ilovecoffee

Member

Here is an official temporary solution from tesla Chinese service center, which will reduce 5~10db sound at 30hz

View attachment 649878

View attachment 649879

View attachment 649880

Thanks for the above image.

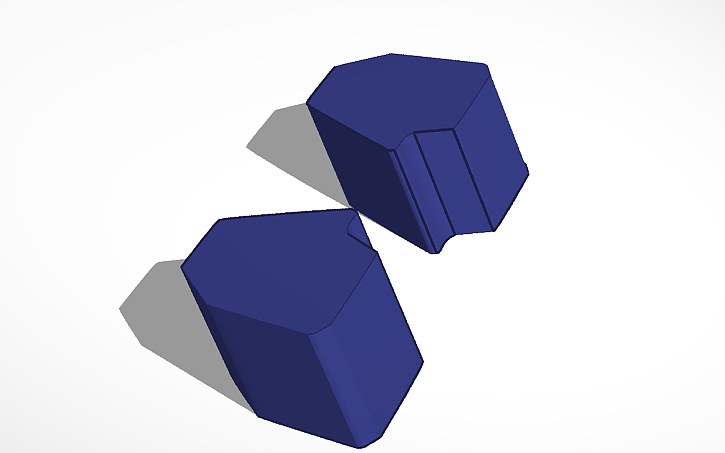

I roughly traced it and made a 3D printable version.

I'm printing it in TPU now and will see how it fits in comparison and if it does anything. I could ask Tesla here in Canada but I doubt they will look into it and order the proper part.

I just don't have those rubber seals they added on the outside above the taillights, nor would I know where to find them in that size (aliexpress maybe?)