2012 P85 #2446 w/130k miles. 2d owner. Bought last Fall from original owner for $27k. Appears to be on original drive unit. All figures in USD.

Since ownership, got BMS_u029 alert 3 days after purchase. Paid $15k for NEW 2022 build replacement pack (got lucky and Tesla honored $15k for reman pack I requested). Paid $1750 plus tax for MCU2 upgrade (that was at my option). Paid $1732 total for PTC replacement with DC-DC convertor fuses.

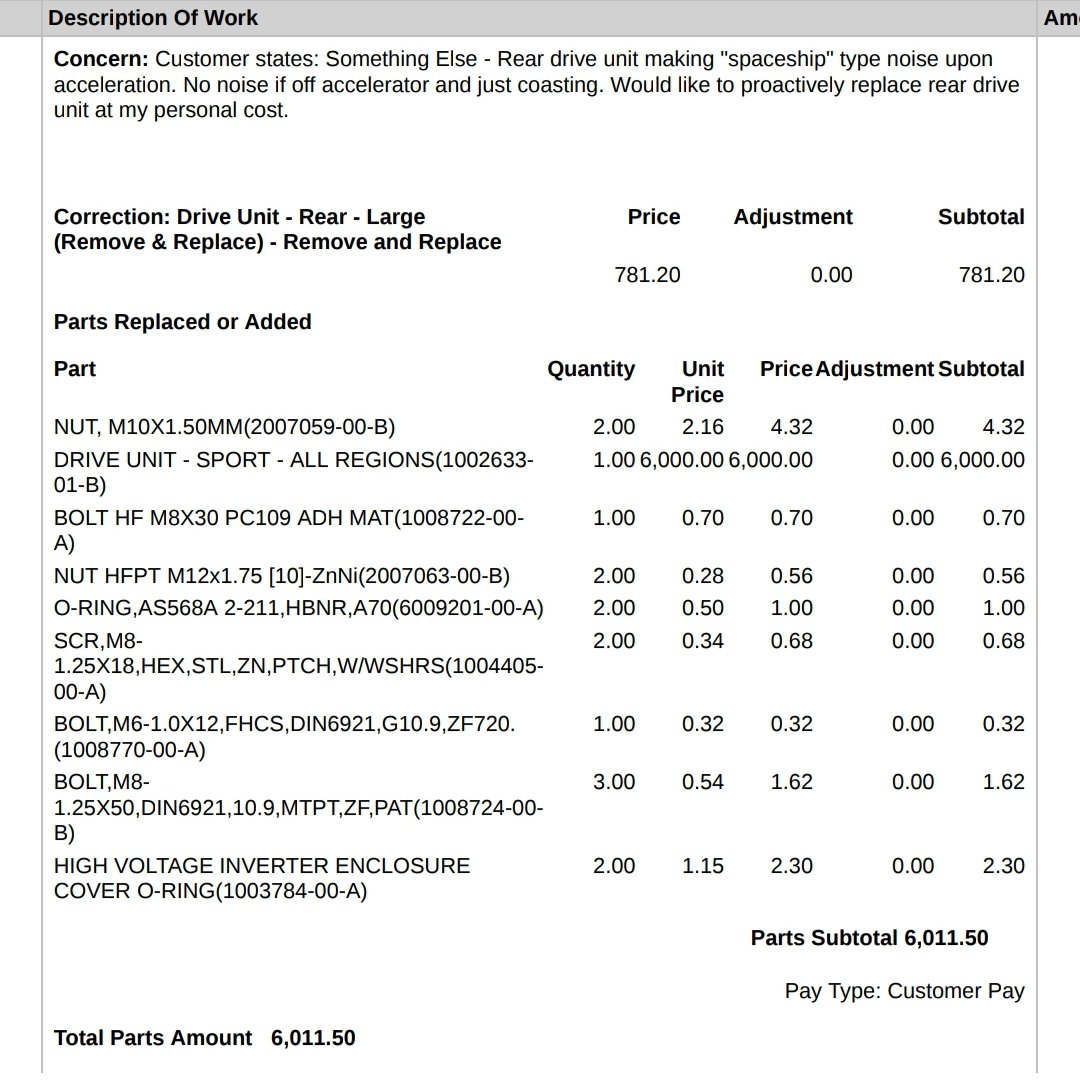

Thinking of proactively replacing RDU due to reason mentioned in my service request. Looking for experiences, advice, etc.

Am willing to cancel this work if convinced. Thx.

Since ownership, got BMS_u029 alert 3 days after purchase. Paid $15k for NEW 2022 build replacement pack (got lucky and Tesla honored $15k for reman pack I requested). Paid $1750 plus tax for MCU2 upgrade (that was at my option). Paid $1732 total for PTC replacement with DC-DC convertor fuses.

Thinking of proactively replacing RDU due to reason mentioned in my service request. Looking for experiences, advice, etc.

Am willing to cancel this work if convinced. Thx.

Last edited: