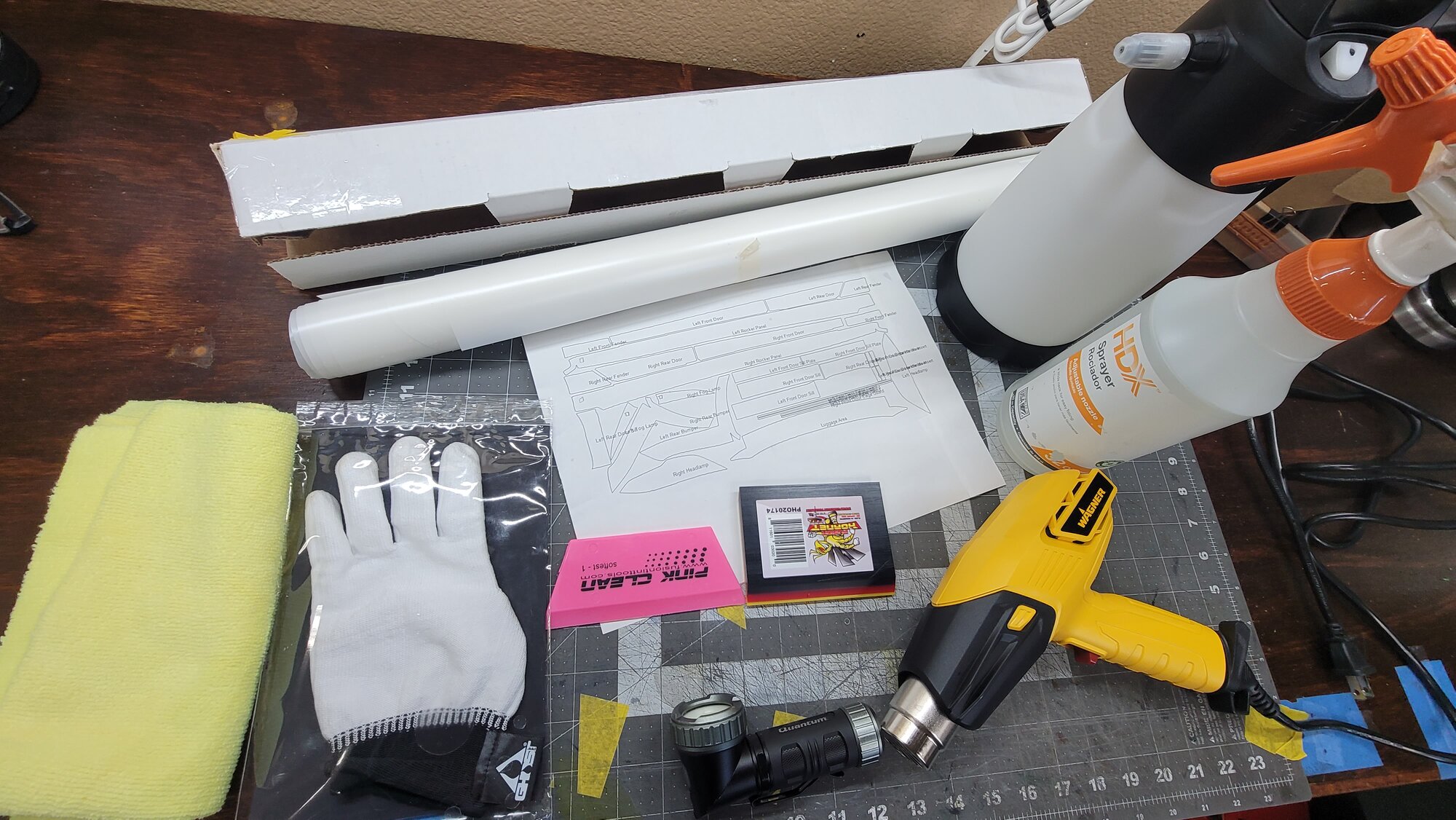

Some tools and the PPF patterns from renoson.com. I have some wear and tear pieces that must go on top of the main pieces, so those will have to wait. Today I can start with head and fog lights, door sill plates, door sills and rocker panels. Clockwise: the roll of PPF precut patterns, soap slip solution, alcohol tack solution, heat gun for edges, hornet dual hardess squeegee, pink clean squeegee for clean off before application, not a very good flashlight, ghost glove used with heat gun on edges. The center is a schematic of the pieces on the film. Each area will be cleaned first with Carpro Eraser, its an alcohol final cleaning solution to prep the area ... lets go!

Easy pieces done in order: door sill caps, fog lights and head lights. I've never done this except virtually via YouTube. Dust is the enemy. Repositioning after squeegee presents ghosting problems. To handle dust have the PPF soaked and ready on the peal board. Car pro Eraser then soap to clean dust off, soap again, peal then soap PPF then right on the car. First sill has ghosting because I repositioned too many times. Second sill is 99% perfect. I learned on the first fog lense that the heat gun can bubble the film. I was not paying attention as I heated and ghost gloved the edges. Still good. Second one perfect. Using tack to position first anchor point on headlight is your friend. I got the hang of heat gun by this time. I found the biggest piece of lint the size of a cotton ball. Lucky it was on the edge and extracted easily. Now it's time to up the challenge ... rocker panel. It will be difficult because it's so low. But it's out of direct line of sight so minor imperfections (there will be some, maybe not) won't be seen. The second rocker panel will benefit from all other previous pieces. Another point(s): have all tools at hand, have process in mind, do one piece at a time then regroup, new stuff but don't be in a hurry. Its hard to see in pics, but head and fog lights done as well as door sill caps. I was happy with use of my temp pealing board ... awesome.

Applied Xpel PPF to rocker panels yesterday. No assistant and no lift, it was a challenge. I discovered this 2022 model S has rubber jacking points which make hockey pucks unnecessary. Rocker panel is a long narrow piece at the lowest part of the car (it's not a car, its a Tesla!) and required tack at the end, reverse rolling off the backing, dry stick in a couple of places and other end. I got soaked while scooting on the ground. I learned a few things on first rocker panel. Important to tack the top edge and squeegee up and over the lip. Use a wet card (hard card with felt wrapped edge) on the door sill wrapped edge to help remove solution. Else solution will seep down. Don't use sill rollover as alignment point, use front and rear edges, rollovers will align by themselves. Now I know where my loose hair goes, under the film. It's easy to take out but it's better to wear a 'do-rag. The second rocker panel film went on very nicely. With each piece I gain experience. I choose rocker panels to do at beginning of this project because they are out of direct line of sight making minor defects hard to see. I learned on them. The next pieces will be the doors. Large flat surfaces that have to be perfect. The patterns will be extended on three sides. I will remove top door trim for three side wrapping. Leading edges will not be wrapped.

Moving right along. A and B pillars done. All four doors done. Doing my own PPF is fun. I ordered the whole car with wrapped edges from renosonfilms in Canada. Chris is very helpful with advice and all his how to YouTube videos. I waited to do the visible big body parts until I had some experience with those parts out of line of sight. The doors went on pretty good, I removed the trim at top of doors for a seemless look. I give myself a 96% grade. If i did this professionaly i would redo some pieces for 100%. Also, if i paid someone i would only accept 100%. Next is the hood ... better be 100%

This is awesome.Moving right along. A and B pillars done. All four doors done. Doing my own PPF is fun. I ordered the whole car with wrapped edges from renosonfilms in Canada. Chris is very helpful with advice and all his how to YouTube videos. I waited to do the visible big body parts until I had some experience with those parts out of line of sight. The doors went on pretty good, I removed the trim at top of doors for a seemless look. I give myself a 96% grade. If i did this professionaly i would redo some pieces for 100%. Also, if i paid someone i would only accept 100%. Next is the hood ... better be 100%View attachment 788438

Mind sharing what the kit cost and what you did for “paint correction”.

I just got a quote from AutoNuvo for full PPF and ceramic coating. They wanted $10,000.00 !!!

It's not cheap and I'm not doing it to save $, doing it because I think I can. I got quotes from professionals from $4,500 to $9,500. Total cost for the Xpel full car precuts was about $3,300. I think I spent less than $200 for tools (squeegees, pump sprayers, white board for peeling and other things i cant remember right now). I spent many hours on YouTube self training during the months waiting for my Tesla. It's doable, it's a challenge....and fun. I did not do any paint correction. I contemplated it. The car is in great shape. Yeah it has a couple of paint nibs, but not enough or in obvious placed to paint correct. The car has absolutely no swirls, I love it. The only thing I did was to use Erasor from Car Pros. That had to be done because there was a lot of little adhesive skid marks everywhere. No need to paint correct, I figured that effort would have got me an extra 2% improvement in the paint ... not worth my time or the expense.This is awesome.

Mind sharing what the kit cost and what you did for “paint correction”.

I just got a quote from AutoNuvo for full PPF and ceramic coating. They wanted $10,000.00 !!!

Last edited:

Mad respect man! This is no easy job! Also your car looks stunning!Moving right along. A and B pillars done. All four doors done. Doing my own PPF is fun. I ordered the whole car with wrapped edges from renosonfilms in Canada. Chris is very helpful with advice and all his how to YouTube videos. I waited to do the visible big body parts until I had some experience with those parts out of line of sight. The doors went on pretty good, I removed the trim at top of doors for a seemless look. I give myself a 96% grade. If i did this professionaly i would redo some pieces for 100%. Also, if i paid someone i would only accept 100%. Next is the hood ... better be 100%View attachment 788438

Thank you, it's definitely a challenge.Mad respect man! This is no easy job! Also your car looks stunning!

The YouTube channels I pay close attention to are Renoson Auto Films, Drive Protected and Pan The Organizer. The first two are PPF installers who also sell precut kits. Pan is an auto detailer.Can you share which YouTube channels you used for your education? I am contemplating doing the same (except using the roll, not precut pieces).

Your installation goes on very well!!! Good luck with the rest.

Last edited:

Nice work. I found a local source here in central Virginia who did my front bumper for $250 total. (I had already done my own hood). Llumar film that had ceramic already embedded in it is what he used. I used the basic offering from northtints for my hood.

Anyways, he came to my home and did it inside my garage. Took him about two hours. He said the S/X bumpers for the refresh are actually "easy". He had a plotter inside his work van and used precut film. Only small issue I could see (and its minor) is here two sections of the PPF come together at the ends of the lower horizontal portion of the front bumper. Again, relatively minor. Rest looks great to me.

Good luck on the rest of your job!

Anyways, he came to my home and did it inside my garage. Took him about two hours. He said the S/X bumpers for the refresh are actually "easy". He had a plotter inside his work van and used precut film. Only small issue I could see (and its minor) is here two sections of the PPF come together at the ends of the lower horizontal portion of the front bumper. Again, relatively minor. Rest looks great to me.

Good luck on the rest of your job!

The precut bumpers come in two pieces, the lower lip and the main piece. It's the best way for precut, hence the seam. $250 ... excellent price!Nice work. I found a local source here in central Virginia who did my front bumper for $250 total. (I had already done my own hood). Llumar film that had ceramic already embedded in it is what he used. I used the basic offering from northtints for my hood.

Anyways, he came to my home and did it inside my garage. Took him about two hours. He said the S/X bumpers for the refresh are actually "easy". He had a plotter inside his work van and used precut film. Only small issue I could see (and its minor) is here two sections of the PPF come together at the ends of the lower horizontal portion of the front bumper. Again, relatively minor. Rest looks great to me.

Good luck on the rest of your job!

It seems I can only handle two large panels per day. Yesterday I have both sides done with the completion of the two rear fenders. The last fender was marked with a comedy of errors. Panel was prepped, mind and process set and the film was on the pealing board ... let's go. One pump sprayer for the board and one for the car. I was pealing when the sprayer slipped from my hand. It landed on the floor and broke the nozzle off. Ok ... I have another. Then while tacking the first corner, the tack bottle fell and also broke. That's fine, I have a backup ready to go. Continuing, tack the second area and .... it did not fall but the cheap hand sprayer exploded. It just came apart in my hand! Ok, I have other bottles so just pour into another. Whew! Got her done. As far as quality, I'm getting about 95% good panels. Not good enough! I will redo the hood as there is some lint under the film. Looks like butt zits. A lesson learned, wipe off each little section of the panel as you go, don't wait until you think your all done to wipe off for inspection. If I did that I could've seen the lint and extracted it. Next is front bumper, I'll redo the hood at a later date. I am still happy with this project. It is really challenging and also exhilarating ... I am enjoying it big time. Oh yeah, one other thing. There is now a 2" Hornet Fussion squeegee inside the passenger door! I took the door trim off (excellent resulting seamless install!!!) and it dropped right in! That is my favorite squeegee and will be with me for a long time.

Last edited:

Great progress. My opinion? I'd really consider leaving the hood alone. I know the very very tiny zit like marks you speak of. My car is white so maybe due to color is why its not really noticeable? But i literally have to get very close at a certain angle in just the right light, to even find them. Also, it's not 100% guaranteed that removal of the PPF wont have potential to lift up a piece of paint. Agree that its not likely that will happen, but for me, risk vs reward ratio..

also, I did a door sill cover with some extra PPF I had laying around. Found it impossible to get a perfectly clean cut with my Xacto knife with fresh blade. Im guessing I need a better blade or use a brand new high quality razor blade

RyanS

Ka-chow

Great job Zoomer. I also diyed both of my M3 and MS with precut 3M for less than $500 each. Not an easy job but doable. The bumper was the most difficult part. As long as you don't expect perfection, it's all good. Nobody will notice except you. My 5yr old MS still looks good and has no issues so far.

the entire car for $500 worth of material? Thats a GREAT priceGreat job Zoomer. I also diyed both of my M3 and MS with precut 3M for less than $500 each. Not an easy job but doable. The bumper was the most difficult part. As long as you don't expect perfection, it's all good. Nobody will notice except you. My 5yr old MS still looks good and has no issues so far.

Similar threads

- Replies

- 15

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 6

- Views

- 1K