Except that 16x3x14kWh = 672kWh

So something isn't quite right there.

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

Except that 16x3x14kWh = 672kWh

Except that 16x3x14kWh = 672kWh

So something isn't quite right there.

Indeed, so not not the full picture. I just threw this in because the source seems to be some sort of quasi-insider in the Tesla Semi program (or at least is playing one on the blue'bird).

Wonder if LR Semi has "3 modules, SR Semi has 2 modules, CT has 1 module" is possible? Obviously, not 4680 cells currently, but I think Tesla would be wise to create a range of CT packs with both cell formats to hedge tech+supply issues, and to provide for lower trim CT options in the future.

Ceres!

Could be but that would mean they were able to extinguish the pack fire before it consumed the cabin.The packs in the S do vent through the side box-section frame rails and vent away from the passenger cabin & doors to the front, so it it plausible. I've seen pics of a few S battery fires where flames were exiting from the rear of the front wheel wells.

Yes, I don't know what year it was and if it had lithium or lead, of course either could catch fire.12V battery perhaps?

Yeah. if they arrive soon enough, and know what they are doing, it can be extinguished in time:Could be but that would mean they were able to extinguish the pack fire before it consumed the cabin.

Implications of the Electric Vehicle Manufacturers’ Decision to Mass Adopt Lithium-Iron Phosphate Batteries

it will have to purchase the batteries from China and incur the associated costs: a 10% import tariff, around 1% shipping costs, and a 3% licensing fee due to the patents. With all the additional costs, Tesla saves only 6% by moving from NCA to LFP batteries, when the original cost of LFP batteries should result in savings of 20% [53]. When the patents expire, however, Tesla will be able to manufacture its own batteries, getting closer to its goal of ‘‘localizing all key parts of the vehicles on the continent’’ (i.e., moving battery production closer to its factories) [96]. This should result in significant cost savings because of the streamlined logistics.

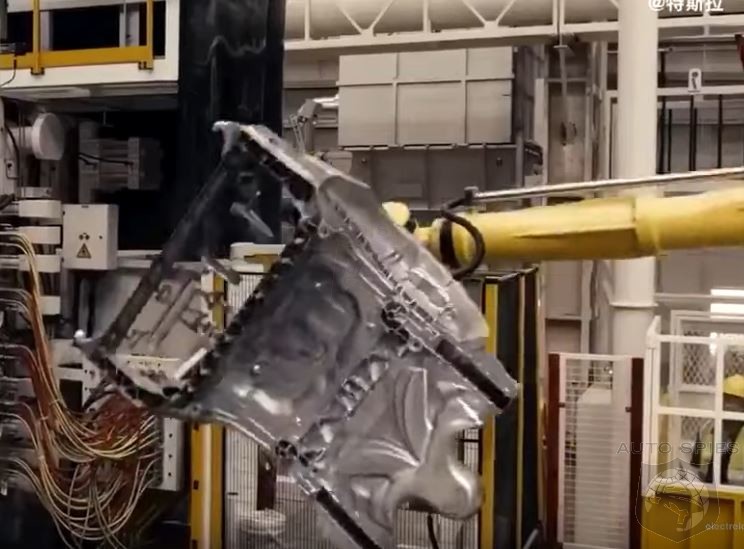

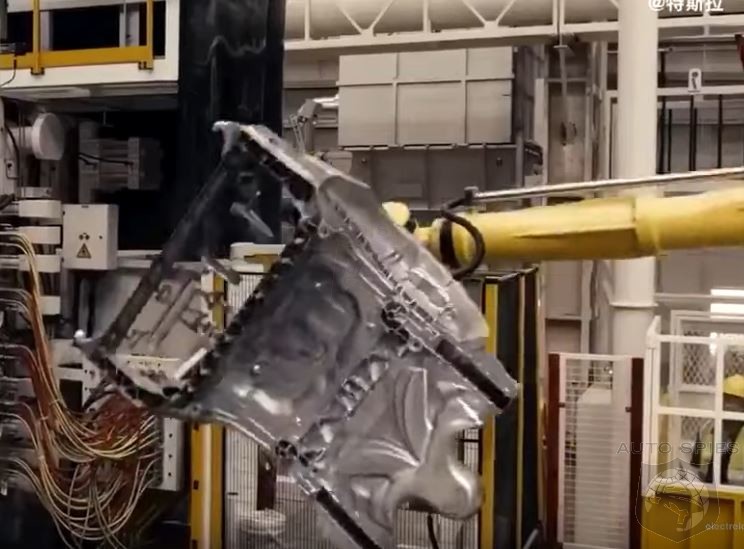

The problem I see is that the smaller channels needed to feed multiple parts may cause cooling issues during casting. Doing single castings means the one part is filled almost instantly and localized cooling is avoided.The press delivers one casting per 45 seconds, afaik. Single cast and you double the press output. Add parts to the casting and it’s almost like getting those parts for the material cost. If they can be mated immediately to the body you’ve eliminated a stock item. A part minus the normal headaches of a part.

You sure those weren't flashings that got removed?Actually, looking at videos of the gigacasts in Fremont, Tesla already does this to a degree. There are "additional parts" that are cast with the main casts, and then cut off. It's not a ton of parts, but it did look like other, smaller parts were in there.

Videos I was looking at were about 18 months old, so don't know how much this has changed.

You sure those weren't flashings that got removed?

Are those extra parts or just runners to tune the flow of aluminum? It seems (from other videos and grip position) only the main casting is removed after the machining step.Actually, looking at videos of the gigacasts in Fremont, Tesla already does this to a degree. There are "additional parts" that are cast with the main casts, and then cut off. It's not a ton of parts, but it did look like other, smaller parts were in there.

Videos I was looking at were about 18 months old, so don't know how much this has changed.

Are those extra parts or just runners to tune the flow of aluminum? It seems (from other videos and grip position) only the main casting is removed after the machining step.

I don't think we've seen anything in the tear downs that looks like parts which might come from that area, I think it's waste from the casting process and is cut out and recycled.